4-Ethoxy-2,3-difluorophenol: A Grounded Look at a Fluorinated Phenol

Historical Development

People working with aromatic fluorine chemistry often wind up crossing paths with niche molecules like 4-Ethoxy-2,3-difluorophenol. This compound’s history reflects broader trends in the development of halogenated phenols, growing out of the rising demand for more selective organic syntheses and a push for greater molecular diversity during the latter half of the 20th century. Early on, chemists pursued site-selective fluorination, a tough challenge given the difficulty of controlling electron density around the aromatic ring. With the rise of better catalysts and directing group strategies, researchers finally mapped out reliable routes toward multi-substituted fluorinated phenols. Industry’s expanding appetite for complex building blocks for pharmaceuticals and agrochemicals ratcheted up interest—4-Ethoxy-2,3-difluorophenol soon carved out its niche in the toolbox of synthetic intermediates that help shape new medicines and advanced materials.

Product Overview

4-Ethoxy-2,3-difluorophenol serves as a specialty intermediate, a critical pit stop in the construction of more complicated targets. Chemists see it as a useful starting point thanks to the interplay between its electron-withdrawing fluorines and its phenolic and ethoxy functionalities, giving it unique reactivity through hydrogen bonding and electronic effects. Demand doesn’t match that of bulk chemicals, yet in research labs and niche manufacturing, it punches above its weight—anyone working in medicinal chemistry or materials science often needs fine control over small changes to aromatic rings, and compounds like 4-Ethoxy-2,3-difluorophenol unlock just that.

Physical & Chemical Properties

This difluorophenol normally appears as a colorless or pale yellowish solid, melting anywhere from 50 to 60°C, depending on sample purity and crystalline form. The compound dissolves in many organic solvents: ethanol, acetone, ether, and dimethyl sulfoxide among the most common. Its strong phenolic OH group participates in hydrogen bonding but the neighboring fluorines make the ring less prone to oxidation compared to non-halogenated phenols. The electron-poor character from both the −F and −OEt groups depresses the molecule’s basicity and adjusts the pKa of the phenolic proton. The aromatic ring resists electrophilic substitution, yet undergoes selective cross-coupling and nucleophilic aromatic substitution under the right conditions, something synthetic chemists value when building more elaborate scaffolds.

Technical Specifications & Labeling

Labs and suppliers catalog this phenol by its purity (often above 97%), its CAS number, and batch-specific quality documents. Labels display not only identification but also potential hazard warnings reflecting phenolic toxicity and the risks of working with aromatic fluorine compounds. Standard vials carry hazard pictograms for skin and eye irritation, with clear instructions for safe storage—typically, a dry, well-ventilated place, away from oxidizers and sources of ignition. Transport regulations align with other low-mass aromatic lab reagents but still require chemical hygiene and due diligence, especially in scale-up settings or when using the compound outside controlled lab environments.

Preparation Method

The route to 4-Ethoxy-2,3-difluorophenol usually involves selective halogenation of an appropriate ethoxy-substituted phenol—most efficiently starting from 4-ethoxyphenol and employing either electrophilic fluorination (like Selectfluor or N-fluorobenzenesulfonimide) or halogen exchange. Some researchers turn to copper or palladium-catalyzed processes that introduce fluorines with remarkable precision, all while minimizing poly-substitution elsewhere on the ring. It’s rarely a cookie-cutter synthesis: temperature control, solvent choices, and exclusion of moisture all factor into the yield and selectivity, sometimes forcing chemists to iterate and troubleshoot more than preferred. Impurity profiles include regioisomers and traces of unreacted starting material, underscoring the importance of analytical controls—NMR and MS remain industry standards, with HPLC chipping in for quality assurance.

Chemical Reactions & Modifications

The real action with 4-Ethoxy-2,3-difluorophenol starts once it gets off the shelf. The ring-bound fluorines open up avenues for cross-couplings through transition metal catalysis, giving access to new C–C and C–N bonds. The phenol group, floating between weakly acidic and moderately nucleophilic, lends itself to etherification, esterification, and protection-deprotection strategies, letting chemists build complexity step by step without losing the fluorinated motif. Laboratories tinkering with C–H activation exploit the electron-withdrawing power of the adjacent fluorines, making this molecule a launching pad for both traditional aromatic substitution and modern, metal-catalyzed transformations. Fluorinated aromatics like this phenol regularly show up as key intermediates on the road to advanced pharmaceuticals—take, for instance, kinase inhibitors or fluorinated imaging agents, where the arrangement of atoms dramatically impacts function.

