Sodium Benzenesulfonate: A Ground-Level Look at a Behind-the-Scenes Chemical

Historical Development

Long before synthetic detergents became standard in every laundry room, the chemical industry grappled with stubborn fats and oily residues. Sodium benzenesulfonate came out of those early efforts as manufacturers explored alternatives to natural soap, which struggled in hard water and fell short in new industrial applications. Laboratories in the late 19th century started reacting benzene with concentrated sulfuric acid, then neutralizing the acid group with sodium hydroxide. From this classic sulfonation reaction, sodium benzenesulfonate emerged as a stable compound, setting the stage for its growth as a workhorse in cleaning, textile dyeing, and even electroplating.

Product Overview

People deal with sodium benzenesulfonate every day without realizing it. This white, crystalline powder with an almost odorless profile gets tucked into cleaning products, mixing easily with water. Its role centers on breaking up grease and keeping particles from clumping together. Producers appreciate its availability, cost-effectiveness, and chemical stability, which allow them to meet tight manufacturing specs in everything from consumer detergents to industrial process aids.

Physical & Chemical Properties

Sodium benzenesulfonate dissolves freely in water, forming clear solutions useful for a variety of household and industrial applications. Its chemical structure—a benzene ring bonded to a sulfonic acid group, neutralized with sodium—endows it with a strong affinity for both polar and non-polar substances. This dual nature means it can suspend oils and organic debris, making it a go-to dispersant. On the shelf, its powder form resists caking and reacts mildly to typical temperature swings during storage and shipment. With a molecular weight around 216.2 g/mol and melting point near 300°C, this compound stands up to rigorous use, whether in the heat and friction of a textile mill or the cold, alkaline slurry of a detergent blending plant.

Technical Specifications & Labeling

Packaging for sodium benzenesulfonate usually lists purity standards driven by customer needs—often above 98% for specialty applications. Labels describe moisture limits, typical particle size, and solubility. These aren't just ticks on a checklist, but practical measures to prevent clumping, speed up blending, and avoid residues in the user’s finished products. Bulk drums carry hazard warnings covering eye and skin contact. Regulatory numbers, batch codes, and recommended storage instructions fill out the label for traceability and regulatory compliance.

Preparation Method

Manufacturers rely on a well-tuned process to produce sodium benzenesulfonate. Usually, it starts with sulfonating benzene using fuming sulfuric acid or oleum under controlled conditions. The resulting benzenesulfonic acid is then neutralized using caustic soda—a process monitored for temperature, pH, and reaction completion. The sodium salt is isolated by crystallization or spray drying, filtered, and washed to remove unreacted materials. Producers monitor waste handling closely, dealing with acidic effluents and maintaining tight controls to limit emissions from the sulfonation step.

Chemical Reactions & Modifications

In the lab, sodium benzenesulfonate serves as more than just a surfactant—it provides an entry point for diverse syntheses. Chemists use it to perform substitution reactions on the aromatic ring, introducing other functional groups and making progress toward pharmaceuticals or specialty dyes. Under alkaline or acidic conditions, it stands up well, resisting breakdown in most environments except under strong oxidizing agents. Its sulfonate group brings water solubility, while the benzene core accepts a range of transformations for material advancement.

Synonyms & Product Names

On shipping documents, sodium benzenesulfonate wears several labels. Some refer to it as benzenesulfonic acid sodium salt, sodium benzenesulphonate, or simply BSS. Retailers sometimes stick with its chemical acronym, while others include trade names crafted by major chemical companies. This string of names hides the fact that users rely on its well-defined chemical profile rather than brand value.

Safety & Operational Standards

Working with sodium benzenesulfonate calls for respect, if not anxiety. Contact with eyes or skin can irritate, and inhalation of its dust brings respiratory discomfort, especially in poorly ventilated spaces. Industry standards advise gloves, goggles, and dust masks in the work area—standard gear found in most chemical plants. Storage away from incompatible chemicals and water sources keeps accidental reactions at bay. Employers lean on clear protocols and training to minimize exposure and avoid long-term issues stemming from repetitive handling.

