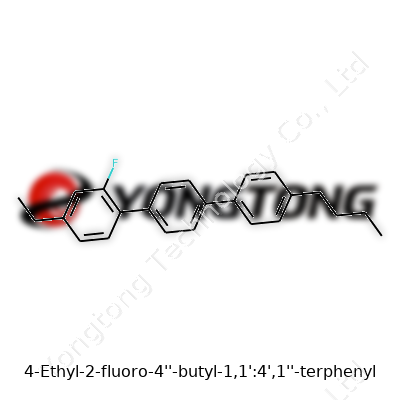

4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl: Development, Properties, Safety, and Beyond

Historical Development

Innovation in organic chemistry often springs from the pursuit of new functionalities in aromatic frameworks. The terphenyl skeleton caught the eye of researchers tackling issues in material science and liquid crystal technologies in the late twentieth century. As advances in display technology demanded higher thermal stability and a range of electronic properties, scientists began modifying the classic terphenyl backbone. The emergence of fluoro and butyl substitutions signaled a push for greater molecular customization, leading to derivatives like 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl. This compound didn’t just appear out of curiosity—decades of liquid crystal development, printed electronics, and organic semiconducting materials drove chemists to experiment with new substituent patterns. The combination of fluorine's electron-withdrawing nature and bulky butyl chains opened doors to tuning melting points, solubility, and mesophase ranges.

Product Overview

4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl serves as a specialty organic intermediate. In my lab experience, the molecule gained traction during efforts to synthesize custom-tailored liquid crystals with high birefringence and adjustable viscosity. Companies producing advanced displays and optical materials hunt for compounds that balance rigid aromatic structure with flexible side groups—terphenyls typically tick that box, and the presence of ethyl, butyl, and fluoro groups offers a flexible blueprint. When discussing its product profile in meetings, engineers and scientists show special interest in its solubility profile, stability under heat, and ability to co-crystallize with dopants.

Physical & Chemical Properties

As a solid at room temperature, 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl displays a white to off-white appearance, with a slight aromatic odor that reminds me of classic organic benchwork. The melting point typically lands somewhere just above 100°C, influenced by both the linear butyl and the steric effects of the ethyl group. The molecule isn’t particularly volatile, a trait appreciated during purification. Solubility leans toward nonpolar solvents—toluene and dichloromethane work well. The fluoro group not only impacts the molecule’s polarity but also boosts resistance to photodegradation. In NMR, distinct splitting near the fluorine and methyl protons allows easy assessment of purity. UV-vis spectra show strong absorbance in the near-UV region, hinting at stability and potential for optoelectronic applications.

Technical Specifications & Labeling

Suppliers offer this compound with stated purities typically exceeding 98%, determined by HPLC and NMR validation. Labels must include batch number, production date, and specific warnings on handling, considering the aromatic core and halogen substituents. Storage recommendations call for cool, dry, ventilated areas, away from sources of ignition and incompatible oxidizing agents. Certificates of Analysis document elemental composition, residual solvents, and a breakdown of by-product levels. In transport, containers require secondary containment, clear hazard communication symbols, and compliance with chemical shipping regulations.

Preparation Method

Synthetic routes for substituted terphenyls revolve around Suzuki-Miyaura and Kumada couplings. The assembly of 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl usually starts with commercially available fluoro- and ethyl-substituted phenylboronic acids. Chemists couple these building blocks sequentially to form the triphenyl arrangement, employing palladium catalysts and dry, deoxygenated conditions. The introduction of the butyl group often comes from a Grignard reaction or via butyl-substituted bromobenzenes. After coupling, crude products undergo chromatographic purification, recrystallization, and finally, spectral confirmation. As with most aromatic syntheses, yields and purity benefit from careful control of reaction stoichiometry, catalyst loading, and moisture exclusion.

Chemical Reactions & Modifications

Researchers interested in pushing this molecule further experiment with electrophilic aromatic substitution, taking advantage of direct functionalization at available positions. The fluoro group makes certain ring positions less reactive, channeling substitution efforts to specific sites. With hydrogenation conditions, the ethyl or butyl arms can be partially reduced or functionalized to alter solubility for downstream applications. Oxidation studies sometimes focus on turning the methyl side chains into carboxylic acids, suitable for polymer backbones or further PEGylation. Metallic catalysts enable direct arylation or borylation, opening the path toward custom liquid crystalline networks or new optoelectronic scaffolds.

