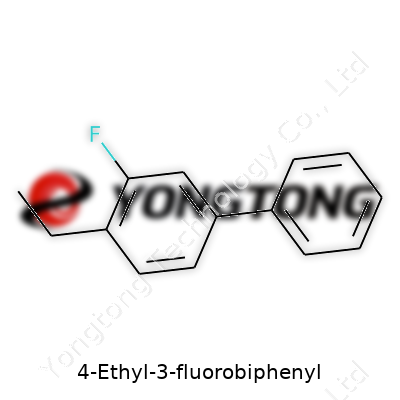

4-Ethyl-3-fluorobiphenyl: A Detailed Commentary

Historical Development

Long before 4-ethyl-3-fluorobiphenyl came into research labs and specialty catalogs, chemists and industry leaders turned their attention to substituted biphenyls for their versatility. By the mid-20th century, biphenyls started featuring in everything from electrical fluids to intermediates for pharmaceuticals and advanced materials. The fluorine atom, valuable for its role in tuning molecular polarity and bioactivity, found steady integration into aromatic systems. Around the 1980s, as the need for selective bioactive compounds ramped up in pharma and agrochemical sectors, more nuanced molecules like 4-ethyl-3-fluorobiphenyl showed up in research. Patent histories from that era mark the compound’s entrance as a functionalized building block, blending the hydrophobic profile of biphenyl scaffolds with an electron-withdrawing fluorine substituent. That change in electronic character opened doors to new chemical reactivity and improved performance in downstream uses.

Product Overview

4-Ethyl-3-fluorobiphenyl takes the biphenyl core and branches it with an ethyl group at the fourth position while fitting a fluorine at the third. The pairing alters both its physical and chemical signature compared to unsubstituted biphenyl or its better-known cousins like 4-biphenyl or 3-fluorobiphenyl. Industry usually deals with the compound in crystalline or powder form, making it easy to store, weigh, and transport. Chemical companies, research labs, and specialty catalog suppliers offer this over a range of purities, usually topping 97%, with transparent trace impurity listing. Practical folks immediately focus on its blend of lipophilicity from the biphenyl and reactivity enhancements thanks to the ethyl and fluorine tweaks. It doesn’t fit as a commodity chemical—this one often sits in R&D circles or as a specialty intermediate.

Physical & Chemical Properties

The molecule weighs in at 200.24 g/mol. If you heat it, expect a melting point in the region of 59–63°C, with a boiling point pushing above 310°C under atmospheric pressure. Its crystalline powder look gives a sense of purity, and it doesn’t tend to attract water. Slip it under a UV lamp and notice strong UV absorbance, which sometimes gets leveraged in analytical work. The ethyl group nudges its solubility profile: you’ll get it into most organic solvents—think ether, acetone, or chloroform—but water will shrug it off. The fluorine’s electron-withdrawing impact resonates through its aromatic system, making certain positions on the rings more susceptible to further functionalization or electronic shifts. It holds up pretty well at room temperature, with no ambient instability issues in the absence of strong oxidizers.

Technical Specifications & Labeling

A supplier’s spec sheet for 4-ethyl-3-fluorobiphenyl reads like a prompt for careful handling paired with chemical precision. CAS number: 403-81-8. Molecular formula: C14H11F. Most labs want at least 98% purity to ensure low interference in sensitive work. Storage notes call for a cool, dark, dry spot away from strong acids or bases. Labels need to follow GHS guidelines, warning about potential skin and respiratory irritation, with batch records linking every bottle back to a distillation or crystallization lot. All containers come with barcode and hazard pictograms; the bottle’s closure should always offer a tight seal to slow down any accidental volatility.

Preparation Method

Industrial chemists looking to prepare 4-ethyl-3-fluorobiphenyl reach for routes combining Suzuki-Miyaura cross-coupling and regioselective aromatic substitution. Conventionally, 3-fluorobromobenzene joins 4-ethylphenylboronic acid under palladium catalysis, pumping out the coupled biphenyl backbone. Tosylate versions of precursors, or directed ortho-lithiation followed by fluorination, give alternate access points with comparable yields. Once coupled, the compound gets a round of purification—silica gel chromatography or recrystallization from ethanol works in most lab settings. Final steps focus on drying under vacuum to rid the product of trace solvents, as even low parts-per-million residues risk interfering with downstream applications. This isn’t a kitchen chemistry project; the routes demand moderate expertise, well-ventilated hoods, and a reliable analytical setup for characterization.

