Sodium Xylene Sulphonate: More Than Just a Surfactant

Historical Development

A century ago, chemists looked for ways to build detergents with power and reliability. Early soap makers leaned heavily on fats and alkalis, which left residues and struggled to work effectively in hard water. As chemical knowledge grew in the twentieth century, the rise of synthetic surfactants changed the game. Sodium xylene sulphonate—a product of organic sulphonation—became known in the 1940s during the postwar boom, when the world demanded better cleaning formulas. Factories started sulphonating xylene, driving down costs and increasing scale. This chemical saw acceptance in household and industrial products facing tough dirt, a rare achievement in a market flooded by options. Few substitutes matched its performance in preventing precipitation of other ingredients in cleaning liquids, and that ensured its spot across decades of innovation.

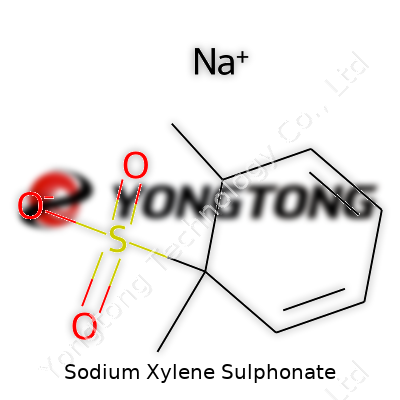

Product Overview

Sodium xylene sulphonate typically shows up as a free-flowing white powder or clear liquid, depending on the intended end use. Its structure—derived by sulphonating xylene and reacting it with sodium hydroxide—makes it an outstanding hydrotrope. Cleaning product formulators lean on it to boost the solubility of surfactants in water-heavy mixtures. Its knack for improving solubility of often-stubborn organic ingredients changes the game for industries that mix oily and watery materials. The product emerges as a practical addition, making production more predictable and reducing waste from unblended mixes.

Physical & Chemical Properties

With a molecular formula of C8H9NaO3S, this product offers clear practical value. It dissolves easily in water, forming nearly neutral pH solutions that avoid the caustic edges or acid stains found with harsher chemicals. Boiling and melting points depend on purity and concentration in liquid or solid forms, but its real-world performance shines due to its resistance to hard-water minerals, which often cripple traditional soaps. The chemical stays stable under normal storage, tolerates wide temperature swings, and resists breaking down in sunlight—a trio of properties that make it fit for everything from concrete cleaners to textile processing aids.

Technical Specifications & Labeling

Manufacturers follow benchmarks guided by International Organization for Standardization (ISO) and regional authorities to keep quality steady. Typically, the powder contains 92% or higher active sodium xylene sulphonate, with limited moisture and low trace sodium chloride. Packaging uses kraft-paper-lined drums or high-density polymer containers, clearly marked with hazard codes, batch numbers, and weight. Labeling standards protect end users and provide downstream traceability, a must for sectors like food processing and pharmaceuticals that demand a clean audit trail. This clear traceability boosts trust, making it easier for buyers to pinpoint any problem or recall batch if manufacturing issues pop up.

Preparation Method

The industrial route to sodium xylene sulphonate starts with sulphonating xylene using concentrated sulfuric acid or oleum. Handling these reagents requires skill and care, as both pose serious health and environmental threats if spilled or inhaled. After the sulphonation, neutralization with sodium hydroxide leads to the sodium salt. The process rejects excess acid, producing manageable byproducts often recovered or neutralized to limit waste. Engineers keep reactors at steady temperature and agitation, watching for runaway reactions and bottle-necking during scale-up. Over the years, plant owners have squeezed efficiency by recycling water and tailoring energy usage, reducing both costs and emissions. The best operators understand that clean chemistry doesn’t just help regulators—it also trims bills and boosts worker safety.

Chemical Reactions & Modifications

Sodium xylene sulphonate, with its strong sulphonate group, remains mostly inert to common household and industrial chemicals. Its limited reactivity means less risk for formulating chemists mixing products with bleach or acids. On the other hand, advanced labs occasionally tweak its side chains, building derivatives for specific environments—a task handled carefully due to environmental scrutiny. Researchers explore modifications to the base molecule, hoping to unlock new properties or reduce any risk to aquatic life. South Korean and European labs have experimented with blends that cut down foam or alter the softening effect of water. These insights drive gradual improvement, each tweak pointing toward safer, more effective next-generation surfactants.

