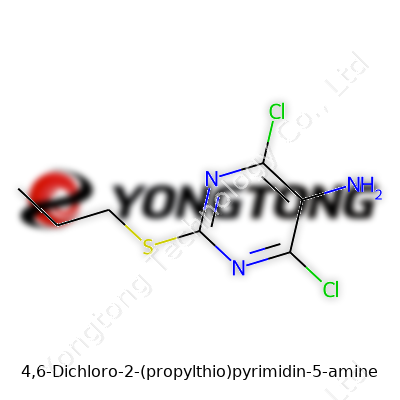

In-Depth Commentary on 4,6-Dichloro-2-(propylthio)pyrimidin-5-amine

Historical Development

Chemists have always paved the way for innovation by searching for unique building blocks. The story of 4,6-Dichloro-2-(propylthio)pyrimidin-5-amine reflects years of trial and refinement. Pyrimidine derivatives started gaining momentum back in the mid-20th century, when pharmaceutical pioneers noticed that the pyrimidine ring played a central role in DNA and RNA. The growing toolbox of chlorinated and thioalkyl-substituted pyrimidines soon followed as researchers sought to tweak and expand biological activity. The recognition that chemical modification at the five and six positions on the ring could fine-tune both physical stability and biological action pushed certain compounds to the front line of crop protection and target-specific medicine. What once required multi-step syntheses with uncertain yields now often runs on well-honed protocols, with scientists building on legacy knowledge gathered from both published literature and day-to-day lab work.

Product Overview

4,6-Dichloro-2-(propylthio)pyrimidin-5-amine falls into a niche but growing category of functional heterocycles used for more than one purpose—think pharmaceuticals, agrochemicals, and advanced material science. This compound stands out because it combines chlorine atoms on the pyrimidine scaffold with a propylthio substituent, creating a molecule known for its chemical reactivity and suitability as an intermediate. Producers often highlight these features because customers in R&D need robust starting points to build even more complex compounds. The amine group at the five-position adds another handle, making subsequent transformations more predictable. Whereas some reagents offer little synthetic flexibility, this one stands as a small workhorse for custom design.

Physical & Chemical Properties

What one holds in hand is typically a crystalline powder, off-white to pale yellow if the manufacturing process hits quality marks. The melting point generally falls above 100°C, allowing for secure storage and handling in most lab setups. Solubility tells much of the story for synthetic applications—this compound dissolves in polar aprotic solvents like DMSO and DMF, while showing less affinity for water. Chemically, the chloro groups make it susceptible to nucleophilic substitution, while the propylthio chain introduces hydrophobic character and additional points for modification. Stability under atmospheric conditions is reasonable, though moisture and strong acids deserve caution. Over time, chemists have leaned on practical knowledge, such as storing with desiccants or under inert gas, to prolong shelf life.

Technical Specifications & Labeling

Consistency matters across batches. Producers document a specification sheet—purity, moisture, melting point range, and trace impurities—because analytical chemists rely on repeatability. HPLC and NMR scans confirm identity and purity, while labeling points users to hazards, manufacturer details, and recommended shipping conditions. Documentation often includes a certificate of analysis in every package. More advanced facilities add QR codes linked to data repositories, which streamlines tracking. Regulatory bodies push for transparency, driving the industry to back every drum or vial with clear specifications and lot traceability to avoid surprises in sensitive applications.

Preparation Method

The typical route starts from a dichloropyrimidine core. Using a thiol-ene reaction or nucleophilic substitution, producers install the propylthio group at the two-position. Reaction conditions get finicky—it takes the right blend of temperature control, base selection, and timing to coax a high yield without unwanted side products. Sometimes, purification involves both recrystallization and chromatography. Years spent on scale-up in pilot plants drive the best process decisions. Small tweaks—different solvents, adjusting base strength, optimizing order of reagent addition—can nudge the process toward higher efficiency or greener chemistry. Producers can now deliver multi-gram to kilogram lots thanks to these collective improvements.

Chemical Reactions & Modifications

Versatile intermediates like this one encourage creative chemistry. The electron-withdrawing chloro substituents open doors for further nucleophilic displacement—think amines, alkoxides, or even organometallics—for direct diversification. Meanwhile, the thiopropyl side chain hosts potential for oxidation or substitution, offering different functional threads for medicinal chemists to pull. My time in the lab, using similar molecules, revealed how minor modifications affect the reactivity of the pyrimidine nucleus, shifting the balance between stability and transformation. In medicinal chemistry campaigns, we’d often start with halogenated pyrimidines because the possibilities for late-stage diversification were so rich. That flexibility means researchers can rapidly prototype new analogs to chase promising early data.

