Fluoroethylene Carbonate – A Close Look

Historical Development

Researchers first synthesized fluoroethylene carbonate (FEC) in the late twentieth century, exploring its potential as a functional electrolyte additive. Battery chemists kept searching for ways to boost lithium-ion battery performance, and attention began shifting to small molecule engineering. FEC’s emergence didn’t come out of nowhere. Concerns about cycle life and stability in early lithium batteries forced significant trial and error. While many additives brought side effects or didn’t deliver in tough conditions, FEC showed real promise. It attracted widespread lab interest when it started to demonstrate more reliable cycling and robust solid electrolyte interphases. Commercial battery manufacturers soon started running their own tests. Over the years, pilot production grew, manufacturers fine-tuned analytical methods, and industry guidelines improved as FEC became a staple in advanced cell design worldwide.

Product Overview

FEC’s role goes far beyond its label as a carbonate solvent. It’s become a sought-after specialty chemical in contemporary lithium-ion battery manufacture. People look to it because it improves capacity retention, especially with high-nickel cathode chemistries and newly developed silicon anodes. Several producers, mainly in East Asia and North America, currently offer FEC at battery-grade purities, targeting both large-scale cell factories and specialty research labs. In principle, vendors bottle it as a clear, low-viscosity liquid, delivering it in moisture-proof containers that guard against contamination. Some producers push even higher purity batches for research and high-precision applications, but this drives up cost.

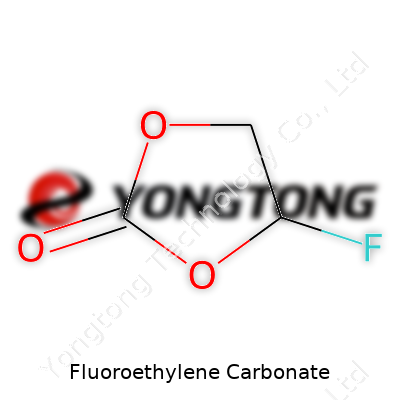

Physical & Chemical Properties

In hands-on lab use, FEC presents as a colorless, water-sensitive liquid, with a faint sweet odor and a moderate boiling point near 180°C. Its molecular formula, C3H3FO3, fits with the carbonate structure, sporting a strategically-placed fluorine atom that changes its behavior markedly compared to conventional ethylene carbonate. Its melting point hovers close to room temperature—around 20°C. FEC dissolves smoothly in common battery solvents and has a dielectric constant that helps to manage ionic conductivity in electrolytes. Its density, registered at about 1.37 g/cm³, means safe handling calls for good ventilation and careful measurement. The high reactivity of FEC with strong bases and acids means workplace protocols should never be relaxed.

Technical Specifications & Labeling

Producers typically offer FEC with purities no less than 98%, and sometimes above 99.5% for the most demanding customers. Technical datasheets usually cite water content under 100 ppm and call out metals below one part per million. Labels on containers bear explicit storage recommendations, warning of hydrolysis risk and the need for cool, dry storage. Drums, steel jerricans, and amber glass bottles are common shipping vessels, often equipped with tamper-proof seals. Labels spell out all international hazard codes and provide first-aid details, which is obligatory for all shipments traversing long routes—especially given increasing regulation targeting lithium battery chemicals.

Preparation Method

Manufacturers follow a multi-step synthesis. The most common method employs ethylene carbonate as a starting material, which undergoes fluorination using a fluorinating agent like DAST (diethylaminosulfur trifluoride). Each batch runs under anhydrous conditions to prevent decomposition, usually in specialized glass or stainless-steel reactors. Purification steps include vacuum distillation to strip off volatile byproducts and achieve the targeted purity. The entire process requires robust quality control since any residual acids, bases, or fluorinated side products can hurt electrolyte performance. Large-scale facilities run this process batch-wise, assigning dedicated personnel for contamination monitoring, with regular updates to their processing manuals as industry specs tighten.

Chemical Reactions & Modifications

FEC changes the game in batteries because of what it does at the molecular level. In reduction environments, such as the initial cycles of a lithium-ion cell, FEC decomposes at lower voltages and forms a fluorine-rich solid electrolyte interphase (SEI) on the anode. This reaction locks in a tough and thin SEI layer, reducing further solvent breakdown and suppressing harmful gas evolution. FEC also acts as a passivation reagent with reactive lithium metal surfaces, helping to slow dendrite growth in next-generation batteries. Chemists often experiment by modifying FEC’s structure or tweaking related carbonate molecules to push stability even further, looking for ways to tailor its breakdown products or reduce its corrosivity. These chemical innovations continue to reshape expectations among both academics and industry leaders aiming for higher-performing and safer batteries.

