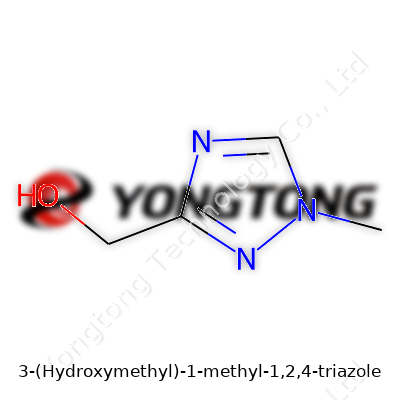

3-(Hydroxymethyl)-1-methyl-1,2,4-triazole: Exploration, Properties, and Perspectives

Tracing the Historical Development

Years back, labs started noticing the versatility of triazole compounds due to the structural possibilities they offer. Chemists found that minor tweaks on these ring systems brought surprising shifts in activity and utility, encouraging researchers to try new combinations. Around this period—mid-to-late twentieth century—the methyl and hydroxymethyl modifications to the 1,2,4-triazole backbone gained traction. Papers began appearing on synthetic strategies that made this group easier to access. Pharmaceutical teams, always hungry for novel scaffolds, quickly spotted this and started their own programs. Seeing the intersection of practicality and bioactivity, the compound’s popularity grew beyond academic curiosity and quietly entered industrial vocabularies.

Product Overview

3-(Hydroxymethyl)-1-methyl-1,2,4-triazole sits on the shelf as a direct response to this demand. Synthesis involves readily available precursors, bringing costs down for fine chemical retailers. It sits as a building block, ready for coupling into more complex molecules. Labs seeking to generate new drug leads or materials science groups pursue it for its robust ring system. Looking at the global catalogues, few derivatives are found so frequently at commercial scale and purity.

Physical & Chemical Properties

In the bottle, it takes a white to beige crystalline form. Melt those crystals and you’ll find a boiling point that remains workable for both lab and factory setups—making matters smoother for further processing. It dissolves well enough in water and common polar organic solvents—especially after a gentle warm-up or agitation. The methyl at the first nitrogen gives it a slightly higher lipophilicity compared to its unmethylated cousins, letting it cross from aqueous to organic phases without fuss. The hydroxymethyl part gives it extra grip for hydrogen bonding, opening doors for both physical manipulation and reactivity.

Technical Specifications & Labeling

Purity standards hover above 98%, flagged by rigid HPLC and NMR checks. Labels reflect both the IUPAC name and its shorter forms, often listing molecular weight and a unique CAS number. Some suppliers go further, listing batch-specific details like residual solvent content or trace metals down to parts per million. Storage suggestions stick close to norm for heterocyclic organics: cool, sealed, and out of the light. Shipping teams treat it with chemical-grade care, double-bagging and sometimes nitrogen-flushing for international journeys.

Preparation Method

Synthesizing 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole calls for a steady hand in stepwise reactions. Most methods begin with constructing the triazole ring, often through cyclization of a hydrazine precursor with a methylated nitrile or aldehyde. Once the core is set, a methyl group finds its place at N-1, typically through methylation using methyl iodide or dimethyl sulfate under carefully controlled conditions. Introducing the hydroxymethyl group at the 3-position often means a formylation followed by reduction, either via catalytic hydrogenation or with a milder reducing agent. These steps don’t just demand accuracy—they reward those who know how to monitor their intermediates by TLC and NMR, reducing impurities before they pose purification headaches.

Chemical Reactions & Modifications

The triazole ring resists hydrolysis and oxidation under standard lab conditions, explaining its favored status in drug development. Both its methyl and hydroxymethyl groups act as reactive handles. Chemists attach esters or ethers at the alcohol, or swap in new functional groups through oxidation or substitution, helping to create derivatives for further screening. Its ring nitrogen atoms invite acylation, alkylation, or cross-coupling attempts. Chemists value this diversity, as it unlocks routes to a range of analogs. Having run some of these reactions, I’ve noticed how robust this backbone remains, often tolerating non-polar solvents or temperature swings that knock other heterocycles out of play.

Synonyms & Product Names

Product listings offer a slew of synonyms—sometimes “1-Methyl-3-(hydroxymethyl)-1,2,4-triazole” or “3-(Hydroxymethyl)-1-methyltriazole.” Shortened forms like HM-MTZ appear in technical documents when space runs tight. Catalogues may group these under “triazole derivatives” or sometimes use custom codes based on internal tracking systems, so it pays to cross-check by CAS number before ordering. In my experience, confusion crops up mostly in translations or in poorly-indexed digital libraries.

