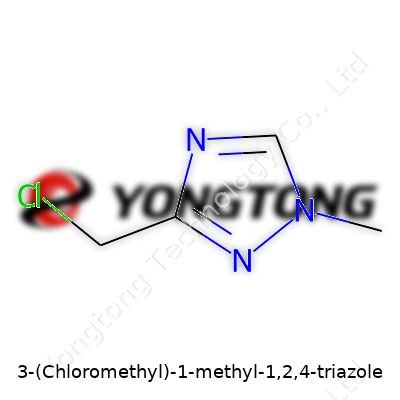

3-(Chloromethyl)-1-methyl-1,2,4-triazole: Yesterday, Today, and Tomorrow

Historical Development

Chemists in the second half of the twentieth century helped shape the family of triazoles as we know them. The quest to discover new heterocyclic compounds was strong, grounded in curiosity and industrial demands. The methylation of 1,2,4-triazole rings initially led to practical compounds that could insert themselves into crop protection work. By the 1970s, research in medicinal chemistry highlighted the importance of triazole derivatives, lighting the spark that drew industrial research toward 3-(chloromethyl)-1-methyl-1,2,4-triazole. This compound bridged the gap between abstract molecular diagrams and hands-on production of fungicides, herbicides, and other agrochemical applications. The process didn’t just expand the inventory of bench chemists—people started tracking the safety, reactivity, and unique properties that make this chloromethyl variant a versatile tool.

Product Overview

3-(Chloromethyl)-1-methyl-1,2,4-triazole offers a manageable entry point for modifications that create value in specialized synthesis. Whether in small lab batches or industrial flow, chemists value its manageable reactivity. This compound brings both confidence and flexibility to the bench, thanks to its single chlorine atom and the point of methyl substitution—two features that decide how the triazole can react or bind with other chemical components. Research teams across pharmaceuticals, crops sciences, and materials see a platform for difference-making derivatives, while suppliers can provide a clear product with robust documentation for anyone needing quality and trace.

Physical & Chemical Properties

The pale solid typically melts between 66 and 70°C. At room temperature, it holds its form and doesn't absorb much moisture, making storage less of a hassle when compared to more hygroscopic triazoles. Chemists notice its density around 1.3 g/cm³ and a molecular weight in the region of 134.56 g/mol. Since the chloromethyl group activates certain reactions, it’s reactive but stable enough for typical storage. The compound dissolves efficiently in acetone, dichloromethane, and ethanol, which matters for every day mixing and application. Its stability at mild pH and moderate heat helps avoid headaches during scale-up or storage.

Technical Specifications & Labeling

Manufacturers list purity levels up to 98% as a sign of confidence in their synthesis routes. People watch for allowed impurities—mainly related starting materials and byproducts—kept within the 0.5-2.0% range. Packaging firms use amber glass bottles ranging from 10g up to multi-kg containers, sealed tightly due to the irritant nature of the chloromethyl group. Labeling always highlights the GHS (Globally Harmonized System) hazard pictogram—an exclamation mark prompting caution. SDS (Safety Data Sheets) go along with each shipment, mapping out storage, handling, PPE, and disposal advice in straightforward language. Researchers know the lot number on a bottle connects back to full traceability, a key point for anyone working in regulated fields like pharmaceuticals or crop protection.

Preparation Method

One of the most common routes relies on the reaction between 1-methyl-1,2,4-triazole and a chloromethylating agent such as chloromethyl methyl ether or formaldehyde with hydrochloric acid. The exothermic nature and toxic fumes make this more than a class demonstration. Chemists rely on reflux setups with tight seals and local ventilation. Yields tend to hover between 60% and 80%, since the reaction typically favors the mono-chloromethyl substitution over other products. Work-ups include extractions with organic solvents, washes to neutralize acids, and recrystallization or chromatographic steps to ensure high purity.