Application Area

Sodium benzenesulfonate steps into many roles beyond household cleaners. In textile processing, it helps dye molecules spread evenly across fibers, improving product consistency batch after batch. The oil and gas industry injects it into drilling fluids to disperse solids and prevent clogging. Water treatment plants value its ability to stop scaling. In laboratories, it occasionally serves as a reagent in organic chemistry. These applications show the compound’s versatility and importance, connecting small-scale research to large-scale industry.

Research & Development

Research teams keep pushing the boundaries of what sodium benzenesulfonate can do. Uncovering better dispersant properties, improving its environmental profile, and finding new uses in material science stand out among current efforts. Alternative production routes—leveraging greener sulfonating agents or using solvent-free processes—draw interest from producers who see regulatory and consumer pressure cranking up about sustainability. Collaborative projects link academic labs with manufacturers, exploring how this chemical can fit into future circular economies.

Toxicity Research

Decades of safety testing have put sodium benzenesulfonate under the microscope. Acute toxicity ranks low, with LD50s in animal models pointing to a moderate level of safety compared to more reactive substances. Concerns focus on chronic exposure, the fate of breakdown products in the environment, and bioaccumulation. Studies show it breaks down in wastewater treatment, though high concentrations can affect aquatic organisms by disrupting cell membranes. Regulatory agencies regularly review data to update handling recommendations, keeping worker and environmental protection front and center.

Future Prospects

Looking ahead, sodium benzenesulfonate’s role could expand as both industry and regulators aim for safer and more sustainable chemicals. If greener synthesis methods reach industrial scale, the environmental impact could drop further. Advances in surfactant chemistry and new consumer product demands press researchers to tweak the molecule for even better performance in demanding settings. There's also interest in blending with bio-based surfactants, marrying the cost and reliability of traditional manufacturing with low-carbon alternatives. As pressure grows for transparency and safer formulations, producers keep investing in analytics, stewardship, and open communication about risks and benefits.

Chemistry Beyond the Lab: Unmasking Common Applications

Sodium benzenesulfonate hides in plain sight for most people. I saw its importance not in a classroom, but at a car wash, where detergents cut through grease and dirt. This sulfonate works as a surfactant, helping water spread out and grab hold of soil and oil, making clean-up a breeze. Dish soaps and laundry powders rely on its punch. The cleanliness you feel on your hands after using dish soap hinges on how easily sodium benzenesulfonate breaks up grime.

Industry Chases Cleaner and Faster Results

Factories look to shed inefficiency and waste. Sodium benzenesulfonate steps in to accelerate textile dyeing. In my experience working with a local textile plant, color streaking happened frequently until a chemical specialist suggested including this sulfonate in the dye bath. The difference showed up quickly: brighter blues and reds, and fewer patches. Dye evenly settles on fibers, thanks to the way this compound stops color molecules from clumping.

Oil companies count on sodium benzenesulfonate, too. It keeps oil flowing smoothly by helping water and oil mix together, which keeps pipes clean and less prone to clogging. Without that mix, extraction costs creep up, and workers face more downtime fixing blockages. Many field engineers I’ve spoken with trust this additive for keeping things running.

Water and the Fight Against Pollution

Cities with growing populations need smart ways to handle sewage. Water treatment specialists add sodium benzenesulfonate to help break down fats and oils in wastewater. At the plant near my home, city engineers explained that this sulfonate lets their filters trap more grime, so more clean water ends up back in the rivers. The compound degrades over time, which reduces long-term risk to ecosystems.

Pharmacy Shelves and Beyond

Not everything about sodium benzenesulfonate is industrial. Drugmakers use it to help medications dissolve more evenly. A neighbor who works in pharmaceuticals explained that tablets containing this additive release their medicine more rapidly and predictably. It’s critical for drugs that need to act fast—think painkillers or fever reducers.

Cosmetic products carry this ingredient as well. Shampoos and facial cleansers use it for lather, and so consumers get satisfying suds with less effort. The cosmetic scientists I’ve spoken with also say it helps other ingredients blend more reliably, so facial scrubs feel smoother and less gritty.

The Balancing Act: Safety and Sustainability

Trade-offs matter. Sodium benzenesulfonate tackles pollution in water systems, but manufacturing it still creates emissions. Researchers in chemical engineering circles push for greener production routes. Consumers and companies both watch regulatory standards. The European Chemicals Agency and the US EPA keep a close eye on safety data, and adjust rules as science advances.