Synonyms & Product Names

In the market, sodium xylene sulphonate carries an impressive list of aliases: SXS, sodium dimethylbenzene sulphonate, and sodium toluene sulphonate. Certain catalogs mark it as Texapon SXS or Vendex SXS. Names shift with region, bulk supplier, and grade, so buyers must confirm chemical structures rather than lean only on names. Mistaken identity in the warehouse can drive up troubleshooting time. Fortunately, product databases from industry leaders emphasize the importance of matching CAS numbers, and seasoned procurement teams rely on these references to get batches that align with process demand. Consistency matters more than a catchy name, a lesson proved time and again by process hiccups from mix-ups at the receiving dock.

Safety & Operational Standards

Sodium xylene sulphonate doesn’t carry the notorious hazardous flags seen in corrosive or toxic industrial chemicals. Still, smart handling reduces unnecessary exposure. Direct inhalation or prolonged skin contact, especially in concentrated solutions, sometimes leads to irritation. Industry standards push for gloves, goggles, and local exhaust ventilation. Facility operators train workers to respond to leaks with containment methods and immediate cleanup, preventing environmental release. Offsite transport requires labeling compliant with the United Nations’ recommendations on dangerous goods. Emergency plans at production sites limit the fallout in case of accidental spill or fire, emphasizing safety as part of daily routine—not an afterthought buried in a protocol binder.

Application Area

Commercial and consumer cleaning solutions make up the biggest home for sodium xylene sulphonate. Liquid detergents depend on it as a solubility booster, trapping dirt and grease in water so that rinsing works as intended. Industrial clients use this chemical for textile dye baths, concrete plasticizers, oil recovery, and even printing pastes. Paper processing, agricultural sprays, and leather finishing tap into its knack for dissolving and dispersing other compounds—where batch consistency saves time and cuts loss. One can see it even behind the shine of automotive cleaners, nestled among fragrance and coloring agents. From a formulator’s view, it fixes problems that others only patch, turning tricky emulsions into smooth flows across food plants, metal shops, or laundry rooms all over the globe.

Research & Development

Academic labs and private R&D teams have looked closely at sodium xylene sulphonate’s interactions with other surfactants, noting that just a bit enhances detergency and increases product shelf life. Chinese scientists push investigations into green synthesis routes, repurposing waste xylene streams from refineries and cutting CO2 footprints. Teams in Germany review biodegradation patterns, working to preempt new environmental stewardship rules. Public datasets from the U.S. Environmental Protection Agency suggest that modern manufacturing plants already reduce emissions by recycling process water and recapturing energy. Real progress depends on collaboration across supplier and customer lines, sharing test results, and being honest about failures as much as successes. This active engagement builds trust in the chemistry—by making each improvement visible.

Toxicity Research

The safety record of sodium xylene sulphonate, supported by both acute and chronic exposure studies, stands on several decades of data. Toxicologists assess the compound using animal models, confirming low toxicity at realistic exposure levels. The EPA and European Food Safety Authority conclude that accidental ingestion or incidental skin contact carries minimal risk for healthy adults, although direct eye contact causes short-term irritation and workers exposed on unprotected skin experience mild dermatitis. Still, some aquatic toxicity shows up when large volumes reach rivers, so wastewater plants must not flush excess material unchecked. Responsible operators invest in pre-treatment systems, cutting load on municipal treatment plants and limiting risk to fish and amphibians.

Future Prospects

The global appetite for more sustainable surfactants drives continued research into sodium xylene sulphonate’s greener manufacture and formula tweaks. Chemical engineers design new catalytic routes and safer plant layouts to trim waste and post-process burdens. As regulations grow stricter on biodegradability, manufacturers pivot to blends with improved breakdown rates, pairing tradition with innovation. Markets might soon redefine product portfolios around non-toxic, resource-light surfactants where sodium xylene sulphonate can play a central role. As an experienced observer, I see that progress happens at the intersection of customer demands, regulatory incentives, and the steady hand of practical chemists who invest in both their people and their products. The material remains a beacon for chemical reliability, innovation, and adaptability—proof that industry and environmental care can grow together.

The Everyday Roles of Sodium Xylene Sulphonate

Sodium xylene sulphonate shows up in far more places than most realize. It's not just a chemical from a warehouse shelf; it works as a helper in products people use every day. I first ran into it while looking into ingredients in a bottle of dish soap. After some digging, it became clear this isn’t just another tongue-twisting chemical name. Manufacturers use it for a reason: it helps liquids blend together that don’t normally mix well. In practice, it improves the way cleaners dissolve grime or dirt, letting them do their job with less effort.

Household cleaners, both the stuff that cuts through greasy sinks and laundry detergents for stubborn stains, depend on this compound. Companies include sodium xylene sulphonate to keep formulas clear and pourable. Thick liquids pour smoother, and thin ones stay stable, even if they sit on a shelf for months. Without it, you might see clumps or separation in the middle of your cleaning routine. It’s one of those quiet workhorses that keeps the product working the way you expect, every time.