Chemical Reactions & Modifications

With both an electron-rich ethyl group and a fluorine, the biphenyl’s reactivity balances both stability and functionalizability. Chemists seeking more complex molecules can run oxidative couplings, halogenations, or nitrations, typically favoring ring positions with the least steric hindrance. Fluorine’s presence tweaks basic aromatic substitution rates, often acting as a director for downstream modifications like cross-couplings or metalations. The ethyl group, being bulky, slows down attack at the adjacent ortho positions but leaves para slots open for more intervention. Hydrogenation, though less common in research with fluorinated aromatics, sometimes helps in testing mechanical robustness or metabolic stability of candidate molecules.

Synonyms & Product Names

Science loves synonyms, and 4-ethyl-3-fluorobiphenyl keeps things lively. You might see it listed as "3-Fluoro-4-ethylbiphenyl" or "3-Fluoro-4-ethyl-1,1’-biphenyl" in catalogs. Certain suppliers add product codes, as in "FLUOETHYLBIPH-98" or similar label jargon, driven by inventory systems. Academic papers lean on IUPAC rules for unambiguous naming, but less formal sources sometimes refer to shorthand like "4-Et-3-F biphenyl" or the simple "EFBP." Keeping track of these names avoids shipment mix-ups and guarantees the right product lands in the right test tube.

Safety & Operational Standards

In my years in the lab, I’ve learned that safety with compounds like this starts with proper ventilation and personal protection. Standard nitrile gloves, lab coats, and splash goggles go on before the bottle even leaves storage. MSDS sheets flag the risks: skin and eye irritation, so avoid careless splashes or leaving residues on scales and benches. Fume hoods or ducted enclosures catch fumes during weighing or dissolution. Spills get a quick cover with absorbent material and are bagged as halogenated organics. Containment remains key if you’re scaling up, and waste heads to specialized disposal streams, never down the drain. Emergency procedures need to cover accidental skin contact, which usually means washing with copious water and notifying a supervisor. Storage gets a shelf away from heat or ignition sources, as aromatic organics tend to volatilize more than people expect. Regular inventory audits pick up any container degradation from light exposure or cracked seals.

Application Area

Researchers and industry pros rarely pick 4-ethyl-3-fluorobiphenyl as a stand-alone performer. It’s all about the role it plays in crafting more advanced molecules. Pharmaceutical chemists eye it as a precursor or side chain in the route toward antifungal, anti-inflammatory, or CNS-active candidates, where fluorine helps block metabolic degradation. Some agrochemical innovators use it to tweak the activity or persistence of crop protection agents, engineering a balance between efficacy and environmental persistence. Materials scientists investigating organic semiconductors or liquid crystals sometimes add the compound to test the impact of small side-chain changes on thermal and electronic properties. Analytical chemists exploit its unique absorbance for trace detection development, while physical chemists see a model system for studying substituent effects in aromatic rings.

Research & Development

You see a steady drumbeat of publications focused on substituted biphenyls in medicinal chemistry, where small tweaks can change a compound’s life in the body. Teams scrutinize how the ethyl and fluorine groups influence binding to enzymes or transporters. Computational folks use the molecule as a reference for molecular dynamics, particularly for halogen effects in aromatic systems. Development teams in specialty chemicals lean on it as a control for process optimization, from purification protocols to catalytic efficiency. Spectroscopists take advantage of its clean NMR and mass fragmentation profile for calibration and method development. With new high-throughput synthesis and automated purification coming online, companies can screen analogs in weeks instead of months, opening up the molecule’s cousins for rapid agricultural or pharmaceutical testing.

