4-Fluoroanisole: The Story, Science, and Future Paths

Historical Development

Chemical discovery often follows curiosity about simple building blocks. 4-Fluoroanisole, also called para-fluoroanisole, came onto the scene as chemists started exploring how small tweaks on familiar structures—here, swapping a plain hydrogen for fluorine on anisole—lead to new and interesting compounds. Researchers traced roots back to the rise of organofluorine chemistry during the middle of the last century. Early days showed basic synthesis, and progress moved in step with improved handling of fluorination reactions. Better analytical tools let scientists map out reactivity patterns and opened new doors in both laboratory and industrial contexts. Fluorinated aromatics, as a group, drew even more attention with the pharmaceutical boom and electronics revolution, both of which uncovered new uses for such specialized chemicals.

Product Overview

4-Fluoroanisole stands as a colorless, slightly sweet-smelling liquid. Structurally, it combines the methoxy group of anisole with a fluorine atom swapped in at the para position. That subtle shape shift gives it a whole new set of characteristics compared to its plain cousin. The commercial story rides on this difference—offering a starting point for more complex molecules and acting as a versatile intermediate. Companies selling bulk chemicals usually offer it at purity levels above 98%, shipping in sealed glass or stainless containers to protect against moisture and contamination. Chemists trust it for both bench-scale work and larger pilot trials, especially in fields pressing toward high-purity needs.

Physical & Chemical Properties

This compound boils around 175°C and freezes below -7°C, so it flows well at room temperature. Density clocks in near 1.12 g/cm³. The presence of fluorine influences how it behaves with various solvents, often making it more resistant to acidic or oxidizing conditions than plain anisole. The methoxy group, still reactive, opens doors for further chemistry, even though the aromatic ring handles substitution more selectively now that fluorine is attached. Infrared and NMR tell the tale quite clearly, letting chemists confirm the structure in just a few scans. With volatility sitting neither too high nor low, it’s easier to handle than lower-weight ethers, another plus for practical use.

Technical Specifications & Labeling

Commercial bottles and drums bear labeling marked by source, batch number, purity statement, manufacturer’s contact, and hazard class. Chemists working on regulated projects expect a full Certificate of Analysis covering appearance, GC purity, water content, melting point, and key impurities down to trace levels. Modern laboratories push for not only the usual specifications but also for traceability of feedstocks and compliance with REACH, TSCA, and global GHS standards. Transport usually follows UN code 1993 for flammable liquids if shipping in larger amounts, but most academic orders move by ground courier given the modest risk.

Preparation Method

Synthesis starts with anisole and brings in a fluorinating agent selectively at the para spot, most often using halogen-exchange reactions. Some protocols begin with anisole and use sulfur tetrafluoride or other modern fluorination tools to cut down hazardous byproducts. Others take a protected phenol, add the fluorine source, then swap on the methoxy group. Industrial players focus on yield, atom economy, and ease of purification—often sending the product through distillation and simple column purification to knock impurities below regulatory cutoffs. Small-batch labs sometimes use cleaner, but less scalable, recipes where efficiency matters more than bulk output.

Chemical Reactions & Modifications

4-Fluoroanisole brings both stability and possibility. It resists many strong acids, but the methoxy group remains a ready handle for demethylation or further substitution. Electrophilic aromatic substitution happens less readily due to the electron-withdrawing effect of fluorine, but directed ortho-lithiation opens a path to new derivatives. Cross-coupling using palladium catalysts can stitch on various aryl or vinyl fragments at the available sites. Hydrodefluorination or demethylation produces new functionalities useful in medicinal chemistry. For folks in materials science, the aromatic structure and fluorine content draw interest for piecing together more robust and heat-resistant polymers.

Synonyms & Product Names

Synonyms show up across catalogs and research papers: 1-fluoro-4-methoxybenzene, p-fluoroanisole, para-fluoroanisole. Some vendors assign product numbers for easy reference, but chemists trading notes rely on both the CAS number (459-60-9) and these basic names. Specific projects that involve radio-labelled fluoroanisole for tracing or PET imaging get called out by heavier labeling, but the core structure stays the same.

Safety & Operational Standards

Safety begins with respect. This ether brings typical risks seen in aromatic chemicals—flammability, eye and skin irritation, and possible respiratory discomfort if vapors build up. Material Safety Data Sheets push for goggles, gloves, and adequate ventilation at every stage, especially in warm settings or closed fume-hoods. In my lab, spills got onto zeolite granules right away and went into solvent waste, never down the drain. Emergency protocols require eyewash and showers within easy reach. Storage stays away from direct sunlight, strong acids, and oxidizers. Disposal sticks to licensed chemical waste contractors, meeting local and national laws for organic solvent disposal.

