Methyl 2,3,4-trifluorobenzoate: A Down-to-Earth Look

Historical Development

Curiosity pushes scientists to poke and prod at the corners of organic chemistry, and that curiosity doesn’t take breaks. Francis Bacon could never have guessed we’d be stringing together benzene rings and loading them with different atoms, but the progress of the 20th and 21st centuries has come a long way from simple benzoic acid derivatives. Methyl 2,3,4-trifluorobenzoate is one of those molecules born out of that legacy. Chemists started getting serious about fluorinated aromatics midway through the last century. It was a time marked by growing interest in modifying physical and biological behavior through smart substitution on aromatic frameworks. Tools for precise synthesis grew sharper, helping folks in the lab move past the unpredictable world of random halogenation and toward more predictable routes. The modern commercial path to making Methyl 2,3,4-trifluorobenzoate leans on progress delivered by advances in selective fluorination, refined acid catalysis, and more reliable downstream purification.

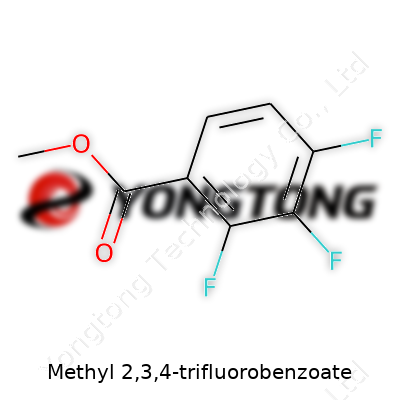

Product Overview

Drop the name Methyl 2,3,4-trifluorobenzoate into a chemistry lab and the reaction—pun intended—is a nod of respect. The compound stands out in the world of functionalized benzoates for its triple fluorine punch across the ring. That fluoro-hand makes a difference, not just in the way the molecule looks on a chalkboard, but in the properties it brings to the table. As a methyl ester of trifluorinated benzoic acid, it packs a hydrophobic edge and shows stubborn chemical stability which brings a lot of attention from polymer scientists and pharmaceutical developers looking to tweak reactivity without making sacrifices in downstream compatibility.

Physical & Chemical Properties

The crystalline form of Methyl 2,3,4-trifluorobenzoate shows up as a white solid, sometimes an off-white powder, depending on the batch and purity. The melting point sits around 35–40°C, with a boiling point stretching out past 200°C. Throw it in a standard organic solvent—something like dichloromethane, ethyl acetate, or THF—and it’ll dissolve with no complaints. The trifluoro substitution changes the usual story of methyl benzoates; the compound takes on greater lipophilicity and a notable resistance to hydrolysis, setting it apart from its non-fluorinated cousins. Chemists see these traits as valuable not only for durability but also for fine-tuning the way these molecules slip into larger molecular assemblies.

Technical Specifications & Labeling

Labs and suppliers publish purity for Methyl 2,3,4-trifluorobenzoate at 98% or better, with NMR and GC-MS data backing the claims. Product containers get stamped with batch numbers, hazard pictograms, and clear expiry dates, aligning with strict chemical safety labeling rules. Labels include structural formulas, CAS numbers, and recommended storage conditions—dry, cool, away from sunlight and oxidizers. Documentation is often available digitally, listing handling practices, chemical compatibility tables, and first-aid summaries drawn from real-world incidents. In my time handling specialty chemicals, digging out the original certificate of analysis and safety data sheet for new batches is about as routine as grabbing gloves before measuring liquids.

Preparation Method

Synthesis matters. For this molecule, most bench-scale preparations begin with 2,3,4-trifluorobenzoic acid. Acid chlorides get generated from the acid, often by reaction with thionyl chloride under a fume hood, given the fumes and reactivity of the intermediates. This acid chloride is then introduced to methanol, usually chilled, with a base to mop up the hydrochloric acid formed during esterification. Work-up routines involve washing with bicarbonate and brine to strip any leftover acid and dry the organic phase, leading up to rotary evaporation and final purification by recrystallization or flash chromatography. These steps demand respect for process safety, since the reagents and exotherms aren’t forgiving to the careless.