Toxicity Research

Toxicologists still see a gap in broad-scale studies around 4-ethyl-3-fluorobiphenyl, partly because it’s not a large-volume industrial chemical. Bench data point to low acute toxicity via dermal or oral routes, but fluorinated aromatics often raise eyebrows over chronic exposure. The molecule’s lack of water solubility reduces environmental leaching risks, yet its persistence in soils or sediments hasn’t seen exhaustive study. My experience suggests that, with proper containment and adherence to recommended exposure limits common for aromatic hydrocarbons, acute incidents remain rare. Chronic testing in rodents, if available, would clarify any concerns about bioaccumulation or endocrine disruption. Regulatory frameworks in the US and EU still ask for detailed data sheets, especially for products with any human contact, reflecting the caution that defines chemical safety in the 2020s.

Future Prospects

With more companies shifting to greener chemistry and improved process safety, the future for substituted biphenyls will depend on both their performance and their environmental footprint. Researchers probe possible upgrades in crop protectants and specialty drugs using second-generation molecules built from this scaffold. Advances in fluorination techniques make targeted substitution cleaner and more affordable, opening the door to new structure-activity relationships in drug discovery. At the same time, increased focus on toxicity and environmental impact means new studies will press for deeper transparency on degradation, transport, and human exposure. The demand isn’t fading, but the threshold for acceptance keeps rising—every lab run and application will demand both data and careful risk management.

What Purity Means for Research and Industry

Whenever you look at chemistry labs, talk about 4-Ethyl-3-fluorobiphenyl always circles around purity. The tiniest contaminant can throw off a researcher’s whole dataset, and industries depend on high-purity chemicals for consistent outcomes. Buying a batch that’s 98% pure versus one that's 99.9% can change everything, from yield to safety profiles. This isn’t just technical jargon—chemical purity changes lives down the line. Mistakes cost money, waste time, and can sometimes put people in danger.

Why Purity Levels Shift

The number stamped on a product—95%, 97%, 99%—depends on a few big forces: crude starting materials, synthesis routes, and the headaches of purification. There’s a gap between producing a compound for lab-scale reactions and scaling up for manufacturing tons of the stuff. Smaller scales let chemists watch every step, use fancy purification like column chromatography, and toss away the dirty fractions. On the industrial floor, the aim often shifts to producing enough, fast, and at a price that makes sense. Sometimes, absolute purity drops a bit, because the cost or effort to squeeze out every last impurity skyrockets.

Testing Tells the Truth

Analytical chemistry gives real answers. Two standout methods: high-performance liquid chromatography (HPLC) and nuclear magnetic resonance (NMR) spectroscopy. HPLC separates mixtures, letting you see peaks for the main compound and any hangers-on. NMR breaks down the chemical skeleton, highlighting funky signals where impurities hide. Labs that sell to pharmaceutical or semiconductor companies can’t fudge these tests. Certificates of Analysis spell out findings—if something claims 99.5% purity, you expect to see the data.

Why Buyers Demand High Purity

For anyone involved in drug development, even a 1% unknown impurity means headaches with regulatory paperwork. Batches destined for synthesis or catalysis behave unpredictably if they’re not clean. Trace metals, leftover solvents, or unwanted isomers can ruin reactions, turn catalysts sluggish, or mess up final products. From my years in the lab, just a sliver of contamination in a reagent has turned simple experiments into week-long troubleshooting sessions. And this isn’t just nitpicking. Big names like Merck or Sigma-Aldrich charge a premium because their analytics catch more junk.

Paths to Higher Purity

Engineers and chemists can chase pure product with better solvents, careful crystal growth, or more rounds of purification. Minor impurities often show up from shortcuts or recycled reagents. The best suppliers run extra purification steps and keep meticulous batch records. One fix: buy from sources with ISO certifications, check batch-specific data yourself. Trust, but verify. Peer-reviewed publications will sometimes provide NMR or HPLC data scans—helpful clues for who actually does quality work.

The Transparency Solution

Greater openness pushes the industry forward. Suppliers who publish full analytical scans, batch reports, and even internal testing protocols make life easier for buyers and researchers. No one wants a mystery sample—especially with the stakes in modern medicine, materials science, or fine chemical synthesis. People use what works, but demand transparency to keep moving forward.