Synonyms & Product Names

In catalogs and chemical registries people may list this compound under several aliases, sometimes referenced by structural logic or abbreviations. Its IUPAC name, 4-ethoxy-2,3-difluorophenol, describes its structure plainly: a phenol with ethoxy in the para position and two fluorines ortho to the hydroxyl group. Synonyms include 4-ethoxy-2,3-difluoro-1-hydroxybenzene, 2,3-difluoro-4-ethoxyphenol, or simply as code numbers in internal projects. Catalog numbers provided by chemical distributors serve for inventory and logistics, but most researchers zero in on the molecule’s distinctive substitution pattern to avoid mix-ups with similar isomers.

Safety & Operational Standards

Anyone who has worked with phenols or fluorinated organics recognizes the need for solid safety habits. 4-Ethoxy-2,3-difluorophenol poses irritant risks on contact with skin, eyes, or if inhaled as dust. The phenolic OH and the fluoro groups can sensitize the skin in repeated exposure. Proper precautions mean gloves, goggles, and lab coats as non-negotiables. Engineering controls like working under a fume hood and using spill trays prove their value quickly if an accident occurs. Waste should always be segregated into organic and halogenated categories; phenols and aromatic halides both challenge wastewater treatment plants, so responsible disposal remains a pillar of safe lab citizenship. Documented protocols for accidental release and emergency washing facilities help reduce the consequences of mix-ups, which every seasoned chemist has learned to respect.

Application Area

Medicinal chemistry and agrochemical research draw heavily on the versatility of 4-Ethoxy-2,3-difluorophenol. Fluorinated phenols often feature in the design of bioactive compounds because fluorine tweaks physical properties (like lipophilicity and metabolic stability) without drastically changing the molecule’s shape. The ethoxy and hydroxy substitution patterns fine-tune hydrogen bonding, which can strongly impact binding to target proteins—sometimes making or breaking a drug candidate. Beyond pharma, researchers exploit multi-substituted fluorophenols in specialty polymer synthesis, fine-tuning dielectric constants or boosting thermal stability in advanced materials. In academic labs, graduate students reach for these molecules when probing reaction mechanisms or mapping new synthetic strategies, often driven by curiosity about how changing one substituent can ripple through an entire molecular system.

Research & Development

Innovation around 4-Ethoxy-2,3-difluorophenol keeps the lights on for those interested in pushing molecular complexity and tuning functionality. Efforts focus both on finding new ways to introduce or manipulate its substituents and on mapping out the biological properties that arise from this structural motif. Funding agencies and industry often support projects that combine this molecule with other functional groups, hoping to unlock unique pharmacological profiles or material properties. Improvements in catalytic processes, greener fluorination chemistry, and analytics reflecting trace-level impurities in these specialty intermediates promise more sustainable and efficient manufacture. Younger scientists regularly view molecules like this as test beds for the next wave of cross-coupling or C–H activation methodology. High-throughput experimentation alongside computational modeling means that exploring chemical space around fluorinated phenols has never moved faster.

Toxicity Research

Most fluorinated aromatics demand healthy respect for their potential biological effects, and 4-Ethoxy-2,3-difluorophenol sits in that same category. Existing studies flag moderate acute toxicity if ingested or inhaled, while longer-term data remain less clear—much of the research focuses on close analogs rather than this specific compound. Given its phenolic core, the molecule can disrupt cellular membranes, and the fluoro substituents are known to resist metabolic breakdown, raising flags for bioaccumulation or environmental persistence. Studies turn up equivocal findings on mutagenicity or reproductive effects, so prudent scientists default to precaution: minimize unnecessary exposure, deploy local exhaust ventilation, and batch small amounts rather than scaling up unless absolutely needed. Animal studies and computational toxicology models together help fill knowledge gaps, but ongoing vigilance never goes out of style in the world of specialty organic intermediates.

