Tetrahydrofuran-3-methanol: Depths Below the Formula

Historical Development

Chemists started talking about Tetrahydrofuran-3-methanol long before lab automation or AI-driven compound searches. It grew from the curiosity of early synthetic organic chemists, eager to squeeze every bit of knowledge from the versatile furan ring. In the late 20th century, folks experimented with tetrahydrofuran as a solvent, then realized certain substitutions at the 3-position brought totally new dimensions to reactivity and utility. This is one of those molecules born from the tradition of pushing chemical boundaries—bridging worlds of solvent chemistry, intermediate synthesis, and functionalized small-molecule design. That journey reveals how researchers don’t settle for following textbooks; they improvise, rerun reactions, and slowly build the bedrock for today’s applications.

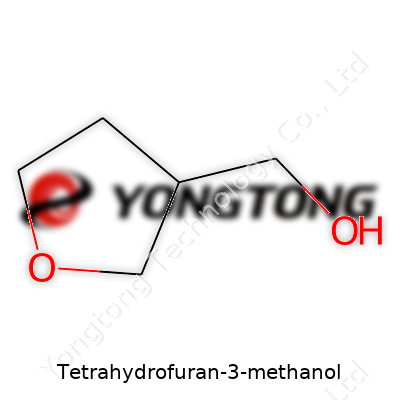

Product Overview

Tetrahydrofuran-3-methanol offers a unique mix of a furan ring married to a primary alcohol group at the third carbon. Strong, colorless, and often turning up in both research and industry labs, this compound bridges the gap between simple alcohols and more complex heterocycles. The presence of both an ether oxygen and a hydroxyl group tunes its chemical personality, inviting use in areas ranging from synthesis to material science. Chemists see it as a stepping stone in multi-step routes, but also as a tool for studying reaction mechanisms, testing new catalysts, or even preparing building blocks for pharmaceuticals.

Physical & Chemical Properties

The compound comes as a clear, slightly viscous liquid. Its boiling point usually falls just above 200°C, making it quite stable under typical reaction or handling conditions. With moderate water solubility, Tetrahydrofuran-3-methanol acts as a decent compromise between hydrophilic and hydrophobic environments, adapting to a range of reaction setups. Its primary alcohol offers a convenient handle for further functionalization, and the cyclic ether structure resists easy oxidation, granting additional stability during storage. The density floats near the 1.1 g/cm³ mark, and the compound avoids much color or odor, which makes spills easier to manage, though proper lab ventilation always matters.

Technical Specifications & Labeling

Batches shipped in glass or high-density polyethylene bottles usually conform to purity grades at or above 98%. Documentation includes clear labeling of CAS number 16829-38-6, hazard pictograms, and barcode tracking. Every container clearly lists flash point—often in the range of 105°C—and information for international transport. Safety sheets come with reference spectra, so users can verify compound authenticity before use in sensitive syntheses. This level of transparency creates trust and accountability that’s genuinely valued in busy research environments.

Preparation Method

Back in the day, chemists often reached for catalytic hydrogenation of furfuryl alcohol derivatives to enter the THF-methanol ring. Raney nickel or palladium on carbon sat at the bottom of small reactors, transforming starting material under atmospheric or mild-pressure hydrogen. Labs soon pivoted to ring-closure approaches, where the furan core took shape before functionalization at the third position and oxidation control dictated the purity of the final alcohol. Modern protocols sometimes skip tedious chromatography by leveraging selective extraction or distillation, reflecting hard-earned wisdom from decades of trial and error.

Chemical Reactions & Modifications

That secondary alcohol function acts like a chemical Swiss army knife. Acid chlorides, epoxides, or sulfonylating agents react quickly and predictably. Chemists can oxidize the primary alcohol to the corresponding carboxylic acid for entry into polymer or pharmaceutical spaces, or reduce it for access to saturated ethers. The molecule undergoes ring-opening, dehydration, and substitution reactions, often under mild conditions—especially important for sensitive substrates. This wide scope invites experimentation, giving chemists room to try unconventional transformations, including enzyme-catalyzed routes just starting to get traction in green chemistry circles.

Synonyms & Product Names

You’ll see Tetrahydrofuran-3-methanol called 3-(Hydroxymethyl)tetrahydrofuran in catalogs, or abbreviated as 3-THF-methanol by researchers scribbling notebooks late at night. Some suppliers sell under trade names that focus on the alcohol group’s utility, but most references in technical literature stick to systematic naming or structure-based short forms. This consistency matters for researchers, who often chase obscure literature or global patents searching for synthesis details or application case studies. A reliable list of synonyms makes all the difference, especially for international teams or interdisciplinary projects.

