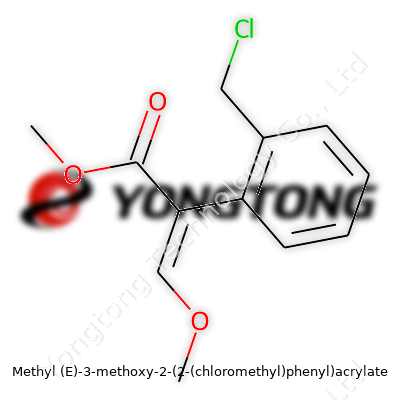

Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate: Exploring Its Journey and Role in Chemistry

Historical Development

Chemistry keeps finding new molecules to solve real-world problems, and the story behind Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate shows that constant search for progress. Decades ago, chemists looking to add new tools to both the pharmaceutical and materials worlds noticed how small tweaks in aromatic compounds could unlock fresh properties. The backbone of this molecule—a chloromethylated phenyl ring linked with a methoxyacrylate group—traces to deep research in esterification, aromatic substitution, and the drive to create more selective reagents and building blocks. Scientists in academic groups and industrial labs started by trying new protective strategies and reaction sequences that could yield more precise products for follow-up chemistry. That push set the stage for related molecules to show up in new research on kinase inhibitors, UV absorbers, and specialty polymers.

Product Overview

What stands out with this compound is how it bridges practical needs in chemical synthesis with enough complexity to matter in research. At a glance, Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate forms a colorless to light yellow liquid at room temperature, and it gives off a faint, mostly sweet odor typical of methoxy esters. Demand from both small-scale labs and specialty product makers means it lands on the shelf under different labels, with packaging designed for careful handling. This speaks to how tight quality control matters with advanced intermediates, especially ones carrying halogenated and unsaturated groups that don’t forgive mistakes in storage or handling.

Physical & Chemical Properties

Here’s a closer look at actual numbers and facts. The molecular formula comes out as C12H11ClO3, and its molar mass sticks close to 238.67 g/mol. A melting point well below 100°C puts it solidly in the liquid camp for most lab conditions, and a boiling point lands upward of 300°C under atmospheric pressure, though it often breaks down before getting there. The density hovers around 1.22 g/cm³. The compound doesn’t blend well with water, tending instead toward organic solvents such as dichloromethane or ethyl acetate. Its reactivity mostly targets either the double bond or the chloromethyl handle—each opening up chemoselective routes for further chemistry or coupling steps.

Technical Specifications & Labeling

Highly standardized labeling follows the guidelines set out under Hazard Communication Standards globally. That means each bottle ships with hazard codes for eye and skin irritation, along with clear advice on safe pipetting, spill response, and use of personal protective gear. Specifications trace purity by GC and NMR, often requiring more than 97% content with water and acid values in the parts per million range for research grades. Manufacturers nearly always run batch numbers and Certificates of Analysis so researchers can tie performance back to source and process. On the shelf or in a database, it can show up as Methyl trans-3-methoxy-2-(2-chloromethyl)phenylacrylate or a set of other IUPAC-driven synonyms.

Preparation Method

Making this compound tends to follow a roadmap researchers have built by trial, error, and a whole lot of literature review. A typical route starts with chloromethylation of a phenylacetic acid derivative, forming the core aromatic motif. Careful control of reagents—especially formaldehyde and acid catalysts—prevents side reactions that muddy the process. After prepping the substrate, chemists push through a Knoevenagel condensation or Wittig-type coupling with protected methoxy esters, keeping the geometry E-selective to preserve biological and photophysical behavior. The process runs under strictly anhydrous conditions, as both chloromethyl and acrylate functionalities suffer in moist or basic setups. After reaction, standard workup pulls the new molecule from the reaction soup, followed by flash column chromatography. Only steps with full documentation and product traceability pass muster for regulated environments.

Chemical Reactions & Modifications

Few molecules invite more diverse transformations than a chromophore-rich acrylate. Here, the chloromethyl arm reacts smoothly with nucleophiles to give ether or thioether analogues, while the double bond plays host to Diels-Alder cycloadditions, halogenation, or Michael additions with both hard and soft nucleophiles. Researchers wanting to protect the methoxy group can convert it to a hydroxy or other masked derivatives to tweak solubility or reactivity. Advanced catalysis, including Pd- or Cu-mediated coupling, lets chemists stitch additional aryl or alkyl groups onto either the aromatic or side chain features. These modifications enable a near endless lineup of derivatives, making the compound a springboard for diverse chemical and physical applications.