Synonyms & Product Names

Labs and suppliers recognize FEC under several trade names, but most catalogues use “fluoroethylene carbonate.” Some references call it 4-fluoro-1,3-dioxolan-2-one, or FEC for short, to avoid confusion with non-fluorinated forms. Brands in different regions might sell minor variants with additives to suit specific battery chemistries, but the core product always tracks back to the core FEC molecule. Catalogues and safety sheets will often list its CAS number (114435-02-8), providing reliable sourcing across geographic regions and supply chains.

Safety & Operational Standards

Factory protocols for FEC never skimp on safety. Teams suit up in goggles and gloves, mindful of splash risks and high reactivity with water. Breathing vapor or mist should never happen—FEC can irritate mucous membranes and lungs even at low concentrations. Workshops install local exhaust ventilation and always fit storage vessels with moisture-absorbing seals. Spill plans call for containment with inert absorbent and immediate disposal by licensed contractors. Emergency showers and eyewash stations stay close to any mixing areas. Suppliers emphasize transport under the current UN number for dangerous goods. Regular training and drills go hand in hand with routine audits, especially in regions where authorities have ramped up checks on hazardous battery supply chains.

Application Area

The main draw for FEC comes in high-capacity batteries. Engineers turn to it not just for run-of-the-mill consumer cells but for high-stress environments such as electric vehicles and grid-scale storage. Silicon-rich anodes gain a real boost from FEC, which helps manage the swelling and shrinkage that hammers these materials during charging. Researchers keep finding new angles—in some labs, FEC shows promise as a stabilizer for sodium-ion and magnesium battery prototypes. The additive turns up in high-power flashlights, drones, and medical implants, all seeking longer lifespans or safer operation cycles. Outside battery research, organic electronics and specialty coatings have started to dip a toe into FEC’s chemical toolbox, though energy storage keeps driving the most rapid uptake.

Research & Development

Investment in FEC-focused research hasn’t let up in the past decade. Companies race to tweak electrolyte blends, using FEC’s unique decomposition pattern to shield anodes from parasitic reactions. Labs run countless cycle life tests, peer-reviewed journals publish regular updates, and international conferences debate the latest blends and byproducts. Academics now use advanced spectroscopy to track the precise composition of SEI layers formed with FEC, searching for clues as to why it outperforms classic carbonates in certain hybrid cells. Patent filings keep climbing, as invention stretches from process improvements to entirely new applications outside classical lithium-ion cells. Collaboration between industry and public labs helps fast-track regulatory feedback and pushes product innovation deeper.

Toxicity Research

Nobody should take FEC’s toxicity lightly. Animal studies at trusted research centers illuminate the compound’s acute and chronic toxicity. Absorption through skin or mucosa can have harmful effects, prompting manufacturers to invest in detailed exposure studies and more rigorous personal protective equipment. Long-term studies flag organ and reproductive issues in model species when exposed repeatedly at high concentrations, pushing for strict exposure thresholds at the workplace. Disposal guidelines classify FEC as hazardous, with strict protocols for solvent treatment and neutralization. Regulators keep evaluating new data, releasing more detailed Storage, Handling, and Use (SHU) reports with every round of publication. As more high-output battery factories move closer to population centers, the health debate surrounding FEC’s lifecycle grows sharper.

Future Prospects

Looking ahead, FEC stands at the frontline of battery innovation. Market watchers expect demand to grow as solid-state and high-voltage batteries gain commercial traction and large manufacturers double down on safety and reliability. Synthetic pathways keep evolving, raising hopes for greener, lower-cost processes by swapping out toxic reagents or recycling byproducts. Over the next few years, the need for life-cycle data, sustainable sourcing, and post-use reclamation will push producers toward more transparent supply chains and eco-friendly standards. As silicon anodes and next-generation metals enter the mainstream, FEC’s chemistry will keep adapting. Progress relies on active collaboration between R&D labs, producers, governing bodies, and environmental groups—a challenging but energizing path for anyone invested in turning safer, smarter batteries from lab results into everyday products.

Behind the Charge

Batteries keep modern gadgets humming. Take a phone, a laptop, or even an electric car—most rely on lithium-ion technology. What actually makes these batteries run longer, work more safely, or re-charge faster? The real trick often comes from specific chemicals and additives mixed inside, and one important player these days is fluoroethylene carbonate, known as FEC.