Chemical Reactions & Modifications

The chloromethyl group turns this triazole into a versatile reagent. The chlorine offers a solid leaving group, which opens the door for nucleophilic substitution reactions with amines, thiols, and phenols. Medicinal chemists appreciate the flexibility—they can attach bulky drug-like substituents, test antifungal activities, or modify the compound for improved pharmacokinetics. For agricultural researchers, the same principle enables the design of new fungicidal scaffolds. Experienced synthetic chemists may oxidize the triazole or even perform cross-coupling reactions, stretching the application further into fine chemicals. Not everything goes as planned, of course; a solid understanding of reaction kinetics and the possibility of competitive elimination reactions keeps bench work interesting.

Synonyms & Product Names

People working in the lab or buying chemicals will hear other choices of name: 3-(chloromethyl)-1-methyl-1,2,4-triazole goes by 1-methyl-1H-1,2,4-triazole-3-ylmethyl chloride in many catalogs. Some list it as methyl triazol-3-ylmethyl chloride. The CAS number (115736-76-6) connects suppliers and regulatory bodies, giving everyone a clear point for documentation and cross-referencing. Mix-ups can happen among trade names, so careful labeling reduces the risk of error, especially in busy research spaces or regulatory filings.

Safety & Operational Standards

This reagent poses a real hazard if handled carelessly. Chloromethyl groups remind seasoned scientists of alkylating agents, which can irritate skin, harm eyes, or affect lungs if breathing protection isn’t used. Fume hoods are a must for all weighing and transfers, not just out of habit but because experience teaches the price of shortcuts in chemical safety. Labs post pictograms and warnings, keep spill kits close, and rely on regular safety drills to train people for exposure scenarios. Waste must be segregated and sent for professional disposal, since triazole derivatives tend to persist in the environment and may contribute to toxicity concerns if poured down the drain. Real world stories of mishaps push people to double-check PPE, storage conditions, and ensure first aid supplies fit the hazard profile.

Application Area

Researchers and companies put this molecule to work in ways that impact food production, medicine, and the development of specialty chemicals. Agrochemical innovators use it as a cornerstone in making modern fungicides that protect wheat, corn, and rice from blights and fungus, helping boost staple crop yields. Pharmaceutical teams find that attaching the triazole ring to other bioactive cores opens up routes to new antifungal and antibacterial drugs. Its role in fine chemicals often means enabling the introduction of useful groups onto molecular frameworks that end up as dyes, specialty resins, or electronic materials. In materials science, the compound sometimes plays a part in functionalizing polymers for coatings or additives, where both thermal stability and reactivity shape new properties.

Research & Development

The hunger for fresh fungicides and the search for next-generation pharmaceuticals drive ongoing work with 3-(chloromethyl)-1-methyl-1,2,4-triazole. Labs run structure-activity relationships using this building block, mapping how new side chains or modifications affect field longevity, toxicity, or resistance. For industry, this research turns into patents and scale-up protocols, since beating resistance in pathogens or delivering lower-environmental-impact crop protection means a new generation of chemicals on shelves. Open innovation models, where academic labs and chemical companies share know-how or libraries, often point to this triazole as a tractable and robust starting point for high-throughput screening. The success of new derivatives can stoke investor appetite and encourage regulatory engagement to fast track greener, less toxic agents.

Toxicity Research

This compound lands in the red zone when it comes to alkylation potential—its chloromethyl group brings real reactivity toward biological systems. Studies show DNA-protein crosslinking and irritation responses in exposed animals, lessons that ground both usage limits and regulatory frameworks. People studying cytotoxicity have pointed out apoptotic potential at low concentrations, indicating the need for thoughtful personal protection and protocol design. For environmental fate, research points to moderate persistence, which puts a strain on aquatic systems if not controlled. State agencies and international bodies set exposure limits, translating lab findings into workplace air or water standards and influencing disposal mandates. Teams tasked with environmental risk assessment keep this in mind, especially where runoff or improper disposal could affect non-target plants or aquatic life.