Synonyms & Product Names

In catalogs and research articles, this compound may turn up under several designations. Some call it 4-Ethyl-2-fluoro-4''-butylterphenyl or simply "EFB-terphenyl" for short. A handful of chemical suppliers list it by its IUPAC name or registry number. Before ordering or referencing, it pays to cross-check with spectral data or molecular structures given in technical sheets to avoid confusion with similar-sounding analogs.

Safety & Operational Standards

The aromatic core paired with fluoro and butyl substituents calls for solid operational safeguards. I recall one project requiring strict fume hood use due to the mild but lingering aromatic fumes generated during scaling-up. Skin contact, swallowing, or inhalation should be avoided; gloves, goggles, and full-length clothing remain non-negotiable. Spillage clean-up involves inert absorbents and prompt removal from ignition sources. Waste disposal must fit local hazardous organic protocols. SDS documentation runs through scenarios like fire fighting (requiring foam, not water sprays) and first aid for accidental exposure—“flush with copious water” became a mantra among team members. Laboratories must post up-to-date chemical hazard charts and reinforce safe handling with regular staff training.

Application Area

Display technology stands as a main beneficiary. The molecule’s tailored solubility and phase transition temperatures help design new generations of electroluminescent and liquid crystal displays with sharper resolution and broader temperature tolerance. Chemists in organic semiconductor and photonic device companies keep seeking such terphenyl derivatives to push optical clarity, reduce power consumption, and raise device life expectancy. Specialty inks for printed electronics draw on its solution processability. Researchers have also eyed its use as a dopant for light-absorbing layers in solar cells, thanks to its strong UV absorption and chemical stability. Some exploratory efforts test its efficiency as a molecular host for guest inclusion compounds—a niche area I encountered through a collaboration with a supramolecular chemist.

Research & Development

Current R&D themes include adjusting molecular length and side-chain density to balance viscosity and switching speeds in flexible electronic devices. Several academic laboratories publish work on mixed-substituent terphenyls, highlighting their ability to tune dielectric constants crucial for new organic light-emitting diode (OLED) technologies. Regulatory attention on halogenated aromatics nudges researchers toward “greener” synthesis—phosgene-free routes, microwave-assisted couplings, and solvent recovery. Toxicology and environmental footprint studies figure more prominently in grant calls these days. Collaboration with computational chemists brings predictive modeling of electronic structure and phase behavior, which saves time and materials during initial screening.

Toxicity Research

The rise of complex organo-fluorine compounds always invites scrutiny. Animal studies show moderate acute toxicity at higher exposure levels, with aromatic hydrocarbons often linked to liver and kidney effects over chronic dosing. Regulatory guidelines call for in-depth testing on bioaccumulation and metabolic fate; in my experience, companies carrying out risk assessments focus on potential for endocrine disruption, particularly with halogenated derivatives. In vitro assays using human cell lines point toward low mutagenicity, but long-term inhalation data remains thin, leading many research teams to err on the side of caution. Waste treatment streams from large-scale processes undergo rigorous checks to prevent uncontrolled environmental release.

Future Prospects

4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl likely faces a rise in demand from next-wave flexible displays and smart window coatings. Technologists expect molecules with customizable solubility and high thermal resilience to become central to these applications. The challenge lies in striking a balance between performance and green chemistry requirements: minimizing halogen content without sacrificing electronic performance. Expanded toxicity screening and push for biodegradable analogs signal the direction for further research. Intellectual property filings point toward more complex functionalization schemes, hinting that next-generation terphenyl derivatives may draw from this blueprint while fixing shortcomings in solubility or cost. Within collaborative teams, I’ve seen growing calls for standardizing data on phase transitions and toxicity, so wider industry uptake proceeds with fewer hazards and better end-user protection.

The Chemistry That Powers Our Screens

Every time you pick up a smartphone, stare at your television, or read news on a tablet, you probably don’t wonder what chemicals bring those bright, crisp images to life. 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl rarely makes headlines, but in the world of electronics, it’s a workhorse. This compound falls into a family called terphenyls. What sets it apart, though, is the way those little tweaks—an ethyl group here, a fluorine atom there—give it new uses. I’ve spent years watching the slow evolution of display technologies, and specialty molecules like this one steer the whole industry toward better performance.