Safety & Operational Standards

Handling Tetrahydrofuran-3-methanol is nothing to take lightly. Its classification as a flammable liquid underscores the need for proper storage, away from open flames and heat sources. Inhalation or prolonged skin contact brings moderate health risks, so standard PPE—gloves, goggles, lab coats—forms a minimum baseline. Ventilation, fume hood use, and clearly-labeled spill kits help reduce incidents. Safety data sheets emphasize first-aid for accidental exposure and give concrete steps for disposal, whether through incineration or chemical neutralization. In a lab, trust is built on these daily habits, with teams running drills, checking containers, and making no exceptions for safety shortcuts.

Application Areas

Synthesis chemistry books fill up with examples where Tetrahydrofuran-3-methanol plays a starring or supporting role. Medicinal chemists see it as a precursor for drug analogs or linker fragments that attach complex side chains. Material scientists incorporate it into specialty polymers, chasing properties only accessible with cyclic-ether functionality. Green chemistry researchers use it as an intermediate in renewable feedstock transformations, hoping to unwind our reliance on fossil-based starting materials. The compound also shows up in academia, where students and faculty work out mechanism puzzles or test new analytical equipment, enjoying hands-on acetone alternatives that bring more versatility to the bench.

Research & Development

Research groups stay busy exploring both classic and cutting-edge modifications of Tetrahydrofuran-3-methanol. Teams focus on tweaking the molecule’s core to create chiral building blocks, or they scan across reaction conditions to find low-impact synthetic procedures. Collaborative projects blend traditional organic chemistry with computational modeling, hinting at uncharted reactivity with transition-metal catalysts or photochemical triggers. Across universities and industry labs, this compound bridges short-term application with long-term curiosity—testing new solvents, surfactants, or polymer additives nobody’s made before. The hunger for lower-toxicity approaches and better atom economy pushes these explorations forward every year.

Toxicity Research

Even safe-seeming compounds get close scrutiny in the modern regulatory landscape. Chronic exposure runs raise questions about long-term liver or kidney stress, especially in manufacturing or pilot-plant environments. High-dose animal studies help draw boundaries, showing that even modest chemical changes to the furan core can shift toxicity profiles significantly. Fortunately, many studies highlight low acute toxicity for Tetrahydrofuran-3-methanol, though vapor inhalation and dermal absorption both demand good controls. Producers keep one eye on evolving EU REACH or EPA chemical lists, tracking any new studies that stretch understanding, not only for lab users but for communities surrounding production sites.

Future Prospects

Innovation doesn’t slow down for compounds like Tetrahydrofuran-3-methanol. As demand grows for sustainable and bio-based chemicals, interest turns toward renewable routes for producing the furan backbone and handling functionalization with less environmental impact. Application possibilities will likely expand in areas like biodegradable polymer synthesis and green solvents. The drive for better process safety and reduced waste inspires safer, more predictable transformations. Teams already push boundaries—replacing specialty solvents, integrating flow chemistry, and optimizing production on both lab and industrial scales. Adaptation and ongoing learning, not just routine manufacturing, shape what comes next for this versatile compound.

Understanding What Tetrahydrofuran-3-methanol Does

Tetrahydrofuran-3-methanol sounds like something out of a chemistry textbook, but its work shows up in more places than expected. From firsthand experience in a research lab, I saw how small molecules like this one can make a big difference. Tetrahydrofuran-3-methanol acts as a building block in chemical synthesis. Its structure, with a ring and an alcohol group, lets it link up or break apart alongside other chemicals. The magic happens in the lab, but its benefits go much further.

Applications in Making Specialty Chemicals

Chemists often add tetrahydrofuran-3-methanol when creating specialty materials. It blends well into processes that prepare pharmaceutical intermediates, meaning drugs start off with it as an ingredient before further transformations. By tweaking the base structure of medicines, scientists aim for safer or more effective drugs. Drug discovery depends on options, and this molecule keeps those options open. A good example is the growth of targeted cancer therapies or antiviral drugs, both of which rely on small adjustments to molecular frameworks. A molecule like tetrahydrofuran-3-methanol gives them a flexible tool.