Future Prospects

The future sees demand rising as the limits of current agrochemicals press researchers and firms alike to reinvent tools for food security and safer medicines. Climate challenges and shifting regulation spur labs to design molecules that break down more easily in the environment, without losing activity. The structure of 3-(chloromethyl)-1-methyl-1,2,4-triazole, robust in its ability to anchor new modifications, aligns with the push for targeted action and reduced collateral toxicity. Researchers with eyes on precision crop protection or medical therapies keep reworking this platform, combining computational chemistry, robotic synthesis, and machine learning. Tighter controls and better labeling help stem environmental damage, supported by increased buy-in from producers and regulators. The future isn’t handed to us—all the stakeholders in agriculture, public health, and industry have to shape safer, more nimble solutions, drawing on the lessons and promise of this functional triazole.

Chemical Formula Details

Chemistry can look complicated just by the way it’s written. Take 3-(Chloromethyl)-1-methyl-1,2,4-triazole, for example. The name alone looks intimidating, but break it down and it gets more manageable. For this compound, the chemical formula reads as C4H6ClN3. Each part of that formula points to something important — four carbon atoms, six hydrogens, one chlorine atom, and three nitrogens. That seems simple, but the richness lies in how these molecules hold together and the functional groups they create.

From Classroom Theory to Real-World Applications

I remember my early chemistry days — drawing out ring structures, mapping where each atom connects. The triazole ring, which forms the core of this compound, brings more than just textbook value. This five-membered ring, dotted with three nitrogen atoms, pushes its way into pharmaceutical development for a reason. Chemists rely on triazole rings since they're stable and readily modify for use in antifungal drugs, plant protection, and other bioactive projects.

Let’s not gloss over the chloromethyl and methyl parts. Chemical tweaks like adding a chloromethyl group ramp up reactivity, offering handles for making even more complex structures. Think of it almost like giving a LEGO piece a new peg. Next thing you know, chemists can link up drugs, catalysts, or dyes with more ease.

Safety and Handling Concerns

It’s tempting to look at these formulas and think they’re just lines and numbers, but safety plays the biggest part when dealing with substances like 3-(Chloromethyl)-1-methyl-1,2,4-triazole. Chlorinated hydrocarbons deserve respect. Even if this specific compound isn’t as notorious as others, proper lab procedures — gloves, goggles, good ventilation — keep accidents out of the headlines.

You won’t find this chemical under the kitchen sink, but labs keep logs and storage rules for a reason. Recent news stories about unexpected lab fires or chemical spills remind me that being meticulous is not optional. Chemists, whether in research or the pharmaceutical industry, count on regulations and Material Safety Data Sheets. Knowing the formula is one part; knowing the possible hazards sharpens the real-world context.

Global Importance and Innovation

Look closely at the past decade in pharma, and you see why 1,2,4-triazole derivatives matter. Many antifungal agents wouldn’t work without them — fluconazole and itraconazole ride on that same backbone. Pressure on world food supplies also pushes agricultural scientists to test compounds like this as new fungicides. These discoveries carry weight. Farmers fight off resistant pests, crops survive brutal seasons, and patients in hospitals see a fighting chance against tough infections.

Responsible innovation needs teamwork from scientists, regulators, and companies. New standards, like those driven by the European Chemicals Agency or the U.S. Environmental Protection Agency, put guardrails up for manufacturing, testing, and disposal. Open collaboration across borders leads to better solutions, cleaner processes, and safer drugs.

Looking Ahead

Everything starts with getting the formula right, but it never ends there. Each molecule like 3-(Chloromethyl)-1-methyl-1,2,4-triazole offers both promise and challenge. Responsible chemistry, paired with clear communication and steady learning, shapes the world far beyond laboratory benches.

Why Chemists Pay Attention to This Triazole Compound

Walking through a chemistry lab or paging through technical journals, 3-(Chloromethyl)-1-methyl-1,2,4-triazole turns up in a surprising number of places. Its backbone pops out as a starting piece for more complex molecules, especially when someone aims to build something new for agriculture or pharmaceuticals. The main reason: this compound’s structure opens doors for adding other chemical groups, letting scientists push the boundaries of what these molecules can do.