Why Manufacturers Turn to FEC

FEC’s main job appears simple: it acts as an electrolyte additive. That means it goes into the liquid or gel that moves lithium ions from one side of the battery to the other. But its effects are anything but minor. FEC helps form a thin protective layer on the battery’s anode, which is usually made from graphite. This keeps the battery from breaking down quickly, lets it charge and discharge many more times, and makes it less likely to swell or overheat. In that sense, FEC helps stretch out the working life of everything from smartphones to electric cars.

Researchers and engineers keep pushing lithium batteries for higher energy and faster charge times, which brings new challenges. Batteries today use high-capacity materials like silicon to pack in more power, but silicon anodes tend to crack and lose power after repeated charging. FEC supports these advanced materials by stabilizing the interface where reactions occur. Scientific studies from major battery makers and academic labs show that adding FEC to electrolytes can boost a lithium-ion battery’s lifespan by over 50% and improve performance in low temperatures—one of the toughest hurdles for electric vehicles on cold mornings.

Real-World Impact

This isn’t just about squeezing more hours out of your phone. Electric vehicles and renewable energy depend on safe, robust storage. FEC increases both lifespan and safety, reducing the risk of battery fires. News stories about e-bike or car battery fires often lack detail about chemicals behind the scenes; better additives like FEC can reduce these risks and make clean transport truly viable.

Car companies now specify FEC in batteries for next-generation models. Tesla and other leading manufacturers build certain cells with advanced electrolytes, including FEC, to extend driving range and improve charging speed. These details rarely make the marketing brochures, but the benefits quietly shape the clean mobility transition.

On the consumer side, batteries with FEC let folks hang onto devices for longer before the dreaded afternoon crash or sudden loss of capacity kicks in. Instead of tossing out a phone or laptop after a couple of years, better chemistry stretches electronics’ usable life. This isn’t just a win for users; it also trims electronic waste, which has become a global headache.

Looking Forward

FEC costs more than many basic additives. Manufacturers must weigh the longer life it gives batteries against the higher up-front expense. Recycling and proper disposal add complication, since fluorinated chemicals need careful handling. Regulators, companies, and scientists must keep working together to manage environmental risks as use spreads.

Chemistry rarely gets flashy headlines, but fluoroethylene carbonate is quietly shaping the rechargeable world. At stake isn’t just convenience—it’s safer transportation, less waste, and more reliable energy as we put more trust in batteries every day.

Plenty of people working in battery labs have come face-to-face with a bottle of fluoroethylene carbonate (FEC). It promises a lot for lithium-ion battery performance. It boosts cycle life, reduces side reactions, and has played a big part in pushing batteries to the next level. That impressive chemistry comes with some important questions. Is handling FEC actually safe?

Understanding FEC’s Hazards

FEC smells faintly sweet, which tricks some into thinking it’s not that risky. Dig into the safety data, though, and the hazards become pretty clear. The liquid can irritate skin, eyes, and airways. Inhaling the vapors over time poses health risks. FEC has a low flash point, meaning it catches fire more easily than water-based solvents. If battery industries scale up, operators could end up working in rooms with worrisome vapor concentrations. That adds a layer of risk not found with less volatile chemicals.

Firsthand Experience in Lab Settings

Years ago, I ran a series of coin cell tests to compare different additives. FEC made a dramatic improvement in cycle life. That said, prepping electrolyte blends with FEC wasn’t casual work. We wore gloves rated for organic solvents, splash goggles, and sealed lab coats. The FEC bottle got opened only inside a chemical hood with good airflow. A colleague who forgot to clean up a spill found his lab bench surface had softened, the clear sign of FEC’s aggressive solvency. FEC stings when it splashes on skin, unlike water or common alcohol. By the end of a long day, everyone wanted those gloves off.

What the Experts and Studies Show

Occupational safety groups have started to pay attention to FEC’s rise in research and manufacturing labs. Studies find that, over time, small FEC spills can break down some plastics and seals, which can create leaks or unexpected vapor sources. If temperatures rise or air handling systems break down, FEC vapors reach levels over the recommended exposure limits set for organic carbonates. Researchers have reported skin rashes or mild breathing symptoms from prolonged accidental contact.

Regulations and Precautionary Tales

EPA regulations in the US and similar agencies in Europe treat FEC as a hazardous substance. Disposal rules are strict, and many academic labs demand spill training before you can use it. Not every factory follows best protocols, though, and news of fires sparked by solvent misuse still hits the wire now and then. When startups hire newcomers, safety steps can slip, and exposures do happen.

