4-Chloro-2-fluorobenzaldehyde: A Close Look at Its Past, Present, and Future

Historical Development

The story of 4-Chloro-2-fluorobenzaldehyde goes back to the surge of benzaldehyde derivatives that began to capture attention in the mid-twentieth century. Chemical industries kept pushing for higher purity and specialized compounds as drug design grew more sophisticated. I remember speaking with colleagues who worked in aromatic compound synthesis during the eighties; they pointed out how research teams sought new ways to substitute benzene rings, leading to better functional group strategies. Over time, chemists found that combining halogens in aromatic aldehydes created new candidates for pharmaceuticals and agricultural products. Test logs and scientific papers show a clear progression from simple halogenations to precise, position-selective strategies like the ones behind this compound.

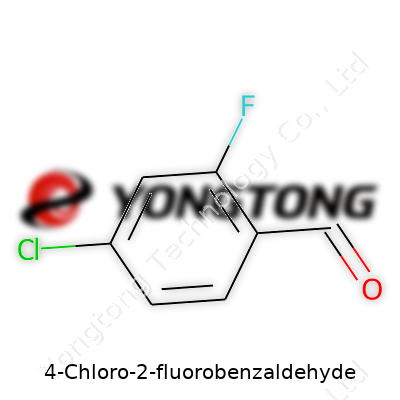

Product Overview

4-Chloro-2-fluorobenzaldehyde belongs to a family of benzaldehyde derivatives marked by tight structure-activity relationships. It carries a chlorine at the fourth carbon atom and a fluorine at the second, giving it qualities prized in both medicinal and material chemistry. Chemists prize this molecule for its reactivity and its critical role as a building block. You'll often see it featured in retrosynthetic analysis courses or in the batch notes of specialty chemical companies. Ingredient logs for advanced agrochemicals, fine-tuned reagents, and even some next-generation dyes trace back to the versatile chemistry of this aldehyde.

Physical & Chemical Properties

People in the lab usually describe 4-Chloro-2-fluorobenzaldehyde as a pale yellow crystalline solid. Its melting point tends to hover around 49 to 53°C, with a boiling range near 86°C at 2 mmHg, making it manageable on a standard rotary evaporator. Practical details get more interesting considering its solubility—it dissolves well in common organic solvents like dichloromethane, ethyl acetate, and acetone. Chemists take note that the compound has a clear, sharp odor, which can become more pronounced in closed quarters. Its molecular formula—C7H4ClFO—helps to quickly calculate molar quantities and understand its reactivity. The density sits at roughly 1.36 g/cm³, and it remains reasonably stable under typical storage conditions.

Technical Specifications & Labeling

Production groups focus on maintaining strict quality parameters for 4-Chloro-2-fluorobenzaldehyde. Purity levels often exceed 98%, with gas chromatography or HPLC checks confirming the absence of isomeric impurities or unreacted precursors. Labels reflect detailed batch numbers, CAS registry (673-33-8), and lot-specific certificates of analysis. Handling sheets detail hazards linked with both the aldehyde and halogen groups. I can recall audits from regulatory bodies pushing for clear hazard pictograms and signal words in multiple languages, an extra step that reflects rising global standards for specialty chemicals.

Preparation Method

I’ve watched the preparation of 4-Chloro-2-fluorobenzaldehyde shift toward greener routes over the years, but the classic method still starts from 4-chloro-2-fluorotoluene. This approach involves careful oxidation, typically with reagents like manganese dioxide or certain chromium(VI) solutions. Some newer methods avoid heavy metals by leveraging catalytic air oxidation under controlled conditions—a welcome improvement for the environment and worker safety. Regardless of approach, reaction times, yields, and purification steps remain central to every synthetic campaign. Column chromatography and selective crystallization help reach high purity.

Chemical Reactions & Modifications

The molecules react most eagerly at the aldehyde site and with the aromatic ring’s halogens. Reductive amination, Grignard additions, and nucleophilic substitutions sit at the center of its synthetic utility. Chemists attach protecting groups, introduce heterocycles, or build up more complex drug fragments from this scaffold. Fluorine and chlorine substitution patterns bring both reactivity and metabolic stability. In pharma R&D, I’ve sat in meetings where teams mapped synthetic pathways, often using this compound as a key intermediate in programs aiming at anti-infectives or CNS-active molecules.