Beyond the Cleaning Aisle

It popped up again during a conversation with a friend in the automotive industry. Sodium xylene sulphonate appears in some car-care products, such as tire cleaners and degreasers. Mechanics appreciate how it keeps tough grime-removers effective without gumming up spray bottles. It doesn’t stop there. Industrial settings, especially in textile mills, also use it to make sure dyes dissolve evenly in water. Without it, colors risk coming out patchy or faded. Many textile workers know the frustration of a batch turning out wrong, and this additive helps keep those mishaps rare.

Farmers and gardeners might spot it in some herbicide and pesticide mixtures. Here, it plays the same role: blending ingredients and stopping separation. Spraying a field demands that every drop be the same as the last, or some areas get too much, others too little. This compound helps solve that puzzle, which matters for both crop yield and environmental safety.

Is It Safe to Use?

With all these uses, safety questions show up often. Research from regulatory bodies like the Environmental Protection Agency and the European Chemicals Agency seems to agree: at the levels used in formulas, sodium xylene sulphonate doesn’t pose a significant risk for most people. Researchers check for skin irritation, allergic reactions, and environmental persistence. My own look at published safety reviews showed that this ingredient tends to rinse away without lingering in soils or waterways. Of course, dumping large quantities down a drain would pose issues, as with most chemicals.

Chemical transparency still counts. While the main health agencies do their job, people deserve to know what ends up in their homes or on their plates. Labels help, though they sometimes bury ingredients in fine print. A little more openness would let folks make decisions confidently, whether they scrub floors or wash dishes nightly.

What Could Be Better?

With so many chemicals in household products, some aren’t sure where to turn for alternatives. Sodium xylene sulphonate doesn’t have a cloud of controversy around it, but plenty of people prefer fewer additives. For those folks, brands experimenting with soap nuts, citrus-based cleaners, or simple baking soda may offer something closer to home chemistry. On the industry side, companies that research more biodegradable, plant-based detergents sometimes use less of these synthetic additives. Slow progress counts.

Learning what sits behind a clean floor or a spotless pan matters. Sometimes, a chemical like sodium xylene sulphonate plays a quiet but key role, making every spray and wipe just a bit easier.

Understanding What Touches Your Skin

Sodium xylene sulphonate pops up in a lot of familiar places. Shampoo, liquid soaps, even household cleaners. It has a knack for helping mix water with ingredients that usually don’t get along, so products better clean and rinse away. Most folks interact with it without ever hearing the name.

Digging Into the Science

Over the years, researchers have looked at whether sodium xylene sulphonate causes skin trouble. Dermatology clinics and toxicology studies from groups like the Cosmetic Ingredient Review and the U.S. FDA all report similar findings: irritation doesn’t turn up unless you put it on at much higher levels than usual. Most consumer products only use it in small amounts, between 0.5% and 3%. That’s far below the levels that trigger problems in patch tests on human skin.

Even so, high concentrations can leave people with red, stinging skin — mostly in test scenarios that simulate spills or undiluted contact. This matches what safety professionals have seen: concentrated chemicals often stress out human skin. A small percent of people who already have allergies or ongoing skin conditions might feel this more strongly, even at everyday levels. Personal experience confirms this. I have sensitive skin and notice discomfort from some dish soaps, but not others. Turning a bottle to check for sodium xylene sulphonate helps clue me in after a reaction.

Why It Matters in the Real World

Daily habits hinge on practicality. Nobody wants an ingredient in their bathroom that secretly stings. Beyond personal comfort, choices about everyday chemicals link to trust in long-term health. A product shouldn’t quietly build up or trigger an immune response after months of use. That’s the reason so many families look up label information or search for “dermatologist tested” on shampoo bottles.

The good news: sodium xylene sulphonate hardly hangs around in the body. It rinses away, breaking down in water. Studies so far point out no clear link to cancer or serious health effects, even after years of use in consumer cleansers and soaps. The European Commission and U.S. agencies watch for new research and update their recommendations if anything new turns up. Right now, safety standards for use in products sit on solid ground.

Watching for Problems and Solutions

Some people still get dry or itchy skin from products even with approved ingredients. For anyone with eczema, contact dermatitis, or unexplained rashes, switching up soap brands can help. My own family keeps a bottle of simple, fragrance-free, low-ingredient cleanser by every sink. That switch cut down on flare-ups at our place, so it’s something others might think about.

Companies can take steps by testing for skin irritation and giving clear guidance on how to dilute cleaning solutions. Parents often reach for child-friendly shampoo not because the regular stuff is always dangerous, but because peace of mind matters.

