4-tert-Butylbenzoic Acid: Unpacking Its Role, Importance, and Future

Historical Development

4-tert-Butylbenzoic acid comes out of a rich backdrop of aromatic chemistry. Chemists started looking into alkylbenzoic acids long before modern synthesis techniques became the norm, hoping to tweak molecules for better stability, function, or compatibility. By the time plastics, coatings, and specialty chemicals gained traction in the twentieth century, 4-tert-Butylbenzoic acid began making appearances as researchers explored ways to customize materials and formulations. Writings from that era talk about its rising use as a precursor in surfactant and polymer chemistry, hinting at a quiet transformation in industrial labs. Instead of overhauling old processes, companies saw promise in swapping out traditional benzoic acid derivatives for ones carrying that tert-butyl group—reaping improvements around resistance, solubility, and performance. Such changes didn’t just stay on paper; they rippled into consumer products that stuck around in everyday life.

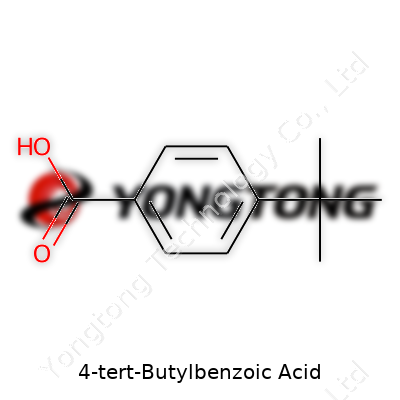

Product Overview

4-tert-Butylbenzoic acid stands out with its clear molecular structure: a benzene ring, a carboxylic acid group, and a bulky tert-butyl side chain. This configuration grants properties that fit industrial needs, ranging from chemical intermediates to practical additives. Chemists like how its molecular makeup adds both bulk and lipophilicity, letting the acid slip into blends that call for balance between solubility in organic solvents and stability under tough conditions. Years on, manufacturers keep returning to it for more than just its flavor as a raw material—they see it performing in adhesives, lubricants, and stabilizer blends, delivering enhanced resistance and shelf life. The demand never feels surprising, knowing how a small tweak in the base structure leads to a product that solves more than one problem off the shelf.

Physical & Chemical Properties

It takes only a cursory look at the white or slightly off-white crystalline powder to appreciate the straightforward handling requirements. 4-tert-Butylbenzoic acid brings a melting point hovering near 164°C, due in no small part to the tert-butyl group’s influence on lattice packing. In terms of solubility, you’ll find it readily wets into organic solvents like toluene or ether, delivering ease for those tasked with dissolving or modifying it. Water solubility stays quite low, which can be an advantage in certain settings, particularly when water-resistance is necessary. The acid demonstrates typical aromatic chemical stability, resisting spontaneous breakdown given room temperature storage. For those formulating new compounds, the predictable acidity, pKa near 4.4, supplies a steady handle in salt formation or neutralization reactions. These physical and chemical markers make equipment cleaning and containment less of a guessing game, reducing operational headaches and product loss.

Technical Specifications & Labeling

Most suppliers deliver 4-tert-Butylbenzoic acid with purity above 98%, often touting low moisture content and minimal byproduct residues such as 2- or 3-tert-butyl isomers. Certified batches arrive labeled with CAS No. 98-73-7, molecular formula C11H14O2, and batch analytics for trace metal contamination, sometimes under 10 ppm. The finer the printout, the more reassuring for both regulatory and customer quality audits. Packaging usually involves tightly sealed plastic drums or lined fiber boxes, banking on limited air exposure to prevent decomposition. Safety sheets reference GHS standard language, with detailed storage guidelines including temperature and light protection. This clarity helps anyone in procurement, inventory, or safety management stay ahead on compliance and risk reduction.

