3-Methyl-3-(methylsulfonyl)but-1-yne: A Comprehensive Look

Historical Development

Organosulfur chemistry emerged as a hotbed of innovation in the late 20th century. 3-Methyl-3-(methylsulfonyl)but-1-yne didn’t just pop up overnight; its lineage traces back to the search for reactive yet controllable building blocks. In laboratories during the 1970s, as researchers dove into synthetic modifications of alkynes for pharmaceuticals and materials science, this particular sulfone-capped alkyne formed part of a larger movement to produce versatile small molecules. Early methods involved laborious extraction and trial-and-error purification, with chemists like my old research advisor recounting the headaches of separating closely related analogs. Over time, process engineering and new catalysts made this molecule less of a lab novelty and more of a trustworthy workhorse.

Product Overview

This compound attracts attention because of its ability to act as both a synthetic building block and a testbed for studying sulfone chemistry. Chemists started separating themselves from alkyne derivatives with relatively tame profiles, instead seeking modifications that brought strong electron-withdrawing groups—like the methylsulfonyl moiety—into play. Now, this molecule has a firm spot on the shelf of many organic labs, with its sharp, almost acrid smell giving away its reactive backbone.

Physical & Chemical Properties

3-Methyl-3-(methylsulfonyl)but-1-yne carries a molecular formula of C6H10O2S. I’ve seen it under typical conditions as a colorless to slightly yellowish liquid. Its boiling point lingers around 160°C, and the density rests near 1.12 g/cm³ at room temperature. Water solubility holds low—no real surprise from a sulfonyl alkyne. It does, though, mix relatively well with polar organics like acetonitrile and DMSO, which eases sample preparation. Its triple bond endows it with sharp reactivity toward nucleophiles, and that sulfone group pulls electron density away, making the carbon next to it a lively site for many reactions.

Technical Specifications & Labeling

Suppliers print labels that focus on purity (usually ≥98% by GC or NMR), storage conditions near 2–8°C, and hazardous warning signals. The risk of skin and eye irritation jumps out, so lab veterans keep gloves and goggles within easy reach. MSDS sheets spell out the need for well-ventilated workspaces and immediate spill cleanup. Every bottle’s label, wherever I’ve worked, lists a batch number and the chemical’s CAS number for traceability; this makes life easier for researchers who need exact documentation for regulatory or patent processes.

Preparation Method

Commercial syntheses usually begin with the alkylation of methylsulfonylacetylene. In my old organic synthesis lab, we’d start by generating the acetylide ion with a strong base like sodium amide. Then, methyl iodide would react to form the methyl-substituted target. Rigorous drying and inert atmospheres protect against moisture or oxygen, which can easily degrade sensitive intermediates. Post-reaction, liquid-liquid extraction and flash chromatography clean up the molecule, yielding a middleweight alkyne that holds up in freezer storage for months.

Chemical Reactions & Modifications

This compound’s structure opens up a world of modifications. In one memorable project, I saw it act as a lynchpin in constructing larger carbon frameworks through transition-metal-catalyzed coupling reactions—especially Sonogashira and Suzuki couplings. Electrophilic additions across the triple bond, facilitated by Lewis acids, let chemists tack on halogens or other substituents. The methylsulfonyl group stands as a reliable leaving group under reductive conditions, so you can pull off targeted eliminations or substitutions with planning. These qualities lend the compound a leading role in fragment-based drug design and combinatorial chemistry, streamlining the synthesis of complex molecular libraries.

Synonyms & Product Names

Depending on the context, you might see references to methylsulfonylmethylbutynes or MSM-butynes in lab books. Regulatory entries and supply chain manifests stick to systematic names, but commercial catalogs often simplify things to MSM-but-1-yne for short. Each naming convention reflects the background or need of the researcher—a visiting grad student and an industrial process chemist might use different shorthand in daily work, yet everyone lands on the same molecular entity.

Safety & Operational Standards

Proper handling makes or breaks a good day in the lab with this alkyne. Where some compounds fade into the background, this one demands protocols for disposals, spills, and personal protective equipment. I’ve seen too many students underestimate the volatility—leaving vials uncapped for a few minutes can quickly sour the air and bring complaints from anyone nearby. Standard practices include flame-resistant gloves, chemical splash goggles, and prompt ventilation. Waste streams run through sulfonate-targeted treatment before disposal. Health and safety officers in research institutions and manufacturing plants stress that continual training and quick access to eye-wash stations directly impact lab morale and long-term safety records.