Making FEC Safer to Work With

Using FEC safely isn’t some fancy or mysterious art. Good lab ventilation, gloves, and proper goggles cut direct exposure. Closed-system transfer equipment keeps FEC contained from bottle to beaker. Automation helps when large batches are needed. Clearly labeled containers and secondary spill pans reduce accidents. Anyone handling the stuff needs refresher safety training, not just an onboarding speech. The safer the setup, the fewer times people have to trust luck if something spills or ignites.

Battery chemistry keeps evolving, and additives like FEC keep pushing performance. Nobody wants breakthroughs at the cost of workers’ health. Safety might slow down a process, but it can prevent a ruined career or worse. Every researcher or operator using FEC should recognize its hazards and treat safety gear as just part of the daily job.

Unlocking What C3H3FO3 Means

Fluoroethylene carbonate, with the chemical formula C3H3FO3, stands out among battery additives. That formula carries a lot of weight, especially in the lithium-ion battery world, and it deserves some careful attention. Manufacturers trying to improve battery life and safety use this compound to help create better electrolytes. As someone who’s spent time working with battery materials and reading up on emerging technologies, it’s clear that the specifics matter—the way those atoms come together directly influences the larger picture of energy storage.

Why C3H3FO3 Is Relevant in Everyday Devices

It’s easy to overlook what powers phones or cars until something goes wrong—like a phone that runs out of juice too quickly or a battery that gets a little too warm. Fluoroethylene carbonate doesn’t show up in flashy commercials, but its role matters. The addition of a fluorine atom to ethylene carbonate makes this molecule more stable during charging and discharging. It reduces side reactions that eat away batteries from the inside. The chemical stability and film-forming capability on the anode extend battery life and decrease the risk of fires. Lab tests and published research back up these benefits: one study reported at least a 30% increase in cycle stability when using fluoroethylene carbonate as an electrolyte additive.

Responsibility in Handling and Using C3H3FO3

C3H3FO3 isn’t something you’d want to spill in a lab or pour into a drain. Safety sheets warn about irritation and toxic effects if mishandled, so responsible storage and usage protect workers and the environment. Regulators pay attention for good reason—chemicals like fluoroethylene carbonate help batteries run better, but only with safe oversight. Trusted sources, including the European Chemicals Agency, require full documentation of safety measures and potential hazards in manufacturing and end-use.

Battery Technology’s Hot Topic: Sustainability Challenges

Every new battery innovation raises questions about environmental impact. Producing fluoroethylene carbonate involves resources and energy, and manufacturers must limit emissions along the way. A raw material shortage can spark ripple effects throughout the tech supply chain, sometimes causing obstacles for researchers and builders. Governments and companies alike tackle these problems with robust regulations and recycling initiatives, but there’s no silver bullet. The rise of battery-powered electric cars has only made these conversations louder and more urgent.

Solutions on the Horizon

Better recycling programs make sure less C3H3FO3 winds up as waste. Process improvements cut emissions before components ever leave the lab. Academic groups and startups continue to pitch greener methods for making additives from renewable sources. These changes grow out of a shared recognition—it’s not enough to push technology forward, you have to do it responsibly, and that requires careful attention to the raw chemical building blocks like fluoroethylene carbonate. The hope is that lessons learned in today’s battery labs will help shape a cleaner, safer approach to tomorrow’s energy storage solutions.

The Real Risks in Everyday Labs

On paper, fluoroethylene carbonate sounds technical and distant—something tucked away in an industrial lab. In reality, I’ve seen how careless storage can turn one small oversight into a big problem. Battery labs, research teams, small start-ups: they all depend on it to stabilize lithium-ion cells, boost longevity, and ramp up performance. But with benefits like those, it’s easy to forget that safety comes first.

Why Control Makes a Difference

Fluoroethylene carbonate reacts sharply to the world around it. I once saw a busy bench left cluttered with open bottles, sunbeams pouring in over the glass. Vapor started to build, and the chemical’s sweet, strong smell said all I needed to know. This compound won’t cause a fire easily, but once degraded, it ruins expensive experiments and creates safety headaches.

Cool, Dry, and Out of the Sun

Every bottle belongs far from heat, moisture, and direct light. In my team, we set aside dedicated refrigeration units. Keep this chemical below 25°C to discourage breakdown—excess room temperature speeds up unwanted changes in color and smell. Fluctuations create byproducts that threaten sensitive battery research. Even ‘ordinary’ humidity can eat through seals, making a previously reliable product unpredictable from one week to the next.

Airtight Means Business

A few years ago, we watched a half-used bottle go milky within days because its cap had been replaced in a rush. Exposure to air isn’t just about some theoretical risk; oxygen and water vapor attack the molecule, forming byproducts that nobody wants winding up in pricey electrodes. It takes a matter of minutes with a wrongly closed bottle for the fluid inside to become next to useless. My advice: swap original seals for chemical-resistant liners, and always check for condensation or crust before pouring out a batch.