Preparation Method

Synthetic chemists lean on well-trodden Friedel-Crafts alkylation to produce the tert-butylbenzene starting material, then oxidize it to yield 4-tert-Butylbenzoic acid. Some teams adopt modified oxidation protocols, switching to potassium permanganate or chromic acid depending on scale and downstream needs. Later, acidification and crystallization function as quick, cost-effective purification steps. During my own time on the bench, working with similar syntheses, we often faced the challenge of minimizing ortho- or meta-products, but careful control of temperature and stoichiometry rewarded us with selectivity toward the para isomer. Not just a matter of academic purity—proper tailoring here reduces waste, downstream rework, and disposal burdens. When the industry gets this right, it cuts both time and cost from a process that can otherwise pile up inefficiencies.

Chemical Reactions & Modifications

For those branching into functional materials, 4-tert-Butylbenzoic acid proves a friendly candidate for esterification, amide coupling, and even designer ligands. Reactivity focuses on the carboxyl moiety, opening avenues to esters for plasticizers or polymers, as well as amides for specialty surfactants. Electrophilic aromatic substitution remains possible—though the tert-butyl group blocks para-positions, directing any substitution toward the less hindered ortho sites, if steric tolerance allows. Friends in custom synthesis talk about deploying it as a starting point for more complex ligands in catalysis research or as a template for light-modifying materials in optics. Given how mild conditions can generate key derivatives, the acid finds itself at the launchpad for specialty chemicals with high added value.

Synonyms & Product Names

4-tert-Butylbenzoic acid travels under alternative names in both literature and commerce. Among them, p-tert-Butylbenzoic acid, 4-t-Butylbenzoic acid, and even para-tert-Butylbenzoic acid show up on bottles and paperwork, each referring to the same core substance. Catalogues might also cite the shorthand TBBA or, less frequently, 1-Carboxy-4-tert-butylbenzene. Regulatory filings often favor the full IUPAC label, though you’ll spot the synonyms in global trade documents, especially when dealing with variant supplier documentation. I’ve seen occasional confusion among new lab staff when acronyms differ, but consistent training and clear storage labelling help curb mix-ups before they affect process safety or batch traceability.

Safety & Operational Standards

4-tert-Butylbenzoic acid enjoys a safety profile that rewards careful, standardized practices. Dust inhalation and direct skin contact bring the most concern, so everyday use includes gloves, dust masks, and goggles per standard COSHH or OSHA routines. MSDS documentation spells out the importance of dry storage, protection from strong oxidizers, and ventilation in weighing or handling stations. Most facilities opt for local exhaust ventilation in their prep rooms, favoring over-engineering to guarantee staff comfort and reduce long-term exposure risk, especially as even mild irritants tend to trigger cumulative workplace issues. In the event of accidental release, standard sodium carbonate neutralization and disposal by incineration keep both workers and downstream water tables secure. Strict inspections and routine staff training build trust between management, operators, and regulatory visitors.

Application Area

Industrial-scale uses of 4-tert-Butylbenzoic acid keep evolving as new polymers, coatings, lubricants, and adhesives demand more stable, specialized additives. Lubricant formulators pick it for oxidative stability and anti-corrosion, cutting maintenance cycles for machinery running hot and hard. It shows up in UV-cured coatings, boosting weather resistance in outdoor plastics without dragging down processing speeds. Synthetic chemists slip it into plastics for both performance and processing, turning out materials that hold up better under stress, heat, or light. There’s a noticeable jump in demand from the electronics industry, where high-purity batches anchor the stability of fine-tuned resins for semiconductors or display coatings. Even outside these blockbuster users, the acid finds life in cosmetics, agricultural sprays, and dye intermediates, wherever a hydrophobic aromatic acid can solve compatibility or lifespan struggles.

Research & Development

Chemists keep chasing new uses and improved processes, and 4-tert-Butylbenzoic acid never seems to lose its edge as a building block. Across recent literature, development projects focus on more efficient synthetic paths, reducing waste and energy loads by swapping green oxidants, developing biocatalytic reactions, and reclaiming solvents. Some public-private partnerships tackle the environmental profile, exploring how to recover or reuse side streams. Intellectual property filings hint at novel polymer blends and advanced coatings where the acid modifies surface energy or adhesion profiles. My own conversations with industry researchers make clear that value grows where tweaks yield measurable improvement in either cost savings, durability, or environmental footprint. Investments target production scale-up, new catalysis, and downstream transformation, eyewitness testimony to the acid’s staying power.