Why Proper Storage Isn’t Optional

Many chemicals come with a laundry list of storage requirements, but some folks still leave them on open shelves, right next to the breakroom coffee. From years working in lab environments, I’ve learned a compound like 4-Ethyl-3-fluorobiphenyl can’t simply be tossed in a cardboard box under the sink and forgotten. Responsible handling isn’t only about preventing accidents or fire codes—it’s a way to avoid wasted money and potential legal headaches.

Stable Temperature Makes a Difference

This particular compound prefers a cool, dry place. Keep it out of direct sunlight. Heat speeds up chemical changes and can make some substances break down. Cool, steady temperatures (2–8°C, or standard refrigeration) slow degradation. Leaving bottles on a warm benchtop lets moisture creep in, and after some time you’ll notice odd smells or changes in appearance. That isn’t safe or good for research.

Dry Matters More Than Most People Think

Humidity sneaks into unsealed containers—even the best screw cap can fail after enough temperature swings. Dampness inside means the compound turns sticky or clumpy, and performance in tests or syntheses goes out the window. Use a desiccator with fresh silica gel or another drying agent inside the fridge or storage cabinet. Never return unused powder straight from a humid workplace into the bottle, either.

Keep Away from Strong Oxidizers and Acids

This compound isn’t looking to pick a fight, but it doesn’t mix well with oxidizing agents or acids. Storing bottles near bleach, nitric acid, or peroxides risks contamination, and nasty reactions happen if there’s a spill or vapor leak. Corrosive cabinets belong far from organic chemicals.

Sensible Labeling Backed by Clear Records

Faded labels lead to confusion and accidents. Print clear labels, note the date it arrived, the source, and open dates. Keep digital or paper inventories so there’s no guessing at what’s on the shelves. Regulatory audits can hit hard if you can’t show up-to-date records.

Personal Safety Means Being Ready

Wearing gloves and goggles should be automatic, not an afterthought. Even if you trust your supplier and have a top-quality bottle, spills happen. I’ve seen gloves eaten through and folks heading to rinse their eyes at the safety shower. Be ready for slips with a spill kit nearby, and always wash your hands after working with chemicals, no matter how tidy things look.

Don’t Buy More Than You Need

Smaller batches keep things fresh. Often, unused bottles stack up, get old, and become a disposal problem five years later. Review inventories before reordering, and share supplies with nearby labs whenever possible. Planning ahead saves storage space and money, and keeps everyone on good terms during safety inspections.

Responsibility Reflects Trust

I’ve seen both spotless and chaotic labs. The ones running smoothly treat every bottle as a responsibility. Storage isn’t just about the bottle itself—it’s about protecting people, budgets, and reputations. Getting it right isn’t hard, it just asks for some common sense and respect for the material. Handle every bottle as if it matters, because it does.

Bulk Chemicals and the Demand Dilemma

Ask anyone working with specialty chemicals what keeps them up at night. It’s not always regulatory paperwork or lab safety, but often the basic problem of supply. I’ve had my share of calls tracking down obscure reagents for urgent projects. 4-Ethyl-3-fluorobiphenyl drops right into that category—an organic compound with a precise structure, valuable enough for chemists to spend hours on procurement.

Most people outside the field probably haven’t heard much about fluorinated biphenyls. In research or advanced manufacturing, these molecules play roles in developing new drugs, liquid crystals, advanced coatings, or probing the workings of catalysts. Most companies don’t churn them out by the ton. So if you want kilograms instead of grams, you need to dig a little deeper.

The Sourcing Reality

Basic market checks show that 4-ethyl-3-fluorobiphenyl isn’t lining warehouse shelves in most countries. Catalog suppliers list it, but only in grams or tens of grams, usually with a lead time stretching into weeks. Some online resellers offer a kilo here or there, but reliability and chemical traceability become concerns. Trying to source this compound in bulk turns into a test of patience and networking.

Behind the scenes, most custom chemical producers assess requests for niche compounds from two angles: availability of starting materials and expected demand. Since 4-ethyl-3-fluorobiphenyl doesn’t appear in household goods or major drug portfolios, the supply chain works best on a made-to-order basis.