Synonyms & Product Names

Different manufacturers, suppliers, and research groups assign their own shorthand, which can puzzle anyone new to the field. Examples extend from the systematic Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate to more digestible titles like “chloromethyl methoxyacrylate ester” or “trans-methoxyesteryl chlorotoluene derivative.” Extra identifiers, such as specific batch numbers or lab codes, track raw material origin for those needing full regulatory compliance, with labels structured to flag any unique impurity risks.

Safety & Operational Standards

Safety sits squarely at the center of every user’s approach to this class of chemicals. The chloromethyl fragment, famous for both its utility and its toxicity risk, draws special caution because it can react with vital biomolecules, posing an inhalation or skin hazard. Adequate ventilation, gloves made from nitrile, face protection, and standardized spill kits all come into play in professional labs. Industrial users often triple-check ventilation and monitor exposure levels, training teams to avoid overexposure or accidental ingestion. Shipment follows local and international rules for hazardous materials, and emergency planning becomes part of job-site protocols, especially wherever bulk handling occurs.

Application Area

You’ll find this compound playing a role in a surprising range of advanced applications. Chemists use it as a synthetic intermediate for pharmaceuticals, particularly in creating targeted kinase inhibitors, where precise placement of functional groups can make or break drug activity. Polymer scientists pick it for specialty copolymers designed to resist UV breakdown or add clarity and toughness to consumer plastics. In the field of materials science, its unique blend of aromatic, ester, and halide functionalities enable researchers to create covalent organic frameworks or test new photoactive films. Analytical chemists also pull it off the shelf to act as a standard or tracer in validating new chromatographic or optical techniques. Each application depends on careful handling and a real understanding of what small changes to the molecule can unlock.

Research & Development

Ongoing research, much of it from university labs and innovative startups, pushes the boundaries. Teams investigate how new catalysts or green solvents streamline its synthesis, cutting both time and environmental impact. Biomedical researchers use its backbone to stitch on bioactive fragments, aiming for new antivirals or cancer therapeutics that leverage the molecule’s ability to fit into multiple receptor or enzyme sites. Materials science groups experiment with embedding related esters into responsive polymers that shift properties when hit by heat, light, or pH changes, potentially opening doors for next-generation semiconductors or flexible coatings. This drive for improvement ensures the compound stays relevant, with patent filings and research publications rising year after year.

Toxicity Research

No new class of compounds moves into the marketplace without a full accounting of its risks. Early studies flagged the likely hazards of chlorinated aromatics and acrylates, prompting years of toxicology exams in rodent and cellular models. Typical results show moderate acute toxicity by ingestion and inhalation as well as moderate to high irritation on direct skin and eye contact, underlining the relevance of protective handling. Longer-term studies work to pin down any risk of mutagenicity or cumulative organ burden, especially for products with potential human contact or use in packaging. Regulatory agencies demand comprehensive dossiers before clearing these chemicals for wider use, and this rigor has kept incidents in the lab rare. Continued vigilance and transparent reporting remain a simple but necessary solution for both makers and users.

Future Prospects

The next decade looks set to bring expanded opportunities for this class of acrylate esters, driven by demand for new functional polymers and more personalized pharmaceuticals. Greater automation and continuous flow chemistry promise safer, more efficient syntheses. Advances in computational chemistry speed up the hunt for new biological targets, guiding teams to tweak the molecule’s core before even stepping into the lab. At the same time, rising pressure to adopt greener, less toxic processes pushes producers to find cleaner reagents, alternative routes, and better recycling strategies. Cross-talk between industry and academic labs will shape the way forward, helping ensure progress doesn’t outpace safety or sustainability.

A Close Look at a Lab Workhorse

Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate doesn't turn many heads outside chemical synthesis circles, but inside the lab, it serves as a building block with real potential. Researchers have leaned on molecules like this because their structure opens new doors for drug discovery and specialized materials. In my time working alongside medicinal chemists and process developers, I’ve seen firsthand how compounds like this drive the creation of novel therapies and specialized polymers.

Stepping Stone for Pharmaceuticals

Drug discovery often begins with a handful of molecules that feature reactive spots and customizable handles. The chloromethyl group, for example, offers a key site for attachment, letting chemists tack on new pieces to create a library of potential drugs. Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate helps renew efforts on challenges like cancer and inflammatory diseases, because its structure makes it possible to quickly test and optimize drug candidates.