Toxicity Research

Toxicology studies indicate low acute toxicity for 4-tert-Butylbenzoic acid, but chronic exposure data remains less extensive. For those in formulation roles, keeping exposures minimal carries prudent wisdom given possible links between aromatic acid exposure and longer-term organ impacts, though current evidence hasn’t landed the acid on major restriction lists. Clinical observation finds mild irritation with direct contact or inhalation, but systemic absorption in occupational settings remains rare with modern safeguards. The biggest toxicological challenge involves environmental stewardship: even with low water solubility, improper disposal risks bioaccumulation in sediment or aquatic life, so keeping processes closed and emissions minimal sits high on best practices. Third-party audits often focus here, insisting on trace monitoring and safe incineration over landfill for disposal.

Future Prospects

As the chemical industry shifts towards sustainability, 4-tert-Butylbenzoic acid’s role may shift, but disappearance looks doubtful. New eco-friendly solvents and chemistries lean on molecules with versatility and manageable risk profiles, and modifications to this acid lead the way in certain advanced materials. For those working toward circular manufacturing, further investments in recycling side streams, reducing heavy-metal catalysts, or switching to renewable feedstocks promise to keep production cleaner and more adaptable. The product’s success story goes hand-in-hand with ever-more-demanding applications, and as polymer and electronics markets keep stretching their standards, chemical engineers will keep rewriting the acid’s application sheet. Tomorrow’s formulations may well treat it as a scaffold for performance materials that must meet both regulatory and consumer pressures head-on. I see it staying not because of old habits but through real, testable value—one molecule at a time.

The Backbone of Lubricant Additives

4-tert-Butylbenzoic acid often finds its way into the world of lubricants. Growing up around machine shops and learning the basics of engines, I’ve seen firsthand how the right additives can extend the life of a car or factory equipment. This chemical acts as a corrosion inhibitor and a stabilizer in the formulations of engine oils and industrial greases. Without a solid additive package, engines can heat, seize, or corrode. Lubricant makers rely on 4-tert-Butylbenzoic acid to keep metals in motion working longer and cleaner, especially under heavy loads or extreme temperatures.

Turns Raw Material into Practical Polymers

Think about the plastic handles on a screwdriver or the casing of a plug adapter. The resins and plastics they use often call for a little help to behave as expected during production. 4-tert-Butylbenzoic acid takes on a big role as a chain terminator in polyester resins. By stopping the growing polymer chain at just the right point, it sets the physical properties for a range of molded or extruded plastic parts. Reliable plastics keep homes and workplaces safer, chiming in as insulation for wires, structural parts for electronics, or lining in containers.

Coloring the World, One Pigment at a Time

Dyes and pigments come packed with unexpected chemistry. Friends who work in textile manufacturing have shown me stacks of finished fabrics. Stable, vivid colors stay on the cloth thanks to intermediates like 4-tert-Butylbenzoic acid. The pigment industry benefits from this chemical, using it as a building block to create brighter, longer-lasting shades in paints, plastics, and textiles. The increase in colorfast products in our daily lives owes much to these stable intermediates, letting clothes look newer longer and paint keep its shine.

Putting Chemistry to Work with Esters and Pharmaceuticals

Esters made from 4-tert-Butylbenzoic acid show up in some pharmaceutical formulations. Drug makers harness these compounds for their specific properties, sometimes to adjust how drugs dissolve or how long they remain active in the body. The details that go into medicine design move beyond the featured active ingredient; the supporting cast of molecules dictate if a pill works as intended or causes discomfort.

Solving Challenges Through Smart Sourcing and Safety

Safe handling matters no matter the industry. Some of my earliest lab jobs showed how vital strict protocols are for chemicals, including acids like this one. Manufacturers must pay attention to proper storage, personal protective equipment, and disposal. Regulatory guidance from bodies such as the Environmental Protection Agency or REACH sets the rules for how 4-tert-Butylbenzoic acid gets managed, from receiving in a warehouse to final use.