Cleaner clothes, safer water, more effective medicine, all ride on small changes made possible by this overlooked chemical. Seeing the everyday impact of a molecule like sodium benzenesulfonate makes it clear—sometimes, progress starts with the simplest chemistry. Keeping that chemistry responsible, and seeking smarter alternatives, matters for everyone.

What Is This Ingredient?

Sodium benzenesulfonate shows up in more products than many folks realize. It’s a white powder used in detergents, cleaning agents, and sometimes industrial products. The main point of using this compound lies in its knack for breaking up grease and soil, making cleaning easier. Despite its effectiveness, many people ask if this chemical belongs anywhere near food or skin.

Human Contact: Cleaning Products vs. Daily Life

Many manufacturers put sodium benzenesulfonate in laundry detergents and dish soaps. These products touch our hands, our plates, even our clothes. If skin gets exposed, there’s a chance for dryness or irritation, especially for those with sensitive skin or existing allergies. The U.S. Environmental Protection Agency and European regulators both point out it can cause skin and eye irritation if handled undiluted or in concentrated form. Most household cleaners dilute it enough to avoid major problems on brief contact. Washing hands thoroughly after use helps lower risk.

Eating or Drinking It: Food Safety Isn’t the Goal

This chemical shouldn’t end up in food or drink. Food safety experts and major health authorities such as the Food and Drug Administration have not approved sodium benzenesulfonate for use in anything meant to be eaten. Swallowing even small amounts may cause nausea, stomach ache, or worse. Many industrial surfactants can cause vomiting, diarrhea, or other toxic reactions if ingested. I wouldn’t recommend treating anything with this compound that might go in your mouth. When spills happen in kitchens or food factories, a proper, thorough cleanup is needed to make sure no residues stick around.

Scientific Research on the Risks

Scientists ran animal studies that point out downside risks from exposure to sodium benzenesulfonate. Rats and mice fed low doses showed some stomach irritation, but higher amounts caused much more serious trouble. Short-term skin contact in lab settings irritated animals’ skin, but long-term tests didn’t show major health issues when used at consumer product levels. For humans, most cleaning formulas keep the concentration well below danger zones, and consumer safety regulators have set limits for good reason.

How to Stay Safe

For families at home, a few common-sense steps reduce worries. Wear gloves if you have skin issues or use cleaning products with strong chemicals. Don’t eat, drink, or smoke when working with detergents or cleaners. Read the label and follow directions. If a spill happens, clean up using water and avoid mixing chemicals. Never use industrial detergents for anything food-related.

In my own experience working with cleaning solutions in restaurant kitchens, I always went for plain soap and water near food rather than anything labeled as “industrial strength.” Once I did get red, itchy skin from using too much cleaner, and it taught me to respect warning labels. Most adverse reactions come from ignoring basic guidelines.

Better Alternatives and Ongoing Change

The market keeps shifting toward safer ingredients for home and personal care. Plant-based surfactants work almost as well for many uses, and products labeled “biodegradable” often cut out harsh chemicals like sodium benzenesulfonate. Reading labels carefully lets shoppers pick the safest option for the task at hand, which lines up with the advice from toxicologists and public health experts. For people particularly concerned about chemical exposure, supporting transparency and better labeling can spur companies to keep raising the safety bar.

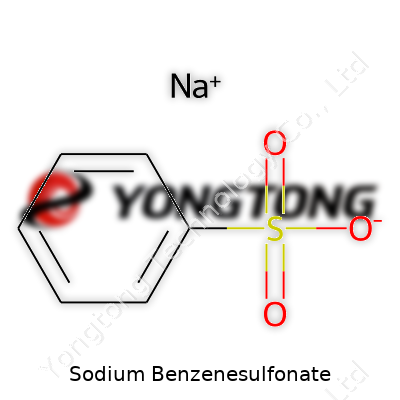

Understanding Sodium Benzenesulfonate

Sodium benzenesulfonate, with its white, crystalline appearance, plays a big part in the world of chemistry and manufacturing. This compound starts with a benzene ring, an essential backbone in organic chemistry, and adds a sulfonic acid group, which then gets neutralized by sodium. This single switch gives it a whole new shelf of possibilities. A small tweak in structure can shape a long list of practical uses.