Synonyms & Product Names

This compound shows up under several names: 2-Fluoro-4-chlorobenzaldehyde, 4-Chloro-o-fluorobenzaldehyde, or sometimes by trade-specific codes in manufacturers’ catalogs. Researchers searching through chemical supply vendors or chemical patent databases benefit from this range of synonyms, making it easier to check sourcing, regulatory status, and application case studies.

Safety & Operational Standards

4-Chloro-2-fluorobenzaldehyde requires serious safety attention—direct contact can cause irritation to skin and eyes, and inhalation poses risks to respiratory systems. Standard practice involves gloves, goggles, and proper ventilation. I’ve noticed companies shift toward fire-resistant lab coats, both to prevent accidental contamination and to lower risks during scaling up. Storage in tightly-sealed containers at ambient temperatures, away from light and incompatible chemicals (especially oxidizers and reducing agents), keeps product quality consistent and workers safe. Regular staff safety training—including spill drills and emergency eyewash station locations—remains essential.

Application Area

The utility of 4-Chloro-2-fluorobenzaldehyde reaches far and wide. In pharmaceuticals, the aldehyde supports the design of several heterocyclic cores found in experimental CNS drugs and anti-infectives. Agrochemical innovation teams rely on its halogenated ring to build pesticide or herbicide candidates with increased potency and metabolic resilience. Specialty dye and pigment chemists exploit these same features to push color intensity and fastness in textiles and inks. The push for new materials has even seen the compound play a role in research linked to high-performance polymers and molecular switches.

Research & Development

Research on this compound keeps building momentum. Teams push for milder, more sustainable synthesis, often inspired by regulatory changes and green chemistry principles. At conferences, poster sessions lay out new cross-coupling reagents and low-waste routes for halogen introduction. One standout area deserves mention: structure-activity relationship modeling, with teams designing derivatives aimed at specific biological targets. Every year, new patents roll in, reflecting the constant pressure for improved synthetic routes and possible therapeutic leads.

Toxicity Research

Ongoing investigation into 4-Chloro-2-fluorobenzaldehyde toxicity keeps regulatory and technical staff vigilant. Animal studies show moderate acute toxicity when administered orally, and repeated exposure can trigger organ-level changes. Standard toxicology screens measure LD50, and hazard documentation covers routes of accidental exposure, including inhalation and dermal contact. Environmental teams worry about aquatic toxicity, given persistence and possible bioaccumulation. Institutional review boards increasingly demand full toxicity dossiers before approving new formulations for commercial or academic use. I see scientists working closer with safety officers to review these data, ensuring lab procedures evolve with current understanding.

Future Prospects

Everything points to a future where demand for 4-Chloro-2-fluorobenzaldehyde rises, especially as personalized medicine and targeted crop protection call for more complex molecular structures. Proposals seek to slash waste, improve precursor sourcing, and use real-time analytics to keep production batches consistently pure. I foresee even tighter integration between toxicology and green chemistry, with research teams testing safer derivatives or creating closed-loop syntheses that reclaim solvents and minimize emissions. Companies with transparent sourcing and data-rich quality assurance win trust among drug designers and regulatory partners alike. Researchers have ambitious goals—better synthesis, safer processes, deeper understanding—and it’s clear the compound’s story is just getting started.

Looking Closer at a Seemingly Simple Compound

Ask any chemist who has ever worked with aromatic aldehydes and they will tell you every atom’s position on that ring matters. 4-Chloro-2-fluorobenzaldehyde goes by the chemical formula C7H4ClFO, and for something that looks so simple on paper, it can throw plenty of surprises your way in the lab. Staring at that string of carbon, hydrogen, chlorine, fluorine, and oxygen, it’s easy to overlook what the formula actually means for real-world use.

The Structure Matters

Benzaldehydes open the door to all sorts of downstream chemistry thanks to the reactive aldehyde group sitting right next to a benzene ring. Here, both a chlorine and a fluorine swap out two of the ring’s hydrogens. One lands in the para (4) position, the other in the ortho (2) slot relative to the aldehyde, which is always at position 1 in the traditional naming system. Put it together, and the arrangement changes everything from how the molecule reacts to how it can be handled safely.

Why the Arrangement Matters in Everyday Practice

Every substitution pattern brings new reactivity. I’ve had situations where swapping just one halogen changed an intermediate from stubbornly unreactive to smooth as butter. Chlorine tends to add bulk and pull electron density from the ring, slightly slowing some reactions but boosting others, like certain nucleophilic substitutions. The fluorine pulls even harder, at times making those carbon-hydrogen bonds less eager to get involved—useful if you want to control where new bonds form during syntheses. That mix lets researchers design routes for drugs or specialty materials with more precision.