Building Blocks in Crop Protection

Years ago, I saw chemists use this molecule to jumpstart the process of designing fungicides. Modern agriculture leans hard on triazole-based fungicides, since these compounds step in when crops face fungal outbreaks that could wipe out yields. 3-(Chloromethyl)-1-methyl-1,2,4-triazole serves as a key “linker” for connecting different active parts of a new pesticide, giving researchers control over how the final product behaves on a field. This triazole’s chloromethyl group sets up the chain of reactions that reads like the first step in a cooking recipe: you can’t finish the dish without that first, adaptable ingredient.

According to industry reports and patents, synthetic pathways that use this chemical often lead to broad-spectrum fungicides. Farmers see results out in the field: less crop loss and stronger harvests, which matters when food security and income tie directly to each growing season. Pesticide regulation in the US and EU keeps a tight leash, spurring continual tweaks and improvements to chemistry. This demand for safer, more effective crop protectants keeps 3-(Chloromethyl)-1-methyl-1,2,4-triazole on the shopping lists for agrochemical developers.

Sharp Tool in the Medical Research Kit

Outside farms, this triazole shows up during pharmaceutical research and development. Researchers need new ways to tackle infections and cancer, and triazole rings feature in key drugs that treat those very illnesses. Chemists start with 3-(Chloromethyl)-1-methyl-1,2,4-triazole to build tailor-made molecules that interact with enzymes or block microbial growth. Years spent reading medicinal chemistry papers taught me that what sets this compound apart is its ability to hook other functional groups in a predictable manner. This opens the door for targeted therapies, such as antifungals or enzyme inhibitors used in cancer treatment or immune suppression.

The triazole backbone passes muster for safety and compatibility, which means fewer headaches when moving from test tube to clinical testing. Data from PubChem and research articles underline that molecules built from this compound figure into promising studies for new drug candidates, from late discovery to patent filings.

What Challenges Follow Its Use?

Access to 3-(Chloromethyl)-1-methyl-1,2,4-triazole doesn’t come without bumps. It’s no secret: handling haloalkyl triazoles rings alarms for safety pros because of potential toxicity or reactivity. The chemical’s structure means it fits well for cross-linking, but this same property triggers concerns about accidental exposure or environmental release during manufacturing. In my own experience working with hazardous chemicals, the best safeguard comes from discipline—fume hoods, gloves, up-to-date Material Safety Data Sheets, and regular safety training. Companies put extra weight on containment and waste handling.

Across the sector, a rising call for greener chemistry has put pressure on companies to rethink synthesis steps. Researchers look for cleaner routes and less hazardous reagents, not just for compliance but also as selling points for green-label products. Innovators pushing for more sustainable ways to make triazole derivatives start to look at enzyme-catalyzed reactions or recyclable solvents, aiming to trim waste and risk without sacrificing performance.

Potential Next Steps in Its Use

Many eyes watch how emerging technologies—like AI in molecule design—could speed up safer derivative production. Chemical engineers might scale up alternative pathways that use less hazardous starting materials or minimize byproducts. Collaboration between chemists, toxicologists, and regulators stays important for keeping benefits high and risks low. The journey from lab bench to product reflects continual negotiation between utility, safety, and sustainability.

Safety Steps That Make a Difference

3-(Chloromethyl)-1-methyl-1,2,4-triazole sits on the list of chemicals that need strict attention in a lab or storage room. A chloromethyl group on a triazole ring tends to make a molecule quite reactive. In my work with fine chemicals, reactivity isn’t something to shrug off—it's something to plan for. If you pop the seal on a bottle of this stuff, you want the area well-ventilated. Vapors from these kinds of compounds aren’t made for your lungs or skin.

I’ve learned the hard way that storing chemicals like this on the wrong shelf can turn a quiet day into a cleanup scene. If heat or humidity creeps in, that bottle might not stay sealed or stable. Stash it with proper segregation, not crowded next to acids or oxidizers. Each chemical carries its own quirks, but with this one, I keep it cool and in the dark. Most of us working in labs stick to ranges of 2–8 °C. Sun and warmth start breaking bonds, and you don’t want that happening inside your bottle or, worse, outside it.