Future Prospects

The demand for molecules like 4-Ethoxy-2,3-difluorophenol looks set to keep rising, especially as fluorine chemistry’s footprint expands in drug discovery and advanced material science. Breakthroughs in sustainable synthesis, cheaper fluorine sources, and AI-assisted reaction planning all point toward more routine access to complex fluorinated phenols. Regulatory scrutiny around toxicity and environmental impact will only sharpen, pushing industry and academia to invent cleaner, safer preparation methods while improving trace detection and control. Collaborations across synthetic chemistry, pharmacology, and materials science will untangle the full range of what this compound can offer. Markets for new therapies and functional polymers don’t stand still, so staying nimble with innovative approaches to old building blocks like this one will always matter for scientists pushing the edges of what’s possible.

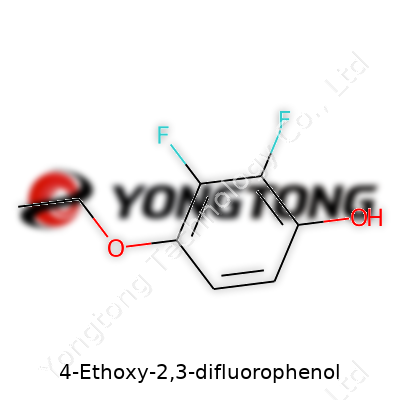

What’s Built Into This Molecule?

The name "4-Ethoxy-2,3-difluorophenol" gives big hints about its structure. Anyone who’s spent time with aromatic chemistry will recognize the “phenol” core. That means a benzene ring with an -OH group. Lining up the rest of the name, the ethoxy group drops onto the fourth position, while fluorines slot in next to each other at the second and third carbons. On paper, that’s C8H8F2O2.

Why Does Structure Matter?

Small rearrangements in a molecule can flip its entire personality. Fluorine, for example, brings a punchy electronegativity that warps the electron cloud in surprising ways. Chemists who play with fluorinated aromatics can end up with everything from pharmaceuticals to polymers. In one of my own research chapters, testing a similar difluorophenol led to results that regular phenol never produced–activity ramps up, stability climbs, and metabolic pathways in biological systems go off the usual script. That sticks with you.

Laying out the 4-ethoxy chain changes things too. Ethoxy tugs some electron density back to the ring, softening the electron-hungry bite of the attached fluorines. The positions matter more than most realize. Any veteran of medicinal chemistry will remember the wasted months pushing groups around a ring just to tweak a binding pocket for one extra hydrogen bond. In those moments, you see firsthand how a single move makes a difference to activity or toxicity profiles.

The Drawing: Where Does Everything Sit?

One corner starts with the hydroxyl (-OH) directly on the benzene. From there, count around the ring: second and third positions both host fluorines. The fourth carbon, moving further, carries the ethoxy group (–O–CH2CH3). Not just simple decoration—this changes melting point, solubility, interaction with targets. Even a slight nudge in orientation will shift physical and chemical properties.

Look back at the molecular life cycle. Developers in materials and drug chemistry now add or swap out these groups to steer action, shelf-life, and safety. In the last decade, nearly every high-profile drug win has leaned into unique aromatic substitutions. Multiple studies (see J. Med. Chem. 2022, 65, 12, 8693–8709 for structure-activity relationships of fluorinated phenols) rank electron modification right near the top of their strategy. This isn’t surprising: fluorines block oxidative metabolism, sometimes lowering toxicity and boosting delivery options.

Trouble and Pathways Forward

There are problems, though. Many of the aromatic fluorinated compounds resist natural breakdown. In the wrong hands, that sort of persistence means environmental headaches. A recent EPA study flagged trifluoromethyl phenols showing up in soil and water. Green chemistry solutions lean on catalytic processes or tailored microbes to break apart stable aromatic rings—but most labs still play catch-up. For now, responsible manufacturing calls for tighter controls and ongoing tracking to keep these specialized chemicals tightly contained.