Safety & Operational Standards

Standard protocols treat 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole as a mid-tier lab chemical—gloves, goggles, and standard ventilation. No evidence supports acute toxicity at standard handling levels, but skin and eye irritation can result from accidental splashes. Teams consult updated SDS sheets, which sketch out risks for chronic exposure and spell out first aid and spill procedures. Waste gets collected in organic solvents, not flushed, in line with EPA and occupational health directives. Custom installations, like closed-system reactors, cap off volatile escapes. Many labs have built-in checks—fume hoods and emergency decontamination stations—so the compound rarely presents surprises if handled with normal caution.

Application Area

This triazole sees steady use across medicinal chemistry, agrochemical trials, and materials development. Drug makers look for new antifungals, antivirals, or enzyme inhibitors, building the compound into larger structures to unlock or enhance activity. The triazole ring resists many metabolic breakdown paths, offering longer life in vivo for drug candidates. I’ve seen research projects aiming to tweak oral bioavailability by adjusting the hydroxymethyl or methyl positions. Agricultural chemists take a different route, tying it into agents meant to protect crops without running afoul of environmental safety rules. Polymers and coatings specialists tap into its chemical backbone as a crosslinker or functional modifier, chasing improved resistance or other engineering targets.

Research & Development

Research teams drive deeper and deeper into this compound’s utility. They run broad SAR studies, making subtle changes to the side chains and measuring how these shifts play out in biological assays. Universities develop greener synthesis, swapping out harsher reagents for safer, more sustainable options. Teams publish new pathways, using microwave or flow chemistry to speed up production and improve overall yields. In one project, we tried enzymatic modifications, hoping to open doors to bio-based processes, and found that certain fungal enzymes could selectively introduce new groups without wrecking the rest of the molecule. Data accumulates, with pharmacokinetic studies hinting at both promise and the occasional red flag related to metabolic intermediates.

Toxicity Research

Toxicology lags behind in open-access literature but continues to surface in private sector reports. So far, acute exposures at laboratory concentrations show low cytotoxicity in standard cell cultures, but longer-term, high-dose studies on rodents or larger animals remain limited or proprietary. Regulatory teams pull data from these studies to set safe exposure levels for workers and consumers. Predictive toxicology, combining in silico modeling and small-animal work, looks for the unwanted byproducts—especially those that could bind unwanted targets or persist in the body. Research so far suggests this compound breaks down more cleanly than some related triazoles, thanks in part to its hydroxymethyl group, but firm conclusions await longer-term data.

Future Prospects

Looking ahead, I see this compound playing a pivotal role in both existing and new markets. As more researchers embrace data-driven design, the building block’s accessibility will accelerate. Teams will expand into structure-activity-relationship campaigns, driving up the diversity of applications in drug discovery, agriculture, and functional materials. Sustainability pushes will likely influence both the synthetic methodology and end-use profiles, favoring routes that minimize waste and use benign reagents. Regulatory clarity will grow, pushed by demand for safer, greener alternatives in both pharma and crop protection. The combined momentum of these trends signals a period of growth for 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole—one fueled as much by curiosity as by clear industrial need, and made possible by the collective expertise gathered over decades of research.

Digging into the Science

3-(Hydroxymethyl)-1-methyl-1,2,4-triazole sounds technical, but what it represents comes with real-world stakes. This compound falls within the triazole family. Chemists gravitate towards triazoles for their stability and versatility. Tiny tweaks to their structure can mean the difference between stopping fungal threats in crops or helping pharmaceutical researchers shape the next breakthrough treatment. The hydroxymethyl and methyl groups attached to the triazole ring open up many chemical pathways, giving researchers a playground of possibilities.

Behind the Scenes in Pharmaceuticals

I’ve seen triazoles come up routinely when reading clinical studies and watching colleagues handle chemical libraries. They’re the backbone for many antifungal medications and also appear in drugs fighting cancer and bacterial infections. Triazole modifications, like attaching a hydroxymethyl group, improve a molecule’s water solubility and metabolic stability. It’s a small mystery that makes a big difference—helping drugs reach the right spot and stick around just long enough to do their job without harming the patient.

