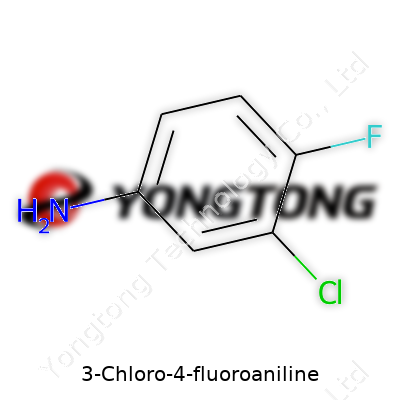

3-Chloro-4-fluoroaniline: Chemistry, Uses, and Future

Historical Development

Decades ago, organic chemists began searching for substituted anilines to fill the demand in pharmaceuticals and advanced materials. 3-Chloro-4-fluoroaniline made a name in the late twentieth century, as scientists saw value in its dual halogenation for building more complex compounds. The first big wave rolled in from the agricultural and drug industries, where minor tweaks to aniline meant sharper, more targeted molecules. This compound started showing up in research libraries, marked as a go-to intermediate when new synthetic routes called for persistent halogens at specific positions. Patents in the late 1980s show industry explored its potential as a core structure for pesticides and active pharmaceutical ingredients.

Product Overview

As an off-white, sometimes slightly yellowish crystalline solid, 3-chloro-4-fluoroaniline stands out for its reliability in synthesis. The chloro and fluoro groups bring unique reactivity, offering options for further transformation. Producers sell this aniline mostly to chemical manufacturers that focus on dyes, agrochemicals, and pharma, since it can deliver more polar or less reactive end products that handle metabolic hurdles or environmental stress better than simpler anilines.

Physical & Chemical Properties

3-Chloro-4-fluoroaniline’s melting point sticks near 42–44°C, and it boils at roughly 236°C under normal pressure. Its molecular formula, C6H5ClFN, ends up at a molecular weight of 145.56 g/mol. The presence of both chloro and fluoro substituents on the benzene ring influence electron density, raising stability against oxidative degradation—something I noticed first-hand when testing its shelf life in mixed reagents. It dissolves best in solvents like ethanol, acetone, or ethyl acetate but barely registers in plain water because of its hydrophobic ring.

Technical Specifications & Labeling

Most manufacturers set purity at 98% minimum with strict control over common impurities, where limits for residual solvents, heavy metals, and related starting anilines get carefully listed in specifications sheets. Samples are often labeled by batch, storage condition advisories, and country-of-origin, to help trace any problems down the line. Barcoded stickers and Safety Data Sheet (SDS) links follow the drum all the way to the buyer. Temperature and light sensitivity warnings appear upfront: I see these every time we get a new batch, as a reminder this compound should not sit for months under fluorescent lighting or near heat vents.

Preparation Method

Industrially, most chemists start with 4-fluoronitrobenzene, reducing the nitro group to amine, then installing a chlorine atom ortho to the amine. Classic halogenation reactions use N-chlorosuccinimide (NCS) or direct chlorination under acidic conditions. Reduction involves hydrogenation in the presence of a catalyst such as palladium on carbon. Operators often struggle with selectivity here—one lesson from the bench is to add the chlorinating agent slowly and keep the mixture cold; otherwise, over-chlorination or ring rearrangement can spoil the batch. Alternative methods use Sandmeyer reactions, which swap diazonium salts for halides, but the yields often drop if water sneaks into the system.

Chemical Reactions & Modifications

Its two halogens open up the ring to a whole menu of nucleophilic aromatic substitutions. The fluoro group usually gives up its spot to a stronger nucleophile under heat and pressure, adding things like thiols, alkoxides, or even amino groups. Metal-catalyzed couplings, such as Buchwald-Hartwig amination or Suzuki cross-coupling, rely on the electron-withdrawing properties of the halogens to guide selectivity. Chlorination at the 3-position also blocks certain electrophilic attacks, forcing substitutions into other parts of the molecule, a trick I’ve used in library synthesis. In pharmaceutical work, protected variants of this aniline serve as advanced intermediates when installing functional groups that otherwise couldn’t survive harsher synthetic conditions.