Market and Safety Dimensions

Companies often need these building blocks for agrochemicals and pharmaceuticals. Requiring exact formulas isn’t just a paperwork exercise; purity and proper substitution help keep reactions on target. Mistakes cost money, slow down projects, and create safety headaches. Chlorinated and fluorinated aromatics can release hazardous gases if overheated, and regulations demand careful record keeping—not just for environmental concerns, but for worker health.

Aldehydes deserve respect as well. I remember the sharp sting of benzaldehyde fumes the first time I worked with them; extra halogenation usually means lower volatility, but accidents still happen. A good fume hood, gloves that actually fit, and gloves with the right resistance (not just the ones lying on the bench), all help limit exposure and avoid those classic chemical burns on the hands.

Controlling the Synthesis

Lab-scale synthesis of 4-Chloro-2-fluorobenzaldehyde usually starts from a benzene ring already decorated with one halogen. Introducing the second often means working through diazotization or Sandmeyer-type chemistry. Each step invites its own risks and troubleshooting. The reaction’s selectivity depends on solvents, temperature, even stir speed. Small things add up—especially since yields don’t always climb as expected, and waste streams grow with each extra halogen atom.

Future Outlook

As regulations grow stricter and green chemistry becomes more essential, attention turns to routes that give high yields with minimal side products. New catalysts, solvent choices, or even biocatalytic approaches might eventually provide cleaner, safer methods for making these compounds. That brings direct benefits—less hazardous waste, lower operating costs, and simpler compliance headaches for researchers and manufacturers.

So a simple formula like C7H4ClFO stands for much more than just its numbers. It’s a snapshot of trade-offs, practical chemistry, and the real world decisions that shape what we put in bottles and ship to the next laboratory or production line.

What Makes This Chemical Useful?

4-Chloro-2-fluorobenzaldehyde stands out in chemical manufacturing because of how well it reacts with other ingredients. Its unique structure gives it a spot in pharma, crop protection, and pigment creation. I came across this compound during a stint in a lab that specialized in developing custom molecules for research clients. The teams loved using it because the chlorinated and fluorinated arrangement lets scientists build more complex chemicals that don’t break down easily.

Active Ingredient Building Block for Pharmaceuticals

Drug research depends on access to small molecules like this one. Pharmaceutical firms use 4-Chloro-2-fluorobenzaldehyde as a building block for anti-inflammatory, anti-cancer, and anti-viral drugs. Its combination of chlorine and fluorine atoms boosts how well a finished medicine behaves in the body. Compounds built from this base can better resist water and work longer inside people, sometimes with fewer side effects.

A study in the European Journal of Medicinal Chemistry (2021) pointed out that molecules built from this kind of aldehyde often showed stronger activity against conditions like bacterial infections. By tweaking one part, the products become candidates for trial in serious diseases.

Chemical Intermediate for Agrochemicals

Farms and food producers look for new crop protectants every year, and new bases like this one keep them ahead in that race. Agrochemical makers combine 4-Chloro-2-fluorobenzaldehyde with other chemicals to create pesticides or fungicides. The arrangement of its atoms lets these companies make formulas that do their job on pests but break down safely in fields over time.

One colleague in the pesticide testing business shared that demand for these types of building blocks keeps rising as older chemicals get banned or lose their punch. It pays to have new possibilities that regulators might approve.

Synthesizing Dyes and Pigments

Color chemists depend on this molecule when chasing stronger, more lasting pigments for inks, plastics or paints. The unique makeup of 4-Chloro-2-fluorobenzaldehyde helps create tones that don’t fade, even after long use. Dye firms often test derivatives for use in bold plastic casings, automotive finishes, and specialty printing inks.

I once talked with a pigment lab manager who said they experimented with dozens of aldehydes to find improved shades, and the ones based on chloro-fluorinated cores lasted longer in direct sunlight.

How can we Make Its Use Safer?

Handling any reactive intermediate means taking care. Factories must carefully manage the risks of leaks and accidental exposure. Proper training and modern containment tech reduce risks to workers and the environment. In research settings, clear protocols keep accidents from turning into disasters.

Chemists stress the importance of local ventilation, gloves, and always double-checking storage labels. Introducing closed systems for transfer and reaction work also shrinks the risk of spills or fumes. The extra steps keep the workspace safer and protect everyone involved.