Picking the Right Containers

A glass bottle with a good screw cap, maybe lined with PTFE, beats plastic for many reactive substances. Glass doesn’t leach or crack, and the lining keeps vapors where they belong. I’ve seen what can happen if someone uses a stopper that fits poorly or if plastic softens—liquid on the outside and fumes sniffed across the room. Safety data sheets from reliable suppliers offer solid details. These days, I’ve seen more folks reading them cover to cover, not just clicking past the warnings.

Your Health Isn’t Expendable

Nobody running a lab wants a trip to the ER because of a careless mistake. Chloromethyl groups hold a reputation as alkylators, known to irritate skin and eyes. Exposure risks tend to show up fast: redness, breathing trouble, sometimes more serious damage. Gloves, eyewear, and proper coats, every single time. I keep extra nitrile gloves and face shields within reach, not in a locked cupboard. Stuff goes wrong in labs—it's not a matter of if, but when.

Don't Cut Corners on Waste and Spills

Once, I watched a junior chemist toss a used pipette into an open bin. Chemical waste shouldn’t meet regular trash. At my workplace, waste from this triazole goes into a labeled, sealed drum of compatible waste solvent, then out the door to certified disposal, never down a drain or left near heat sources. Good lab habits mean spotting leaks early. Drips dry to hazardous residues, and you never want to clean those up without the right kit.

Solutions and Good Habits

Training isn’t something to skip, especially with chemicals showing mutagenic or carcinogenic potential. Refresher sessions help keep everyone sharp. Labels, logs, and double-checks make a world of difference. I always pair new people with seasoned staff, letting experience fill the gaps where checklists run thin. Some labs invest in fireproof cabinets with alarmed doors to back up human error. Over time, these precautions seem boring, right up until they save your skin—literally.

Real Risks in the Lab and Workplace

Walking into a lab or chemical manufacturing site, few bottles raise eyebrows faster than those labeled with halogenated triazoles. 3-(Chloromethyl)-1-methyl-1,2,4-triazole lands in this camp. My own run-ins with chlorinated intermediates taught me early on: expect surprises, both with human health and workplace rules. What seems unremarkable on a shelf could end up causing skin irritation or respiratory sensitivity with casual contact.

Hazard Profile That Deserves Respect

Chemical safety data sheets flag this compound for a reason. Even without a skull-and-crossbones label, triazoles substituted with chloromethyl groups bring some baggage. Direct skin or eye exposure can result in redness, burning, and sometimes long-term sensitization. Inhaling dust or vapor isn’t much safer, leading to coughing and shortness of breath. I’ve worn double gloves handling similar triazoles, and for good reason. The chemical can penetrate common glove materials, so nitrile or double-layered gloves make sense. Goggle use isn’t an overreaction—it’s a smart standard.

Studies from the past decade warn about the genotoxic potential of some triazoles, especially those carrying methyl or halogenated side chains. Triazoles occupy a spot at the edge, where a simple cough or splash becomes more than a nuisance. Chronic exposure to related compounds sometimes triggers mutagenic effects in animal trials. The evidence, while not absolute, offers enough for most safety officers to urge caution over convenience.

Why Ventilation and Storage Practices Matter

Some shops downplay the need for proper fume hoods or respirators until an employee reports a rash or breathing problems. It doesn’t take a dozen incidents to see why dedicated ventilation belongs in any routine involving this molecule. Safe work-up means closed systems, low exposure windows, and waste that never gets dumped down the drain. In my lab time, careless handling of even a few grams turned simple cleaning into a big event with the spill kit.

Storage away from acids, bases, and strong oxidizers? That’s not just a regulatory demand—it’s based on the stability of triazoles. Incompatible mixing causes decomposition or, worst-case scenario, toxic fume evolution. Keeping reactives like this in tightly sealed containers and labeled secondary containment isn’t overcautious. It’s experience talking, informed by enough stories of reactions gone wrong.