Chemical Reactions & Modifications

With three fluorines hugging one side of the aromatic ring, the molecule resists many electrophilic substitutions that would work fine on simpler methyl benzoates. Nucleophilic aromatic substitution, though, becomes a real possibility, particularly at the ortho or para positions relative to the fluorines, creating new handles for even trickier modifications. Reduction of the ester group, say with lithium aluminum hydride, flips the methyl ester into a primary alcohol. On the flip side, alkaline hydrolysis takes the methyl off, swinging the molecule back to the parent acid. The stability of the trifluorinated core makes it useful as a building block—it doesn’t fall apart easily in the kind of aggressive chemistry routines that scare off less robust aromatics.

Synonyms & Product Names

This compound carries several alternate titles. Besides Methyl 2,3,4-trifluorobenzoate, chemists might call it 2,3,4-Trifluorobenzoic acid methyl ester. Some catalogs include trade names or catalog codes that reference lab suppliers, which sometimes helps track down batch history if you’re troubleshooting. Synonyms exist mainly to navigate language and regional differences, but the IUPAC name cuts out confusion across research papers, customs forms, and multinational collaborations.

Safety & Operational Standards

Working with fluorinated aromatics involves non-trivial safety expectations. Direct exposure through skin or inhalation should be avoided. Gloves, eye protection, and fume hoods serve as standard lines of defense. In fire scenarios, combustion releases corrosive HF fumes and other fluorinated byproducts, requiring more than casual firefighting. Many institutions I’ve worked in require regular updates to chemical hygiene plans whenever new fluorinated stocks arrive on the shelf. Disposal of waste streams containing this ester demands specialized approaches, focusing on the environmental persistence of organofluorine compounds. Emergency protocols include water sources for eye washing, neutralizing agents, and clear paths to fresh air if inhalation occurs.

Application Area

If you walk through the corridors of chemical research labs, you’ll spot fluorinated benzoates in surprising places. Agrochemicals absorb these building blocks, harnessing the fluorines for improved pest resistance and stability in the field. Pharmaceutical companies keep them close for their impact on metabolic pathways—fluorine often softens the edge when it comes to biological breakdown, providing a longer half-life in drug candidates. Materials science groups see new potential in polymers and coatings, where chemical ruggedness and specific solubility profiles are essential. In my conversations with colleagues in the specialty chemicals sector, formulation scientists keep one eye on the reactivity of these intermediates and the other on their regulatory profiles, knowing customer demand can shift rapidly.

Research & Development

More groups are dialing in on structure-activity relationships involving the trifluorinated ring systems. Universities and private labs push for variations that deliver greater selectivity—maybe a drug with lower clearance rates or a polymer that shrugs off environmental degradation. Funding often comes from partnerships with end users who want custom-engineered molecules. Patents list not only the compound, but synthetic routes, purification tweaks, and specific use-cases spanning pesticides, drugs, and electronic materials. Industry consortia press toward greener, more atom-economic preparations, minimizing hazardous byproducts. The feedback loop between the lab and applications engineers results in a steady flow of modifications, each with supporting documentation to satisfy auditors, patent lawyers, and public safety organizations.

Toxicity Research

Every fluorinated aromatic raises eyebrows in toxicology. Animal studies evaluate skin sensitization, acute inhalation risk, and chronic organ exposure from both intentional handling and accidental release. Data on benzoyl derivatives show the potential for moderate irritation and persistent organ bioaccumulation. The challenge lies in linking structure to toxicological impact: three fluorines can make clearance tougher, but in some cases, structural bulk limits crossing into cells and tissues. Human volunteer studies don’t exist for these research chemicals, so assessments rely on analogs and in vitro screens. Advanced research now includes computational approaches, such as QSAR models, to anticipate and preempt possible toxicity issues before scale-up. Discussions with risk assessment specialists center on worst-case accident scenarios and the steps necessary to limit exposure for both workers and the environment.