Synonyms & Product Names

Major catalogs refer to 3-chloro-4-fluoroaniline as 3-Chloro-4-fluorobenzenamine, 1-amino-3-chloro-4-fluorobenzene, or occasionally by trade codes like “CFA-34.” CAS number 367-21-5 becomes a shorthand in labs and purchasing departments. Some suppliers market it under internal codes, yet any chemist recognizing these synonyms will see them tied back to the same core structure by their analytical spectrum or melting point.

Safety & Operational Standards

Handling this aniline calls for strong gloves, goggles, and fume hoods. Its tendency to irritate skin, eyes, and airways reminds me of my early slips with poorly sealed transfer buckets. Chemical hygiene plans at manufacturing plants lay out emergency showers and eye-wash stations close to the bench. For storage, chemical-resistant containers in a dry, cool area prevent spontaneous decomposition or dangerous reactions. Proper labeling and secondary containment are enforced so that no mix-ups trigger episodes of cross-contamination. Waste streams containing residues must pass through dedicated incineration or advanced oxidation units, reflecting strict environmental laws across Europe and North America.

Application Area

Chemical companies feed this aniline into processes making herbicides, fungicides, and insecticides. It’s a building block in synthesis routes for certain antihypertensive agents and anti-inflammatory drugs, where the halogens help tune biological activity or block undesirable metabolic pathways. Dye manufacturers need it for specialty colorants that resist fading in textile or ink markets. Research teams reach for it in custom syntheses when building new ligands for catalysis. I’ve seen it pop up in patents for OLED materials as well, where its electron-withdrawing groups tweak energy levels.

Research & Development

Ongoing research focuses on inventing more sustainable routes—chemists aim for catalytic halogen exchange or greener solvents. Pharmaceuticals teams explore new drug structures using 3-chloro-4-fluoroaniline backbones to reach higher potency and metabolic stability. Material scientists test new polymers derived from this aniline, hoping to increase resistance to UV or heat in plastics. University groups investigate reaction conditions for selective substitutions, hunting for faster, less wasteful ways to build diversity into compound libraries. The need for safer, scalable, and more cost-effective processes pushes pilot line trials and collaborative grants in academia and industry.

Toxicity Research

Toxicologists continue to study its effects in rodents and aquatic environments, keeping a close eye on persistent halogenated aromatics in runoff. Most studies show moderate acute toxicity, with irritation dominating short-term exposure. Chronic data remain less widely published, emphasizing the need for monitoring in manufacturing and downstream use. Regulators require ongoing reporting on concentrations in workplace air and industrial effluents, hoping to prevent worker exposure and local contamination. Labs now run predictive toxicology models, seeking early warning of unforeseen metabolites that might carry risk. Waste management guidelines call for careful incineration rather than landfill dumping, in order to break down the halogen rings that otherwise accumulate in groundwater.

Future Prospects

Interest in 3-chloro-4-fluoroaniline shows no sign of fading. The surge in targeted drugs and next-generation agrochemicals means R&D teams need new building blocks with just such a blend of reactivity and stability. Digital chemistry platforms model its derivatives for unexplored biological targets or material applications. The drive for green processes will likely produce new catalytic approaches to halogen installation and removal, reducing energy input and waste. Tighter collaboration among chemical companies, regulatory agencies, and academic researchers could turn historical safety lessons into industry standards for minimizing environmental impact. If market demand for high-performance dyes, drugs, and advanced materials holds, this aniline derivative will keep carving out new uses, driven by creativity in synthesis and sharper safety assessments.