Application Area

Industries turn to 4-fluoroanisole mainly as a starter molecule. Drug discovery teams use it as a precursor when building more exotic fluorinated drugs with special metabolic or receptor properties. Polymer researchers build on it to introduce controlled fluorination into specialty plastics, raising toughness or resistance to chemical attack. Flavor and fragrance sectors mix it in to provide subtle notes or serve as a stand-in for more volatile substances during test runs. Some applications push beyond basic research—touching on OLED and display chemistry, where precisely tuned ring structures determine brightness and lifespan. Analytical labs use it as an internal standard when calibrating detection of more complex fluorinated aromatics.

Research & Development

Today’s R&D stretches across synthetic methodology, green chemistry, and functional application. Recent years saw a focus on less hazardous fluorination reagents. Catalytic routes that cut down waste, energy use, or raw material costs draw heavy investment from industry. Bioactive molecule synthesis leans on 4-fluoroanisole for lead discovery, testing how a fluorine at the para position shifts drug binding, metabolism, or even blood-brain barrier penetration. Materials science teams tinker with the molecule, building higher-value intermediates for batteries, coatings, or even sensor arrays. Computational chemists model electronic distribution and reactivity, hoping to predict new synthetic targets before benchwork starts. In my academic days, simpler benzenes dominated, but today’s push for property tuning drives ever more detailed fluorinated routes.

Toxicity Research

Knowing how chemicals behave in and out of the body matters more than ever. Early animal studies showed low to moderate acute toxicity for 4-fluoroanisole, with typical ether exposure symptoms—drowsiness or mild irritation at higher doses. Chronic data remain sparse, though methylated aromatics in general raise concern for liver or kidney load, especially during long-term exposure. Studies probe for routes of metabolic breakdown, checking for transformation to reactive phenols or conjugates. Inhalation studies matter most for workplace safety; skin or oral routes draw more concern for occupational incidents or environmental spill scenarios. Regulatory authorities ask for more data before approving wide use in consumer items.

Future Prospects

Looking ahead, demand for tailored fluorinated building blocks stands to grow. Pharma, agrochemical, and specialty materials advances all trace back to the ability to add or swap a single atom, like fluorine, in just the right spot on a molecule. Green synthesis will likely drive change, seeking safer, more efficient ways to make 4-fluoroanisole and relatives, perhaps even via biocatalysis or flow chemistry. Regulatory focus on environmental fate and toxicity keeps tightening, so sourcing and production align more closely with sustainable principles. Laboratories press for ever-purer, better-characterized supplies, meaning more analytics and transparency make their way into procurement routines. Researchers know that even small molecules like this can launch new discoveries, so attention paid to quality, safety, and creative chemistry keeps paying off—for both science and society at large.

The Role of 4-Fluoroanisole in Industry

Chemistry ties into more of our daily lives than most of us realize. 4-Fluoroanisole is a chemical often mentioned quietly in technical settings, but its reach extends well beyond the lab. With a molecular structure that includes both a fluorine atom and a methoxy group on a benzene ring, this compound has carved out a place in several key industrial applications.

Chemical Synthesis and the Search for Better Medicines

Pharmaceutical research teams turn to building blocks like 4-Fluoroanisole because small adjustments in a molecule can change how a future medicine works. The presence of both the methoxy and fluoro substituents brings unique electronic properties, making this compound handy for creating more complex molecules. Chemists value 4-Fluoroanisole as a starting point for synthesizing substances with potential for treating human disease. This process isn’t quick or cheap—anyone who has worked in a chemistry lab knows the grind behind screening thousands of chemical structures to produce something useful. By using molecules like 4-Fluoroanisole, researchers get more control over making targeted modifications, which can save months or even years when chasing a promising drug lead.

Building New Materials from the Ground Up

Material scientists rely on 4-Fluoroanisole in research focused on polymers and advanced materials. Adding this compound changes the chemical landscape, sometimes lending durability, chemical resistance, or new electrical properties. This kind of research feeds into the electronics industry. Companies are always on the lookout for components that withstand heat, humidity, and mechanical stress. When manufacturers seek to create specialty plastics or coatings, 4-Fluoroanisole becomes part of their toolkit. Its influence might be invisible to most users, but the improved lifespan of certain electronics owes a debt to these chemistry choices.