Future Prospects

Next-generation synthetic chemistry is shifting toward more sustainable approaches to functional group modification, and these trends will shape the direction for trifluorinated methyl esters. Demand grows for specialty plastics, new therapeutics, and high-stability coatings—markets that trust the chemical stability and biological profile delivered by fluorination. As environmental scrutiny tightens, industries seek more information on persistence and degradation products. Chemists and policy teams must work together to develop safe scaling, improved analytical methods for trace detection, and alternative routes to handle waste. From firsthand experience, conversations about sustainability interest chemists as much as discussions about performance—there’s a shared goal of meeting both today’s technical demands and tomorrow’s stewardship responsibilities.

The Formula: More Than Just Letters and Numbers

Methyl 2,3,4-trifluorobenzoate carries the chemical formula C8H5F3O2. This sounds technical, but for people interested in chemistry, these numbers give you the entire foundation for how this compound reacts, behaves, and even how it smells or tastes, if you care about lab hazards. Let’s break it down just a bit. C stands for carbon, H for hydrogen, F for fluorine, and O for oxygen. Eight carbons, five hydrogens, three fluorines, and two oxygens—right away, this tells you it’s a benzoate with some dramatic changes thanks to those fluorine atoms.

Why Fluorines Make a Difference

Fluorine atoms don’t pop into chemical structures for show. In the case of methyl 2,3,4-trifluorobenzoate, they can bump up the compound’s stability and push its chemical behavior somewhere quite different from its non-fluorinated cousin, methyl benzoate. That’s especially important in pharmaceuticals, where a single fluorine can decide if a pill is stable on a shelf for months or falls apart in a week.

There’s another flip side. Fluorinated compounds like this one don’t break down in the body or the environment as easily as non-fluorinated versions. The carbon-fluorine bond is one of the strongest you’ll find in organic chemistry, so products made with these chemicals can linger. That could spell trouble if disposal and environmental care aren’t priorities. Anyone handling or making trifluorinated compounds knows it’s smart to think about waste management from day one.

What’s Behind the Rise of Trifluorobenzoates?

Chemists chase fluorinated molecules for more than bragging rights. Introducing fluorines changes the way molecules interact in living cells, often making them more useful in drugs, imaging, and agricultural uses. Sometimes, all it takes is swapping a hydrogen for a fluorine to improve a compound’s absorption, change its metabolic pathway, or bump up resistance to breakdown. Trifluorobenzoate esters have made their way into research on new medicines, pesticides, and specialty materials.

Here’s my experience from the lab: fluorinated aromatics like methyl 2,3,4-trifluorobenzoate aren’t just an academic puzzle. They come with real challenges in making them, keeping them pure, and storing them. I remember how we had to use glassware free of scratches, since these compounds sometimes draw out trace metals that can ruin an experiment’s outcome. Minor details, but they matter when you’re after reproducibility.

What Should Makers and Users Keep in Mind?

Anyone thinking about using this compound for synthesis or research should weigh both the opportunities and the responsibilities. On the one hand, a chemical like this can solve tough challenges in pharmaceuticals or material science. On the other, its remarkable stability can also mean it sticks around in soil or water systems unless managed thoughtfully.

Industry and academia do have practical steps for tackling those risks. Green chemistry approaches, such as using milder reagents or recycling solvents, can cut down on waste. Researchers have started to engineer bacteria that break down persistent pollutants, including fluorinated ones. Regulatory bodies now keep a close watch on their industrial use for environmental safety.

Final Thoughts

The chemical formula C8H5F3O2 only tells part of the story. The rest gets written in the lab, in regulations, and in long-term environmental responsibility. Science can push boundaries, but it needs to remember the bigger picture along the way.

The Backbone of Chemical Innovation

Often, the public doesn’t think much about compounds like methyl 2,3,4-trifluorobenzoate, but this isn’t just some forgettable item on a lab shelf. On a regular basis, chemists put this molecule to work, especially in the world of pharmaceuticals and specialty chemicals. What stands out right away is its trifluoromethyl group, which transforms how the molecule interacts with everything around it. This one modification can tweak volatility, improve durability, and make products safer and more effective.

