3-Fluorophenol: A Ground-Level Look at a Specialized Chemical

Historical Development

Chemists started looking into 3-Fluorophenol several decades back, once advances in fluorination opened doors for more than just Teflon and coolants. The drive mainly came from medicinal chemistry, searching for tweaks to phenol structures that would give new behaviors in drug candidates. Adding fluorine at the meta-position on phenol shakes up both electron distribution and metabolic pathways. Back in the eighties, most reactions used elemental fluorine and toxic intermediates. Research labs reported hazardous conditions and low yields. After new methods for selective fluorination arrived—including Balz-Schiemann and direct electrophilic substitution—making 3-Fluorophenol became both safer and more cost-efficient for larger production runs. These days, companies across North America, Europe, and Asia synthesize it for both research and manufacturing, although the methods keep evolving as green chemistry principles shape the future.

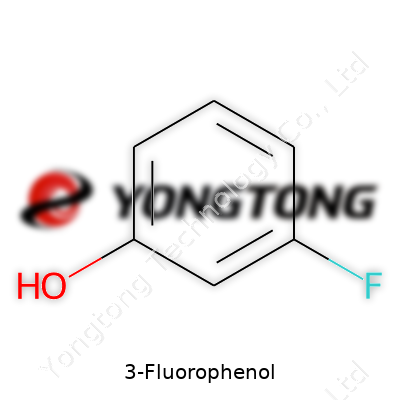

Product Overview

3-Fluorophenol offers a particular twist to phenolic compounds by swapping hydrogen for fluorine at the third position on the aromatic ring. On a shelf, it comes either as an oily, colorless to pale yellow liquid or a low-melting crystalline solid, depending on the storage temperature. Laboratories prize 3-Fluorophenol for its niche as an intermediate in pharmaceutical synthesis, as well as for making agrochemicals and specialty materials. Its niche utility hangs on the fact that it brings the high electronegativity and metabolic resistance of fluorine into otherwise classic phenol chemistry. That makes it useful in preparing molecules that demand both reactivity and resilience under harsh metabolic or environmental conditions.

Physical & Chemical Properties

3-Fluorophenol has a molecular formula of C6H5FO and weighs in around 112.10 g/mol. Its melting point hovers near 30 °C, so it drifts between oil and crystal depending on local conditions. The boiling point pushes up to about 178-180 °C under normal pressure. The molecule dissolves readily in common polar organic solvents like ethanol, acetone, and diethyl ether, while showing moderate solubility in water—less than unfluorinated phenol, mostly due to fluorine’s hydrophobic influence. Smelling it even at low concentrations is unpleasant; the volatile phenolic character comes through sharply. Its electron-deficient aromatic ring resists certain oxidative reactions that plain phenol struggles with, and its reactivity makes it a prime scaffold for downstream derivatization, from Suzuki couplings to etherification.

Technical Specifications & Labeling

Manufacturers list typical purity above 98%, with water content below 0.5%. Impurity profiles have to be tightly controlled, since downstream uses in pharmaceuticals or materials science demand it. Drums or bottles arrive labeled with UN numbers for hazardous goods, CAS Registry Number 372-20-3, hazard pictograms for skin and respiratory irritation, and storage suggestions that keep temperature swings and moisture out. Detailed safety data sheets ride along, outlining compatibility with plastics, glass, and metal. For analytical purposes, high-performance liquid chromatography (HPLC) and gas chromatography-mass spectrometry (GC-MS) check purity, since even trace residual acid or halogenated contaminants disrupt further reactions.

Preparation Method

Laboratories and factories most often reach for selective fluorination starting with m-aminophenol or meta-nitrophenol derivatives. Diazotization of m-aminophenol forms a diazonium salt, which then treats with fluoroboric acid in the Balz-Schiemann process, yielding the target compound after thermal decomposition. Some newer methods swap out harsh conditions for milder electrophilic fluorinating reagents like Selectfluor, paired with transition-metal catalysts to drive regioselective substitution on phenol rings. Every route brings trade-offs—old school offers cheap starting materials but more waste, while updated techniques demand pricey reagents yet grant cleaner yields and easier purification. In industry, the choice often boils down to balancing raw material price, waste disposal costs, and regulatory compliance for environmental impact.