Uses in Polymer Chemistry and Material Science

Polymer scientists often hunt for better building blocks. I’ve seen research where tetrahydrofuran-3-methanol slips into polymer chains, adjusting the final properties of plastics or rubbers. Flexible, strong, or clear—these qualities get tweaked by changing tiny components. Products like specialty coatings and adhesives don’t just happen by accident; sometimes, the right backbone unlocks those results. The push for sustainable materials nudges researchers toward new starting materials. Small changes at the molecular level can help reduce plastic waste or make recyclable products easier to create.

Contribution to Research and Development

Academic labs and industrial R&D teams draw on tetrahydrofuran-3-methanol for custom syntheses. Sometimes new drugs fail because nothing fits together quite right in the molecular jigsaw. Versatile molecules like this one help snap those pieces in place. For example, creating new battery materials or catalysts requires fine control over atomic arrangements. Tetrahydrofuran-3-methanol gives researchers more control over functionalization, which often means faster progress. Faster progress turns into cost savings—something every company wants.

Safety and Environmental Considerations

Safety in the lab comes first. Any material with reactive groups can pose a hazard. Tetrahydrofuran-3-methanol doesn’t break that rule, and the safety data reflect that. Technicians must handle it with proper equipment and ventilation, especially since it has the potential to irritate skin or eyes. From a broader viewpoint, concerns about organic solvents and chemical disposal remain important, as both individuals and companies push for greener practices. Many labs are looking into recovery systems or safer alternatives, not only for Tetrahydrofuran-3-methanol but for all solvents.

Moving Forward with Smarter Chemistry

Anyone working in chemistry knows progress rests on small steps. Tetrahydrofuran-3-methanol shows up as one of those unsung heroes—unfamiliar to most but critical for researchers and developers. Whether it’s speeding up medicine discovery or improving everyday materials, this compound’s value comes from the doors it opens in the lab. Smarter chemistry demands both strong technical knowledge and responsible practices. That’s where the real change starts—one molecule at a time.

Digging Into the Backbone of Tetrahydrofuran-3-methanol

Chemistry sometimes throws out names that sound intimidating, but breaking them down can reveal something pretty simple and important. Tetrahydrofuran-3-methanol sounds technical, although its makeup builds on easy-to-grasp building blocks. Think of it as a ring with a twist—almost like a bicycle tire with one special spoke. At its core, this molecule sports a five-membered ring called tetrahydrofuran, made mostly of carbon atoms with one oxygen sitting in the ring. Numbering on this ring starts at the oxygen, so position three is two carbons away from the oxygen.

The “methanol” part of the name brings another layer. Methanol means there’s a –CH2OH group, which is a carbon hooked to a couple of hydrogens and an OH (hydroxyl) group. In Tetrahydrofuran-3-methanol, this group plugs directly into the third carbon on the ring. Draw this out, and you’ll see a simple but elegant structure: a five-membered ring, an oxygen tucked away in the ring, and a –CH2OH tail reaching off the third position.

Why This Structure Matters in the Real World

I’ve come across this compound in discussions around organic synthesis and lab-scale engineering, and its nature makes it memorable. That oxygen atom in the ring isn’t just window dressing—it gives the molecule flexibility and makes it dissolve in water. This trait makes it handy in making polyethers, resins, and specialty polymers. The side chain (–CH2OH) paves the way for more reactions, since alcohol groups open the door to all sorts of chemical tweaks.

Industry experts often compare Tetrahydrofuran-3-methanol to its simpler cousin, plain old tetrahydrofuran (THF). THF is well known in chemical labs as a solvent. Add a methanol group, and the chemistry changes. This alcohol attachment lets researchers build longer chains, sticking together like toy blocks, and the molecule can even serve as a model for exploring more complex biochemical structures. That small change opens doors for inventing new materials and even drug candidates.

Quality Control and Safety Issues

Poking around online and in the lab, I’ve noticed safety and purity come up all the time in handling Tetrahydrofuran-3-methanol. Impurities, even in small amounts, can mess with reaction results—especially if you’re developing pharmaceuticals or specialty plastics. That has led chemists to push for better quality checks, dry conditions, and safe storage. Moisture and air can play tricks with oxygen-rich chemicals, so working with it takes careful planning.

Health experts at government agencies warn that both THF and similar compounds can irritate the eyes, nose, and throat, and overexposure causes headaches. Everyone from lab techs to factory engineers is trained to ventilate workspaces and use gloves and goggles. Strict hazard communication and up-to-date safety data sheets make a difference, and sharing these materials in the community ensures nobody slips up.