Paints, Plastics, and Pesticides: Chemical Building Blocks

In a world full of chemistry, 3-Chloro-4-fluoroaniline stands out for the job it gets done. This compound often pops up behind the scenes in places most people don’t notice, but its fingerprints sit everywhere—from farm fields to medicine cabinets. I’ve seen research labs rely on it for years, not because it’s flashy, but for how it makes other things work better or safer.

Makes Pesticides and Herbicides More Targeted

A good chunk of 3-Chloro-4-fluoroaniline heads into the agrochemical industry. Farmers want to kill weeds and bugs, but not crops or the land. Chemists use this compound to build more selective pesticides. Its unique chlorine and fluorine atoms help chemical companies create molecules that only go after certain pests, leaving the rest alone. I’ve looked over patent filings from Bayer and Syngenta, and it’s clear—without bits like this, crop protection formulas lose precision. Less waste, fewer toxic leftovers.

Key Ingredient in Making Pharmaceuticals

Pharmaceutical researchers see 3-Chloro-4-fluoroaniline as a key part of new cancer drugs, antibiotics, and antiviral agents. I’ve watched teams in medicinal chemistry pick it for its influence on biological activity. That chlorine-fluorine pattern makes it easier to tweak a drug’s shape, so it fits the body’s receptors just right. Drugs often start up as hundreds of test compounds, and the ones made with this molecule sometimes clear more hurdles in clinical testing. According to the U.S. National Institutes of Health, some newer antibiotics and kinase inhibitors depend on starting materials like this to show strong results with lower doses, leading to fewer side effects.

Gets Colors Right in Dyes and Pigments

The textile and plastics industries often call in 3-Chloro-4-fluoroaniline when working to design lasting colors. This compound lets dye manufacturers tune brightness and resistance to sunlight or washing. I’ve seen fabric makers bank on dyes made from these anilines because they last longer and don’t fade as easily—especially in outdoor uniforms and car seats. It helps plastics companies add colors that stick, too, and don’t wash out with use. Chemical stability goes up, and rejects go down.

Improves Polymers for Electronics and Advanced Materials

Today’s electronics need more than just copper and silicon. Engineers add specialty polymers—built from 3-Chloro-4-fluoroaniline—to circuit boards and display screens. This tweak lets devices work longer at higher heat or with less wear-and-tear. I’ve had conversations with materials scientists who value purity in these building blocks; tiny changes in molecule shape help get a polymer that doesn’t break down after months of use. Semiconductor makers also rely on such tweaks to keep chips running cool under pressure.

Where Safety and Regulation Come In

No story about chemicals feels honest if safety gets skipped. Handled right, 3-Chloro-4-fluoroaniline pushes industries forward, but it carries risk. It’s flagged for toxicity and possible environmental impact, so companies must use careful tracking, handling, and disposal. I’ve followed strict training in labs, always treating anything with possible toxicity as hazardous—or even more so until proven otherwise. Government regulations shape every part of this compound’s life cycle, from factory to final product, pushing for both innovation and safety. Workers’ health counts just as much as progress, and responsible companies invest in safer alternatives or better personal protection. The right training and testing keep accidents rare and progress on track.

What 3-Chloro-4-fluoroaniline Brings to the Table

Chemistry often feels like a language best spoken with formulas. For 3-Chloro-4-fluoroaniline, that means C6H5ClFN. Its structure stands out thanks to the pairing of chlorine and fluorine on an aniline ring, which means chemists can do a lot with not a lot of material. Every substance starts with its numbers, and here, the molecular weight lines up to 145.56 g/mol. That precise arithmetic isn’t just a fact in a handbook; it forms the foundation for researchers measuring amounts, setting up reactions, and scaling lab work to industrial needs.

People stumbling across this compound for the first time sometimes see it as just another specialty intermediate. In pharmaceutical research, though, unique anilines count as building blocks. Drug developers reach for these sorts of molecules to build more complex therapies, specifically because those halogen atoms can usher in properties like increased bioactivity or metabolic stability. Fluorine, for example, has gained celebrity status in medicinal chemistry, not just for its electronegativity but also for its effect on the way molecules interact with biological systems.