Chemical Reactions & Modifications

The electron-withdrawing power of fluorine at the meta-position gives 3-Fluorophenol a unique spot on the reactivity map. Nucleophilic aromatic substitution, typically slow for phenols, becomes more feasible. Researchers use the compound as a handle for introducing other functional groups through palladium-catalyzed cross-coupling reactions—think Suzuki, Buchwald-Hartwig, or Ullmann couplings. Benzylation and alkylation on the oxygen work smoothly under both acidic and basic conditions. Nitration and halogenation at other ring positions run more selectively compared to unfluorinated phenol. For pharmaceutical intermediates, its resilience under bio-transformative conditions lets researchers slip fluorine atoms into drug molecules without risking rapid breakdown; this slows down metabolism and changes how finished drugs act in the body.

Synonyms & Product Names

The lab crowd knows this compound as 3-fluorophenol, but catalogs also list it under meta-fluorophenol and m-fluorophenol. CAS number 372-20-3 tags it internationally. Academic articles toss out numbers like NSC 25799 or even MFPh for shorthand. Purveyors of fine chemicals use commercial product codes, but the core nomenclature sticks to the IUPAC convention to prevent confusion. In drug and patent literature, it pops up under precursor identifiers linked to candidate molecules for cancer, CNS, or anti-infective pipelines.

Safety & Operational Standards

Working with 3-Fluorophenol requires eye protection, gloves, and chemical-resistant lab coats because phenols attack skin, and fluorination can worsen irritation or sensitization. Inhalation of vapor brings a sore throat, coughing, or worse effects in unventilated spaces. Safety data sheets mandate usage in fume hoods, proper waste collection, and no mixing with strong oxidizers. Storage means cool, dry shelves in compatible containers. Routine monitoring for leaks or spills protects both people and equipment, since any phenolic spill corrodes surfaces over time. Transport remains regulated under UN 2811; labeling and documentation line up with both local and international standards, and disposal follows procedures for halogenated organics, not just regular waste streams. Regulatory oversight keeps accidents rare, but every technician learns firsthand that complacency with hazardous chemicals only brings trouble.

Application Area

Research teams grab 3-Fluorophenol as a building block for diverse pharmaceutical candidates, shifting drug metabolism or activity profiles by a single atom. The same shift makes it valuable in developing novel insecticides or fungicides, where metabolic stability fights breakdown in the field. In materials science, incorporating it into polymers or specialty coatings produces surfaces with altered wettability, sticking power, or resistance to chemical attack. Analytical applications crop up in reference standards or in mapping metabolic products of fluorinated drugs, where a well-characterized source simplifies quality control and regulatory reporting. Chemists see it as a springboard; every added functional group moves the project closer to a finished industrial or medical product.

Research & Development

The mad rush in R&D focuses on two fronts: making synthesis greener, and developing new reactions for downstream derivatization. Researchers aim to avoid hazardous fluorinating agents, switching to mild, selective reagents that cut environmental impact. Metal catalysis and electrochemistry receive attention, shrinking waste and improving yields. On the application side, drug discovery teams use 3-Fluorophenol to design candidates for oncology or CNS disorders, since fluorine tweaks interaction with metabolic enzymes. Big pharmaceutical companies run high-throughput screens to see which analogs give desirable profiles, while specialty manufacturers look for new surfactants and specialty monomers from the core skeleton. University and corporate labs collaborate, sharing pilot data and tweaking processes for both academic papers and scalable supply chains. Patents keep piling up on both new reaction conditions and application claims; the global interest shows no sign of slowing.

Toxicity Research

Toxicological data shows that 3-Fluorophenol irritates eyes, skin, and respiratory tracts at low exposure. Animal studies point to acute toxicity by ingestion or inhalation at concentrations similar to or slightly higher than phenol, with evidence of central nervous system depression and effects on organ function in higher doses. Chronic exposure remains less studied, but the presence of both a hydroxyl and a fluorine group raises extra flags for metabolic byproducts. Environmental fate studies find that the molecule resists rapid breakdown, lingering in water or soils without significant photodegradation. Regulatory agencies advise strict control measures both at the workplace and downstream waste treatment steps. Risk assessment balances potential human health impacts against the benefits in drug and crop protection development, and ongoing monitoring supports further refinements to operational standards.