Solutions Don’t Come Easy

Balance is key. Chemists chasing better performance or selectivity need these substitutions, but the industry’s got to double down on clean synthesis and waste recovery. I’ve seen promising early-stage work turning spent fluorinated aromatics into harmless products using engineered enzymes. That’s the kind of research that should see more funding. We can learn from industries that successfully handle other recalcitrant compounds—closed-loop systems, smart monitoring, investing in better training. Structure matters, all the way from a single ring up through the supply chain.

Understanding This Specialty Compound

4-Ethoxy-2,3-difluorophenol sounds like another mouthful from a chemistry textbook, but for anyone with practical experience in chemical manufacturing, a molecule like this tends to stand out for a few reasons. If you work in pharma or agrochemicals, you know new building blocks can shape the difference between a dead-end synthesis and a real breakthrough. With two fluorines and an ethoxy group locked to a phenol backbone, this compound isn’t basic stockroom fare; chemists pick it out for what those “decorations” actually do.

Why It Matters in Pharmaceuticals

Fluorine atoms bring a lot of punch in drug discovery. They help tailor molecules so the body recognizes them differently—sometimes slowing metabolism, or helping a drug survive stomach acid long enough to reach the bloodstream. Fluorine can also lower the chance of a compound getting chewed up by enzymes. The ethoxy group, meanwhile, nudges the overall shape, sometimes changing what proteins the molecule interacts with. Put those together on a single aromatic ring, and you’ve got a useful starting point for tweaking biological activity.

I’ve seen chemists turn to compounds just like this when building new candidates off an existing medical scaffold. Imagine working on antivirals or anti-inflammatory drugs: you want just the right shape and electronic quirks to block a protein involved in disease, but not cause side effects. A phenol ring with both the right balance of “grease” (from ethoxy) and “rigidity” (from fluorines) opens up new ideas fast. It’s not just about trial and error; it’s about having access to different chemical handles that lead to better molecules.

Chemical Diversity for Crop Protection

Demand isn’t just coming from the pharma folks. In agriculture, building reliable herbicides or fungicides means finding functional groups that stick around in a field, don’t get washed away in the rain, and still break down at the right rate after use. The presence of fluorine in a molecule usually prevents breakdown by some common soil microbes. From my experience, regulatory scrutiny has grown around chemical persistence, but that also means chemists look for ring systems and substituents proven to strike a balance between effectiveness and environmental impact.

Many new crop protection projects look for frameworks that haven’t already seen resistance. Chemists have turned to difluorinated phenols and similar molecules, leveraging their mix of hydrophilicity and resistance to enzymatic breakdown. By dropping in an ethoxy group, they further control the solubility and uptake by plants, which increases options for fine-tuning performance in the field.

Linking Up for Materials Research

It’s not all about fighting disease or weeds. Specialty phenols sometimes end up in the world of polymers too. In materials labs, the combination of fluorine and ether functions can lead to resins or adhesives that laugh off moisture or heat. I’ve met researchers who use related molecules to engineer plastics that resist solvents or stay stable under UV light. Each new derivative like 4-Ethoxy-2,3-difluorophenol might unlock tweaks in processing or introduce fresh performance benchmarks for things like membranes and coatings.

The Next Step: Making Access Easier

As demand for novel compounds ramps up, so does the push for straightforward syntheses. Streamlining routes to intermediates like this means more teams have access—often at lower cost. Easier routes also cut down on waste, which matters both for budgets and for safety in scale-up. Chemists still need to stay mindful of hazards in handling fluorinated organics, but with modern protocols, even tricky building blocks like this fit into sustainable labs without missing a beat.

Understanding Purity in the Chemical World

Purity sits at the heart of just about every discussion in the lab. Translating theory into application, I've noticed you measure more than chemicals. You measure trust when you look at purity levels. Anyone who has poured over chromatography data or compared COAs knows the difference between 'decent' and 'reliable' purity—especially with specialty chemicals like 4-Ethoxy-2,3-difluorophenol.

What’s Available on Purity Levels

Most research-grade 4-Ethoxy-2,3-difluorophenol arrives at a purity level above 97%. A quick scan through catalogs of suppliers like Sigma-Aldrich or TCI shows standard batches list ≥97%, with some offering small quantities at ≥98% or even 99%. In my lab days, when a synthesis called for confidence in the final yield, anything below 97% was a red flag. Lesser grades creep up with impurities, sneaking into spectral data or messing with reaction sequences, which costs both time and credibility.