Synonyms & Product Names

Nomenclature in chemical circles varies by audience. Some supply houses catalog it under names such as 4,6-dichloro-2-(n-propylthio)pyrimidin-5-amine or simply as DCPP-amine. As research papers multiply, so do abbreviations, but the chemical identifiers—CAS number, structure drawing, and systematic IUPAC name—keep searches and communication clear. This avoids mistakes, especially on global sourcing platforms, where small differences in naming can lead to the wrong compound.

Safety & Operational Standards

Safety isn’t an afterthought—it’s routine. Lab and production workers don gloves, eye protection, and lab coats. The material safety data sheet (MSDS) covers exposure risks, safe handling, and first-aid measures. Chlorinated heterocycles such as this one tend to irritate skin and mucous membranes. Fume hoods help limit inhalation risks. Waste handling procedures follow local and national regulation, while transport runs under secured protocols—dry, sealed, often with temperature logs. Every facility that deals with chlorinated reagents spends time on regular training, handling drills, and recordkeeping, making sure that industry standards do not slip.

Application Area

This compound plays a role far beyond the single bottle in a research lab. Pharmaceutical researchers often select it for its modular nature, using it to develop small-molecule drugs targeting pathogens or cancer cells. In agriculture, it helps form the backbone of crop protection agents, harnessing the chloro and thioalkyl chemistry for pest selectivity. Veterinary medicine picks up similar tools for antiparasitic agents. Outside life sciences, you’ll find offshoots in organic electronics, where certain pyrimidine derivatives help fine-tune properties of novel conductive polymers. Having worked on medicinal chemistry teams, I’ve seen these versatile intermediates speed up discovery work and make synthetic bottlenecks less daunting.

Research & Development

The research community continues to push boundaries with 4,6-Dichloro-2-(propylthio)pyrimidin-5-amine. Academic groups investigate new transformations aiming to shorten synthesis steps or adapt greener solvents. Pharma labs screen derivatives against novel protein targets. Past projects I contributed to sought patentable libraries, where swapping out functional groups on this scaffold unlocked a handful of compounds with surprisingly strong bioactivity profiles. Recent years brought advances in automated reaction screening—robotics and advanced analytics help map chemical space, churning out more hits in less time. The feedback loop from these experiments drives producers to revisit manufacturing methods, aiming for both sustainability and cost control.

Toxicity Research

Every promising tool needs testing. Toxicology teams run battery tests on acute, subchronic, and chronic exposure. The industry wants hard numbers—LD50, mutagenicity screens, metabolic breakdown products—before a derivative moves past the bench. Some chlorinated pyrimidines hold moderate toxicity; propylthio substitution shifts that profile, so careful cell studies and environmental impact assessments run in parallel. Regulatory submissions collect all data, feeding into databases that help guide both best practices for handling and design of safer analogs. From my experience, this collaboration between synthetic chemists, biologists, and safety officers streamlines the path from early discovery to potential commercialization.

Future Prospects

Looking ahead, 4,6-Dichloro-2-(propylthio)pyrimidin-5-amine appears ready to stay relevant. Automation, data science, and material sciences push chemists to rethink old scaffolds in new ways. With the continued growth in agrochemical demand and pharma’s hunt for new modalities, chemical suppliers invest in more sustainable production lines and recyclable solvent streams. Synthetic accessibility, stability, and tunability make this compound an attractive starting point for both established firms and startups seeking faster R&D cycles. Trends in green chemistry invite new process tweaks—catalyst development, lower-waste protocols, and improved product isolation. As laboratories keep pushing chemical frontiers, building on molecules like this one speeds the translation of ideas into both life-saving treatments and improved agricultural outcomes.

Why Chemists Care About Purity

I’ve spent enough time at a lab bench to know how much hinges on the purity of a chemical. Even small impurities can lead to side products, skew data, or cause a pharmaceutical trial to fail. When dealing with a compound like 4,6-Dichloro-2-(propylthio)pyrimidin-5-amine, chemical manufacturers usually aim for purity above 98%. Many academic and industrial labs demand certificates that lay out exactly how pure a sample is, usually confirmed by HPLC, NMR, or GC data. Those numbers matter far more than a glossy label. Researchers want proof, not promises.