Future Prospects

Interest in 3-Fluorophenol keeps growing, powered by demand for new drugs, more durable agrochemical products, and smart materials. Researchers look for faster, greener synthesis—electrosynthesis, photochemistry, and biocatalysis all get tested, hoping to avoid dangerous reagents and waste. Pharmaceutical companies value every new way to tweak molecular properties; replacing hydrogen with fluorine remains a key strategy for changing drug lifetimes or activity. Countries with strong chemical manufacturing sectors invest in scaling up both old-school batch methods and continuous-flow processes. The detailed study of toxicity and environmental impact keeps guiding which applications move forward and which stall out, but the basic fact remains: as chemistry unlocks new transformations on 3-Fluorophenol, its importance in research and industry looks set to keep expanding for years ahead.

What Sets 3-Fluorophenol Apart

Anyone who has spent time around chemical research labs knows that even small tweaks to aromatic compounds like phenol can open doors to all kinds of possibilities. 3-Fluorophenol, as the name hints, carries a fluorine atom attached to the third position of a phenol ring. This change sounds minor, but it makes a difference that both researchers and manufacturers appreciate. My background in academic chemistry showed me just how much value a single atom switch brings. The presence of fluorine changes the molecule’s reactivity and physical properties, and those differences turn out to be useful for more than just textbooks.

What’s It Used For in Practice?

In chemical manufacturing, 3-Fluorophenol is more than a curiosity. Pharmaceutical researchers often see it as a foundational building block. It plays a role as a starting material or intermediate for synthesizing more complex drug candidates. Drug developers chase specific effects or stability in new medicines, and swapping in a fluorinated piece can shift the performance of a molecule. Fluorine atoms help medicinal compounds avoid rapid breakdown in the body, which means the end medication can stick around longer and do its job better. Big players in the pharma sector—Pfizer, Novartis among others—regularly explore fluorinated intermediates while working on everything from antivirals to cancer drugs.

My own time in a process chemistry group made it clear that 3-Fluorophenol stands out when looking for ways to adjust bioactivity without a complete redesign of a compound. Introducing a single fluorine on an aromatic ring disrupts metabolic pathways in the liver, influencing how drugs act and how long they last in the system. Plenty of early-stage synthesis projects use it for exactly these reasons.

Beyond Drug Research

It doesn’t stop at medicines. Agrochemical development frequently depends on compounds in the same family as 3-Fluorophenol. Pesticide and herbicide research makes use of fluorinated intermediates because they help tailor effectiveness and increase durability outdoors. Chemicals that resist quick breakdown matter in modern agriculture, helping reduce reapplication rates and costs for farmers.

A number of manufacturers, especially in specialty chemical sectors, use 3-Fluorophenol to give performance materials new characteristics. Dyes, liquid crystals, and certain polymer additives call for customized building blocks to improve stability or light-fastness. Fluorine’s inclusion sharpens those properties in final consumer products such as electronic screens or specialty coatings.

Safety and Stewardship Matter

Handling compounds like 3-Fluorophenol, I learned respect for safety data sheets and clear labeling. Fluorinated aromatics come with issues: possible toxicity, the need for proper ventilation, and rigorous waste management. Responsible labs make sure that personal protective equipment isn’t an afterthought, and that procedures for spills or disposal don’t get ignored. Regulatory agencies such as the EPA in the U.S. and ECHA in Europe remind us that specialty intermediates should never leave the lab or plant without mindful tracking and controls.

Openness in chemical sourcing and documented traceability help maintain responsible use, especially as 3-Fluorophenol often gets shipped on a global scale. I believe companies should be transparent about supply chains, not only for compliance but to protect worker health and environmental safety.

The Path Forward

There’s no one-size-fits-all answer for balancing innovation and responsibility. Most chemists I meet act with care—and I’d like to see more public interest in how industrial chemicals get used, not just in seeing the finished medicines or crops. Investing in green chemistry approaches, proper training, and updated safety standards will allow industries to benefit from building blocks like 3-Fluorophenol without increasing risk.