Risks and Realities in the Market

I’ve worked with research teams frustrated by missing out on grant approvals and losing time because a single building block couldn’t be found in bulk. It’s easy to underestimate the chain reaction from lack of supply: halted synthesis, lost productivity, and sometimes the scramble to redesign experiments. In rare cases, teams face counterfeits or mislabeling when resorting to little-known intermediaries. The old adage holds—quality matters, not just quantity.

According to an industry survey from the American Chemical Society, over 60% of labs have experienced delays due to limited chemical availability. This reflects deeper issues: globalization means longer supply chains and increased risk, while stricter regulations around transport, storage, and use of specialty chemicals create further hurdles. For something as specific as 4-ethyl-3-fluorobiphenyl, these factors stack up quickly.

How Teams Navigate Sourcing Hurdles

Researchers and process engineers often get creative here. Some approach custom synthesis partners in China, India, or Europe. In my own experience, long-term relationships with reliable suppliers—ones who won’t cut corners—count for far more than scouring every online marketplace. Good suppliers share analytical data, batch specifications, and deliver what’s promised, even if it costs extra or takes longer.

For larger projects, pooling demand with collaborators sometimes tips the scale, making it worthwhile for producers to run a bigger batch. Open communication, early planning, and sharing detailed specifications can smooth out eventual delivery.

Building a Stronger Supply Culture

There’s a real need for more transparent, up-to-date chemical supply databases tracking actual quantities, not just catalog listings. Government and industry-led platforms could play a bigger role, helping research teams avoid costly delays. Those working with rare compounds like 4-ethyl-3-fluorobiphenyl benefit most from reliable access, open supplier reviews, and a community approach to rare chemical sourcing.

Chemical Building Block

4-Ethyl-3-fluorobiphenyl brings a unique combination of ethyl and fluorine substituents on a biphenyl backbone, making it a prized intermediate for specialized synthesis in modern chemistry labs. I’ve seen research chemists prioritize such molecules because the addition of fluorine can alter the biological properties of drug candidates. Pharmaceutical development teams often introduce fluorinated biphenyls while fine-tuning new anti-inflammatory or anticancer molecules. This approach sometimes leads to enhanced target selectivity or improved metabolic stability. The presence of these functional groups opens possibilities for making bioactive molecules that would otherwise be difficult to access.

Material Science and Liquid Crystals

Display technologies have pushed research into advanced liquid crystalline materials. 4-Ethyl-3-fluorobiphenyl fits right in due to its rigid biphenyl structure and the polar character from fluorination. These features allow the compound to tune the electro-optical responses of display panels. Engineering teams have blended biphenyl derivatives into prototype OLED and LCD screens to get sharper colors, faster switching times, and more energy-efficient displays. Material scientists look for ways to combine physical stability, light transmission, and the ability to respond quickly to electric fields—qualities fluorinated biphenyls tend to provide.

Agrochemical Research

Working alongside researchers, I’ve encountered growing demand for new crop protection agents. Many lead optimizations stem from biphenyl cores since they form the backbone of fungicide and herbicide candidates. The ethyl and fluorine groups add just enough molecular uniqueness to explore patent space. Synthesis teams evaluate how those structural tweaks impact selectivity—as a result, 4-ethyl-3-fluorobiphenyl might end up part of herbicide libraries meant to disrupt weed metabolism with fewer hits on crops or on the surrounding ecosystem. In practice, every substitution can mean a change in activity or environmental half-life.

Aromatic Substitution Research

Organic chemists frequently need model compounds to study the electronic effects within aromatic substitution reactions. 4-Ethyl-3-fluorobiphenyl provides rich teaching material. The ethyl group sits at the fourth position, the fluorine at the third, offering a useful case to investigate how these groups change reactivity or direct substitutions. Undergraduate students often learn about these positional effects using small series of biphenyls. Such research finds its way into graduate-level demonstrations on catalysis and coupling reactions, including Suzuki or Heck protocols. Having real data and working with actual fluorobiphenyls adds depth to discussions around selective aromatic functionalization.