Why Proper Care with 4-Chloro-2-fluorobenzaldehyde Matters

Storing and handling 4-Chloro-2-fluorobenzaldehyde isn’t just a box-ticking exercise. Sitting in a lab years ago, I watched a careless approach with chemicals lead to unnecessary panic: leaks, wasted time, and health scares that could have been avoided with a little more attention. A simple review of this compound's traits underlines its potential hazards. This chemical doesn’t offer any second chances if vapors escape or if a spill goes unchecked. According to the European Chemicals Agency, it brings both health and environmental concerns. Skin and eye contact can irritate, and inhaling its dust brings respiratory risks. So, handling it safely isn’t red tape—it’s just common sense.

Best Ways to Store 4-Chloro-2-fluorobenzaldehyde

It’s not complicated but does require vigilance. Store this compound in a cool, dry place. Moisture or heat turns storage into a guessing game; water leads to slow degradation or hazardous byproducts, while warmth speeds up volatility. Try to keep temperatures under 25°C. That often means a ventilated chemical storage cabinet with temperature controls—universities and research labs already use these.

Containers matter. Glass with tight, screw-on lids works well, as does high-grade plastic tested for chemical resistance. In my time packing samples for international shipment, I always double-wrapped glass bottles in secondary containment and checked seals—those extra steps caught weakened stoppers more than once. Label every container with the name, the concentration, and hazard warnings. Faded or missing labels will get you in trouble with both regulators and your own colleagues.

Do not store this chemical near incompatible substances. Examples like acids, strong oxidizers, and reducing agents—if stored side by side—raise the likelihood of an accident. Reviews of chemical injury claims across North America show that mixing incompatible reagents accounts for a huge share of lab accidents.

Good Habits for Handling

Wearing the right gear beats hoping for good luck. Lab coats, nitrile gloves, and eye protection serve as the basics. Handling powders or transferring the chemical should happen in a fume hood. The slightly sweet-almond aroma that sometimes slips through means you’re already exposed, and volatility rises with temperature.

Keep spills contained. My group always kept absorbent pads and spill kits within reach. One careless bump in a chemistry teaching lab emptied a beaker onto the floor. Fast action, using the right neutralizing pads, limited our exposure and the damage. If skin contact does happen, wash immediately with soap and water and alert a supervisor.

Material safety data sheets (MSDS) are not just for audits. I’ve seen many new lab workers skip MSDS review, trusting their experience with similar chemicals. Every preparation, every cleanup, starts with that sheet—otherwise, you gamble with your health.

Keeping Up with Safety

Regulations don’t remain static. Authorities, from the U.S. Occupational Safety and Health Administration (OSHA) to European safety agencies, update recommendations based on new data. Chemical suppliers also revise safe-handling guidance. Periodically reviewing storage and handling procedures, no matter how routine things seem, protects both people and property. With so much on the line, proper storage and handling for 4-Chloro-2-fluorobenzaldehyde reflect more than protocol. They mark real respect for the science and for each other.

What This Chemical Brings to the Table

Few people outside of chemical research ever think about 4-chloro-2-fluorobenzaldehyde. Still, this compound pops up in pharma and industrial labs—usually in the process of building other, more complex substances. Anyone who catches a whiff of it at work or reads its label probably wonders: how dangerous is a liquid like this?

Health Hazards in Plain Language

From personal experience working in chemical environments, most aromatic aldehydes with chlorine and fluorine groups raise red flags. Direct skin contact can cause irritation pretty quickly. If someone spills a bit of it on unprotected skin, the burning sensation sends a clear signal to rinse and get gloves on. Eyes deal with much harsher outcomes—a small splash can lead to redness and pain that doesn’t just disappear after a rinse.

Inhalation risk sits high on the list, too. Even the faintest vapor can trigger coughing or dizziness after a few deep breaths. Central ventilation and fume hoods should never be considered optional around volatile aldehydes like this one. Data from manufacturer safety sheets describes similar issues: skin redness, eye watering, some respiratory irritation—none of which ever feel like small matters for people working with chemicals for years on end.

Environmental Impact and Persistence

4-chloro-2-fluorobenzaldehyde doesn't just vanish after use. It's not one of those molecules that breaks down quickly in water or soil. Fluorinated compounds, in general, resist natural breakdown. The chlorine atom brings another layer of trouble—compounds with this structure linger in the environment and sometimes collect in living tissue.