Breaking Down 3-Fluorophenol

Walk into any chemical lab, and you’ll find more than a few bottles with complicated names. Still, one name that stands out in organic chemistry is 3-Fluorophenol. This compound catches attention because it blends the well-known phenol structure with a fluorine atom, right at the third position. For anyone who enjoyed working with aromatic compounds in the lab, picking apart names like this comes as second nature. But for folks outside those circles, the logic can seem almost like a foreign language.

The chemical formula of 3-Fluorophenol is C6H5FO. That single line of letters and numbers tells chemists a whole lot. Here’s how it breaks down: six carbons form a ring, five hydrogens kick in, a lonely oxygen makes up the distinctive hydroxyl group, and fluorine lands on the third carbon, counting from the hydroxyl group. This matters in ways few people see because structure tells you how a molecule is going to behave, how it’ll react, and what value it might bring.

Why 3-Fluorophenol Gets Attention

Organic chemists lean on compounds like 3-Fluorophenol as building blocks. I’ve worked in research labs where swapping out just one hydrogen for a fluorine made all the difference in synthesis. Fluorinated aromatics change chemical reactivity, resist breakdown, and often carry biological activity that non-fluorinated cousins just can't match. For those working on new materials or pharmaceuticals, that single “F” on the ring sometimes offers a breakthrough: drugs last longer in the body, or materials become more durable and heat-resistant.

Examples stack up quickly. Adding a fluorine to a phenol ring shifts acidity, pushes electrons around, and changes how the molecule attaches to other atoms. That means you can use 3-Fluorophenol as a starting point for all sorts of custom molecules. Everything from new antibiotics to crop-protection agents might begin with tiny tweaks like the sort used with this compound.

Health, Safety, and Real World Impact

Anyone who’s ever worked with phenols understands their hazards—skin and eye irritation, a bitter smell that signals caution. Toss in fluorine, and you up the ante. Safety data for 3-Fluorophenol calls for gloves and goggles. This isn’t just bureaucracy; I still remember a teammate learning that lesson the painful way in college, and not forgetting afterward. Chemical formula alone doesn’t tell you the whole story, but knowing what you’re working with offers the first layer of protection.

Having standards helps the world avoid dangerous mix-ups. Regulatory agencies use formulas like C6H5FO to track production, transport, and disposal. Precise identification supports everything from customs paperwork to pollution control. It’s easy to overlook until a small spill causes a big scare—then everyone scrambles for clear labeling and effective cleanup.

Next Steps: Responsible Use and Research

If industry continues to depend on fluorinated compounds, researchers need to keep asking hard questions about long-term health and environmental risks. Some fluorinated organics turn up in groundwater or resist breaking down in nature. Teams worldwide are pushing to develop alternatives, safer practices, and better disposal methods. Chemical formulas stay the same, but how we handle those molecules can't stay stuck in the past.

For teachers and students, taking the time to unpack what C6H5FO means pays off. Clear thinking about structure leads to safer labs, sharper research, and breakthroughs that improve daily life. Each formula on the chalkboard—3-Fluorophenol or any other—holds more than just numbers and letters; it opens a door to opportunity or risk, depending on how wisely it gets handled.

What 3-Fluorophenol Really Means for Lab Safety

People working in chemistry labs often see 3-Fluorophenol show up in reagent lists. Some folks may glance at the bottle and move on. Others might pause, wondering what kind of risk this chemical brings into the room. Over two decades bouncing between small research outfits and industrial plants, I’ve found that dismissing any fluorinated compound’s risk invites problems. Safety data tells part of the story, but lived experience fills in the rest.

A Closer Look at Toxicity

3-Fluorophenol falls under the umbrella of halogenated phenols. These don’t often make it into household cleaners, and that’s for good reason. Toxicology reports show that 3-Fluorophenol can irritate skin, eyes, and respiratory systems shortly after exposure. Coughing or a burning sensation after accidental inhalation pops up in safety logs. One crowded undergraduate lab I worked with had a spill go unnoticed for a whole half-hour—complaints followed quickly, from sore throats to watery eyes. This kind of chemical doesn't give people much warning before symptoms hit.