Setting the Record Straight

Sodium xylene sulphonate in everyday concentrations doesn’t pose a danger for most users. It blends science with experience: as long as concentrations stay regulated, major problems don’t show up. If irritation crops up, users should check labels, try switching to gentler options, and let manufacturers know about reactions. Chemical safety depends on information, awareness, and an honest look at what’s best for each family.

Household Cleaning Products

Take a look under your kitchen sink, and there’s a good chance you’ll find products made better by sodium xylene sulphonate. Detergents and liquid soaps use it to thin out the texture so the product pours smoothly and lathers up. Surfactant chemistry means every drop rinses away grime, which matters when dishes need to shine or laundry has to come out fresh. Cleaning companies need these results to keep their customers happy and cut back on residues left behind. I’ve used concentrated floor cleaners that depend on this ingredient to break up stubborn grease easily—no heavy elbow grease required. Reports from the American Cleaning Institute highlight broad reliance across hard surface cleaners, dish soap, and laundry applications.

Personal Care: Shampoo and More

Cosmetics manufacturers blend sodium xylene sulphonate into shampoos, bubble baths, and body washes. Thicker ingredients can clog up pumps or cling to the side of a bottle. This chemical helps loosen things up, allowing formulas to flow easily and rinse out without trouble. In the lab, researchers note its low skin irritancy compared to alternatives. For people with sensitive skin (like someone in my family), brands who use it in balance can offer mild, gentle washes without leaving behind waxy residue. Ingredient lists for everything from high-foam shampoo to frizz-control conditioners often include it for better consistency and cleansing.

Textile Manufacturing

Fabric processing centers have their hands full with heavy loads, dyes, and treatments. Sodium xylene sulphonate steps up, helping mix dyes evenly and keep chemical baths stable. With this boost, dyes penetrate fibers better, and the colors appear even without splotches. The Indian Textile Journal documents its widespread use, as finishing treatments depend on level dispersion. Textiles treated this way hold color longer, reducing waste and saving money on re-dyeing. By keeping machinery clean and boosting bath efficiency, the chemical cuts production downtime—a direct shot in the arm for busy mills.

Industrial and Institutional Cleaners

Hospitals, schools, and factories can’t afford products that leave residues or lose strength in tough water. Sodium xylene sulphonate lets sanitizing products blend perfectly with hard or saline water without dropping cleaning power. From my own stint as a janitor, I can tell you how crucial this is for cleaning high-traffic hallways fast, leaving no film behind. Research published by the Journal of Surfactants and Detergents points out its ability to maintain powerful performance across misuse and varying water conditions. In industries where every surface matters, that reliability means safer, cleaner environments for staff and visitors alike.

Oilfield Chemicals and Agriculture

Oil drilling operations and large farms run on batches of solutions that need exact performance day after day. Sodium xylene sulphonate acts as a dispersant and wetting agent in oilfield chemicals, helping ingredients spread quickly and do their job even under harsh conditions. In agriculture, it keeps pesticides and fertilizers blended, reducing clogged sprayers and uneven coverage across fields. CropLife America notes more consistent harvest outcomes thanks to this chemical’s inclusion in tank-mix products. For farms working on tight budgets, fewer reapplications save time, money, and water.

Room for Improvement

Some watchdogs and researchers keep a close eye on surfactants like this, especially around wastewater and environmental toxicity. Responsible companies explore greener alternatives or closed-loop water systems to minimize runoff. By making thoughtful manufacturing and formulation choices, industries can keep delivering quality while protecting the water we all share.

Understanding Sodium Xylene Sulphonate

Sodium xylene sulphonate goes by the formula C8H9SO3Na. This name might seem a mouthful, but anyone who's washed dishes or scrubbed a floor has felt the impact of this compound. It's more than just a string of letters and numbers. The real story of sodium xylene sulphonate is about its presence in everyday cleaning products and the chemistry that helps it do its job.

Inside the Formula: What Makes It Tick

Chemistry can seem intimidating. But knowing what goes into the products we use can really matter, especially for those concerned about health, environmental safety, or simply making the right purchase. Sodium xylene sulphonate brings together xylene (a molecule with eight carbon atoms and nine hydrogens) and a sulfonic acid group, neutralized with sodium. It’s this combination—represented as C8H9SO3Na—that lets the chemical keep various ingredients in a cleaning solution from separating. That property means your favorite dish soap stays mixed, works right, and cleans up life’s everyday messes.