Based on research journals and pharma pipelines, 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole’s main pull lies as a building block. Medicinal chemists use it for constructing more complex molecules—many of which will never see a pharmacy shelf, but a few carry forward and become the next wave of medicine. Imagine the headache of drug resistance. Bacteria and fungi seem to outsmart last year’s medication with ease. The flexible core of triazoles gives scientists a fresh shot by swapping functional groups, adjusting structures, and blocking resistance pathways.

Crop Protection and the Chemical Industry

Walk through a field with a seasoned farmer, and the impact of crop disease quickly comes up. The loss is not just personal—it hits prices, supply chains, and even the food available at your grocery store. In that fight, triazole derivatives, underpinning fungicides, carry heavy weight. 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole shows up as a key intermediate when manufacturers produce new crop-protection chemicals. Tailoring these molecules helps them break through to fungi that sidestepped older fungicides.

Molecules like this also fuel work on corrosion inhibitors and specialty coatings. The metal pipes that keep factories humming or the multi-story buildings that line any city block last longer thanks to corrosion prevention. Certain triazoles form protective films on metal, and adding the right functional groups, like hydroxymethyl, tunes the interaction between metal and molecule, stretching equipment lifespans and keeping costs down across industries.

Moving Forward with Responsible Innovation

Working with chemicals demands good sense—safety, transparency, and respect for regulations. 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole joins a long line of intermediates whose potential only broadens with each year. The key is measuring progress by both the benefits and the risks. Lab workers know the routines: safety goggles, fume hoods, careful documentation. Regulations, whether from the FDA, EPA, or their global counterparts, hold everyone to the same high standards so that a promising compound in the lab becomes a safe, helpful solution in the real world.

The next steps call for collaborative research, strong data, and listening to those impacted—whether they’re researchers in the lab or families in rural communities. Chemicals like 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole may never be household names, but their fingerprints stretch across the fields we walk and the medicines we take.

Getting Down to Chemistry: Why Details Matter

Everywhere you look in science, details make the difference. Take 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole as an example. Its name alone hints at layers of information packed into a tidy compound. The molecular formula, C4H7N3O, maps out what’s inside—carbon, hydrogen, nitrogen, and oxygen. If you’re stepping into the world of medicine, agriculture, or materials, knowing exactly what you’re dealing with often starts at this simplest level.

Treating the Numbers Seriously: Calculating Molecular Weight

The molecular weight of this compound plays a big part in practical science. Take each element: carbon (C) weighs 12.01, hydrogen (H) 1.01, nitrogen (N) 14.01, and oxygen (O) 16.00, all measured in g/mol. Four carbons add up to 48.04. Seven hydrogens reach 7.07. Three nitrogens, a heavier piece of the puzzle, bring in 42.03, and a single oxygen gives 16. Putting it all together gets you 113.14 g/mol.

Plenty of scientists make a habit of checking these steps because small mistakes ripple out. Accurate numbers keep lab notebooks honest and experiments reproducible. I remember early days in the lab, double-checking calculations with a mentor who drove home that a tiny decimal slip-up could mean a failed experiment. Over time, that care with numbers became instinct, and most experienced chemists will tell you the same story.

Why Such Precision Makes a Real Difference

Lots of projects hang on the edge of these molecular details. Developing medicine or pesticides, you need a tight grasp on both structure and weight. This guarantees doses get measured correctly and that the compound behaves the way you expect when mixed with others. A researcher testing 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole as a lead in new antifungal drugs, for instance, would never risk a guess at the compound’s weight. If the numbers are off, the efficacy results swing and safety gets complicated.

History reminds us of chemistry disasters from miscalculations and sloppiness; the thalidomide tragedy from the 20th century stands as a solemn lesson about getting every calculation right. Checking formulas and weights shows respect for both science and people. Students and researchers ought to stick to these lessons as their careers grow.

Big Picture: From the Lab Bench to the World

Precision with chemical formulas goes past academic rigor. It matters to product safety agencies, pharmaceutical companies, and regulatory boards. Chemicals shipped across borders need exact documentation to pass customs, hit compliance standards, and avoid legal headaches. For me, paperwork has never been the appealing side of science, but I’ve seen regulatory officers stop a project in its tracks because a data sheet didn’t match the actual formula. Those are expensive mistakes to fix and totally preventable.