Digging into animal studies and safety papers, the oral LD50 for rats sits between 190 and 400 mg/kg, pegging it as acutely toxic. If humans absorb it through the skin, the risk level sits a bit lower, but routine exposure remains a concern. Gloves and eye protection do more than follow some bureaucratic checklist. They actually protect workers from cumulative, low-level damage.

Why the Hazards Go Beyond Label Warnings

My own experiences match the broader scientific consensus—chemicals like 3-Fluorophenol can disrupt natural cellular processes. Fluorinated aromatics, by their structure, can resist breakdown inside both lab equipment and the human body. So handling 3-Fluorophenol means considering not just single-incident risk, but what chronic exposure does over time. Nobody likes chemical smells lingering in coat sleeves for weeks, but that’s nothing compared to what long-term accumulation can do to the liver or kidneys.

As someone who’s seen senior researchers develop unexplained health issues, I find it irresponsible to chase short-term productivity by ignoring safety advice. At one place, routine solvent disposal practices led to chemical residues building up on shared equipment. A few people developed stubborn skin rashes, only clearing up when protocols tightened. Many fluorinated compounds don’t show immediate and dramatic effects. Yet subtle symptoms tell their story sooner than people expect.

Reducing the Risk: Practical Steps in Labs and Workplaces

Most modern labs have good ventilation and training on hand. That’s only half the battle. Harm comes from relaxed attitudes and shortcut habits—mixing up waste bottles, skipping protective gear, or shrugging off small spills. Procedures mean little unless people buy into their importance. Spreading awareness about long-term organ toxicity pays off more than handing out safety sheets.

For anybody working with 3-Fluorophenol, wearing gloves and proper goggles takes priority. Installing local exhaust works well in keeping vapors low. Sharply separating waste streams and regular cleaning stops cross-contamination. Shared workstations magnify risk, especially if people assume previous users cleaned up. Transparency—flagging incidents or near misses—keeps risk from snowballing.

Looking Forward

Scientists keep pushing for greener alternatives, but some tasks still require these hard-to-handle compounds. My advice draws from years of seeing preventable injuries and near-misses. Stop treating 3-Fluorophenol like just another flask-filler. Attention to handling doesn’t slow research; it keeps doors open for future work and healthy careers.

Why Storage Matters for 3-Fluorophenol

Anyone who’s handled chemicals in a lab knows most substances come with their own quirks. 3-Fluorophenol demands a little respect—one small misstep and you might end up with a bigger issue than expected. With its sharp smell and potential hazards, safe storage isn't just about following rules; it’s about protecting people, equipment, and research. Overlooking these basics has caused headaches in more than a few labs, and in some cases, property losses or exposure incidents. Proper storage prevents both immediate accidents and long-term degradation of the chemical.

Controlling the Environment

Keep moisture out. 3-Fluorophenol breaks down if it mingles with water or humid air, losing chemical purity and possibly forming impurities nobody wants in their experiment. I learned quickly during my early research days that skipping the dry, cool cabinet led to batches ruined in a single week. Stash it in a tightly sealed amber glass bottle—give air and water as little room as possible to get inside. Because sunlight nudges lots of phenolic compounds toward unwanted reactions, choose storage in a dark spot or behind UV-blocking glass. Compromising quality through careless placement sets back work and wastes money.

Isolation Is Part of the Plan

3-Fluorophenol brings some volatility to the table, so avoid clustering it with oxidizers, acids, or even bases. Combining the wrong neighbors has started fires and toxic incidents in more than a handful of university storerooms. I’ve seen shelves labeled and organized by chemical compatibility—simple step, major risk reduction. This chemical’s tendency to react calls for its own spot, never on a shelf crammed with random bottles.

Temperature and Ventilation

A temperature-stable environment makes all the difference. Store it in a cool spot (room temp or a little below, never freezing). Heat stirs up vapors—these can escape with each bottle opening, posing both health risks and contamination issues. Stuffiness helps no one; good ventilation, not a gusty breeze, helps sweep away wayward fumes quietly before they can collect. Sitting a bottle in direct line with an air conditioner or leaving it near a heat vent shortens the lifespan and drives up risk. Nobody benefited from swapping efficiency for carelessness.