Working Towards Sustainable Chemistry

With the world leaning more toward greener chemistry, folks in research and development now ask pointed questions about the environmental impact of solvent production. Synthetic routes using Tetrahydrofuran-3-methanol must weigh waste, energy use, and recycling options. A friend at a chemical plant shared stories of switching from old-school, high-waste synthesis to cleaner, more circular processing methods. Compared to older solvents, THF derivatives sometimes offer a greener profile in the right context. Tools like catalysis, reclamation, and biotechnology are turning what used to be one-way, throwaway chemistry into closed-loop cycles developed for safety and sustainability.

What We Know About Tetrahydrofuran-3-methanol

Tetrahydrofuran-3-methanol shows up on chemical supply lists for research and specialty manufacturing. Not many people outside labs see this material, but anyone handling chemicals has reason to stop and check the safety data before opening a bottle. Whenever I’ve worked with glycol derivatives or solvents that sound similar, I learned to respect them. Some substances surprise you with unexpected side effects or hazards—skin sensitivity, vapor irritating your lungs or, in rare cases, damage when absorbed or swallowed.

Hazard and Toxicity Profile

Direct information about this exact compound can be sparse. Instead I look at related chemicals. Take tetrahydrofuran (THF): a widely used solvent that can cause dizziness, drowsiness, or headaches after breathing in too much. It also carries a risk for kidney and liver stress at high doses, based on animal studies and worker exposure stories. Add a methanol group to the ring and you have every reason to be cautious. Methanol itself is notorious, with toxicity that shows up as neurological symptoms and, at higher doses, blindness or worse. Nobody wants an emergency response just from opening a container.

So, what about tetrahydrofuran-3-methanol? Material safety data sheets flag it as an irritant, harmful to eyes and the respiratory system. Contact can lead to rashes, irritated eyes, or coughing. Swallowing it could do damage, since small alcohols often break down into toxic metabolites after entering the body. I have seen researchers give chemicals like this a wide berth, using gloves, lab coats, and proper fume hoods, based on these risks.

Workplace Exposure and Real-World Precautions

Factories, universities, and specialty labs usually control access to these chemicals. Workers get training, and supervisors urge people to limit direct handling. I remember getting briefed on safety routines, carefully labeling bottles, and washing skin right away if anything spilled. Science and industry evolved because folks paid attention—not just to the big dangers but the daily stuff, like what seeps through nitrile gloves or lingers in the air after a spill.

The National Institute for Occupational Safety and Health (NIOSH) pushes for airborne limits, labeling, and personal protective equipment for these classes of chemicals. They know that chronic exposure, day after day, raises the risk of headaches, respiratory issues, or organ damage. I learned early on that skipping the basics leads to trouble.

Safer Alternatives and Engineering Controls

One solution involves swapping out hazardous chemicals for safer alternatives when possible. Process engineers in research environments constantly search for solvents or intermediates that cut down on risk. Not every chemical process allows for such a switch, so fume hoods, glove boxes, and spill containment become critical. No shortcut beats building in redundancy and clear communication if a material has nasty side effects on health.

Regulatory agencies worldwide ask companies to document hazards and train their staff. Where exposure to tetrahydrofuran-3-methanol looks likely, basic steps—like checking ventilation, using goggles and gloves, and maintaining clear emergency protocols—reduce injuries. The right mindset counts as much as the right equipment. Comparing safety habits among skilled techs, it’s obvious: local culture and strong leadership steer people toward fewer incidents and better long-term health.

Practical Steps Matter

Tetrahydrofuran-3-methanol isn’t the flashiest compound on any shelf, but anyone who’s handled it knows it brings up real storage concerns. You quickly figure out why storage guidelines mean more than just a line in an SDS. A lab spill starts out as a distraction but can lead to lost time, health risks, and even project shutdowns. Experience in research labs taught me that even seasoned teams make mistakes with chemicals like this—often because small rules get overlooked for the sake of convenience.

Keeping Air and Moisture Out

This compound absorbs water from the air, so storing it in tightly sealed glass containers pays off every time. Plastic containers sometimes compromise the purity or react with the liquid. I’ve seen labels peel off or stoppers crack, so double-checking seals and keeping containers clearly labeled goes beyond bureaucracy. Always use freshly stopped glassware—no one wants to fish out droplets of water and risk a ruined sample.

Avoiding Light and Heat

Tetrahydrofuran-3-methanol breaks down with light and heat exposure. I learned to tuck bottles away in a dark cabinet, away from windows or hot places like steam pipes or heating vents. Even an unplanned equipment failure—say, a fridge left ajar after a late-night experiment—leaves you with question marks about chemical safety. Aim for cool, stable temperatures that don’t fluctuate daily.