Finding New Ways to Reduce Waste

The demand for greener chemistry grows as waste stream rules tighten. Recycling programs, process improvements, and greener synthesis routes will become more important. Chemists talk about “designing for degradation,” figuring out how a compound will break down safely after use. Seeing this shift, especially among younger engineers and scientists, brings hope for a balance between performance and sustainability.

At a glance, 4-tert-Butylbenzoic acid blends quietly into the fabric of countless behind-the-scenes processes. Right now, it helps products last longer, stay more vibrant, and perform better. Thoughtful sourcing and a nudge toward sustainability will secure its place in a responsible industrial future.

Breaking Down the Structure

4-tert-Butylbenzoic Acid looks simple on paper, but its arrangement shapes how it behaves in industrial and everyday applications. Its backbone features a benzene ring, which is a six-sided ring of carbon atoms famous for its stability and presence in tons of everyday chemicals. Attached to this ring are two important groups: a carboxylic acid group (–COOH) and a tert-butyl group (–C(CH3)3).

The position of each group makes a difference. The carboxylic acid group attaches to the ring at what chemists call the “one” position. Count four spots over, and you’ll find the tert-butyl group, which pushes a cluster of three methyl groups outward, making this molecule bulkier compared to regular benzoic acid. Its full molecular formula tells the story: C11H14O2.

Why Structure Matters in the Real World

This extra bulk from the tert-butyl group doesn’t just add weight. It gives the acid properties that chemists and manufacturers put to use every day. That tert-butyl chunk blocks certain reactions, making the molecule less likely to get broken down by sunlight or air compared to straight benzoic acid. As a result, products using 4-tert-Butylbenzoic Acid tend to last longer and perform with more consistency.

Working as a researcher in coatings, I’ve watched how additives like this one help paints stay strong against weather and wear. It offers a shield, slowing down the breakdown caused by water and oxygen. This isn’t just theory – studies back it up. For example, chemical reviews published in journals like the Journal of Applied Polymer Science point out how the bulky tert-butyl group increases thermal stability by keeping radical degradation at bay.

Antioxidant Activity and Practical Uses

The way the tert-butyl group crowds the ring helps curb oxidation, making the compound useful as a stabilizer in plastics and varnishes. Oxidation can ruin polymers, turning them brittle and weak. By plugging 4-tert-Butylbenzoic Acid into a mix, manufacturers help keep plasticizers and resins fresh during storage and processing. The acid group (–COOH) lets it mix with polymers, and the tert-butyl group does the protecting.

Companies making lubricants, adhesives, or paints lean on this dual role. Reports from the European Chemicals Agency detail how its structure allows it to work at relatively low concentrations, reducing the need for more hazardous additives. Its known breakdown pathways have been studied, showing limited toxicity and making recycling and handling simpler compared to more complex alternatives.

Looking Ahead — Balancing Innovation and Safety

Though 4-tert-Butylbenzoic Acid shows strong promise as a stabilizer, users should stay alert to long-term effects. Some aromatic acids have raised questions about environmental buildup. Current data suggests this chemical avoids most major pitfalls, but green chemistry teams continue searching for additives with even safer profiles.

Making sure that chemicals like this are handled safely means going beyond lab tests. Training workers, sticking to best practices, and keeping an eye on changing regulations all matter. A well-understood structure, matched with honest communication, brings out the best in any chemical, 4-tert-Butylbenzoic Acid included.

The Basics of Safe Storage

Working with chemicals like 4-tert-Butylbenzoic Acid, I’ve learned that a lot of problems start from small lapses. Temperature in the storage area often doesn’t get enough attention. This acid keeps best at room temperature, but sudden shifts make it clump or degrade. Cool, dry conditions work better than relying on the fridge in most labs, which can build up condensation. Humidity, more than cold, starts trouble in bottles and bags, turning fine powders into sticky messes.

Why Containers Make a Difference

Leaving chemicals in flimsy bags has led to more headaches than I care to admit. For 4-tert-Butylbenzoic Acid, I reach for tightly sealed glass or high-density plastic jars. The acid isn’t volatile, but it picks up moisture and absorbs odors. A lid that screws down, not just snaps on, goes a long way for keeping it in good shape. Every year, stories come out about big messes from leaky chemicals, so it’s smart not to cut corners.