Some studies show when chemicals like these leak into waterways, they disrupt aquatic organisms’ ability to reproduce or develop normally. Anything with stable halogens can cause subtle long-term damage by altering hormone systems in fish and amphibians. Knowledge from environmental monitoring confirms even trace levels can add up over years, leading to a slow but real buildup.

Reducing Exposure and Harm

Lab safety routines matter. Nitrile gloves, splash-resistant goggles, and good lab coats keep skin and eyes safe. I’ve seen colleagues downplay the risks early in their careers, only to regret it after one minor accident. Every lab should train newcomers to check hood airflow before opening bottles and keep chemical waste streams tightly managed. That means labeled waste containers, never regular trash or sinks.

On an industry level, the path to safer handling starts with understanding alternative chemistry—swapping in less persistent substances when possible. Vendors sometimes push for “greener” alternatives in synthetic processes. Not every company jumps on board; short-term cost savings usually win. Still, consumer pressure and regulatory frameworks can shift decisions, the same way we’ve seen with other persistent pollutants in the past decade.

The Bigger Picture: Staying Accountable

4-chloro-2-fluorobenzaldehyde may stay out of the headlines, but ignoring its risks brings long-term health and environmental costs. People using it learn soon enough—respect for proper handling isn’t just regulatory hoop-jumping. Small setbacks from one overlooked exposure can put health and ecosystems at risk, far beyond the walls of any single lab. Every step taken to reduce that risk makes a difference, whether in improved workplace routines, cleaner waste streams, or better chemical designs.

Purity: Why It Matters

Stepping into a research lab or chemical plant always highlights one crucial fact: purity isn't just a number. Every percentage point reflects the reliability of reactions and the accuracy of results. For 4-Chloro-2-fluorobenzaldehyde, most reputable suppliers offer a minimum purity of 98%. Some batches arrive at purities closer to 99%, and this higher level matters. Think about a pharma company searching for the next effective compound—impurities can easily derail trials or skew data. Even small research teams at universities will pay extra to avoid cleaning up after messy side reactions. Inconsistent purity across batches forces teams to halt work for additional analytics, and in competitive research, wasted time hits budgets hard.

I’ve worked on projects where a single percent drop in purity led to column chromatography headaches and unusable yields. One study from the American Chemical Society showed that variable purity in intermediate building blocks caused delays of several months in drug development pipelines. It’s not just about getting a good number on the certificate of analysis. It’s trust in every step afterward.

Packaging: Options on the Market

Ask any bench chemist about the surprises that come from packaging choices. Standard practice for 4-Chloro-2-fluorobenzaldehyde is amber glass bottles. Why amber? That three-dollar bottling decision protects aldehydes from light. With a light-sensitive group like benzaldehyde, too much exposure can lead to breakdown or spoilage—nobody wants to explain a failed experiment because of a leaky UV seal. Typical packaging falls into the 25-gram, 100-gram, and 250-gram sizes, with larger industrial clients able to order up to kilogram scales in HDPE drums or steel cans lined with inert material. In one project, my team lost a week to prepping a drum repack from an off-brand supplier, thanks to a misshapen lid that let in air and ruined the top layer of powder. This mishap forced everyone involved to pay closer attention to vendor audits and QC reports.

Handling volatile intermediates also means avoiding humidity at all costs. Poor sealing or single-use plastic vials won’t hold up long for sensitive chemicals. Shippers label every container with sharp warning symbols—exposure to skin or air isn’t just a minor annoyance, it can turn a safe workspace into a health risk.

Making Smart Choices

Researchers and buyers who pay attention to product specs stay ahead of trouble. Before the first order, experienced chemists ask for documentation: certificates of analysis, stability data, and storage recommendations. They read lot-to-lot comparisons, run small test reactions, and call technical reps with blunt questions about average impurity profiles. Lab managers prefer sticking with suppliers who have ISO certification and traceable quality control systems. People in procurement learn from word of mouth—last year, a failed synthesis using generic-grade benzaldehyde cost a biotech company thousands, just from a contaminated batch. Suppliers who consistently deliver what they advertise tend to earn long-term business instead of one-off orders.

Reliable chemical sourcing isn’t about luck or guesswork. It depends on data, careful vendor selection, and understanding exactly what goes into each bottle or drum. Anyone using 4-Chloro-2-fluorobenzaldehyde in a sensitive reaction will tell you the same story—mistakes around purity and packaging don’t just waste time; they cost real money and introduce safety risks. Teams willing to do their homework and partner only with proven suppliers keep projects on track and results trustworthy.