Pharmaceutical Research: Quiet Catalyst for New Medicines

Drug discovery rides on innovation. Over the years in the lab, I’ve watched how researchers use molecules like methyl 2,3,4-trifluorobenzoate as a building block for new medicines. Chemists gravitate toward trifluoromethyl groups when they want to change how a drug is absorbed or processed. These subtle tweaks can lead to pills that stay effective longer or cause fewer side effects. Companies turn to this compound to create pain relievers, anti-inflammatory agents, and antivirals. Its unique structure lets scientists spot new paths in designing therapies, making it essential in early drug pipeline stages.

Pushing the Boundaries in Crop Protection

In the fields, science fights a different battle: pests and weeds. Agrochemical companies often pursue improved herbicides, fungicides, and insecticides. My connections in agricultural chemistry share that methyl 2,3,4-trifluorobenzoate becomes a handy starting material when tweaking pesticides for higher selectivity and faster breakdown in the environment. Fluoroaromatic building blocks let scientists craft chemicals that target specific problems, helping growers boost yield without ramping up environmental risks.

Creating Advanced Materials and Coatings

Anyone who’s dealt with coatings or polymers knows durability is king. The trifluoromethyl part in this compound pushes resistance to strong chemicals and heat. That’s no small feat in the world of electronics or protective coatings. Over the years, development teams have added it to liquid crystal displays or specialty resins, seeking a blend of resilience and performance. The plastics industry loves these types of benzoate derivatives for the way they help shape lightweight, tough materials that hold up in harsh settings.

Diagnostic Reagents and Biotech Progress

Outside drug discovery, biotech labs use methyl 2,3,4-trifluorobenzoate to build molecular probes. In diagnostic chemistry, sensitivity matters. The trifluoro aspect gives a distinct signature in nuclear magnetic resonance (NMR) and mass spectrometry. That makes it easier to confirm a compound’s identity or spot markers for disease. Diagnostics that stem from these building blocks can help hospitals catch illnesses sooner, guide surgeons, and support personalized medicine strategies.

Addressing Environmental and Safety Concerns

Safety always ranks high, whether in a pharma plant or a pesticide research facility. Any chemical packed with fluorine commands healthy respect. People in the field keep their eyes on manufacturing waste and breakdown products. Regulators have started tracking persistence in soil and water. There’s a push for green chemistry—safer reactors, lower-impact solvents, better waste handling. Chemists keep adapting, guided by fresh research and evolving compliance standards. Creative minds in academia and industry alike now search for ways to recycle or neutralize these byproducts, aiming to shrink the ecological footprint.

Looking Forward

Continuous learning sits at the center of chemical progress. As tools grow sharper, scientists keep discovering new traits and applications for specialty chemicals like methyl 2,3,4-trifluorobenzoate. Open collaboration between industry, academia, and regulators can drive safer and more sustainable innovations. The real-world impact of such molecules reminds us that small details in chemistry ripple into everyday products, from medications to smart devices and the food we eat.

Why Purity Matters in Chemical Work

Anyone who spends time in a laboratory quickly learns that purity isn’t just a number on a fact sheet. Methyl 2,3,4-trifluorobenzoate, a building block for pharmaceuticals and specialty chemicals, shows this in practice. Even small impurities in a reaction step can foul things up down the line—unexpected byproducts, ruined yields, or wasted hours troubleshooting columns. Chemists count on a clear standard: for this compound, a purity specification above 98%—often hitting 99% or higher—is the norm. This isn’t just a formality; it marks the difference between data you can trust and results that don’t hold up when tested again.