Clear Labeling Prevents Mix-ups

I’ve seen disasters start with unclear labels. Permanent marker on frosted glass works, but I go for pre-printed labels with bold text. It’s not about being fancy—it’s about glancing at a shelf and grabbing the right bottle every time. Write down the date when you open a new container. This one habit has caught stale or clumped acid early, before it spoils a batch or ruins a whole afternoon.

Why Separation Reduces Risk

Some people keep all their acids together, thinking it saves space. After dealing with spills and harsh smells, I learned that 4-tert-Butylbenzoic Acid deserves a dry shelf, away from bases and reactive metals. Direct sunlight breaks down certain chemicals faster than you’d think. A closed cabinet away from other powders keeps reactions from getting out of hand if something tips over. Regular shelves collect dust and humidity, which make more work down the line.

Ventilation and Safety Gear—Not Just for Lab Rats

Protective gear gets left in drawers too often. Even stable powder can send up a small cloud if the lid sticks and pops free. I’ve seen people cough and rub their eyes after a careless pour. Lab coats and goggles are basic, and nitrile gloves avoid skin irritation. An old lab mate kept wiping his hands on his jeans—his rash lasted weeks. The lesson stuck. With good habits, even small labs avoid big troubles.

Disposal and Long-Term Storage

Every bottle runs out, and leftover acid piles up. Treating old 4-tert-Butylbenzoic Acid like trash creates hassles later. Local guidelines matter; tossing it down the drain isn't just risky—it’s illegal. Many chemists partner with hazardous waste vendors who pick up spent product. Storage areas stay cleaner when leftovers don’t pile up, and fires from packed shelves drop off. It’s a habit worth starting early.

The Payoff

Taking care with storage brings peace of mind. Chemical storerooms feel safer, and supplies last longer. With a few tweaks to daily routine—tight lids, dry shelves, proper labeling—people keep messes and mistakes to a minimum. Labs and factories move smoother, accidents stay rare, and nobody loses time or product to simple oversight.

The Nature of 4-tert-Butylbenzoic Acid

Chemicals with names as long as 4-tert-Butylbenzoic acid often spark more suspicion than necessary. It serves mostly as an intermediate in the chemical and plastics industries, shaping the texture of adhesives and enhancing the performance of resins. Its journey rarely crosses paths with everyday folks, but it does matter to people working in labs and manufacturing facilities.

Hazards in Industrial Environments

Anyone who’s opened a drum of industrial chemicals knows the importance of basic safety measures. 4-tert-Butylbenzoic acid has irritant qualities. Breathing in its fine dust may irritate your throat or nose, and it doesn’t bode well for sensitive skin. Eye contact brings a burning sensation. Data from suppliers and agencies like the European Chemicals Agency make it clear: always handle this chemical with gloves, goggles, and preferably under ventilation.

The US National Library of Medicine notes that 4-tert-Butylbenzoic acid’s acute toxicity scores low, meaning a moment of contact will not lead to life-threatening symptoms for the average worker. Still, common sense and workplace standards demand respect, even with chemicals lower on the hazard scale.

Facts on Toxicity

Researchers keep a close record of anything that might pose hidden dangers. Large doses of 4-tert-Butylbenzoic acid, like many benzoic acid derivatives, challenge the body’s defenses. The oral LD50 in rats sits above 2000 mg/kg, showing relatively low acute toxicity compared to genuine poisons. No evidence links it directly to cancer or birth defects. Chronic risks turn up mainly in animal studies, where absurdly high doses over long periods show minor changes in liver and kidney tissues.

I’ve learned that the risk profile sits lower than real hazards such as benzene or formaldehyde. It won't escape from plastics into your food or drink. It doesn't bioaccumulate significantly in the environment or in living organisms, so there’s little cause for alarm over long-lasting ecological buildup.

Environmental Impact and Disposal

No chemical deserves carelessness. Even with mild toxicity, dumping any amount can cause trouble for aquatic life. The acid structure means it won't dissolve easily and can hang around in soil and sediments for a while. Waste disposal laws direct users toward collection and managed destruction, usually by incineration. Never pour lab waste down the drain—cleanup always carries a price.

