3,5-Difluorophenol: Exploring an Essential Chemical Building Block

Historical Development

3,5-Difluorophenol emerged during the expansion of organofluorine chemistry in the 1960s. Early research aimed to improve crop protection and pharmaceuticals, and simple difluorinated phenols, including 3,5-difluorophenol, became tools for investigating reactivity and biological activity. The backbone of many agrochemicals and medical agents started with small changes in structures like phenol. Chemists saw the impact of added fluorine on basic aromatic rings, noticing sharper bioactivity and altered metabolism profiles. Laboratory synthesis grew more reliable through improvements in halogenation techniques, and standardized production arrived as demand spread through sectors like dye chemistry and fine chemicals. Over the decades, peer-reviewed papers detailed its nuanced reactivity and growing catalog of applications, setting a solid historical foundation for today’s industrial relevance.

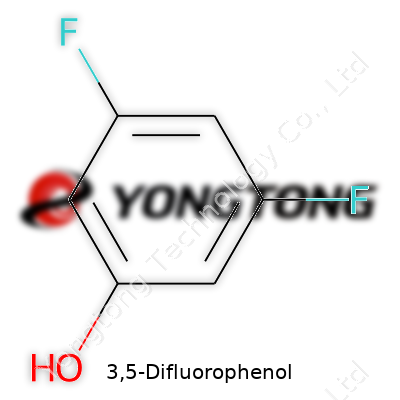

Product Overview

The phenolic ring substituted with two fluorine atoms at the meta-positions makes 3,5-difluorophenol a valuable intermediate. The compound’s layout seems simple at first glance, but small changes to aromatic rings can create huge leaps in solubility, reactivity, and biological effects. As a solid at standard conditions, it moves through industry as both a pure laboratory reagent and as a bulk intermediate in specialty chemical manufacturing. Companies keep stocks for use in R&D labs as well as for routine batch production. In my own bench work, the integrity and purity of this compound make a clear difference in downstream yields and reproducibility.

Physical & Chemical Properties

With a molecular formula of C6H4F2O and a molar mass around 130.09 g/mol, 3,5-difluorophenol stands out due to its stability and moderate melting range. White to off-white crystalline solid, its melting point falls near 51-54°C, with a boiling point just above 180°C—enough to handle most common organic syntheses without decomposing. Its limited solubility in water but good dissolution in organic solvents like ether, chloroform, and acetone gives flexibility for both analytical and preparative chemistry. The hydroxyl group offers a hydrogen-bonding site, while paired fluorine atoms reduce basicity but increase resistance to oxidative degradation. Handling it reminds me how small structural tweaks shift everything from shelf life to compatibility with reagents.

Technical Specifications & Labeling

Labs source 3,5-difluorophenol with purity usually above 98%, measured by gas chromatography or HPLC. Typical packaging uses amber glass to protect from UV-induced decomposition. Clear CAS labeling (at 3131-52-0) and batch traceability reflect growing pressure from regulators and end-users for transparency. Data sheets list melting point, appearance, storage temperature (preferably between 2 and 8°C), and recommended handling protocols. The reliable supply chain makes routine reordering and experimental planning more straightforward, reflecting improvements compared to chemical sourcing even a decade ago. Digital inventory systems tie labels to safety sheets, which makes compliance checks straightforward in both research and industrial environments.

Preparation Method

Standard synthesis relies on selective fluorination of phenolic rings, with routes leveraging direct halogen exchange, metal-catalyzed cross-coupling, and electrophilic aromatic substitution. One established method starts with meta-bromophenol, swapping bromine with fluorine through nucleophilic aromatic substitution using metal fluorides or fluorinating reagents like DAST. Some routes use difluorination of phenol under controlled conditions, but controlling position selectivity remains challenging without expensive catalysts. Improvements in green chemistry now aim to reduce hazardous byproducts, using milder conditions and recycling catalysts as much as possible. Synthesis often runs at kilogram scales in pilot plants, scaled for specialty batches rather than bulk commodity output.