How Purity Gets Measured

Most suppliers back up their claims with chromatographic data. High-performance liquid chromatography (HPLC) tends to be the go-to, with nuclear magnetic resonance (NMR) and gas chromatography (GC) as further confirmation. A quality certificate should show clear chromatograms: one crisp main peak, with only tiny bumps allowed for other traces. The most reputable suppliers also include checks for moisture, ash content, and heavy metals, which sometimes hide in raw materials or sneak in during synthesis. I’ve had batches in the past where water content looked low, but a trace of iron changed everything in follow-up experiments. These tests matter.

Risks of Cutting Corners

If someone cuts a corner on quality control, you see it quickly. Impure Methyl 2,3,4-trifluorobenzoate can trigger side reactions, introduce unidentified peaks on spectra, and jeopardize regulatory compliance. Drug makers face tough scrutiny by the FDA and EMA: each impurity above 0.1% often needs to be identified and quantified, then proven to be safe if the compound’s heading for a living body. Research labs lose precious time chasing ghosts in their spectra. Too often, hidden contaminants mean extra purifications stage after stage, soaking up solvents and budgets.

Industry Standards and Real-World Practice

A standard purity of at least 98% doesn’t come from nowhere. Suppliers adopt this baseline because they’ve seen what subpar material costs—unreliable synthesis, inconsistent bioactivity, regulatory headaches. Trusted producers link each batch to a lot number, so analytical data is traceable. Researchers who buy from unknown sources sometimes get a surprise, especially if they accept vague claims like “high purity” without documentation. In my own projects, cross-checking supplier certificates and running an independent NMR or HPLC sample often catches problems before they snowball.

Better Solutions for Purity Tracking

Digital tracking has brought improvements. QR codes on bottles link directly to the full certificate of analysis—no more digging through file cabinets or navigating inscrutable websites. Some labs now archive their own spectra on shared drives, building up a data trail for every input to a synthesis. This kind of transparency saves both time and reputation.

What to Look for in a Specification Sheet

A reliable purity specification lists more than just a single percentage. It gives details on how the analysis was performed, shows spectral or chromatographic data, and spells out limits for water and heavy metals. Trusted suppliers keep open feedback channels and update their specifications if regulatory changes or customer feedback point to a gap. It pays to treat the specification as a living reference, not just a static number at the bottom of a page.

Real-life Choices Matter with Chemical Storage

Methyl 2,3,4-trifluorobenzoate pops up in a lot of research labs, especially where people work on pharmaceuticals or advanced materials. I’ve spent long days working in chemical stock rooms, so I know what can go wrong when storage gets sloppy. There’s no shortage of horror stories about careless practices that led to ruined samples or, worse, risk to health. I want to share a straightforward take on how to store this compound safely.

Keep It Cool and in the Right Spot

Every chemist learns early on: temperature control matters. Methyl 2,3,4-trifluorobenzoate sticks around longest in a cool spot—refrigerators designed for chemicals work well, running between 2°C and 8°C. Cold storage slows down any risk of decomposition, so the compound keeps its integrity. Don't wedge chemical bottles next to lunch or water bottles. Cross-contamination is real and can cause all kinds of unexpected headaches.

Avoid Light and Moisture

Many aromatic esters, this one included, show sensitivity to light and moisture over time. I’ve seen labels faded almost to nothing, and contents turning cloudy after a few weeks in a sunlit room. That’s a clear sign things aren’t right. Opaque containers save the day here. Use brown glass bottles with tight, screwed-down caps. Sealing the lid properly and storing in a dark cabinet pays off in chemical purity and safety.

Labeling: Simple but Easy to Get Wrong

Labeling feels basic, but mistakes here creep in fast. Permanent marker soaks through most labels during cleanup, so opt for chemical-resistant printouts or laminated tags. Write the compound name, date received, and any hazard warnings. In one lab, a missed toxic symbol meant someone grabbed the wrong bottle. Clear labeling stops that confusion cold.

Ventilation Means Safety for Everyone

Fluorinated compounds often have unfamiliar odors or risks, especially if someone drops a bottle. That’s why I always steer clear of makeshift stacks or crammed shelves. Store this material in a chemical storage cabinet with good ventilation—no ordinary office shelf. Find a place with air extraction or a safety vent. Breathing fumes by accident has sent more than a few coworkers to first aid, so don’t skip proper cabinets.