Chemical Behavior

This sulfonate packs a punch in water. It dissolves with zero trouble, breaking apart into sodium ions and the sulfonated aromatic ring. That high solubility hangs on the sulfonic group. Compared to other organic molecules, sodium benzenesulfonate does not cling to oily patches or hang back when it hits water—this property turns it into a reliable player as a surfactant and dispersant.

Its structure resists oxidation and sits stable under normal conditions. Toss it in with strong acids or bases, and it holds steady. Harsh acids don’t rip it apart. Strong bases don’t force it back to its acid form. If you ever worked in a lab, you know the value of a chemical that will not break down mid-reaction, especially if you are cleaning up or trying to separate out products.

Applications Built on Its Chemistry

The real test of a compound’s value comes not in the textbook, but in how it works in daily products. Sodium benzenesulfonate’s ease in water makes it the backbone for detergents and cleaning agents. It sits in dish soap, laundry solutions, and even industrial degreasers. That sulfonate group gives dirt and oil fewer places to hide, breaking them up and washing them away. Sometimes the old ways, the chemical standards, keep proving their worth year after year. According to peer-reviewed studies and product datasheets, this compound contributes to both cleaning power and foam stability (Journal of Surfactants and Detergents, 2021).

Pharmaceutical labs use it, too, especially in crystallization of certain drugs where a sulfonate salt form is more stable or water-friendly. Wastewater treatment plants put it to work as a dispersing agent, helping solids spread out and settle more predictably. My experience in an environmental testing lab showed how little tweaks to the sulfonate chain can shift the way sludge or hazardous materials behave during cleanup.

Environmental Presence and Health Aspects

Sodium benzenesulfonate has a safer profile than some of its aromatic relatives. It doesn’t pile up in living tissue, and the body flushes it out pretty quickly, which matters for anyone using products at home or at work. Reports from regulatory agencies like the European Chemicals Agency confirm it shows low acute toxicity, but high concentrations in waterways may still affect aquatic life. Responsible use and disposal top the list of musts for manufacturers. Washing machines in cities dump billions of liters each year, and treatment plants don’t always filter everything out. So, the push for greener chemistry makes sense—aiming for alternatives or adjustments that work just as well, but break down faster in the environment.

Responsible Solutions and Better Chemistry

Finding the right balance between cleaning power, safety, and environmental impact takes real work. Industry leaders and researchers keep testing new tweaks—shorter chains, different salts, or additives that enhance biodegradability. Supporting these efforts requires not only regulation, but also input from those who use and handle these chemicals day in and out. The story of sodium benzenesulfonate continues to unfold—its chemical properties set the stage, but human choices shape the impact.

Understanding the Chemical’s True Nature

Sodium benzenesulfonate often shows up in labs and warehouses because folks rely on it for surfactant and cleaning applications. Behind the scenes, it’s a white powder or granule with a chemical punch. It dissolves in water, but if overlooked, it can cause trouble for both people and equipment. I’ve worked with a variety of chemicals over the years, and every one came with its own lessons—the same holds true for sodium benzenesulfonate.

Safe Storage Matters to Everyone

Let’s break it down. Moisture is the big enemy here. Leave this stuff in the open or in a humid room, and clumping or caking soon follows. That damages both performance and shelf life, causing headaches later. Air-tight containers save a lot of grief: glass jars, plastic drums with tight lids, or lined metal bins keep it dry and clean. Clear labels go a long way, especially in shared spaces. In my experience, confusion over unlabeled tubs is never just an inconvenience—it’s a safety risk that can lead to accidental misuse or costly disposal when nobody knows what’s inside.

Direct sunlight increases temperature swings, which can speed up degradation. Shelving away from busy windows or hot pipes keeps conditions consistent. I’ve also seen more than a few mishaps where chemicals ended up close to oxidizers, acids, or flammable materials. Segregation in storage is about peace of mind: sodium benzenesulfonate should have its own spot, well away from those other substances.

Smart Handling Keeps People Safe

Decent handling begins with simple habits. Don’t touch sodium benzenesulfonate with bare hands. Skin and eye protection matter a lot in the real world—nobody likes a chemical burn. Gloves and goggles don’t just check off a safety box, they prevent long-term health issues. Dust can get in the air quickly, especially in dry environments. I learned early on that a basic dust mask saves lots of sneezing and eye-rubbing.