Diagnostics and the Analytical Edge

In analytical laboratories, 4-Fluoroanisole often serves as a reference standard or internal standard for instrument calibration. When spectrometers or chromatographs need tuning, having a reliable sample with distinct properties simplifies troubleshooting. In my own experience running GC-MS tests, spiking a control sample with 4-Fluoroanisole gives a predictable response—one less variable to worry about when the goal is accuracy. Analytical rigor like this is crucial, especially when public health or environmental safety rides on it.

Risks and Responsible Practices

Using chemicals like 4-Fluoroanisole responsibly shapes real-world safety outcomes. Its manufacture and handling require good ventilation, proper storage, and strict attention to personal protective equipment. Fluorinated compounds can stick around in the environment, potentially building up if not managed with care. People working in labs or manufacturing plants benefit from training about exposure limits and environmental safeguards. This keeps accidents rare and reduces unintended consequences, like pollution or chronic health risks. By following best practices, companies protect workers, communities, and natural resources.

Better Access and the Future

As research grows more global, dependable sources of chemicals like 4-Fluoroanisole matter. Whether shipped to a pharmaceutical company or a university lab, transparency about purity and sourcing helps everyone trust the results. The world’s scientists rely on consistency for their discoveries to stand up to scrutiny. Real problems get solved when labs and factories work together, investing in reliable supply chains and sharing knowledge about safer ways to use and dispose of specialty chemicals.

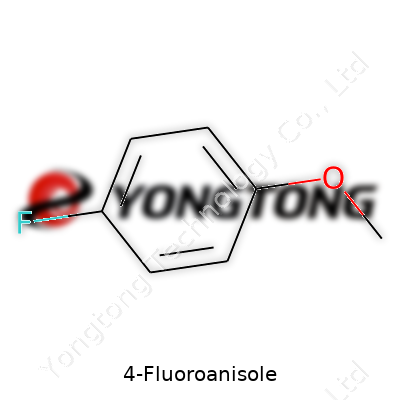

Chemical Formula of 4-Fluoroanisole

4-Fluoroanisole goes by the formula C7H7FO. It might look like just another name in the chemistry world, but this compound combines an anisole structure with a fluorine swapped onto the benzene ring in the para position. To most people, that’s the 4-position—right across the ring from the methoxy group.

What Sets 4-Fluoroanisole Apart?

During college, my hours in the organic chemistry lab introduced me to countless aromatic ethers. Out of them all, substituting a ring with fluorine changes how a molecule interacts with its environment. It’s not only about sticking a new atom on a familiar frame. The para-fluoro group steps up the compound’s resistance to breaking down, and it changes how the molecule smells, boils, and dissolves in different solvents.

Everyday Uses and Industry Needs

This chemical may not show up in the news as much as plastics in oceans or antibiotic resistance, yet behind the scenes, it plays a part in making perfumes, building blocks for drugs, and specialty solvents. Research labs and pharmaceutical companies prize compounds like 4-Fluoroanisole because fluorine can nudge a molecule’s properties in valuable ways—greater metabolic stability for a drug candidate or just the right note in a fragrance blend.

With research moving at a rapid pace, manufacturers look for new routes to synthesize compounds efficiently and cleanly. C7H7FO sometimes gets prepared by methylating 4-fluorophenol, which highlights the need for steady supplies of starting chemicals. Some syntheses create loads of waste or require harsh reagents, and greener chemistry remains a tall order across the sector.

Risks Behind the Formula

After a few too many spilled vials and cautionary tales from experienced chemists, I learned to respect aromatic ethers. Inhaling vapors from compounds like 4-Fluoroanisole dries out the respiratory tract. Handling without gloves brings the risk of irritation. Ethereal odors might seem innocent, but without careful ventilation and good storage, accident rates climb.

Beyond the lab, disposing of waste takes vigilance. No one wants more persistent organic pollutants leaching into soil or water, so treating residuals from synthesis and product testing keeps environmental chemists up at night. Policies from agencies like the EPA or EU REACH push for substituting hazardous reagents, controlling emissions, and keeping detailed logs from shipment to disposal.

Why This Compound’s Formula Actually Matters

Understanding C7H7FO goes deeper than just passing a chemistry test. Fluorinated aromatics show up in new medicines, fragrances, and smart materials. With AI-powered screening and high-throughput synthesis, chemists who know the effects of simple substitutions—like a para-fluoro—carry a real edge. People who work in these businesses juggle speed, quality, and safety, often with tight budgets and tighter deadlines.

Finding new, greener ways to prepare compounds like 4-Fluoroanisole will shape who leads in the next decade. Smarter analytical techniques cut down on waste, automation prevents avoidable spills, and support for research drives better decisions. My time in the lab taught me: mastery of molecules like this one pays off not just in patents, but in safer workplaces and cleaner neighborhoods. That’s where chemical formulas and daily choices line up, directly affecting lives well outside the lab.