Chemical Reactions & Modifications

As an aromatic compound with both activating (hydroxyl) and deactivating (fluorine) groups, 3,5-difluorophenol strikes a unique reactivity balance. Nitration, sulfonation, and alkylation reactions all shift compared to the parent phenol, reflecting the electron-withdrawing effect of fluorine atoms. Coupling reactions—for instance, Suzuki or Buchwald-Hartwig cross-coupling—open the door to larger molecular frameworks, and the hydroxyl site enables ether or ester formation with acid derivatives. The compound shows resilience during many transformations, and in medicinal chemistry, chemists often exploit the altered metabolic fate provided by the fluorine atoms while protecting the phenolic site until the final synthetic step.

Synonyms & Product Names

Across catalogs and patents, 3,5-difluorophenol appears under varied synonyms: 3,5-DFP, m-difluorophenol, and 3,5-difluoro-1-hydroxybenzene. Chemical suppliers and pharma documentation sometimes use trade names, though the International Union of Pure and Applied Chemistry (IUPAC) designation remains preferred in academic journals. While the CAS number provides clarity, routine projects in the lab or factory may list an abbreviated form—saving time but sometimes causing confusion across multidisciplinary teams. In my own project notes, sticking to the complete name avoids cross-wires during peer review and regulatory audits.

Safety & Operational Standards

Though fluorinated phenols tend to be less volatile or outright hazardous than their halogenated cousins, strict protocols stay in place to prevent accidents. Exposure to 3,5-difluorophenol can cause irritation to skin, eyes, or respiratory tract, so standard operating procedures call for gloves, goggles, and fume hood work. Companies follow GHS (Globally Harmonized System) hazard classification, listing potential risks on all labels and certificates of analysis. Emergency fix—like eyewash stations and spill kits—must be close to storage or handling areas. International transport enforces DG (dangerous goods) codes, which has become more closely monitored since the rise in global chemical trade. Training for new users always runs alongside written safety documentation, closing the gap between theoretical risk and day-to-day lab realities.

Application Area

Much of modern fine chemical synthesis uses 3,5-difluorophenol as a precursor to herbicides, pharmaceuticals, and diagnostics. The compound’s core structure shows up in anti-inflammatory agents and advanced imaging compounds like radiotracers. Chemists value its ability to modify electronic properties and boost metabolic stability, especially in drugs that need to resist rapid breakdown. The fluorinated ring tunes binding profiles against biological targets, either for tightening receptor lock-in or loosening solubility for better tissue penetration. Agrochemical firms invest in its use as a building block for potent, selective weed control agents that do not harm major crops. These applications feed downstream demand, driving bulk shipments from specialty manufacturers to innovation-driven companies in pharmaceuticals and agriculture.

Research & Development

Research teams treat 3,5-difluorophenol as a starting point for new molecular scaffolds meant to solve emerging medical and environmental problems. I have seen grad students spark new approaches to cancer drug design by tweaking the pattern of fluorine placement, guided by recent progress in computational molecular docking. R&D programs often focus on green synthesis of difluorophenols, which trims costs and answers customer calls for reduced waste streams. Working with this compound also means building predictive models for reactivity, using quantum chemistry and machine learning. Journals document creative adaptations, including catalysis breakthroughs and late-stage functionalizations, and patent filings keep rolling in from both startups and multinationals seeking first-mover edge in crowded fields.

Toxicity Research

With any new chemical, questions about toxicity drive careful experimentation before bulk production. Animal models and in vitro systems show that 3,5-difluorophenol remains less acutely toxic than similar chloro-phenols, reflecting lower reactivity with DNA or vital enzymes. Chronic, low-dose exposures still require monitoring for subtle endocrine or mutagenic effects, so regulatory filings include detailed breakdowns of metabolic fate and byproduct risks. Environmental fate studies show resistance to rapid biodegradation, demanding tighter waste controls and up-to-date remediation practices. In response, labs develop tighter process controls, and recent research points toward enzyme-based treatment of phenolic waste as a safer disposal route. Open data sharing in toxicity research, a major step forward compared to decades past, shapes both manufacturing best practices and public regulatory policies.