Sensible Labeling Prevents Mix-Ups

Bottles have a nasty habit of looking similar from a distance. We label everything twice—once with a clear chemical name, and again with red warning tape. I’ve learned new personnel easily mistake fluoroethylene carbonate for more benign solvents, simply because secondary containers lack details. Every time a bottle moves, date it. We track opened containers using a shared log, so nobody ends up working with something past its best.

Original Containers and Secondary Storage

Manufacturers ship this chemical in specific packaging for a reason. I only transfer to glass bottles rated for reactive solvents, and never big open-mouth containers. Store every jug upright, tucked inside chemical-resistant bins to catch leaks. Refrain from using thin plastics—over time, even a slow vapor release leaves inside air dangerous and chemistry questionable.

Planning for Accidents—Before They Happen

I learned the tough way that even professionals make mistakes in the rush of an experiment. Keep spill kits next to storage spaces, stocked with absorbent materials and gloves. Avoid pushing bottles to the back of shelves—quick access speeds the clean-up. Consider your waste container as carefully as your main storage—stale leftovers introduce volatility into a waste drum, so regular disposal schedules matter more than most realize.

Responsible Care Shapes Trust

Safe storage isn’t just about ticking boxes for compliance. It shapes trust with teams, keeps costs steady, and protects reputations. Over years in the lab, I’ve seen shortcuts come back to haunt people. For anyone serious about chemistry, treating fluoroethylene carbonate with respect pays off in steady results and peace of mind.

What This Additive Really Brings to the Table

Batteries power most of today’s portable gadgets, electric bikes, and even family cars. Folks want batteries that can last longer, charge quickly, and won’t catch fire after months of heavy use. Lately, a lot of engineers and chemists have started using fluoroethylene carbonate (FEC) in their quest for stronger, safer lithium-ion batteries. It’s not just some mystery chemical—FEC is clear and works behind the scenes to solve big headaches in battery design.

Stopping the Gunk—Protecting the Battery’s Heart

Every rechargeable battery comes with one big snag: after hundreds of cycles, the stuff inside degrades. Lithium ions need an open road to move back and forth, but every charge and discharge builds up gluey junk, called the solid electrolyte interphase (SEI), on the anode. FEC helps form a thin, tough SEI film right from the first cycle, which keeps the anode from breaking down. Without that extra build-up, batteries hold more charge for a longer time. Real-world testing shows that batteries using FEC keep over 80% of their charge after 1,000 cycles, compared to less than 60% for older recipes.

Fire Risk and Heat—Why FEC Lowers the Danger

Any battery can heat up in a hurry, especially fast-charging smartphones or big electric car packs. Breakthroughs in safety don’t always come from shiny new materials but from smart chemistry tweaks. FEC has a knack for withstanding high voltage and high heat, so it doesn’t spark runaway reactions. Researchers at South Korea’s top labs found that FEC-cut batteries ran cooler and were much less likely to puff up or catch fire, even after being deliberately abused.

Boosting Silicon Anodes—Pushing for Bigger Performance

Battery makers have been itching to switch from graphite to silicon in anodes for years. Silicon can, in theory, store over ten times more energy. In reality, silicon anodes swell and crack, which kills most batteries in a flash. Add a little FEC and the silicon anode holds together much better. The surface layer built with FEC’s help bends and flexes with the silicon, so the battery doesn’t fall apart. Startups rolling out next-gen batteries almost always keep FEC in their formula for this reason.

Efficiency and Everyday Use—Why It’s Not Just a Lab Gimmick

People want phones that last a day, cars that travel more miles, and tools that don’t die after a year. Battery companies now include FEC because it helps each battery give up more of its stored energy. Quick charging puts extra stress on electrolyte additives, but FEC keeps performance stable, with current and voltage staying closer to “as new.” Leading consumer electronics firms have posted public data showing device batteries with FEC additives stay above 85% original capacity even after 500 heavy uses.

What’s Next—Looking Beyond the Buzz

Cost always matters. Scaling FEC for millions of batteries means balancing chemistry, safety, and price. Most manufacturers report only a minor cost bump for big stability gains. Cleaner, longer-lasting batteries also mean fewer waste packs in landfills and fewer hazardous spills. That means more reliable gadgets at home, a greener planet, and fewer recalls in stores. After spending years talking shop with battery engineers, it’s clear: FEC isn’t just a quick fix. This chemical upgrade really delivers where it counts.