What is 4-Fluoroanisole?

4-Fluoroanisole shows up in labs as a colorless liquid with a faintly sweet or aromatic odor. Chemists might recognize it as an intermediate for producing dyes, fragrances, or pharmaceuticals. At a glance, it might not seem any more threatening than household cleaning agents. That quick judgment doesn’t tell the whole story.

Understanding Toxicity: Not All Hazards Are Obvious

Many folks assume that if you can’t see immediate danger, there’s little to worry about. Chemical risks often hide behind long names and obscure lab backgrounds. 4-Fluoroanisole is not the most notorious substance, but its structure—a methoxy group paired with a fluorinated ring—makes it something to handle with respect. Some fluoroaromatic compounds resist breaking down in the environment, and certain derivatives in this family raise suspicion for long-term exposure concerns.

Health Risks from Exposure

Based on research and workplace safety data, inhalation or skin contact with 4-Fluoroanisole can cause irritation. Chemical suppliers list the need for gloves, goggles, and fume hoods. In my own experience running a chemical inventory, even small spills of similar aromatic compounds can reveal their potency with headaches or dizziness if ventilation isn’t right. Animal studies hint at mild acute toxicity, but hard facts on chronic exposure are rare. With few long-term studies on 4-Fluoroanisole specifically, the safer bet is to compare it to related anisoles and fluorinated aromatics, some of which have connections to liver stress or nervous system impacts.

Environmental Concerns

Fluorinated organics resist breaking down in soil and water. My time volunteering for an environmental group taught me that even trace amounts of persistent chemicals upset aquatic life, and labs often ignore the role of down-the-drain disposal. Wastewater plants don’t always filter out specialty chemicals like 4-Fluoroanisole, so it floats downstream into ecosystems. Over time, trace buildup changes water chemistry, which stresses fish and other wildlife. No direct evidence links 4-Fluoroanisole to major pollution disasters yet, but there’s an uneasy silence from regulators about long-term bioaccumulation.

Handling Safely in Workplaces

Lab professionals and industrial workers know the drill—proper gloves, eye protection, and working under a fume hood make up basic safety. I have seen new lab techs underestimate less famous solvents, only to suffer chemical burns or respiratory irritation after accidental splashes. Calling substances “mildly hazardous” leads people to take shortcuts that aren’t worth the trouble later. Standard Material Safety Data Sheets (MSDS) set guidelines for exposure limits, which should not be taken lightly because gaps in long-term data can mask risks until accidents pop up.

Reducing the Hazards

Limiting exposure starts with basic habits: good ventilation, careful labelling, and storing chemicals away from heat or sunlight. Small changes, like switching to less volatile containers, go a long way. Spill kits and clear emergency plans help too. Waste needs separate disposal—never down the regular drain. In my time coordinating chemical pickups, I learned that segregating fluorinated waste kept hazardous reactions to a minimum. Training and refreshing safety drills make a real-world difference, especially for those who think a minor exposure is “no big deal.”

Final Thoughts on Awareness and Education

Curiosity and caution belong together in chemistry work. Though 4-Fluoroanisole flies below most regulatory radars, working with chemicals always demands a healthy respect for what remains unknown. Investing in better safety education and stricter waste management lessens risk for everyone—at home, at work, and far beyond.

The Science Behind 4-Fluoroanisole

4-Fluoroanisole pops up in chemical labs pretty often. This compound, which carries a fluorine atom on the anisole skeleton, attracts organic chemists like moths to a flame. Some may wonder why anyone pays attention to its boiling point—turns out, boiling points really matter once the vials come out and reactions start bubbling.

Why Boiling Point Information Matters

I once watched a new lab assistant look puzzled over distillation instructions for an ether derivative. The problem wasn’t about equipment or skill. It boiled down to uncertainty about the correct boiling point. For 4-Fluoroanisole, the commonly recorded boiling point falls near 172 to 174 degrees Celsius (342 to 345 degrees Fahrenheit). This narrow range can make the difference between catching a compound at its cleanest and chasing a contaminated sample across hours of work.

Handling volatile compounds under pressure or outside precise temperature ranges turns a routine process into a guessing game. That’s not just an inconvenience. Extra impurities lead to unreliable results in both research and industry settings. Sometimes, even a single missed degree means an entire batch falls short of quality standards. Publications like the Journal of Chemical & Engineering Data confirm those figures for 4-Fluoroanisole, reinforcing just how critical accuracy becomes in real-world processes.