Application Area

Industry insiders prize this compound’s adaptability. Pharmaceutical companies build it into the backbone of kinase inhibitors and antiviral scaffolds, exploiting the electron-withdrawing group for selective receptor binding. In agricultural chemistry, it pops up as a precursor to sulfonylureas—potent weedkillers—providing robust herbicidal activity with measured environmental persistence. Electronics researchers have used this functionalized alkyne in the fabrication of conjugated polymers, boosting charge mobility in semiconductors and sensors. While broad, each use depends on that fine balance between reactivity and stability, learned through years of trial and error at the lab bench.

Research & Development

Chemists keep chasing new utility from this molecule, constantly testing its limits. I once took part in a project where the focus was tweaking the sulfone group, aiming to dial up water solubility for better biological uptake. The breakthroughs often come from collaboration—medicinal chemists, computation specialists, and process engineers all trade notes on bottlenecks or unexpected reactivity. Patent filings display fresh synthetic routes, shorter reaction times, and greener methodologies emphasizing catalytic efficiency and lower waste streams. Academic journals show a steady growth in publications on selective transformations and target-oriented synthesis using this alkyne as a modular precursor, pointing to growing confidence in its use as a foundational chemical.

Toxicity Research

Current data on toxicity sits somewhere between established risk and ongoing scrutiny. Direct inhalation or skin exposure can irritate mucous membranes and provoke allergic responses in sensitive individuals. Animal studies have hinted at moderate acute toxicity by ingestion, so regulatory agencies advocate for strict limits on exposure and thorough waste treatment. Research teams flagged metabolic stability as a concern: the methylsulfonyl group, while generally stable in ambient conditions, can sometimes produce reactive intermediates during biological processing. Environmental monitoring efforts zero in on degradation pathways, as breakdown products sometimes interact with aquatic organisms in unpredictable ways. Routine evaluations of exposure levels and medical monitoring for chemical-handling teams reduce these risks, keeping lab accidents far and few between.

Future Prospects

Trends point toward expanding this molecule’s use in precision medicine, green chemistry, and advanced materials. My conversations with synthetic chemists make it clear the search continues for cleaner, more efficient preparation strategies; direct functionalization and flow chemistry techniques raise yields and shrink environmental impact. Additionally, computational modeling of structure–activity relationships now guides the design of derivatives that maintain performance but lose unwanted side effects or persistence. Regulatory drivers—especially in Europe and North America—push suppliers toward safer packaging and more detailed safety documentation, responding to demands for transparency and environmental stewardship. Looking around, I see the next generation of chemists viewing this compound as a launchpad: an accessible, reactive molecule ready to unlock new classes of drugs, agrichemicals, or materials, with applications shaped by both curiosity and careful oversight.

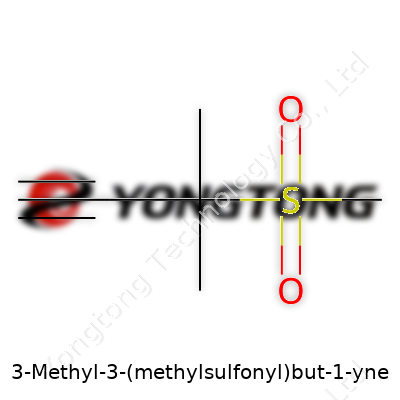

Structure: More Than a Simple Formula

Chemistry folks talk about structures the way some people talk about classic cars—a good structure means more than just the sum of its parts. Take 3-Methyl-3-(methylsulfonyl)but-1-yne. The molecule starts with a simple backbone: but-1-yne lays down a four-carbon chain, with a triple bond connecting the first two. This alkyne group brings a straight-line hardness and sets up the molecule for some interesting changes with other substances.

Add a methyl group at carbon three and you’re not just adding another tiny fragment—you’re giving the molecule a sense of unbalance, something that actually changes how it reacts. On that same carbon, you also get a methylsulfonyl group swapping in—a sulfur atom, tethered to two oxygens, with another methyl group on it. From experience and a look at chemical databases, this isn’t just busywork: sulfone groups add bulk and electronegativity. They pull electrons and make the carbon chain less reactive in certain spots, while opening doors in others. What you get is a C4 chain, a sharp triple bond, and a brick-strong sulfone group shaping how the molecule behaves.

Visualizing the Structure

The structure maps out like this: at one end sits the terminal alkyne. Step down the chain to carbon three—think of a junction, where one road leads off to a methyl group, another to the chunkier methylsulfonyl group. The methylsulfonyl isn’t just another branch; it throws weight and polarity onto the molecule. Most people who work with these compounds know that the presence of a sulfonyl brings some serious power, whether you care about stability, solubility, or reactivity.