Sharp Displays Rely on the Details

In today’s display panels, such as liquid crystal displays (LCDs) and organic light-emitting diode (OLED) screens, not every molecule plays the same role. 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl helps control how liquid crystals align and respond to electric fields. This property matters more than most people realize. Slight changes at the molecular level shift how fast pixels react and how well screens handle intense light. Device manufacturers want those improvements because they lead to brighter images, better contrast, and smoother motion.

People like me, who have fumbled with older, blurry screens or watched colors shift from odd angles, owe small victories to this type of chemistry. Better molecules mean better user experiences. In particular, the fluorine atom in the structure often boosts thermal and oxidation stability, so displays last longer and withstand heat. Adding a butyl group tightens control over molecular shape. The ethyl group balances solubility and performance for large-scale manufacturing. Chemical companies don’t just chase novelty—they tune these features so millions of panels can roll off factory lines without defects.

Not Just Screens—Broader Applications Unfold

Display technology gets most of the attention, but terphenyl compounds don’t stop there. Some research points toward their use in organic semiconductors, where they help charge move efficiently in solar cells or sensors. Anyone following the push for renewable energy will see the connections: more effective organic semiconductors cut costs, and performance rises, opening the door for flexible solar panels on cars, windows, and backpacks.

There’s another point to keep in mind. Each tweak to the chemical structure opens a different pathway—sensors for healthcare devices, coatings for anti-static packaging, even unique thermal management materials in electric vehicles. The story here isn’t just about a single application, but a pattern of innovation: chemists make new building blocks, engineers discover new uses, and real-world devices get closer to what users want.

Environmental and Safety Considerations

With every new molecule, environmental impact matters. Over the years, I’ve learned that regulatory compliance isn’t just paperwork. Fluorinated organic compounds face scrutiny because persistent ones can damage ecosystems. Chemical makers test for biodegradability and keep an eye on toxicity, aiming for balance between high performance and minimal long-term harm. Governance shapes which compounds keep moving forward.

Innovating With Responsibility

This story tracks the quiet chain of progress. Consumer complaints about dull screens nudge scientists to rethink molecules. Researchers publish tweaks, manufacturers run pilot lines. At each stage, chemists, device makers, and regulatory agencies keep asking: Does this material really help people—and at what cost? The fate of molecules like 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl will always hinge on how much value they deliver to real people, and how responsibly the industry handles both benefit and risk.

The Risks in the Lab

Working with chemicals like 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl makes every chemist think twice about safety habits. The structure alone—multiple aromatic rings and halogen substitution—points to some real risks in exposure and environmental impact. I remember handling similar terphenyls, and their greasy consistency always stuck to gloves and glassware much longer than most solvents. The risk isn’t just in getting it on your skin; inhaling tiny particles or vapors seems harmless at first, but chronic exposure can cause unpredictable effects long after the experiment ends.

Dusts or powders from this family of compounds tend to stick around in the air, especially during weighing or transfer. I keep all operations involving these materials in a well-ventilated fume hood. Splash goggles protect the eyes, but gloves are just as critical—a layer of nitrile or Viton blocks skin absorption, which is real even if you can’t see or feel anything at first.

Fire and Chemical Stability

Terphenyl derivatives often combust at high temperatures. Just because a chemical feels stable at room temperature doesn’t stop it from turning dangerous next to a heat source or a careless spark. I’ve seen old stir plate motors fail and send out a flash of heat, which could set off an oily terphenyl easily. Fire extinguishers rated for chemical fires (Class B) stay close by. Simple water squirt bottles won’t help—dense aromatic compounds don’t mix with water, and liquid spreads flames. Early in my lab career, an instructor showed a runaway reaction that escalated because someone grabbed the wrong fire extinguisher and splashed burning material everywhere.

Don’t forget about the impact on air quality—heating fluorinated aromatics can produce toxic fumes, including hydrogen fluoride, which nobody wants wafting through lab air. Respirators rated for organic vapors aren’t overkill for spill clean-ups, especially in places without top-notch air systems.

Spill Response and Disposal

Any spill, even a small one, can leave a slippery mess and toxic residue. Absorbent pads designed for chemicals, not just water, work best. Old towels or paper create more waste and don’t trap oily substances. After cleanup, the material and any soils go into hazardous waste containers. Proper labeling on waste drums—listing every risk, not just the generic chemical name—makes a difference. Down the drain isn’t an option, not with fluorine and aromatic structures. Waste detectors in the building will flag improper disposal.