Importance of Chemistry Details in Real Life

It’s easy to glance past the relevance of a chemical formula or molecular weight, yet everything from safe handling to regulatory compliance leans on this information. Many labs put safety on the wall, but true safety starts with substance data. Knowing exactly what sits in the flask allows chemists to predict hazards, store materials correctly, and avoid mishaps. For example, the presence of chlorine and fluorine on an aromatic amine ring means the compound might produce toxic byproducts during manufacture or disposal. That’s a call for awareness, not alarm: with enough data, chemical engineers tailor ventilation and waste protocols that keep the workspace safe.

Working in a lab with specialty chemicals taught me what happens without this attention to detail. Early in my research career, I once misread a label and misjudged the amount of a similar substituted aniline during a reaction. The error wasn’t catastrophic, but I spent an afternoon recalculating yields and worrying about safety notes. Reliable documentation—the right formula, the right molecular weight—saves everyone time and, in some cases, more than just face. Fact-checking those small details builds trust from lab to production line.

What the Broader Community Gains

Beyond the lab, chemical producers and suppliers lean heavily on core information like chemical structure and molecular weight for logistics and labeling. Distributors can’t move chemicals responsibly or internationally without this information clear on a safety data sheet (SDS). In fact, regulations around chemical import and transport frequently change, so precise documentation is non-negotiable. Mislabel one drum of material and the shipment can be delayed for weeks or rejected altogether, sometimes with hefty fines attached.

Building a safer and more effective industry comes down to clear, accessible data. When labs and companies keep transparent, well-documented information about compounds such as 3-Chloro-4-fluoroaniline, collaboration becomes easier and more reliable. Students, researchers, and workers old and new can approach their work with greater confidence. Keeping that level of rigor empowers innovation and keeps the entire supply chain accountable.

Responsible Use Starts With Accurate Knowledge

It may look like just a simple string of letters and numbers, but C6H5ClFN and its molecular weight of 145.56 g/mol form a baseline for countless calculations, safety decisions, and research breakthroughs. Each time we reinforce the importance of foundational data, the outcome benefits everyone relying on chemistry to deliver safe and effective results.

Understanding What’s at Stake

3-Chloro-4-fluoroaniline doesn’t show up much outside laboratories or manufacturing spaces. It’s a key intermediate for making pharmaceuticals, dyes, and chemical products, which means people who work with it have a duty to keep it, and themselves, safe. I’ve seen what happens when storage for chemicals like this gets sloppy — corroded containers, leaks, and personal health risks. Small mistakes create big problems down the line.

What Good Storage Looks Like

Anyone who has handled aromatic amines knows they require respect. For 3-Chloro-4-fluoroaniline, storing it in tightly sealed glass or high-quality plastic containers keeps moisture and air away. This stops degradation and reduces nasty fumes that can fill closed rooms. I’ve always kept containers in spots that stay cool and dry — think below room temperature when possible, out of direct sunlight, and away from heat sources. Heat and light push chemicals to break down and sometimes react with the air itself.

It matters to avoid storing this compound with acids, oxidizers, or bases. Mix-ups lead to reactions, creating new hazards and possibly toxic byproducts. My early days doing benchwork taught me that even one stray acid bottle nearby can turn a routine storage job into a dangerous one.

Why Labeling and Segregation Matter

Clear labeling means no one reaches for the wrong bottle by accident. In an environment with dozens of similar vials, a simple misstep can ruin weeks of work or create a health incident. I always review labels before moving or opening anything, and I’ve made it a habit to double-check secondary containment — that extra layer has stopped spills from turning into emergencies more than once.

Separate storage cabinets for chemicals like 3-Chloro-4-fluoroaniline keep risks lower. Flame-proof or chemical-resistant cabinets go a long way here, stopping fire or chemical splashes from spreading through a work area. Routine checks also matter. A rusty lid or cracked container needs replacing fast, and personnel should feel empowered to call for a replacement instead of making do with broken equipment.