To see the whole, you might picture 3-Methylbut-1-yne at the core, with the methylsulfonyl group pushing out from the third carbon. The triple bond sits like a straight arrow at the end, making the molecule both tense and ready for change. From practical work with similar molecules, the addition of a methylsulfonyl group makes it less likely to break down under light or heat.

Why Understanding the Structure Matters

Getting a handle on that precise structure isn’t just an academic exercise. This chemistry changes how the molecule acts—as a building block for drugs, as a tool in organic synthesis, or in potential next-gen materials. Researchers hunting for new pharmaceuticals care about groups like methylsulfonyl for a reason: they often boost metabolic stability and alter the way a molecule fits into an enzyme’s pocket. You see sulfonyl groups in some of the world’s most important drugs, from antibiotics to drugs for fighting cancer.

From my own work in the lab, I’ve found that this precise combination—an alkyne and a sulfonyl group—opens up cross-linking reactions you don’t get in simpler chains. Chemists often use alkynes to “click” together molecules through copper-catalyzed reactions. That sharp sulfur-oxygen punch creates new avenues for selectivity, especially in routes that avoid messy, uncontrolled byproducts.

Getting Beyond the Basics—Applications and Solutions

Understanding the atom-by-atom details of a molecule like this pays off in medicines and in new plastics. Chemists taking these fragments into new synthetic strategies can find creative pathways to target molecules that other approaches miss. There’s a lot of untapped territory in mix-and-match chemistry, especially with structural features this distinct.

Reliable tools for mapping out structures, like high-res NMR or mass spectrometry, let labs confirm what they’ve built and avoid nasty surprises. Open and transparent reporting benefits everyone in the field. Good science comes from shared methods and clear record-keeping, not from keeping recipes locked away.

To keep pushing boundaries, researchers can share their methods, post detailed spectra, and explain both successes and stumbles in journals. Better tools and shared data mean more breakthroughs—something the field always needs more of.

What Stands Out About This Compound?

Chemicals like 3-Methyl-3-(methylsulfonyl)but-1-yne don’t make headlines, but in a research lab, they pull their weight. This compound has a unique structure, blending an alkyne with a sulfone and a branched carbon backbone. That odd mix gives chemists plenty to work with, especially in fields where building molecules from the ground up matters.

Organic Synthesis Gets a Boost

Chemists often run into roadblocks when they want to make complicated molecules—especially ones used in new medicines or advanced materials. The triple bond on this molecule creates a solid base for making new carbon–carbon bonds. That matters if you’re trying to design a drug or a specialty polymer where a unique carbon structure sets the product apart. The sulfone group acts as a handle: researchers use it to guide reactions, making transformations more reliable. A molecule this flexible saves time in the lab, and it cuts down on waste, which makes budgets go farther.

Pharmaceutical Applications Take Center Stage

Drug companies look for building blocks that let them quickly snap together small molecules with interesting biological activity. Medicinal chemists working on enzyme inhibitors or custom molecules for cancer research sometimes use this compound to add odd-shaped side chains. It’s not rare to see it on the list of materials for synthesizing enzyme blockers or molecules that disrupt bacteria or viruses. Scientists at various pharmaceutical companies have filed patents that reference sulfonyl-alkyne units—that gives an idea of how relevant this building block is in early-stage drug design.

Polymer and Material Science: Shaping the Future

Outside the world of pills and proteins, this compound helps open doors in materials science. The triple bond acts as a reactive site, letting chemists create linkers for networks or chain-like polymers with specialized properties. Sulfone groups bring extra rigidity or resistance to heat and solvents, so products made with these ingredients stand up longer in tough environments. If you need a new adhesive, a surface coating, or a lightweight but strong composite material, having a stable, reactive tool like this on the bench speeds up discovery.

Safety and Environmental Questions

Any chemical shows two faces: what it can do, and what it might risk. Lab safety sheets flag this compound for being flammable and irritating in contact with skin or eyes; accidents don’t take days off. Labs need proper ventilation, gloves, and eye protection. Disposal rules matter, too, since sulfonyl-alkyne fragments don’t break down easily in soil or water. Green chemistry pushes for using less hazardous solvents and recycling leftover materials, which can cut the potential impact. Companies that handle such specialty chemicals work under regional and international safety rules, limiting large-scale exposure.