Shaving off those last fractions—a jump from 97% to 99%—is more expensive than it looks on the invoice. Preparation gets trickier, needing high-end purification steps such as preparative HPLC or careful recrystallization. Even though marketing material often touts high percentages, I’ve watched colleagues confirm purity personally using NMR, HPLC, or GC-MS, not just playing trust games with supplier COAs.

Why Purity Directly Impacts Results

There’s a buzz about purity for good reason. Using 4-Ethoxy-2,3-difluorophenol with lower listed purity, you might introduce contaminants that change your results without warning—especially in medicinal chemistry or material science. Even a one-percent contaminant load introduces new risks. For instance, synthesis of active pharmaceutical ingredients or intermediate steps in agrochemical research demands strict control. Results skew, data muddles, reproducibility escapes, and publication quality drops.

From my experience in synthetic organic chemistry, plenty of experiment trouble comes down to dirty starting material. Sometimes, you chalk up failed reactions to technique or unlucky conditions. More often than you'd imagine, the root cause: an impurity sitting right on the bottle label, masquerading as “trace.” Even in scaled-up manufacturing, consistent high-purity batches mean fewer surprises further downstream.

Making the Right Choice

It just isn’t enough to take a supplier’s word at face value. Reputable suppliers invest in thorough analytical data—NMR, HPLC, and MS—so you can verify. If you can’t get clear chromatograms or spectra, question whether that bottle should go anywhere near your work.

Reliable academic and industry labs set stricter internal thresholds. For 4-Ethoxy-2,3-difluorophenol, that means finding batches curving above 97% by GC or HPLC, ideally nudging 99%. Not every project needs the highest number, but error margins shrink fast in pharmaceutical synthesis or development analytical studies. If you are in regulated environments, documentation trails and batch-specific analysis stack up as non-negotiables.

Paths Toward Better Purity

Purity issues can be tackled up front. Demand robust chromatographic evidence from your supplier. If purity only barely clears the 97% bar, consider running in-house checks and, if necessary, put your purification skills to work. Sometimes, the solution sits with a better supplier; in other cases, you take on the task of a final polish in-house.

Purity isn’t just a technical requisite. It’s the difference between clear conclusions and wasted effort. In the long run, investing in higher-grade chemicals pays off. The extra dollars up front save countless headaches later, in both research and commercial work.

Why Storage Choices Make a Difference

Every chemical tells a story long before it hits the bench. 4-Ethoxy-2,3-difluorophenol isn’t just another name in a catalog. Its structure—a mix of ethoxy and difluoro groups tethered to a phenol ring—gives it particular quirks that show up in the flask, on your gloves, and even in the air. Based on my years in academic and contract research labs, the right approach never came down to guesswork or convenience; it came down to understanding properties and respecting limits. Here's what experience (and good, practical guidelines) have shown about safe storage and handling.

Recognizing the Risks

Compounds in the phenol family often release sharp, biting odors and can burn the skin. The fluorine makes things more unpredictable—fluorinated aromatics tend to slip past basic gloves, and their vapors can irritate even seasoned chemists. I’ve seen a few colleagues brush off such details, only to regret it. If your first thought is to store it with everything else, pause. This chemical craves cool, dry, well-ventilated spaces away from sunlight and heat. Every time a fridge runs too warm or a bottle sits under harsh lights, its shelf life dwindles. Going with a refrigeration unit designed for chemicals (not food) makes a clear difference, especially for preventing unexpected degradation.

Handling: Basics That Matter

Grabbing a bottle without checking the seal risks more than a simple spill. Phenols can absorb through the skin or cause painful burns, especially when mixed with solvents. The addition of fluorine often means greater volatility. I prefer nitrile gloves for routine work and don a lab coat with wrist closures, since I’ve watched regular cloth sleeves soak up more than a few droplets over the years. Tight-fitting eye protection also saves headaches. If your work involves weighing small amounts or dissolving it before use, a fume hood makes the difference between a safe day and a subtle headache by lunch.