Modern Research and Real-World Uses

Pharmaceutical and materials researchers count on accurate boiling points for efficient purification, especially with fluorinated aromatic compounds like 4-Fluoroanisole. Over time, I’ve seen teams waste precious days due to reliance on outdated or approximate values. Instead, well-sourced technical literature and MSDS data point to reliable confirmation of the correct boiling point, avoiding frustration down the line. For instance, Sigma-Aldrich reports 172°C under atmospheric pressure—one of several references available to double-check this piece of information.

Possible Challenges in the Lab

Students and new professionals might hope to breeze through a distillation step, but skipping careful boiling point verification sets them up for costly mistakes. Chemicals with fluorine atoms sometimes behave unexpectedly. Small differences in boiling points cause cross-contamination if fractional distillation equipment isn’t calibrated for the specific compound in use. Purity tanks, glassware, and safety equipment take a beating if the vapor pressure or laser focus on temperature gets ignored.

From my own benchwork, I can recall at least three projects where a misreported boiling point led to misidentified products. The only fix required starting over with fresh, pure chemicals and a double-check on data. That always felt avoidable—so I push for a reality check on trusted sources, not just word of mouth or hastily Googled info.

Building Better Habits With Accurate Data

Easy access to thoroughly vetted property data takes a lot of pain out of chemical synthesis. Teams that make habit of checking the right value before they start spend more time on discovery and less in damage control. Groups working under E-E-A-T guidelines—focusing on expertise, experience, authoritativeness, and trustworthiness—get ahead and build a lasting reputation for reliability in their results.

If you find yourself prepping for a reaction involving 4-Fluoroanisole, lock in that boiling point at 172–174°C, verified by trusted databases. That early diligence protects people, equipment, and outcomes. In science’s hands-on world, details like these never fade into the background.

Understanding the Risks Involved

4-Fluoroanisole comes with its own set of risks. The chemical can irritate skin, eyes, and lungs, and releasing vapors in workspaces could put colleagues in harm’s way. Most experienced chemists remember at least one near-miss in a storeroom, usually involving poorly labeled or casually handled chemicals. I've seen how careless storage habits can lead to leaky bottles, toxic fumes, or even ruined experiments.

Temperature and Light Control

Lab experience tells me that heat and light change the behavior of many chemicals. 4-Fluoroanisole prefers cool, shaded storage. Warm rooms turn volatile liquids into hazardous vapors. Avoid sunny windowsills and radiators, since these amplify breakdown and pressure inside glass containers. Cold, dark cabinets—especially those fitted with exhaust systems—offer the safest home.

Proper Container Practices

Glass with airtight tops keeps fumes in check and prevents outside moisture or air from sneaking in. Plastic sometimes absorbs odors or slowly reacts with organic compounds over weeks or months, so glass bottles make sense for storing sensitive liquids. Don’t rely on ancient hand-written labels. Always print the substance name, date received, and hazard symbols. For those rare times when secondary containment comes into play, having a sealable plastic tray under the bottles reduces clean-up headaches from accidental spills.

Keeping Incompatibles Separate

Any veteran lab manager can recall stories about explosions caused by careless mixing of chemicals. 4-Fluoroanisole won’t react violently with water, but storing it near acids or oxidizers raises the risk of unwanted reactions or corrosion of containers. Never cluster flammable solvents near oxidizers—one knocked-over bottle could create a fire risk in minutes. Flammable-safe cabinets remain the best solution in shared labs.

Air Quality, Ventilation, and Spill Response

Good storage goes hand-in-hand with solid ventilation. Fume hoods and vented cabinets help suck away lingering vapors and protect you from accidental whiffs. My own worst bout with headache and dizziness in a lab always traced back to poor airflow and unnoticed solvent fumes. Know where the nearest eye-wash and spill kit are located. Even the most careful lab tech has dropped something slippery at least once.

Training and Supervision

Most chemical accidents happen because someone skipped steps or didn’t have supervision. Walk new staff through chemical storage protocols and double-check everyone knows emergency numbers and procedures. Mistakes feel costly, but learning from past near-misses makes every workplace safer. Experienced chemists keep calm, even when cleaning up spills, thanks to solid habits.

Labeling is Everything

Faded handwriting and missing hazard symbols turn dangerous if an emergency happens. Designers recommend using chemical-resistant labels so vital information stays readable. Routine checks, every month or so, help catch leaks, broken glass, or labels peeling off. A well-run lab spots these things early.

Conclusion

Safe storage for 4-Fluoroanisole doesn’t require miracle fixes—just attention, regular maintenance, and the right equipment. Habits formed from experience, backed by good training, keep the lab running smoothly and everyone healthy.