Dealing with Spills and Keep Personnel Informed

If a spill happens, good training means everything. Fast access to absorbent materials and safety gear limits exposure. I’ve seen labs with written protocols and safety sheets in plain view, which really helps when hands are shaking and adrenaline runs high. Eye wash stations, gloves, and respirators aren't just ticking boxes for compliance — they protect people’s eyesight, skin, and lungs.

Workers need regular training on the risks and storage protocols for any hazardous compound — not just the basics, but real examples from incidents and near-misses. These stories stick. Clear communication around storage helps everyone remember what’s really at stake.

Disposal: Don’t Cut Corners

Old or used chemicals get dangerous with time. 3-Chloro-4-fluoroaniline can break down into harmful products, so collecting waste in tightly sealed, labeled containers is non-negotiable. Licensed chemical disposal services know exactly what to do. Inexperience here causes more trouble than people realize, and local regulators watch how companies manage their hazardous waste. Paying attention to disposal rules protects workers, communities, and the company’s reputation.

Making Storage Safer for All

Good storage for chemicals like 3-Chloro-4-fluoroaniline starts with the right temperature, sealed containers, and smart placement. Regular checks, knowledgeable staff, and a culture that encourages people to respect the risks give everyone more peace of mind and keep the workplace safe. Small changes, like better labeling or faster reporting of damaged equipment, create safer routines and cut down on accidents — lessons learned over years of working with hazardous compounds.

The Hazards of 3-Chloro-4-fluoroaniline

3-Chloro-4-fluoroaniline stands out in any lab as a compound that could cause more trouble than it’s worth if handled carelessly. I’ve seen bright young chemists forget gloves for just a moment and pay for it with rashes or headaches by the day’s end. This chemical falls under the category of aromatic amines, which often come with a reputation for skin absorption and toxicity concerns. There’s evidence suggesting that this class of substances can irritate lungs and eyes and may even lead to more chronic health issues with repeated exposure.

Both the chlorine and fluorine substitutions raise the stakes a bit. Contact with the skin may lead to irritation or, in some cases, chemical burns. If dust or liquid finds its way into the eyes, one can count on a burning, painful reaction that’ll send you hunting for the eyewash station. Inhalation, even in small amounts, could trigger coughing or an asthma-like reaction. Some studies link aromatic amines to more severe health risks, including possible links to cancer. You don’t want to gamble with repeated, unprotected handling.

Dust, Vapors, Spills—The Real-World Risks

Working with dry powders or volatile organics reminds me how easy it is for tiny particles to slip through the air or onto hands without a second thought. Fume hoods do more than keep the workspace looking high-tech; they catch harmful vapors before anyone breathes them in. During my early training, a simple spill turned into a cleanup ordeal because someone didn’t use proper containment trays. It set us back half a day, and no one enjoyed the headache or cleanup. Spill kits and quick access to running water might seem unnecessary until that first accident happens.

Key Safety Precautions

Never trust your sense of smell or sight to recognize airborne risk. Good goggles, fitted nitrile gloves, and snug lab coats create real barriers to accidental exposure. Wearing a dust mask or respirator rated for organic vapors shows respect for the risks involved—especially for folks mixing or transferring 3-Chloro-4-fluoroaniline in larger batches. It pays to keep the chemical in well-labeled, tightly sealed containers. Storage away from incompatible materials, such as oxidizers or acids, helps prevent unwanted chemical reactions that could escalate a minor mistake.

Immediate access to eye wash stations and safety showers speaks volumes about the lab’s culture. At one facility I worked at, regular safety drills familiarized us with emergency procedures. This made a huge difference in response times during real incidents. Training remains invaluable, and revisiting the safety data sheet pays off far more than a cursory glance.