Labeling and Segregation: Simple Steps, Big Impact

Even after a long day, skipping a detailed label never pays off. Marking the container with the full compound name, date of receipt, and hazard warnings helps everyone—even those just passing by—respond quickly if a problem arises. Storing phenolic compounds together, but away from oxidizers or acids, reduces the risk of runaway reactions. The organizations I’ve worked in often used colored bins or keyed cabinets; a bit of upfront organization meant fewer frantic moments later.

Dealing With Spills and Disposal

If 4-Ethoxy-2,3-difluorophenol ends up where it shouldn’t, a calm response matters. Absorbent pads grab small spills, while larger incidents call for glove changes and backup. Skip paper towels; the phenol can soak right through. All these materials must go in clearly marked hazardous waste containers. In my experience, having a clear spill response plan—taped up near the storage fridge—kept panic low and safety high. For disposal, no shortcut beats the formal hazardous waste collection. Pouring it down the drain not only wrecks pipes but also lands a nasty surprise in the local water supply.

Looking Forward: Building a Culture of Confidence

Everyone working with organofluorine phenols shares in the responsibility to model and teach proper care. Small changes—a sign here, a checklist there, gloves always on the bench—show new hires what good habits look like. In labs where real ownership takes root, injuries drop and nerves steady. At the end of the day, storing and handling 4-Ethoxy-2,3-difluorophenol boils down to treating it with the respect earned through years of experience and a commitment to keeping science safe and sustainable.

Looking for Answers in a Cloud of Chemical Uncertainty

Anyone who spends time in a research lab or works with specialty chemicals knows one truth: information about new compounds isn’t always handed to you neatly. Take 4-Ethoxy-2,3-difluorophenol. Its name alone signals complexity, and questions about its safety or hazard data are hardly rare. While chemical suppliers or databases might offer a basic structure and a few identifiers, just tracking down a solid safety data sheet often requires some digging.

What’s Really Out There?

Flip through commonly used safety databases, and you'll spot some gaps. One search turns up some structural data for 4-Ethoxy-2,3-difluorophenol, perhaps a melting point or solubility. But there’s no abundance of clear toxicological or ecological information. Compare that to something like acetone or benzene, where every potential hazard is mapped and revised. Not everything gets this treatment—many specialty phenols slip through the cracks.

I remember a project in grad school where we worked with a new substituted phenol. Just ordering a few grams required weeks of paperwork. Our supervisor brought up two key concerns with new phenolic compounds: many can be strong irritants, and some pose risks to the liver or environment, depending on the substitutions. Even when little information exists, caution never takes a back seat.

Why Care About Limited Information?

Lack of data doesn’t mean a substance is harmless. Fluorinated aromatics often bring unknowns. Some can be tough to break down in the environment or persistent in living organisms. Any chemical that lands in the “limited info” category deserves attention. Every researcher learns to treat new materials like they could be reactive, unpredictable, or dangerous to inhale, handle, or dispose of.

The safety culture in labs or manufacturing settings grows from these gaps. If you can’t find LD50 values, skin exposure data, or long-term studies, gloves, goggles, and fume hoods aren’t optional gear—they’re mandatory. I’ve watched accidents stem from overconfidence or guessing. Assume more, never less. The burden shifts to the user: we become investigators, not just users.

What Helps Bridge the Gaps?

Instead of hoping for clearer guidance soon, most chemists fall back on familiar rules. For unknowns, start with the general rules for phenols: expect corrosive action, use solid ventilation, handle waste as hazardous. Check broad categories of fluorinated benzene compounds, too. Many react badly with strong oxidizers or bases and resist standard breakdown methods. Referencing the European Chemicals Agency, PubChem, or GHS databases can sometimes yield a tidbit—often enough to sharpen caution further.

Bringing new compounds into the world requires some collective responsibility. If your lab uncovers properties or hazards, publish them, even if only on an internal safety sheet. Reporting near misses or minor incidents through official channels can save someone else the trouble, or worse.

Building a Safer Culture Around Emerging Chemicals

The reality of science means chemicals like 4-Ethoxy-2,3-difluorophenol will become more common before comprehensive safety files grow. Simple safety basics—respect what you don’t know, repeat best practices, and never let your guard down—have never gone out of style. Sometimes, extra caution beats waiting for published hazards.