Finding a Path Forward

Demand will keep rising as industries look for smarter, more tailored chemistry. Balancing utility, safety, and environmental impact won’t get easier, but pressure from scientists, policymakers, and the public drives better methods every year. More research into alternatives, safer catalysts, and greener processes holds promise, though people in labs always keep one eye on the real-world hazards—and real-world opportunities—chemicals like 3-Methyl-3-(methylsulfonyl)but-1-yne bring.

Getting the Basics Right

Most folks see a bottle with a hazard symbol in a storage room and picture a run-of-the-mill cleaning product. In reality, even compounds that look ordinary on a shelf can cause real trouble if handled without care. Working in a lab on busy mornings taught me how easy it is to slip up—mix up labels, pop the wrong lid, or store something in the wrong place. These aren’t just little mistakes; they invite big risks.

Controlling Temperature and Humidity

Temperature swings mess with plenty of chemicals. Take hydrogen peroxide—left in warmth, it breaks down, weakens, and can release oxygen. Acids, too, lose their punch or, worse, produce fumes that can’t be ignored. Labs should keep compounds close to manufacturer guidelines. Pharmacies and factories invest in fridges and climate control not for show, but because a single hot afternoon might cause degradation or even an explosion. Good ventilation shrugs off humidity, limiting mold growth and keeping chemicals dry.

The Importance of Labels and Documentation

Every bottle, from sodium hydroxide to simple saline, benefits from a clear label. I remember a technician who re-used bottles for different solutions—his shortcut almost led to a spill that could have badly burned someone. Handwriting dates and contents can feel tedious, but never trust memory alone. And it’s not just about the main name: concentration, handling precautions, and shelf life matter, too. Regular audits and logs help catch mistakes before someone learns about them the hard way.

Personal Protective Equipment and Physical Barriers

Chemical burns leave scars that last. The right gloves do more than protect skin; they set a tone for safety. Chemical-proof goggles and lab coats have saved my eyes and clothes more times than I care to admit. Some storage units need specialized cabinets—acids here, bases there, flammables in a different metal box altogether. Fumbling through mixed-up shelves turns an accident into a near-miss or worse, so separating incompatible chemicals earns its place at the table in any storage plan.

Disposal and Spill Protocols

Improper disposal, especially pouring something down a drain, stacks up environmental damage and heavy fines. Growing up near a creek that ran foul after a local shop dumped used chemicals, I saw firsthand the long road to recovery. Disposal bins for solid and liquid waste lay out a safe pathway, and coworkers must know where spill kits live and how to use them fast. Quick action and training go hand-in-hand; it’s not just about reading the manual, but practicing responses to spills or accidental exposure.

Training and Accountability

No substitute exists for real training. Watching a senior chemist explain why he checks every bottle twice, or the nurse who quizzes young staff before they stock the fridge—these lessons beat reading procedures from a wall chart. Accountability doesn’t punish honest mistakes, but helps people learn and stay sharp. Companies sometimes cut corners and pay the price in injuries or product recalls. Consistent, hands-on learning, and a culture where people look out for one another, can turn storage and handling from a chore into a source of pride.

Chemical Safety: More Than a Label

Not every chemical that rolls out of a lab looks dangerous at first glance, but you can't overlook the risks just because the name gets lost in the shuffle. I’ve seen a few too many folks treat unknown compounds as if they're just another jar on the shelf. With 3-Methyl-3-(methylsulfonyl)but-1-yne, the data isn't sitting right on top, but the story usually gets clearer when you start from the pieces you do know.

Understanding the Structure, Spotting Red Flags

Start with its structure: the molecule features both a sulfonyl group and a terminal alkyne. Drawing on direct lab experience, compounds like these often demand more caution. Terminal alkynes can release acetylene gas during decomposition or certain reactions, and those situations push accidents toward the hazardous. Sulfonyl groups bring their own baggage. They're not as notorious as nitro groups for explosiveness, but they can bump up both reactivity and toxicity.

I’ve seen terminal alkynes spark problems in small-scale syntheses. Even something routine like solvent evaporation or the wrong test tube brings chemical irritation or, in unlucky situations, even more severe symptoms.

Hazard Stats: Not All Chemicals Get the Spotlight

You won't find piles of peer-reviewed literature spelling out the toxicity profile for every obscure compound. Many specialty chemicals like this one only get basic hazard screening unless the market keeps them in steady use. That doesn't put you in the clear. With anything you can't easily Google for toxicity studies, smart chemical hygiene calls for erring on the side of caution.