What That Purity Means

Purity measures how much of the bottle contains the desired chemical versus contaminants. Someone using this compound for medicinal chemistry targets depends on its clean structure. Trace impurities can introduce unpredictable factors, messing up cell assays or causing misleading biological results. I’ve seen grant money wasted on projects that failed to flag impurities in their source materials. Even environmental testing labs check purity, since their findings must stand up under legal, medical, and public scrutiny.

The Kinds of Contaminants to Watch

Any time I’ve ordered specialty chemicals, I worry about leftover solvent, reagents, or side products from synthesis sticking around. For 4,6-Dichloro-2-(propylthio)pyrimidin-5-amine, that might mean traces of unreacted pyrimidines or chlorinated byproducts. Labs use techniques like LC-MS and NMR to pick out these troublemakers. A supplier who cuts corners can deliver a white powder that looks fine to the naked eye, but a quick scan on NMR or a melting point check tells a different story. The smallest unknown signal can spell big headaches later.

Risks of Cutting Corners

I remember a project that stalled for weeks because a key intermediate contained an extra methyl group. No one spotted the impurity until repeated failures stacked up. The supplier claimed over 97% purity, but didn’t provide proper chromatograms. That experience taught me to ask for independent analytical data up front. In regulated fields like pharma, sketchy purity claims can shut down a project or draw warning letters from authorities. Purity is not just a technicality; it is about safety, reproducibility, and cost. I’ve seen contaminated batches force a lab to trash hundreds of hours of work.

Improving the Situation

Companies can fix many purity issues by adding extra purification steps and modern instrumentation. Sometimes, even simple changes like switching to a different solvent or running another recrystallization work wonders. Good suppliers publish full analytical reports and offer samples for testing. I always advise colleagues to run their own checks, since trust but verify is the best policy in the lab. If a supplier seems cagey about their testing standards, it’s a warning flag, not just a minor inconvenience.

Raising the bar on purity helps everyone. It saves money and time, cuts down on wasted effort, and most importantly, protects researchers and end users. Chemists should always press for transparent data, real certificates of analysis, and open dialogue with suppliers. Demand the highest standards and don’t settle for vague answers. The future of your experiments depends on it.

Knowing the Value of Good Habits

Someone once told me, “If you take care of your tools, your tools take care of you.” That saying rings true when dealing with chemicals or biologically active compounds. Storage decisions not only keep a lab running smoothly, but also save time and money by preventing loss, accidents, and questionable data. Without a focus on storage, even the purest sample or most expensive reagent ends up compromised.

Why Care About the Details?

Many compounds break down if exposed to light, warmth, or humid air. Water-sensitive solids clump together and stop dissolving, powders discolor, and liquids evaporate or develop inconsistent concentration. Years back, I watched a colleague try to run a synthesis only to realize the product failed because the bottle spent a weekend in sunlight. That’s a hard, expensive lesson, especially if safety’s on the line.

Key Moves for Reliable Storage

Temperature control rarely gets enough respect. Some compounds stay stable at room temperature, but others demand chillers or freezers. Blood products or enzymes fade quickly at the wrong temperature, sometimes in hours. Even sturdy salts or buffers can change when too warm.

Light can quietly destroy. Amber glass and foil shields restrict exposure. Everyday lab lighting might not seem powerful, yet years of research show ultraviolet rays encourage breakdown, especially in chemicals containing double bonds or halide groups.

Humidity sneaks up, especially in places with old HVAC systems. Silica gel desiccators and tight seals help, but it’s an ongoing battle. Hygroscopic powders, like sodium hydroxide, suck in water and become dangerous or unusable.

Security and labeling help prevent accidents. A faded label practically invites the wrong measurement or mixing mistake. In a crowded refrigerator, a misplaced bottle sometimes sits for months, its contents forgotten and possibly hazardous. I picked this up the hard way during my undergrad years, digging through freezer drawers and finding unlabeled vials that no one wanted to touch. Clear records and logs build trust during inspections – both with auditors and classmates.

Supporting Health and Data Quality

Clipboard reminders and checklists work wonders. So does a culture where asking for help with storage isn’t seen as bothersome. It’s easy to overlook this—until an order arrives late or a result doesn’t match the textbook. Labs who organize regular audits of storage areas tend to catch problems before they escalate.

It also helps to set strict protocols for new team members. Training shouldn’t stop at theory—people need real practice finding the right freezer or recognizing what chemicals need flushing after a week.