Data from global patent offices and pharmaceutical pipelines show a steady rise in the use of acrylate derivatives for biologically active compounds. Some researchers have leveraged this class to develop enzyme inhibitors or molecules that block protein-protein interactions. The journey from molecule to medicine remains long, costly, and full of roadblocks, so any scaffold that speeds up the trial-and-error process brings real value to both science and patients.

Paints, Coatings, and Polymers

The acrylate core of this molecule pays dividends outside medicine too. Paint and coatings industries seek ingredients offering both durability and functionality, and acrylates play a starring role. Adding a methoxy or chloromethyl group to the mix brings unique surface properties—improved adhesion, better photostability, or extra reactivity for crosslinking. Years ago, during a stint in the materials science lab, I watched these additives in action—batches with fine-tuned acrylates outlasted others under sunlamp testing and rough abrasion.

Manufacturers keep looking for formulations that deliver tougher finishes and meet tightening environmental rules. Bringing in molecules like this allows for smaller tweaks and custom polymers that help products stand out on crowded shelves. The end result benefits car owners with longer-lasting paint jobs, electronics makers needing thin yet robust coatings, and builders searching for safer, stronger adhesives.

Research, Challenges, and What Comes Next

Acrylate chemistry keeps proving itself in both public and private labs. The main challenge isn't just making these molecules—it's keeping costs manageable and production environmentally sound. Regulatory bodies—EPA in the US, REACH in Europe—have raised the bar on chemical safety, while customers are pushing for greener processes.

To meet these demands, some research groups use renewable feedstocks or develop one-pot synthesis routes to cut waste. Others switch to continuous flow reactors, dialing in precision and scaling up more safely. From firsthand experience, new production methods can drop costs and waste, but take real planning and investment.

Chemists, manufacturers, and regulators all keep moving the goalposts. Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate remains part of that conversation because it bridges the worlds of discovery and large-scale application. With the right investment in safer and cleaner chemistry, its future looks promising across many industries hungry for innovation.

Understanding Chemical Stability in Daily Lab Life

Chemists meet all sorts of molecular personalities in the lab, and compounds like methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate can be particularly touchy. My own benchwork made it clear—chloromethyl groups don’t take kindly to moisture, heat, or sunlight. If you’ve ever popped open a bottle of a new compound only to find it degraded or discolored, it sticks. This one demands respect from the start.

How Light and Air Change the Game

Direct sunlight won’t do it any favors. Over months, even fluorescent lab lights speed up yellowing or breakdown—trust me, those color changes in a vial tell you something’s going wrong. Strong light gives unstable electrons the nudge they need to leap into new, often unwanted, reactions. For this molecule, the mixture of aromatic rings and a chloromethyl group raises red flags around light sensitivity.

Opening a container too often can also let in air, setting off slow hydrolysis or oxidation. Anyone who’s scrubbed residue out of flasks because the contents “went bad” overnight knows why airtight containers matter. A screw-cap bottle with a sure seal—an old glass-stoppered flask if you want to keep it vintage—keeps unwanted reactions at bay.

Temperature: The Silent Stability Partner

Leaving chemicals at room temperature can seem harmless, but even a few extra degrees above 20°C can help side reactions creep in. In my experience, cold storage—between 2°C and 8°C—makes a clear difference for esters and anything with a good leaving group like chloromethyl. Inside a lab fridge, away from the humidity of kitchen fridges and the frost of a deep freezer, you can stretch the usable life months beyond what a warm shelf offers.

Why Moisture Is Public Enemy Number One

Skip on the desiccant, and you’ll regret it. Esters don’t like water, and the presence of a reactive chloride turns a storage mistake into an all-day clean-up. Desiccators, silica gel packets, or even a little calcium chloride tucked near the bottle can save a lot of headache later. Working with small samples, labs often move the bottling process to a glove box just to keep things dry.

Practical Tips and Better Lab Habits

There’s little glamor in jotting a date or snapping a photo of bottle labels, but tracking that information has pulled me out of trouble more than once. Watching for changes—color, clarity, odd smells—often means catching a storage slip before you lose an entire batch or compromise a reaction. For new students and old hands alike, it’s worth investing five minutes on good labeling, clever storage, and respecting the sensitivity of your reagents.

Some labs bank on using nitrogen or argon to blanket the headspace over sensitive compounds. That move keeps out air and moisture even better than a tight cap. In big projects, random sampling and testing purity with TLC or NMR heads off disaster and wasted funding. It’s no surprise—good storage pays off in pure product and a happier lab life.