Stay Far from Ignition Sources

With organic solvents, flames in the same room spell trouble. One time, someone thought it was safe to plug in a heating plate for a different project nearby, but the fumes made the risk real. Keeping storage away from such sources not only avoids emergencies—insurance audits pick up on this, too. Fire-resistant cabinets, fitted with proper ventilation, cut down on both risk and regulatory headaches.

Ventilation Saves More than Comfort

You might think a sealed bottle solves fume problems, but over time, even small leaks add up. I’ve found proper ventilation—such as dedicated fume hoods or extraction systems—improves both air quality and lab safety. This means fewer headaches for the team and less worry about occupational limits. According to OSHA, keeping airborne concentrations low saves money on medical costs and turnover.

Emergency Preparedness

It’s tempting to store chemicals in random drawers or makeshift storage just to clear a bench. My biggest regret in the lab was skipping a safety review, only for a minor spill to lead to panic—because there wasn’t absorbent nearby or anyone sure where the eyewash station was. Spill kits, updated safety training, and labeling every solvent bottle seem basic until something goes wrong. The best labs I’ve worked in never take shortcuts here.

What Works In Day-To-Day Life

Following these storage habits means fewer surprises and healthier workspaces. Tetrahydrofuran-3-methanol doesn’t attract attention like some chemicals, but storing it right protects people, equipment, and experiments alike. Safety doesn’t slow down good science; it prevents the setbacks nobody needs. Clear procedures, teamwork, and structured checks take a lot of stress off everyone in the lab.

Understanding the Basics

Tetrahydrofuran-3-methanol sits in a unique spot in both labs and factories. Plenty of folks haven’t heard the name, but chemists and technologists depend on this compound more than most realize. It serves as a building block for complicated molecules. In a world where labs rush to make new medicines, plastics, and coatings, this compound pulls its weight.

Real-World Uses on the Lab Bench

Strong evidence shows that tetrahydrofuran-3-methanol gives synthetic chemists ways to build and tweak molecules. Researchers use it to prep certain biologically active compounds. In my own time working with organic chemistry groups, I watched how reliable reagents never stay on the shelf for long. They show up in reaction sequences like the Mom-and-Pop stores in small towns: always there, filling gaps, quietly making local life possible. Tetrahydrofuran-3-methanol often crops up in the step where scientists connect different chemical features to a central skeleton. This gives researchers wide-ranging ways to experiment with chemical diversity.

Another role for this compound: it works as a solvent or a stabilizer. In particular, folks synthesizing polymers or specialty plastics reach for it as a controlled agent, guiding tricky reactions to the finish line. Anyone who has run an unpredictable reaction knows solvents like this one help dodge headaches that come from runaway solutions or unwanted byproducts. You want every dollar spent in the lab to count. In this way, a compound like tetrahydrofuran-3-methanol supports research that cuts waste and boosts the odds of breakthrough discoveries.

Industrial Production and the Push for Innovation

Big companies drive production lines that need reliability in every batch. Specialty coatings or high-performance resins include chemical intermediates like tetrahydrofuran-3-methanol for their unique ability to change the properties of the final product. Manufacturers have found that using this compound as a reactive intermediate can tune flexibility and durability in consumer goods like electrical connectors and engineered surfaces. When a company builds something meant to last years exposed to heat and cold, these chemical tweaks keep the product in use instead of in the landfill. Not every innovation looks like a smartphone; sometimes, it lives inside the plastic holding electric cables together behind the wall.

Beyond plastics and coatings, researchers working on new medicines or agricultural compounds find tetrahydrofuran-3-methanol valuable because it allows for precise changes to the molecules involved. The compound’s ability to add functional groups helps explore huge “chemical spaces” in drug discovery. Drug designers race to find the next molecule that could treat tough diseases—from cancer to antibiotic-resistant infections. Speed and accuracy tip the balance in these quests, and the right building blocks save time during each experiment. This sort of progress builds on experience and last year’s work, carrying lessons forward.

Improving Safety and Environmental Impact

Laboratories and industry have learned from past mistakes. Old solvents and chemical intermediates sometimes left health or environmental risks in their wake. Current research pushes toward using safer options, and tetrahydrofuran-3-methanol has a solid record when handled by trained people with good ventilation and proper gear. Still, safer disposal and greener alternatives are always worth exploring. A few companies are investing in recycling or recovery processes for solvents, cutting both costs and pollution. In the long term, every improvement in worker protection and emissions counts toward a safer future in science and industry.