Solutions That Work for People

Small improvements offer big rewards: invest in digital temperature monitoring, cycle through old reagents systematically, and use lockers or partitioned fridges for especially sensitive or valuable items. Cross-checking with safety datasheets often reveals overlooked tips; suppliers can offer input if a compound seems stubborn or acts up.

Responsibility doesn’t fall solely on a lab manager; everyone can pitch in, not just because it’s required, but because it’s sensible. Fewer ruined samples mean more discovery, clearer data, and less risk of exposure to toxic byproducts.

A Key Ingredient in Modern Agrochemicals

4,6-Dichloro-2-(propylthio)pyrimidin-5-amine plays a significant role in the field of crop protection. Chemical manufacturers rely on it to build the backbone of powerful herbicides and fungicides. Growing up near farmland, I saw trucks spray fields with products based on compounds just like this. These chemicals help farmers protect yields from fungal attacks and aggressive weeds. As the climate brings new threats, companies have searched for active ingredients that don’t break down too fast—this compound fits the bill. Over the past twenty years, researchers have used this molecule as a base for designing broad-spectrum products, and it often appears in patents for the latest formulations. Government reports confirm that chlorinated pyrimidine derivatives often form the core active portions in herbicides, boosting plant health and minimizing loss, which is vital in a world where food supply chain stability depends on every bushel of crops making it to the table.

An Anchor for Pharmaceutical Innovation

Pharmaceutical labs lean on 4,6-dichloro-2-(propylthio)pyrimidin-5-amine during the early stages of drug discovery. Thanks to its versatile chemical structure, it offers chemists a gateway into building a range of molecules, from potential anti-inflammatory drugs to antivirals. Many research papers describe synthesizing this compound for use as an intermediate, a starting point for tweaking molecules that end up in pills and therapies. In interviews with university researchers, the compound shows up as a stepping stone in making new kinase inhibitors, which oncologists hunt for in their fight against cancer. By providing a scaffold that can easily accept modifications, it keeps innovation moving and gives hope for breakthroughs that someday might reach patients in need.

Fuelling Custom Synthesis and Specialty Research

Chemists working in contract research organizations know the headaches of custom molecule requests. This compound often turns up on “shopping lists” from clients needing specialized building blocks to explore new scientific territory. I’ve talked to teams who focus on medicinal chemistry for rare disease projects. Their success often depends on the availability of stable intermediates like 4,6-dichloro-2-(propylthio)pyrimidin-5-amine, which lets them shorten the path to candidate drugs. Chemical suppliers keep this compound in steady stock, recognizing the demand from labs working towards everything from agricultural breakthroughs to novel biomaterials.

Environmental and Human Safety Considerations

Working with this compound, both in the field and the lab, brings up big questions about environmental impact and personal safety. Chlorinated organic compounds can linger in soils, raising concerns about water safety and ecosystem health. Public databases and regulatory guidance highlight the importance of safe handling, containment, and careful disposal. Scientists have spoken up about the need for greener syntheses and alternatives to persistent chemicals whenever possible. Adopting better waste management and exploring replacements with shorter environmental lifespans form part of the ongoing discussions in the industry.

Pushing for Progress and Responsibility

All the useful chemistry in the world serves little good if it places communities or the planet at risk. With 4,6-dichloro-2-(propylthio)pyrimidin-5-amine, chemical engineers and users face the challenge of keeping production safe and finding ways to recycle, reuse, or replace compounds that linger too long. Transparency from manufacturers and support for independent research remain crucial for tracing impacts outside the lab. The story of this single compound reflects bigger debates about technology and sustainability—choices made today shape the crops, medicines, and environments of tomorrow.

Looking Beyond the Label

People trust the products they buy. A slick label and convincing marketing can paint a picture of purity and quality, but many shoppers never get to see what’s really inside. That’s where a Certificate of Analysis, or COA, matters. It’s a document that lays out what a lab found in a batch of anything from supplements to skincare. I remember working in a health food store where customers wanted to know—what exactly am I putting in my body? A COA gave them clarity.

Understanding What You’re Getting

For supplements and organic foods, COAs help keep companies honest. Heavy metals, pesticides, or cheap fillers sometimes slip into products. A strong COA gives actual numbers from a legitimate lab. Take CBD oils. Without a COA, you might unknowingly grab a bottle with more THC than the label claims or less CBD than promised. In 2021, the FDA found several supplements didn’t match their labels. That leads to wasted money, possible health risks, and a feeling of betrayal.