Surfactants like sodium xylene sulphonate get talked about for good reason. They find their way into laundry detergents, carwash solutions, and shampoos. These products rely on the ability of the sulfonate group to interact with water, while the xylene part likes oils. That duality lets sodium xylene sulphonate lower surface tension, making water work harder to pick up dirt. I remember years ago trying to use homemade soap; it never cleaned quite like store-bought blends. The difference comes down to science—not just marketing. Sodium xylene sulphonate helps create a stable, powerful cleaner you can trust to lift grease off a plate or grime off a shirt. This sort of practical chemistry plays out daily, often in the background.

Why Should You Care About the Formula?

Trust is a big deal in personal care and cleaning products. You want to know what goes in your home and on your skin. Sodium xylene sulphonate’s straightforward, documented formula gives consumers and manufacturers confidence. Global chemical safety bodies, like the European Chemicals Agency, maintain fact sheets and safe use guidelines because responsible handling protects both people and waterways.

Transparency builds confidence. If you look at a bottle and see a chemical you recognize, you make choices with more control. The widespread use of C8H9SO3Na wouldn’t make sense unless it contributed significant value: dissolving tough stains, keeping shampoos clear, or letting concentrated cleaners mix with water on a cold winter day. I’ve volunteered at community cleanups where safe, effective cleaners meant we could remove graffiti or oil without spending hours scrubbing. Those memories underline the real-world benefits that start with simple formulas, not marketing buzzwords.

Paving the Way for Safer Products

There are always concerns about chemical ingredients—sometimes for good reason. It’s smart to ask whether compounds like sodium xylene sulphonate present risks at the concentrations used in household items. Peer-reviewed studies show that at typical use levels, the compound poses low toxicity and biodegrades in the environment. Still, it makes sense to keep seeking greener alternatives, cut down on unnecessary additives, and support companies that disclose ingredients. Sometimes, a better product comes not from removing all chemicals, but from picking the safest, best-studied ones and using them with respect for people and planet.

What We Know About Sodium Xylene Sulphonate

Sodium xylene sulphonate shows up in a lot of everyday products, especially in cleaning supplies. Some folks look at the chemical name and worry, though terms like “biodegradable” on certain labels can ease concerns. The truth about this ingredient goes a bit deeper.

Understanding Biodegradability

Biodegradable doesn’t always mean “harmless,” but it tells us if something breaks down naturally in the environment. Quick breakdown by microbes matters, because slower breakdown often means chemical leftovers stick around in water or soil. Sodium xylene sulphonate comes from a family of compounds used to help things like detergents mix together or stay liquid. Its structure—an aromatic ring with a sulfonate group—can pose problems in nature.

Based on publicly available research and government safety sheets, sodium xylene sulphonate does break down in the environment, though not as quickly as some other surfactants. Studies show that with the help of sunlight and certain bacteria, it gradually decomposes. Complete breakdown usually happens in water treatment plants, where bacteria feast on all sorts of chemical leftovers. But that only covers part of the story.

Why Biodegradability Matters

People flush all kinds of household cleaners down the drain, and this puts pressure on wastewater treatment systems. Research published by agencies like the European Chemicals Agency suggests moderate biodegradability for sodium xylene sulphonate under typical conditions. So, some lingers if it slips by water treatment or gets dumped in large quantities.

Communities living downstream from landfill sites or near factories sometimes deal with runoff that carries chemicals. Aquatic life—especially fish and small invertebrates—can suffer even from mild pollution. Scientists at the US EPA note that if this compound piles up in streams, it could harm sensitive species. We don’t always see it in large amounts, but slow, steady releases cause concern.

Rethinking Our Choices

Years of working in a small commercial cleaning business showed me how easy it is to ignore ingredient lists. One supplier switched to “greener” cleaners, promising everything used in the formulas was safe for the earth. Most customers, myself included, felt better seeing “biodegradable” stamped on the side of a bottle. Looking back, nobody really looked past the marketing to check how fast or completely these chemicals would break down. Education gaps like this make a difference in what we put into our water and soil.

Possible Paths Forward

Regulators could demand clearer numbers from manufacturers about how long chemicals linger in the environment. More pressure might help companies move toward using chemicals that not only break down faster but cause less harm in the process. People can also shift buying habits toward truly low-impact cleaners and ask hard questions at the point of sale.

Water treatment operators bring up the extra costs of filtering out tougher chemicals. Increased investment in advanced treatment could filter out more before treated water returns to rivers. At home, collecting leftover cleaning solutions for hazardous waste disposal helps, instead of flushing or dumping outside.

The question isn’t only about “Is it biodegradable?”—it’s about how we look at our responsibilities with the chemicals we rely on every day, and how much thought we give to the safety of our water, our wildlife, and our neighbors downstream.