Understanding the Risks up Close

Work in a lab long enough, and fancy names like methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate stop sounding intimidating. Then you see the safety data and realize every unfamiliar molecule deserves attention. This compound, like many phenyl acrylates, carries a number of chemical risks, especially with that chloromethyl group hanging off the ring. For folks who work with chemicals, experience starts with reading the data and ends with clean hands and a proper mask. Messing with this stuff, even a drop on skin, creates bigger issues than most people expect.

Touch, Breathe, Swallow: How You Get Hurt

That chloromethyl spot doesn’t just sit there quietly. These kinds of groups make molecules more reactive, so a spill can start an itch, cause a burn, or worse. I’ve seen colleagues shrug off a glove tear, only to complain an hour later about redness or blistering—never a good sign with halogenated organics. Inhalation risk rises fast during weighing or pipetting, since fine dust or vapor escapes easily. People don’t notice irritation until they’ve already inhaled more than feels comfortable. Anyone who has used a poorly ventilated fume hood has felt their throat go raw or start coughing uncontrollably.

Accidental ingestion isn’t common in the lab, thankfully, but poorly stored bottles pick up residue. Unmarked vials or casual sips of coffee after handling the material can expose an untrained hand. Acute symptoms show up quickly with chemicals like these. Skin becomes sensitive, eyes burn, breathing feels difficult, and in serious cases, systemic toxicity can follow.

Why Hazard Ratings Aren’t Just Numbers

Glancing at standard hazard labels doesn’t paint the real picture. Sure, you’ll see phrases like "harmful if swallowed," “toxic by skin absorption,” or “irritant,” but that doesn’t tell you how quickly a little laziness can go wrong. Chloromethyl-containing aromatics haven’t earned a reputation for safety—think of older research on alkylating agents and their link to mutagenicity and even carcinogenicity. Few chemicals in this family get the all-clear from regulatory agencies. If it isn’t well studied, caution increases.

PPE goes beyond gloves and goggles. Double-gloving is common. Engineers install fume hoods specifically because these compounds don’t belong in open air. In my experience, storing this compound with incompatible chemicals (strong bases, oxidizers) or in glassware with questionable seals often spells disaster. Labeled spill kits and a phone number for poison control aren’t “extra”—they’re a routine part of the day.

Fixing the Real Problems in the Lab

Ignoring proper handling comes down to culture, not ignorance. Leadership sets the bar: every team meeting covers incident reports and updates on new hazards. I’ve seen training programs require hands-on practice with simulated spills and real feedback on donning gear. Peer reminders save more skin than any poster on the wall. Quick access to updated MSDS, clear labelling, and restrictive access for undergraduates or visitors all prevent rookie mistakes.

Waste doesn’t solve itself overnight. Chlorinated aromatic waste means following strict disposal protocols and using approved containers. Labs partner with hazardous waste professionals instead of relying on shared sinks or municipal bins. From a health perspective, open discussions about symptoms, even embarrassment, lead to quicker responses and medical care.

Choices That Build Trust

Chemistry isn’t some game of who got away with the least cautious behavior. Trust forms in the lab when everyone agrees: one careless move can put people in harm’s way or wreck years of research. This compound, with all its hazards, reminds me every day how much those habits matter. Handling it safely starts with respect—for science, and for the folks beside you in the lab coat.

Understanding Chemical Purity in Everyday Research

Researchers and synthetic chemists pay close attention to the purity figures listed on bottles of specialty chemicals. In the lab, experience teaches that purity is not just a nice-to-have. It impacts reaction outcomes, safety, and reproducibility. A pure sample of Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate opens doors to reliability in downstream synthesis whether the project involves medicinal chemistry or new material development. I have watched a notebook full of brilliant ideas fade away thanks to an unexpected contaminant.

For this particular compound, most suppliers set the purity specification at ≥98%. This means nearly all the substance in the bottle matches the compound listed on the label. That’s the level you expect for structural chemistry work, and nobody wants funky peaks showing up on the NMR that stem from some gang of unknown byproducts. At ≥98%, purity already exceeds rough industry standards for initial research and suits scale-up, pharmacological screening, or advanced synthesis.

What Happens if Purity Drops?

Read the data sheets closely and you see why it matters. I spent months scaling a reaction, following the original protocol with my compound, and only hit a brick wall after the first shipment ran out. With a new batch at 90% purity, yield dropped dramatically. The difference? Hidden impurities that nobody caught early. These ghosts may slow reactions, poison catalysts, or throw off analytical data.