How Better Practice Starts Early

Building good habits in the lab starts with accurate work like double-checking molecular formulas and weights. This forms the backbone of trustworthy results in everything from cleaning products to life-saving drugs. Young scientists who commit to getting these basics right set themselves—and their teams—on the road to solid, respected work. In every lab I’ve worked, the unglamorous job of reciting formulas and reviewing calculations always separates attentive professionals from careless shortcuts.

Why Storage Details Matter

Storing chemicals with care protects people, property, and the chemical itself. 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole, like many specialized compounds, requires more attention than tossing it on a shelf. A misplaced drum or poorly sealed bottle can lead to product loss, accidents, or headaches nobody wants. In my years around research labs and chemistry prep rooms, the best approach leaned on being practical and consistent, not just checking off rules in a binder.

Choose the Right Location

This compound has a triazole backbone, so keeping it away from direct sunlight and extreme heat is a good move. Sunlight and fluctuating temperatures can nudge certain chemicals into breaking down, even if their structure looks tough on paper. Picking a dry, cool spot—think a well-ventilated storeroom or a chemical refrigerator—protects both the integrity of the compound and the safety of those working nearby. In real-life labs, a high-up shelf near a drafty window proved far riskier than a locked, gently chilled cabinet.

Avoiding Moisture and Contamination

Water vapor from humid air, or even small spills nearby, introduces risk. A tight-sealing bottle or drum vastly outperforms a half-shut jar. I’ve watched even seasoned chemists get burned by a simple lid left loose, ending up with clumpy, weird-smelling leftovers. Silica gel packets help mop up stray moisture—throwing a pack or two into the storage box or cabinet keeps things drier, and that matters with sensitive lab materials like this one.

Keep It Contained and Labeled

Clear, bold labeling on the container prevents confusion and protects against dangerous mix-ups. I've seen more than one frantic lunch break where someone realized they'd mixed up reagent bottles because the sticker had faded or fallen off. Chemical storage isn’t about fancy signs; a heavy black marker and durable label go a long way. Setting aside one shelf for similar triazoles or related small molecules, and separating them from acids or oxidizers, minimizes unwanted reactions or accidents.

Protecting People and the Space

Storing this compound in shatter-proof bottles or plastic containers prevents messy cleanups and cuts the risk of broken glass. Using trays underneath chemical stocks adds a second line of defense if a bottle leaks. Personal stories from older colleagues taught me the simple habit of never stacking chemicals high up or behind bulky boxes. Easy reach means less risk of dropping or knocking something over.

Monitor Inventory Regularly

Checking expiration dates and chemical condition keeps surprises in check. Each semester, I’d help take stock and throw away anything discolored, caked, or expired. That habit helps prevent unexpected reactions or lost research samples.

Training and Safety Awareness

No system works without people understanding why it matters. Labs and workshops where everyone gets the basics about chemical storage see fewer accidents. A five-minute run-through on the difference between a dry room and an old closet beats any long, dusty safety manual. By keeping practices clear and practical, it becomes second nature to treat chemicals like 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole with respect and care.

Why Safety Information Matters

Working with chemicals creates risks if you don’t pay attention to the details. Even chemicals with unfamiliar names like 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole turn up in different industries, whether in lab research or specialty manufacturing. When you’re around chemicals, questions about toxicity aren’t just academic—they’re about real safety for the people using them or living nearby.

What We Know About This Compound

3-(Hydroxymethyl)-1-methyl-1,2,4-triazole isn’t a household name, but it gets use in some pharmaceutical and agricultural applications. Finding straightforward, detailed toxicology data isn’t easy. Chemical suppliers often provide safety data sheets (SDS), and some list mild irritation risks when the product contacts skin or eyes. Official large-scale hazard designations don’t exist yet, making it trickier for users to be certain how risky it is in the real world.

Some triazole compounds used in fungicides or drugs show a range of effects on animals and the environment. Mild triazoles sometimes break down in the environment, but others hang around and cause more trouble. Using one of these compounds without a clear breakdown of who it harms, when, and how, raises serious questions about how much we know—or don’t know—about long-term effects.

Looking For Clues: Lab and Animal Data

Academic articles and chemical registries list data points from animal tests, though usually at much higher doses than people would see in a typical lab. Some versions of methyl triazole have shown low levels of oral toxicity in rodents. Skin and eye exposure can cause minor irritation, which lines up with what you see in white powders and granules. What’s missing here is long-term data—will someone who works with this stuff every day develop respiratory issues, or see allergic reactions after chronic contact? We don’t always get a straight answer.