Staying Safe at Work

Most workers have seen the inside of a Material Safety Data Sheet (MSDS) binder. 4-tert-Butylbenzoic acid sits among the chemicals marked for “use with caution,” not “deadly threat.” Wear gloves and goggles. Don’t eat at your workbench. Wash up before heading home. Responsible storage matters—keep containers sealed away from acids, oxidizers, and moisture.

Factories rely on team communication. New employees learn from the habits of experienced ones. Often, it’s not just what you’re handling, but how you handle it that shapes the outcome.

Moving Forward: Practical Solutions

The best approach starts with education and regular reviews of safety protocols. Keep safety data updated so everyone stays aware of new findings. Invest in proper ventilation and protective gear. Report spills immediately. Shift toward green chemistry where possible, using less hazardous alternatives. The chemical industry keeps improving these processes with each generation, working toward solutions that keep people, property, and the environment safe.

Understanding a Solid with Substance

Walking up to a sample of 4-tert-Butylbenzoic acid, most folks will notice it’s a solid at room temperature. In my experience with organic chemicals, handling this compound feels like working with many other white crystalline powders, yet its distinct odor and neat crystals set it apart. The compound barely dissolves in water, so labs often keep some ethanol or acetone handy to clean up. Its melting point sits around 164-168°C, which comes in handy during purity checks—a batch that melts much lower usually spells trouble with contaminants. The sharp, reliable melting point makes it valuable for running quick tests during synthesis or formulation.

Solubility: A Challenge in the Lab

The t-butyl group sticking out from the benzene ring means 4-tert-Butylbenzoic acid hardly wants anything to do with polar solvents like water. It prefers dimethyl sulfoxide, ether, or chloroform. In practice, I’ve wrestled with this low water solubility while trying to run reactions relying on aqueous solutions—the acid just clumps at the bottom of the beaker. This trait pushes researchers to seek out the right mix of solvents to coax it into solution. From an environmental point of view, having poor water solubility can simplify disposal, yet it also slows down breakdown outside the lab, as organisms in water can’t always access and break it down quickly.

Looks Can Matter: Appearance and Handling

The powder’s color and shape reveal a lot about its quality and safety. Pharmaceutical and plastics manufacturers want a consistent appearance, because those small differences in crystal size can throw off how a batch flows or blends in larger-scale mixing equipment. Unless stored in airtight containers, 4-tert-Butylbenzoic acid will slowly absorb atmospheric moisture. I’ve seen samples turn clumpy after a humid week on the shelf, so most folks stash it in dry, cool spots. That keeps weighing accurate and limits unwanted chemical reactions.

Boiling and Thermal Stability

Heating this acid doesn’t send it bubbling off as a vapor; it decomposes well before reaching a boiling point under typical atmospheric pressures. In manufacturing environments where safety comes first, knowing a substance flashes off or burns at high temperatures makes a difference. The thermal stability here means workers rarely face surprise vapors or pressure spikes, as long as the handling temperatures stay below the melting range. The challenge pops up with large-scale processes—inefficient heating can scorch the acid, leading to incomplete reactions or byproducts.

Density and Practical Applications

The theoretical density of 4-tert-Butylbenzoic acid hovers near 1.1 g/cm³. This just about matches other substituted benzoic acids, slotting into manufacturing pipelines without fuss. Density isn’t only a number; it tells you how the powder pours, how it weighs out, and how much it bulks up in a given vessel. A consistent density keeps formulation math simple and reduces slick handling errors in fast-paced production.

Room for Solutions

Over the years, working with this compound led me to value precise storage practices and strict housekeeping, especially in humid climates. Labs and factories that monitor for airborne particulates keep areas dry and test regularly for moisture develop far fewer problems. For solubility hiccups, finding the best solvent blend and working at slightly elevated temperatures often untangles stubborn clumping. Manufacturers hoping to streamline their process need to train people on safe handling, investing in quality containers and monitoring equipment to flag changes early.