Keep spills contained. I’ve watched seasoned workers use too little caution, and granules ended up outside their work zone. Sweep up with care, not with a blast of compressed air or a dry broom, which just spreads dust. Wet methods work best—dampen spilled material, sweep gently, and collect it in a sealed bag. That makes disposal easier and less hazardous to anyone cleaning up later.

Ventilation and Housekeeping Rules

One thing I always stress is keeping the workspace well-ventilated. Odor isn’t strong with this material, but inhaled dust can still set off allergies or worse. Simple fans or proper exhaust hoods do wonders. Housekeeping also plays a bigger role than people realize. Sweeping dust off benches, keeping floors clean, and wiping down containers make accidents a lot less likely.

Training and Emergency Measures

Nobody benefits from a casual approach in handling chemical stocks. Good training saves both time and health. Emergency showers and eyewash stations aren’t just for show. Everyone on site needs to know how to use them before there’s ever a spill or splash. Fast action during mistakes makes a huge difference between a close call and a hospital trip.

Treating sodium benzenesulfonate as “just another cleaning agent” misses the point. Respecting basic handling and storage practices goes further than meeting regulations—it protects the people doing the real work, and keeps supply quality up for the long haul.

Big Impact in Cleaners and Detergents

Sodium benzenesulfonate finds its main calling in everything from basic household cleaners to heavy-duty industrial products. Check the back of your dish soap or laundry detergent. The chemical helps dirty water lift away grime, giving us spotless plates and fresh clothes. Industrial cleaning solutions lean on it too, especially where greasy residues can put a stop to factory workflows. Thanks to sodium benzenesulfonate, factories keep their lines moving efficiently, and homes stay healthy and presentable.

Textiles: Softening and Dyeing Without Surprises

The textile industry relies on this compound during dyeing and finishing. The dye has got to distribute evenly on each fiber — patchy colors wouldn’t make for happy customers. Sodium benzenesulfonate acts as a dispersing agent here, keeping vibrant color in place and helping clothes resist static. Textile workers see fewer headaches with tangled yarns and stubborn stains, meaning machines can run longer and produce items ready for store shelves at a quick pace.

Agriculture: Helping Farmers Get More from the Land

Pesticides and herbicides need to spread out smoothly over crops or weeds. A decade working around agriculture taught me the value of products that don’t clump or run off during wet sprays. Sodium benzenesulfonate does its job by keeping chemicals even from leaf-tip to root, raising the odds that farmers get stronger, fuller harvests. It helps protect crops with less wasted chemical, which matters both for the environment and the family paycheck at the end of a tough season.

Personal Care: Inside the Shampoo and More

Shampoos, bubble bath, and even toothpaste owe some of their usefulness to this compound. Sodium benzenesulfonate helps products foam and makes sure rinsing feels complete, leaving hair and skin feeling clean rather than sticky. From a user’s point of view, it’s about comfort and trust in the bottle. It’s the sort of thing most people never notice, but the difference stands out in poor-quality products that feel heavy or leave a residue.

Paper Processing: Smoother Production and Better Print

Papermakers add sodium benzenesulfonate to pulping processes and coating applications. It reduces clumping, helps fibers separate, and keeps coatings consistent. This brings out smoother paper that prints clearly and handles ink without blotching. Anyone who’s ever worked in printing or publishing knows how frustrating a run of poor-quality paper can be, both for deadlines and for budgets.

Potential Issues and Safer Paths Forward

Companies using sodium benzenesulfonate face big questions about environmental impact. Wastewater with leftover chemicals doesn’t just disappear — it can end up in rivers, affecting wildlife ecosystems and drinking supplies. In my own experience working near industrial sites, community trust relies on transparent wastewater management. Regular monitoring and updated treatment technologies can head off bigger problems. Manufacturers benefit from investing in closed-loop systems that recycle water and cut discharge volumes. Switching to greener substitutes where possible also keeps companies ahead of changing regulations and public expectations. Looking closely at each stage of production, from sourcing to disposal, serves both business interests and the communities that support them.