Security and Labeling

Lots of chemical mishaps start with poor tracking or casual storage habits. Wide-open shelves or shared benches never cut it, especially for something as reactive as 3-Fluorophenol. Install physical barriers or use dedicated cabinets with locks. Accurate, up-to-date labels matter—a scribbled name and date spare everyone from guessing games. The right hazard symbols and safety guidance reduce the chance of casual exposure or mix-ups. In my lab, we ran through drills and audits twice a year, catching small problems before they had a chance to grow.

Planning for Cleanup

Spills and leaks still surprise even the cautious. Always keep spill kits, nitrile gloves, and eye protection close to storage areas. It’s easy to think accidents only happen to the careless, but anyone moving in a hurry might slip up. OSHA and the CDC recommend kits featuring absorbents, neutralizers, and heavy-duty bags for quick safe disposal. Training people—especially the new ones—pays off. Dealing with an incident swiftly means everyone gets home in one piece, and the project keeps rolling without major delay.

Digging Into the Details

Chemistry tends to force precision on anyone interested in it, whether you are working with dyes, pharmaceuticals, or agrochemicals. 3-Fluorophenol catches a lot of attention, especially from researchers who need clear identification and consistent results. If you scan a bottle labeled “3-Fluorophenol,” you’ll often see a number that feels more like a fingerprint than a label: CAS 372-20-3. This is the unique identifier set by the Chemical Abstracts Service, which helps scientists around the world know they're talking about the same compound without any confusion.

Why Purity Levels Aren’t Just a Statistic

There’s more to this substance than its name or CAS number. The purity, usually reported at 98% or higher in most catalogs from trusted chemical suppliers, tells you a lot about what you can expect during an experiment. Labs rely on this number because a batch with lots of contaminants turns predictable chemistry into a guessing game. Impurities can skew high-performance liquid chromatography results, throw off yields in synthesis, and even change the color of reactions. Having spent hours troubleshooting chemical reactions, I’ve learned that trying to save money by using lower-purity material almost never works out in the end.

That percentage isn’t about perfectionism—it’s about avoiding side products that sneak in during manufacturing or storage. Industry standards push for 98% as a basic starting point, with some pharmaceutical-grade processes reaching for 99% or higher. Analytical testing backs these claims, usually through methods like NMR, GC-MS, or HPLC.

Real-World Applications Count on Consistency

Bench chemists and production managers alike link purity to final result and safety. For example, if a researcher uses 3-Fluorophenol to introduce a fluorine atom into a drug molecule, they’ll want the fewest number of unknowns in the system. Even trace residues of other phenol derivatives can wreck a whole batch or throw off toxicology testing. Regulatory agencies such as the FDA care about traceability; having a specific CAS number matched to high-purity material makes it much easier to document and defend your process.

This reliability isn’t just an academic hang-up. Pharmaceutical companies check every bottle and batch at receiving docks. Chemical distributors provide certificates of analysis showing batch-by-batch purity, often including methods and numerical results. This information becomes part of the regulatory file for any drug or crop protection product.

Improving Quality Across the Board

If purity slips, so do trust and success rates. One simple move is demanding certificates of analysis with every batch. Partnering with suppliers with ISO-certified labs and transparent quality control processes reduces surprises. On the manufacturing side, improving synthesis and purification—think advanced crystallization or better distillation—drives purity up and price down over time.

People who use 3-Fluorophenol at the bench or on a pilot scale know that shortcuts in raw material sourcing often saddle downstream teams with troubleshooting and wasted effort. Clear labeling, open communication with suppliers about intended use, and willingness to reject off-spec material all help to keep chemistry productive and honest.

Key Takeaway

3-Fluorophenol, defined with CAS 372-20-3 and often supplied at 98% or better purity, remains a great example of why attention to chemical details matters. Those who rely on it—from students running experiments to engineers scaling up processes—benefit from demanding tighter standards and sticking to them.