I’ve seen risk assumptions made on far less, and it worried me. If you’re a chemist, you learn not to take these gaps lightly. Lab safety depends on acting as if a chemical could cause more trouble than the bare paperwork says, at least until stronger evidence comes along. For now, common sense calls for gloves, goggles, and solid ventilation just to be on the safe side.

A Call for Transparency and Testing

Most public databases and regulatory bodies haven’t flagged this compound as carcinogenic or as an environmental threat. That shouldn’t mean we treat it like baking soda. Lack of data isn’t safety. Chemical companies could invest in broader animal studies, long-term workplace exposure reports, and better environmental fate modeling. Regulatory groups should urge sharing of raw test results—not just summaries. It helps keep users from getting lulled into a false sense of security.

Until those results appear, responsibility falls on everyone from suppliers to employers to label the risks clearly and push for more research. I’d rather see an abundance of good data, even if it reveals risk, than leave people guessing about a chemical’s true impact—because “unknown” doesn’t mean harmless.

The Basics Behind Its Solubility

There’s no shortcut when figuring out how easily a compound will dissolve — you have to dig into the structure. 3-(Hydroxymethyl)-1-methyl-1,2,4-triazole brings a mix of features to the table. The triazole ring is packed with nitrogen atoms, which helps the molecule interact with water. Then there’s that hydroxymethyl group tagging along; it doesn’t just sit there for show. Instead, it opens up more places for hydrogen bonding with water molecules. The methyl group on this one looks simple, but it nudges the rest of the structure, shaping how tightly everything holds together.

Solvent Interactions and Real-World Outcomes

Drop this compound in water, and things happen quick. Its polar nature makes it about as eager to mix as you could ask for in a lab that works with drug discovery or agrochemical design. I’ve seen researchers lean on compounds like this during early screening — nothing slows down a project quite like gunky, partially dissolved material on the bottom of a flask. When you spot a solid disappearing into solution without a struggle, it saves time and keeps results clean. Lab groups testing new antifungal or antibacterial leads often want molecules that dissolve well, since poor solubility clouds answers and makes animal dosing fiddly.

Some compounds with a triazole ring can resist dissolving; they get drawn to organic solvents instead. This one breaks away from that mold thanks to the hydroxymethyl group. A quick dive into solubility data shows high milligram-per-milliliter levels — that makes formulation and purification more flexible. You avoid adding harsh solvents or relying on heat, which preserves sensitive molecules. Searching through databases, this triazole typically lands in the “freely soluble” to “very soluble” category in water, ethanol, and methanol. That means powder goes in and vanishes quick, with no help needed.

Importance for Research and Application

Having reliable water solubility is more than a convenience. For chemists developing small molecules, a structure with solid solubility can turn an impossible formulation into a practical treatment. Hospitals and clinics rarely have patience for tricky reconstitution steps during emergencies. Global supply chains can get disrupted, and unpredictable weather or transport can force quick adaptation of protocols. Water-soluble compounds lower barriers for frontline workers and reduce waste since far less ends up tossed out because of failed mixes or mismatched solvents.

Addressing Limitations and Seeking More Data

The flip side: what if too much solubility isn’t always your friend? Some pharmaceutical teams want a molecule that sticks around a bit, spreads through fatty tissue, or chases a slow-release profile. For those groups, a triazole that dissolves before you blink could speed up clearance and mean frequent dosing. Animal studies and preclinical trials highlight these challenges every year. You can shift gears — embed the compound in a matrix, explore salt forms, or try prodrug approaches — but each step brings new regulatory hurdles.

Those with a chemistry background know experience teaches more than theory; trial and error with batch work and actual formulation drives deeper understanding than charts alone. Solubility keeps showing up at every stage, from first synthesis to clinical production. Getting the numbers right, backed with hands-on data and input from practical labs, sets real-world possibilities for something that otherwise remains an obscure piece of IUPAC jargon.

Potential Solutions for Handling Solubility Mismatches

No one answer solves every formulation puzzle. Sometimes, you pair water-soluble molecules with stabilizers that cut down degradation. Other teams blend with excipients that buffer pH swings. Research can dig deep into computational modeling, but the best companies back up predictions with bench results before wide release. Open access to published solubility findings, checking standards, full datasets, and transparent reporting — that’s the path forward to avoid reinventing the wheel and to cut down unnecessary setbacks in both basic and applied science settings.