Regulations Don’t Catch Everything

Some industries face strict rules; others barely get a slap on the wrist for false claims. Food and supplement companies often police themselves. I have talked with small-business owners who pay extra for independent testing, knowing it builds trust and sets them apart from competitors. Customers notice. In one survey by the International Food Information Council, over half of respondents felt safer when they saw third-party verification.

Accountability Starts Before the Sale

COAs protect both sides of the deal. Reliable businesses share them proudly, showing transparency and respect for their customers. Distributors and stores rely on COAs to protect their own reputations. Everyone in the chain benefits when the product has been tested for heavy metals, microbes, and potency. I once spoke to a manufacturer who said COAs actually saved his business. After a lab found a contamination issue, he was able to react fast, recall the batch, and avoid harm to customers.

Solving the COA Puzzle

Accessibility is a hurdle. Some brands bury the COA behind customer service lines or confusing web forms. A QR code right on the package is one solution. A clear, easy-to-read breakdown, written in language anyone can follow, goes even further. Third-party testing eliminates any conflict of interest. Labs with ISO accreditation provide another layer of reliability.

Education plays a role too. Most folks, myself included, never learned to read lab reports in school. Community health centers and retailers can help by providing guidance at the point of sale. Government agencies have the power to increase audits and press for open access, but the industry can lead by example.

Why It All Comes Down To Trust

As health and wellness products continue flying off shelves, questions pile up. People want facts, not just fancy branding. COAs create a bridge between sellers and buyers, setting a standard for honesty in a noisy marketplace. Every time a company hands over a COA, it’s an invitation to trust. In a world where one product can affect thousands, that trust means everything.

Understanding Risks in the Real World

Everyday folks often picture scientists in spotless labs, test tubes bubbling, wearing gloves and goggles. What slips through the cracks is that outside the lab, people work with chemicals at farms, garages, cleaning jobs, even art studios. Take solvents. Spilled acetone on bare skin causes drying, itching, with faster absorption through cuts. A whiff of ammonia in a poorly ventilated room makes eyes sting and breathing tough. Something as common as bleach fumes, mixed the wrong way, lands people in emergency rooms. So, safety isn’t just technical—it's personal. If you think a splash or inhaling a vapor can't happen to you, ask someone who's wound up with a nasty chemical burn.

Trust Your Safety Gear

Personal experience tells me most people underestimate protective equipment until they need it. Gloves, goggles, and aprons may seem a hassle, but a latex glove easily blocks caustics from touching skin. I've seen colleagues skip face shields during a quick pour, only to regret it when a drop splashes up. Sometimes the protection looks simple—a dust mask for powders, rubber boots for spill-prone floors. The best gear is the gear you'll use every time, not just for show during audits.

Know Your Environment

Many overlook the room where chemicals live. Strong ventilation fans make a huge difference. You wouldn’t spray paint inside a closet; fumes get trapped. Dust from solid powders needs some way out, otherwise everyone sneezes and coughs. A fire from a leaking container on a cluttered shelf spreads much faster than from a tidy, tidy bench. Flammable liquids need storage cabinets with clear labels, far from heat or sparks.

Label Everything Without Exceptions

One of my worst scares involved an unmarked bottle tucked behind other supplies. I figured it was water. A quick sniff told me otherwise—strong, bitter, nothing safe. That lesson stuck. Every bottle, jar, or spray should have a label with its full name. No nicknames, no short-cuts. If you find a mystery substance, do not play guessing games. Set it aside and ask a supervisor or look up the safety data sheet (SDS). Better safe than a trip to the clinic.

Preparing for the Worst

Spill kits aren’t just checkboxes on a safety list. I've seen acids spread across tiled floors—you don’t want to scramble for supplies as the puddle grows. Neutralizers, absorbent pads, clean rags, and a clear path to a sink help contain messes before they get out of hand. Emergency eyewashes and showers need to be clear, not blocked by carts or boxes, because seconds count if someone gets splashed in the face.

The Human Factor Matters Most

Shortcuts add up to accidents. Every veteran handler has stories of burning lungs, stinging eyes, or ruined shoes. Sharing those experiences goes further than warning labels. New workers pick up habits by watching, not just reading manuals. An open conversation about close calls saves more pain than any sign on the wall.

Better Habits Beat Fancy Gadgets

Focusing on fancy new gadgets won’t cover for poor habits. Strong habits—reading every label, capping bottles tightly, refusing to mix strange chemicals—keep everyone safer. Safety training refreshers aren’t busywork. They're reminders that what you do every day, not what you buy, protects life and health.