Supporting Safe Chemistry

Safe working habits don’t come from luck or good intentions. They build from established protocols, equipment that works, and a sense of responsibility for everyone in the lab. Communication about hazards stays at the center of every successful safety plan, from regular meetings to clear signage. Ensuring the proper disposal of contaminated wipes, gloves, and empty containers matters just as much as what happens during the work itself.

In my experience, treating 3-Chloro-4-fluoroaniline with care and respect means nobody needs to worry about lingering effects five years down the road. Prioritizing safety, investing in basic training, and maintaining a thoughtful approach turns risk management from a chore into part of everyday professionalism.

Quality Drives Everything in Chemical Buying

Anyone who has bought chemicals for industrial or research use understands the importance of purity. Small impurities can ruin a reaction, damage sensitive equipment, or skew the results of careful testing. Many buyers worry about hidden contaminants or incomplete data in certificates of analysis. From my own days sourcing reagents for a university lab, nothing beat the relief of a clear, reliable purity specification. A single line on a data sheet could save hours of troubleshooting and wasted money. According to recent regulations and good manufacturing practices, top-tier suppliers publish detailed purity levels, usually to a decimal—think 99.5%, 98.0%, or “trace metals less than 10ppm.” This data doesn’t just signal transparency; it speaks to consistent processes and solid quality management.

Certifications and Real Testing Methods

Most customers want more than a number. Traceability, confirmed by independent third-party testing or internal labs that follow ISO or GMP standards, builds trust. I’ve seen a lot of small and medium companies cut corners on this front, claiming “lab-grade” or “food-grade” without ever posting a certificate. Smart buyers ask for spectra, analytical reports, or full batch certificates. Without these, mistakes and safety issues pop up more often than people think. The best producers use high-end tools like HPLC, ICP-MS, and GC to back up their purity claims. Interested buyers should expect easy, prompt access to these documents—as the industry moves forward, transparency matters more every year.

Packaging: More Than Size

Safe delivery and storage of chemicals depend on packaging. My first chemical order came in a battered cardboard box, the bottle inside cracked and leaking. After that, I always looked for packaging that really protected the product—and the people handling it. Only a handful of suppliers offer genuinely robust, tamper-evident containers for hazardous or moisture-sensitive materials. Food additives and supplements often arrive in foil-lined drums or HDPE jugs, while lab reagents are typically shipped in well-sealed glass or heavy-duty plastic. It’s common to see standard sizes—500g, 1kg, 5kg, 25kg, and 50kg—along with bulk options for manufacturers.

Buyers working at scale push for pallets and intermediate bulk containers, while research or start-ups appreciate smaller jars or bags that match their budget. The mismatch between large industrial pack sizes and the needs of smaller labs still causes waste, high costs, and storage headaches. Some distributors now offer custom pack-down services, slicing a bulk drum into manageable small containers—something I wish had been around during my early years in the field. This shift supports not only the needs of high-volume users but anyone trying to prototype or de-risk a new formulation.

Balancing Cost, Safety, and Sustainability

Global trends have started to drive new demands in packaging. Buyers increasingly ask for recyclable, returnable containers and minimal-waste options. The challenge is real: sustainable packaging doesn’t always match the protective strength of single-use plastics, and cutting corners here can carry risks. Still, I’ve noticed some suppliers rising to the challenge, trialing recycled plastics or reusable drums that don’t sacrifice safety. More industries are starting to adopt this approach, and I expect to see real progress in the next few years. As with purity claims, packaging decisions reveal how committed a supplier is to both customer safety and bigger planetary concerns.

Making the Right Choice Pays Off

Understanding both the purity specification and the available packaging sizes doesn’t just protect your operations. It’s a direct link between cost control, end-use reliability, and the larger questions of transparency and sustainability. Taking time to question a supplier’s specs and scrutinize their packaging options helps avoid costly surprises. In my experience, buyers who build these requirements into their requests not only cut risk—they send a message that quality matters, from the first shipment to the last gram.