High-end processes such as pharmaceutical lead optimization or specialty electronics work leave no room for error. You want control and you want it from the start. My old PI once drilled home: “Garbage in, garbage out.” If you sacrifice on source purity, any amount of troubleshooting downstream becomes a wild-goose chase.

How Are Specifications Set?

Purity specifications don’t get picked out of thin air. Chemical suppliers rely on rigorous methods such as HPLC, GC-MS, NMR, and elemental analysis to benchmark batches. A 98% mark isn’t just symbolic: it often reflects the limitations of synthesis, or the cost of intensive purification. Push higher, and prices jump. For industrial use, sometimes 95% suffices, if the user plans further purification or if side products are benign. In academic or pharmaceutical environments, high purity lands closer to non-negotiable.

What Lies Beyond the Numbers?

A number on a data sheet doesn’t tell the whole story. Even two lots marked “≥98%” can differ. Is the impurity water? Or something that subtly interferes? When running sensitive experiments, don’t trust the number alone. Independent verification by NMR or LC-MS can save grief. I’ve ordered material labeled 99% pure, but an unanticipated side-product nearly sabotaged a publication.

Getting Purity Right: Approaches That Work

Hand-selecting suppliers with a strong track record pays off. Requesting certificates of analysis, and even structure elucidation of trace impurities when possible, heads off mishaps. For the most critical projects, working from single-lot material and characterizing it yourself takes time, but guarantees trust in your workflow.

Striving for purity isn’t about chasing arbitrary numbers. For breakthroughs that last, reliable purity lays the foundation. It may not look exciting on a spec sheet, yet the evidence is everywhere: clean inputs power discovery.

Why the Right Solvent Matters in Organic Chemistry

Working with compounds like Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate calls for a solvent that does more than just break things down. From personal lab experience, taking shortcuts with solvents leads to wasted time and ruined samples. Picking the wrong one could even introduce impurities or slow down reactions, putting months of hard work at risk.

Solvent Choices: Testing Solubility

In the lab, a chemist pays attention to polarity, boiling point, reactivity, and ease of removal. For esters with aromatic rings and halogen substitutions, solvents like dichloromethane (DCM), ethyl acetate, and tetrahydrofuran (THF) stand out. I have watched DCM dissolve compounds that gave others a hard time, and its low boiling point means removal under reduced pressure happens quickly. Ethyl acetate often serves as a backup for those wanting a greener approach or less toxicity than chlorinated options.

During one rushed undergraduate project, I reached for ethanol without thinking. Minutes later, a cloudy mess stared back at me. By shifting to DCM, everything cleared up, leaving a perfectly clear solution. That small mistake hammered home the lesson: not all “dissolve-it-all” solvents play nice with every organic compound. The structure of Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate, with its polar regions and aromatic nature, fits right into DCM’s sweet spot.

Health, Safety, and Sustainability Considerations

The convenience of DCM and similar solvents comes with trade-offs. DCM can irritate the skin, eyes, and lungs. Use it in a well-ventilated fume hood, and respect guidelines from regulatory bodies like OSHA and the European Chemicals Agency. For those shaking up old habits, alternatives like ethyl acetate shine because of their relatively tame safety profiles, even if removal can take a bit longer.

Sustainability continues to push scientists toward less toxic and more biodegradable options. The ACS Green Chemistry Institute promotes solvents with minimal environmental and health impacts. Ethyl acetate and acetone get top marks here. In my experience, ethyl acetate has handled many aromatic esters well, though it tends to struggle with very high or very low polarity substances. Acetone brings versatility and is easy to remove, but for certain esters, its solvency falls behind DCM or THF.

Mixing Solvents for Tough Cases

Complex molecules demand more. For some stubborn compounds, mixing solvents like DCM and hexanes or switching to THF can provide that extra push. In troubleshooting tough dissolutions, a mixed solvent system worked wonders for me during an organic synthesis project, saving me from the headache of batch failures and product loss.

The Takeaway: Let Chemistry Dictate the Choice

No one-size-fits-all solution exists for dissolving compounds. In practice, DCM usually gets the nod for Methyl (E)-3-methoxy-2-(2-(chloromethyl)phenyl)acrylate, thanks to its balance of polarity and volatility. Ethyl acetate stays close behind for those watching health and environmental impacts. Testing on a small scale, checking compatibility, and handling all chemicals with respect makes a bigger difference than anything a protocol can dictate. Good chemistry starts and ends with smart choices at the bench.