Spill Kits: More Useful Than Most Think

Even the most careful person slips up eventually. Spills happen. Keep an absorbent spill kit or at least some paper towels and gloves right by the storage site. Not everyone thinks about it until a bottle cracks. Quick containment means a cleaner workspace and fewer problems later.

Why All This Trouble Matters

The reason all these steps feel important comes from real problems in real spaces. Chemicals stored the wrong way break down or mix with moisture, leading to unpredictable results in research outcomes. More than that, mishandling can create dangerous situations for everyone nearby, not just the person checking the inventory. By taking these steps, anyone in a lab—beginner, student, or veteran—can work safer and produce more reliable work. It’s less about rules and more about looking out for each other.

Practical Importance of the Right Information

Reading the label on a bottle does not cut it when you’re standing in a lab with a chemical you’ve never handled. Methyl 2,3,4-trifluorobenzoate, with its tongue-twister name, turns up in chemistry labs and industrial setups that love tweaking molecules. Touching or inhaling an unfamiliar compound can rapidly shift from routine to dangerous. A Safety Data Sheet (SDS) is not some bureaucratic hoop—think of it as your quick-access manual to staying out of trouble.

Health and Safety at the Bench

I have vivid memories of my first stint in a chemical research lab. Gloves, goggles, and respect for unfamiliar names made up the difference between smooth sailing and an emergency dash to the eyewash station. SDS pages set out what catches fire, what causes irritation, and what helps you keep an accident under control. Methyl 2,3,4-trifluorobenzoate contains three fluorine atoms—these tweak not just how the molecule reacts, but how it behaves in the air and on your skin. Reports highlight that trifluorinated benzoates may irritate mucous membranes and could be toxic if inhaled in quantity. An SDS warns you what not to breathe, splash, or mix together if you care about your lungs and eyes.

Emergency Response: Don't Guess

You could say the test of an SDS comes during chaos. Spilled methyl 2,3,4-trifluorobenzoate on a lab bench isn’t fixed with paper towels alone. The SDS spells out safe clean-up procedures, what kind of ventilation you should have, and how to dispose of leftover bits. Relying on guesswork or habits from using a different compound adds risk. An SDS for this chemical would record its boiling point, reactivity with bases or acids, and whether it lingers in the air. Such details all help decide if running water, special absorbents, or simply opening a window gets the job done.

Legal Backing and Worker Protection

Regulations are more than red tape—they protect workers from shortcuts that hurt. OSHA—and authorities in Europe and beyond—insist that any workplace with chemicals must have an SDS ready for each one, making sure that first responders and employees gain immediate access if things go sideways. Without a posted and updated SDS, employers put staff at risk, and injuries get harder to treat. Not long ago, a friend of mine navigated an incident where a new hire skipped consulting the sheet, only to end up with chemical burns that a simple warning could have avoided.

Where to Find a Reliable SDS and What Needs Fixing

Sourcing a proper SDS should not be a scavenger hunt. Trusted suppliers like Sigma-Aldrich, Alfa Aesar, or Thermo Fisher usually provide them on their websites. Some startups or smaller distributors sometimes fall short, delivering minimal or outdated sheets, or skipping them entirely. This gap gets worse outside big academic or corporate labs. For casual buyers or educators, it often means going without essential safety advice. Pushing for better public access—possibly through an international, open database—could resolve this. Simple, multilingual, and verified sheets can help workers, teachers, and students everywhere make smart decisions about what they touch and breathe.

Final Thought: SDS as a Habit, Not a Hurdle

Grabbing the SDS for Methyl 2,3,4-trifluorobenzoate isn’t about bureaucracy—it’s practical common sense. This habit reinforces trust, cuts down on injuries, and helps everyone return home unharmed after a day with chemicals that most people never hear about. No one wants to regret skipping that “extra” step after something goes wrong. Make the SDS the norm, not the afterthought.