From my own experience, preparation beats improvisation every time. That means reviewing the latest SDS (Safety Data Sheet) before opening the container. This data changes fast as research shows new risks. If a workplace skips regular training about emerging chemical dangers, workers can get sick from exposure and the company could face heavy fines or legal trouble. A culture of safety means supervisors and new hires know exactly what to check before a shipment leaves the storeroom or a flask goes onto the hotplate.

Training, Equipment, and Culture

At the end of the day, the right equipment—goggles, gloves, fume hoods, proper containers—makes labs safer for everyone. Ongoing training shapes habits. One time, a careless moment left an oily fingerprint trail from the balance to the fume hood, a line visible only under UV from spilled terphenyl solution. The lesson stuck with me: any shortcut with hazardous compounds means long-term regrets. Precaution habits catch hazards early, not after the damage is done.

Tackling the Structure

4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl tells a story straight from organic chemistry. The molecule comes shaped by three benzene rings connected in a linear fashion through single bonds, forming what research folks call a “terphenyl” backbone. Each modification along this backbone points toward specific chemical and physical behavior. Tack a fluorine at the 2-position on the first benzene, an ethyl on the 4-position of the same ring, and a butyl hanging off the 4''-position of the third ring, and you get a bulky, hydrophobic shape.

To picture this in my own mind, I take a ruler and lay out three coins in a straight line, each coin standing for a benzene ring. Spots get assigned for every substituent—ethyl sticking out at one end, fluorine at another, and that longer butyl swaying at the opposite tip. Each substituent brings a certain "weight" and interaction potential, including how the molecule will dissolve or stack within a crystal.

Why Details Matter

Every atom tacked onto a core like terphenyl changes its dialog with the world. 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl’s structure isn’t a lab curiosity. Fluorine, an electronegative brute, often shifts electron density just enough to impact how a molecule absorbs energy, resists breakdown, or grabs at electrons, which matters for everything from organic semiconductors to pharmaceutical scaffolds. Tossing a butyl on the distant 4'' position turns the molecule bulkier and throws its solubility profile toward less polar solvents.

Every alteration—ethyl, butyl, fluorine—shapes both intermolecular and intramolecular behavior. In my own research, shifting even a small group onto a phenyl ring spun out new chemical and physical traits: different melting points, new solubility quirks, tougher or softer crystals, and even shifts in electronic properties if the molecule entered a circuit.

Crunching the Numbers

The molecular formula reads as C28H29F. Calculating its molecular weight takes some back-of-the-envelope arithmetic:

- Carbon: 28 × 12.01 = 336.28

- Hydrogen: 29 × 1.008 = 29.232

- Fluorine: 1 × 18.998 = 18.998

Why Should Anyone Care?

Molecules like this terphenyl derivative crop up in research focused on OLEDs, plastic electronics, and even specialty coatings. The unique pattern of substitution tunes how it behaves—sometimes resisting breakdown under heat, sometimes conducting current just right for a tiny chip or display.

To better make use of this compound, researchers could improve synthetic pathways—fewer steps, higher yields, cleaner reactions. Regulatory attention also sits in the mix, with close tracking needed for environmental breakdown, just as much as how the molecule performs. Understanding both the chemical structure and exact molecular weight remains less about trivia, more about setting up for progress in research labs and across industries.

Why Storage Matters

Chemicals like 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl get their share of attention in science labs for good reason. Safety slips quickly turn a routine week in the lab into panic, so proper storage becomes not just a rule but a basic practice for every chemist or technician who works with specialty compounds.

Back when I spent days in a synthetic chemistry lab, no one felt comfortable handling a reagent until they checked every label and cross-checked SDS sheets twice. I saw what sloppy labeling did—leaked caps, strange smells, even corroded shelves. Experience says: treat every new compound the same way you’d treat anything unknown. With chemicals like this one, questions come up about volatility, fire risk, and potential reactivity.

Best Storage Practices

Solid organic compounds—especially ones with halogens and long alkyl chains—often need stable conditions. Too much light, heat, or moisture can degrade some chemicals or change their properties. With 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl, the structure tells a few things right away. It isn’t highly volatile. No obvious functional group that screams out for a fridge. Still, don’t toss the bottle on an open shelf near sunlight.

Keep it out of reach of direct sunlight.- Organic molecules can slowly change or break down with enough light, and aromatic compounds in particular sometimes act up after weeks of bright exposure.