Advanced Polymers and Electronics

Industries chasing thinner, more resilient electronics test out new ways to incorporate rigid, planar molecules. 4-Ethyl-3-fluorobiphenyl frequently enters polymer synthesis because the aromatic nature and substituent pattern can enhance the mechanical and electrical qualities of specialty plastics. For example, some semiconducting polymers used in printed circuit boards owe their low dielectric constant and high heat resistance to biphenyl-based monomers like this one. Modern labs watch for improvements in circuit speed and device lifespan, often tying these advancements back to fundamental changes in polymer chemistry.

Considerations and Future Directions

Production and handling of fluorinated biphenyls bring environmental responsibility front and center. Compounds with fluorine resist degradation, which prompts the need for tight controls in waste management and synthesis design. Accurate tracking and safe disposal lower risks and make the field more sustainable. As companies continue to push for greener manufacturing, techniques such as flow chemistry and catalysis improvements fight unnecessary by-product generation. Publishing robust toxicity data also builds public trust and keeps new chemical developments on the right track.

Getting to Know 4-Ethyl-3-fluorobiphenyl

4-Ethyl-3-fluorobiphenyl, a mouthful to say, belongs to the group of biphenyl compounds. You see it slip quietly into the world of specialty chemicals, building blocks for more complex molecules, probably in pharmaceuticals or materials science.

Nothing about its structure screams danger at first glance. Still, just because something looks benign on a page doesn’t mean it shouldn’t get respect in the lab.

Why the Safety Data Sheet Matters

The safety data sheet (MSDS or SDS) turns into your best friend any time you handle an unfamiliar lab chemical. Not just a bit of paperwork—it gives you everything: physical properties, hazards, safe handling, and first aid. You're not just protecting yourself. Shared spaces, teams, and cleaners all depend on everyone using the right information.

With 4-Ethyl-3-fluorobiphenyl, SDS sheets from major suppliers like Sigma-Aldrich or Alfa Aesar don’t show it as explosively reactive. No wild peroxides, no autoignition at room temperature. But many biphenyls share the same quirk: they're not especially nice to skin, eyes, or your lungs. Dust or vapors from organic compounds tend to irritate, sometimes well beyond a mild cough.

Risks You Can’t Ignore

Eye contact with crystalline organics, especially aromatic ones, brings burning and tearing. Mishandling—say, an accidental spill on the bench—makes for easy absorption through your gloves or skin. Problems often follow chronic exposure, even at low doses.

Breathe deeply around aromatic hydrocarbons and your body reminds you of its ability to absorb through the lungs. Long-term exposure to similar compounds has led, in some cases, to liver or kidney complaints, even cancer. Specific research on this compound still feels thin—another reason not to work with any aromatic derivative as if it’s as safe as salt. The eco corner comes up quickly, too: biphenyls like to stick around, and some break down slowly, so careless waste turns into a groundwater headache.

If you’ve ever done chemical synthesis in a crowded academic lab, you know small errors snowball. Spilled powder tracked into elevators, shared tongs spreading contamination, waste jugs mixed with incompatible solvents—lab safety isn’t theoretical.

Personal Protective Gear Makes a Difference

Lab coats only work if they’re worn, not tossed on a chair. Safety goggles keep a moment of carelessness from turning tragic. Organic vapor cartridges in masks matter if you’re weighing powders near your face. It only takes one tired afternoon to forget why the rules exist.

Gloves form the last line of defense. Nitrile usually works well for aromatic organics, as latex will eventually dissolve. Washing hands and not eating or drinking in the lab—small rituals, but they save you.

Safer Handling and Better Solutions

Training new workers or students before they use 4-Ethyl-3-fluorobiphenyl pays dividends. Clear labeling—compound name, hazard symbols—cuts down mistakes. Waste streams from synthesis work need real attention: segregate organics, check the disposal route, use activated carbon or incineration if needed.

Pulling safety data from vendors or databases like PubChem or ChemSpider helps fill the gaps. No one needs to guess the hazards. Updating those sheets in shared folders keeps everyone honest and informed.

Building a safety-first attitude takes effort. It’s not a slogan. It’s the difference between an ordinary workday and disaster. Give every new bottle and compound the same curiosity and respect as you would a powerful acid. That habit doesn’t just protect science—it protects people.