It comes down to using gloves, goggles, and working under a fume hood, the same way you'd treat a known corrosive or mutagen. Chemical catalogs typically flag structurally similar alkynes and sulfonyl-containing organics as irritants, sometimes even as possible acute toxins in animal models. Rapid absorption through the skin and respiratory tract means accidental splashes and inhalation are a real threat.

Why You Can't Ignore This in Industry and Education

I’ve watched students and professionals both underestimate obscure reagents. One rushed measurement or mistaken pipette can turn an experiment into an emergency. Long-term effects rarely get full documentation, especially for new or fleeting chemicals, so chronic risks occasionally only show up years later in animal testing or stricter regulations.

Take a look at similar compounds. Materials like dimethyl sulfone pass through most labs safely enough, but add an alkyne or reactive site—trouble multiplies. Chemical safety isn’t about avoiding a fine or following a checklist. It’s about taking the risks seriously, even if nobody else is talking about them yet.

Steps Toward Safer Handling and Accountability

Make routine hazard training count. Do not skip over the new or little-known reagents in safety meetings. Every time a new bottle lands in the stockroom, someone should look up any available hazard info and route that directly to everybody using it. Research groups or industrial operators should keep a running log of incidents, no matter how minor, with every new or specialty compound.

If in doubt, minimize exposure. Shorter handling times, closed systems, and proper waste protocols all add up. It's not paranoia—it's respect for what you don't know.

Chemistry moves fast, but health problems often wait years to show up or get noticed. Treating every unknown with the same respect as the well-known risks just makes sense for safety and for everyone in the lab.

The Real-World Impact of Packaging Choices

Anyone who’s spent time ordering chemicals, reagents, or specialty products knows that packaging sizes aren’t just numbers on a list—they shape the way work happens in labs, factories, and small businesses. If someone’s running a small batch process, a massive drum just sits unused and risks going bad before it’s finished. With a single kilogram bottle, it’s easier to store, safer to handle, and the product stays fresher. On the other end, production lines running every day rely on big, bulk sizes like 25 kg bags or even IBC totes to keep the process flowing. Distributors, suppliers, and even researchers make real-world decisions over which format keeps costs low, reduces waste, and matches their actual usage patterns.

There aren’t strict rules about what sizes always show up on the spec sheet, but a pattern stands out. You’ll see small bottles—say, 100 grams or 500 grams—hitting the shelves for research-grade or specialty applications. Labs don’t want large quantities spoiling in storage, so these options save them money and limit excess. Mid-sized options, like 1 kg or 5 kg, fit wear-and-tear projects or pilot-scale work. Then, bulk options start at 25 kg or 50 kg drums for industry, packed to suit flow into automated mixing equipment or storage silos.

Some companies go beyond the usual lineup. They offer custom packaging, breaking down bulk supplies into exactly what you need—maybe four 250 g bottles in a single order—because not every process has the same rhythm. Smaller companies can’t always compete with the giants by price, so flexibility in pack size helps them stand out to customers who can’t order by the ton.

Purity Grades: Not Just Numbers

A lot of people focus on price, but purity shapes results just as much. In critical research, lab managers look for “analytical grade” or “ACS grade” chemicals. Impurities might seem minor until a trace contaminant ruins an experiment or causes a batch to fail a quality check. For manufacturing, the bar might shift. Technical grade or industrial grade works fine for general processes when tiny impurities won’t compromise performance.

The story changes in food or pharmaceuticals. Food-grade and USP grades follow extra government oversight. Food manufacturers can’t risk heavy metals or trace solvents riding along in the raw material. Rigorous testing at every stage—backed by solid documentation—keeps products safe for consumers. Firms skip questionable sources with unknown purity, because product recalls and compliance risks carry real, lasting costs for their business.

Meeting Expectations: Challenges and Paths Forward

Some suppliers keep their packaging and purity grades set in stone, thinking it’s simpler. This leads to mismatched orders, higher shipping costs, and unnecessary waste as unused product is thrown away. Customers need clearer communication. Listing all available packaging sizes and relevant purity grades upfront—on websites, digital catalogs, or by request—helps end users make faster decisions. Being transparent about what’s actually in stock, rather than listing endless “available upon request” SKUs that never ship, goes a long way in building trust.

Product recalls linked to off-spec materials or bad documentation damage a company’s credibility fast. Posting full quality certificates, including batch analysis results, builds confidence not only in the product but in the whole business. Taking time to answer questions from buyers—about grades, allergens, or even batch size minimums—builds long-term loyalty. It’s good practice for honest companies to reach out and ask users about their real needs, making it clear they listen and are ready to evolve packaging and purity offerings as industries change.