- Many labs lump their organic solids in a cool, dry cupboard for a reason. Warm rooms accelerate unexpected reactions, so look for a location that stays at consistent room temperature.

- Organic powders and low-melting solids pick up moisture faster than expected, and condensation causes clumping or contamination. Try to store the container with a tight seal. Snap it shut as soon as you finish using it.

- Fluorinated compounds don’t always play well with strong acids, bases, or oxidizers. Accidental spills get much worse if something reactive sits beside the terphenyl on the shelf. Use a separate space, or at least a secondary containment tray.

Choosing the Right Container

Thick-wall glass bottles with PTFE-lined caps offer reliable storage for many non-volatile solids. Plastic bottles may react, especially if the compound has traces of residual solvent or leaches plasticizer. Avoid repurposing old food jars or clear plastic containers—leaching, static build-up, and cross-contamination creep in unexpectedly.

Label everything with the compound’s full name, hazard warnings, and the date received. Chemical storage gets tangled over time, so regular review and relabeling stop small problems before they grow.

Accessible Records and Communication

Open communication shifts a lab from risky to reliable. Make sure everyone knows where safety data lives (electronic or paper). All coworkers should recognize what to do in case of a spill or exposure. A shared spreadsheet or an old-school notebook, updated with every bottle’s status, works wonders when audits or emergencies hit.

Ignoring basic storage can invite property loss, contaminated results, or personal risk. The effort you put into organizing chemical shelves pays dividends in safety and peace of mind.

Realities of Sourcing Specialty Chemicals

There’s something sobering about hunting for specialized chemicals like 4-Ethyl-2-fluoro-4''-butyl-1,1':4',1''-terphenyl. Years ago, finding obscure ingredients meant paging through thick supplier catalogs and faxing quotation requests. Now, even with all the search engines, sourcing a unique molecule is still a mix of technical savvy, solid contacts, and, sometimes, plain luck.

For researchers or procurement staff at advanced materials companies, the search begins with verification: does anyone actually make this compound? Chemical search engines such as ChemSpider or Sigma-Aldrich’s catalog help set the stage. Plenty of times I’ve typed in a complicated name only to find it’s not stocked in the large databases. That usually signals limited demand. In practice, these compounds tend to be produced in small runs or custom batches.

Navigating the Marketplace

Bulk buyers can’t afford to rely on academic suppliers who sell by the gram at high markups. Genuine bulk procurement works through one of a few routes. First, some global chemical traders based in Germany, India, or China act as intermediaries, sourcing directly from contract manufacturers. Reaching out by phone or email, not just order forms, gets you answers about bulk pricing, lead times, and certified documentation.

I’ve run into plenty of chemicals, including terphenyl derivatives, where the best move is contacting chemical custom synthesis firms. They ask for your specs, volume, and purity requirements. You’ll hear quotes, not just on price, but also on how many weeks of lead time and what sort of regulated shipping they can handle. It’s a process with negotiation, paperwork, and build-up of trust—especially if it’s not a stock item.

Risks and Regulatory Pressures

Industry folks need to keep REACH registration, TSCA, or local chemical control laws in mind. Importing or ordering a kilogram isn’t the same as ordering a bottle of acetone. Down-to-earth risk management means having a lab or in-house analysis ready for incoming shipments. I’ve had cases where a delivered bulk product required extra purity checks or spot validation because the paperwork from an overseas vendor didn’t look right. Fake certificates do pop up, especially with lesser-known suppliers advertising on slick new websites.

Solutions for Buyers in 2024

Reliable supply begins way before the order. Companies in electronics or custom materials often build relationships with loyal distributors who already have logistic channels tailored for importing fine chemicals in bulk. I’ve found trade shows (like Chemspec Europe or CPhI China) helpful for meeting suppliers face-to-face and clarifying capabilities. Networking matters. Anyone jumping between anonymous suppliers runs into price jumps, long delays, and sometimes, border seizures if the compound is flagged as novel or hazardous for shipping.

Due diligence should never end with the catalog. Ask for references. Keep samples from every shipment for testing, and read between the lines of each invoice and certificate. Bulk quantities are rarely “off-the-shelf” for complex molecules. Genuine suppliers take the time to confirm every detail, discuss stability, and outline the route for logistics and compliance. That’s where experience—both good and bad—teaches us the habits that avoid headaches and save money in the long haul.