Training and Routine Checks

Even the most robust storage and PPE cannot fix ignorance of risk. My experience tells me that successful workplaces build awareness into every handling step. Safety starts with clear training, daily checks that PPE fits, and immediate reporting of small splashes or inhalation. Companies with impressive safety records bring in experts to update protocols. Good habits, like logging any mishap and tracking near-misses, drive a culture where no one writes off red eyes or an odd smell.

Looking Ahead: Layered Controls

Ongoing education, regular hazard assessments, and smart process controls beat any single safety rule. 3-(Chloromethyl)-1-methyl-1,2,4-triazole deserves respect because health consequences hang in the balance. Proven solutions? Use closed transfers, invest in quality ventilation, upgrade to chemically resistant gear, and train every handler as if they will make a mistake at some point. With these steps, workplaces balance efficiency with real, practical safety.

Why Purity Matters in Specialty Chemicals

Anyone who has spent time in a lab knows that purity isn’t a buzzword, it’s a baseline. Working with 3-(Chloromethyl)-1-methyl-1,2,4-triazole brings this into clear focus. Even a small fraction of unwanted compounds can create setbacks—side reactions pop up, analytical results grow unreliable, costly batches drift away from their goals. I’ve seen pharma teams lose months because an intermediate wasn’t as pure as advertised. For this compound, industry standards expect purity at or above 98%, and serious projects might demand 99% or higher, with certificates of analysis and HPLC or NMR data to prove the point. The difference between a 95% and 99% sample isn’t just numbers; it shows up as fewer headaches during process scaling, tighter regulatory compliance, and smoother synthesis downstream.

Packaging Options and Real-World Impact

Even seasoned chemists sometimes underestimate how much packaging shapes project success. I’ve handled plenty of specialty chemicals that came in an unwieldy drum or a bottle prone to static buildup. Every mishap risked exposure, spills, or even product degradation before the work began. With triazole-type intermediates, I expect suppliers to use sturdy, tamper-evident containers—amber glass bottles or fluorinated HDPE jugs for small volumes and metal drums for large-scale orders. For kilogram lots, 25 kg fiber drums with polyethylene liners seal out moisture and air, which helps prevent hydrolysis and decomposition. If access to the compound spans weeks or months, a resealable container isn’t just nice to have—it preserves chemical integrity and helps budget-conscious teams avoid over-ordering.

Safe Handling and Quality Control

Stability isn’t just a data sheet bullet point. Every time I’ve worked on scale-up projects with sensitive triazole derivatives, transport and storage held as much weight as reaction conditions. Light and atmospheric oxygen can break down 3-(Chloromethyl)-1-methyl-1,2,4-triazole, so keeping the compound in opaque containers and storage at 2–8°C can save a lot of troubleshooting later. Suppliers sometimes add desiccants or inert gas blankets for extended shipment. Years ago, colleagues received a poorly packaged delivery in the summer. The compound arrived as a sticky mess—reacted and unusable. Since then, I always clarify packaging specs before ordering.

Mistakes here translate into waste and higher costs. Even if you buy from a well-known manufacturer, third-party testing never hurts. Cross-check HPLC traces, ask to see impurity profiles, and don’t hesitate to question the batch lot numbers on every container. Regulatory teams in the pharmaceutical and agrochemical industries will want that documentation to survive auditing. Skimping on QA or buying from vague sources too often turns into quality recalls or dangerous working conditions.

Addressing Issues and Moving Forward

Relying on the cheapest or least-proven source rarely ends well. I learned to forge relationships with reputable suppliers and chemical distributors that value traceability as much as prompt delivery. Still, even the best packaging can’t make up for subpar handling after delivery. Storing materials by hazard class, using dedicated drying cabinets, and equipping the lab with material tracking software brings fewer broken seals, lost batches, and unexpected exposures.

To reduce risks, industry groups keep pushing for more transparent supply chains and clearer documentation. Chemists who prioritize quality in ordering, storage, and handling give themselves fewer problems and more control. Ultimately, the real win comes from making every batch count, not just on paper but in real-world impact.