Future Prospects

Demand for high-purity 3,5-difluorophenol shows little sign of slowing as global markets invest in precision medicine, advanced diagnostics, and sustainable agriculture. Fine-tuning electronic effects on aromatic rings underpins the next generation of active pharmaceutical ingredients and crop science molecules. Trends toward green manufacturing spur fresh investment in catalyst development and flow reactor technology to achieve higher selectivity with less environmental footprint. Advances in analytical chemistry and metabolomics will further clarify downstream safety profiles, letting manufacturers and users navigate regulatory hurdles with confidence. As more researchers look closer at the effects of fluorine incorporation across life sciences and materials chemistry, I expect to see 3,5-difluorophenol at the center of creative molecular engineering for years to come.

Rethinking Everyday Chemistry

Step into a lab and tracking down a bottle labeled 3,5-Difluorophenol might feel like hunting for something obscure. Yet, this chemical shapes more of our surroundings than you’d expect. Experiences in research and time working alongside chemists show how much thought gets funneled into every odd-sounding molecule, especially the ones with tongue-tripping names.

Pharmaceutical Roots Run Deep

Plenty of drug-making starts with tweaks to old molecular skeletons. 3,5-Difluorophenol offers a straightforward structure: a benzene ring with a couple of fluorine atoms and a single hydroxyl group. Pop those fluorine atoms onto a phenol, and the result carries enough difference to matter in the next step of synthesis. Medicinal chemists hunt for changes that might boost activity or cut side effects in a new medicine. Fluorine earns its spot in the formula because it nudges the shape and behavior of drugs without adding bulk. Hard to forget the explosion in “fluorine chemistry” after the industry saw how one atom could shift a whole drug’s purpose.

3,5-Difluorophenol shows up as an ingredient in several research efforts aimed at newer antibiotics, antifungals, and even anti-inflammatory agents. Labs probe chemicals like this, linking them to other fragments, searching for that sweet spot where potency meets safety.

Chemistry as a Building Game

Outside the world of health, this compound catches interest among developers of agrochemicals. Farming technology rarely gets the spotlight, but so much food security leans on subtle changes in pesticide and herbicide design. The star here comes from how 3,5-Difluorophenol allows a scientist to fine-tune a molecule’s resistance to the environment. Plants, bugs, fungi—all cope with chemical barriers differently. Adjusting a ring of carbon with fluorine swaps can stop a weed or pest cold, sometimes with a smaller environmental footprint.

Further down the supply chain, you’ll find work in polymers and specialty coatings. Plastic engineering borrows organic compounds to add bite or weather resistance to finished products. Municipal water pipes, cell phone cases, and electrical insulation take on new durability with the right additives. Watching a friend test polymer blends in a quality control lab, small tweaks with specialty chemicals spelled the difference between market-ready goods and wasted batches.

Managing the Hidden Hazards

As much as these specialty phenols matter, attention turns to safety and environmental behavior. Many phenol derivatives pack a punch, so careful handling tops the list in labs and factories using this compound. Waste disposal rules force a rethink of every step, from storage to spill control. In the late-2010s, headlines on persistent chemical pollutants pushed companies to re-examine their protocols. Data from environmental monitoring continues to show how trace residues can show up miles from their origins.

Improvement doesn’t come easy. Some chemists test out alternative starting materials with less hazardous footprints. Green chemistry pushes the conversation further, looking for new ways to make essential ingredients with lower risks and fewer byproducts. Between tighter regulations and the real headaches of chemical accidents, sharing best practices saves everyone time and lives.

Solutions Aren’t Static

Experience from the field shows that working with chemicals like 3,5-Difluorophenol goes beyond just serving industry or medicine. Keeping an eye on safety, transparency about chemical sourcing, and supporting greener synthesis routes matters for trust, both among scientists and with the public. It takes ongoing effort and shared responsibility to use these building blocks wisely.

What Makes 3,5-Difluorophenol Stand Out?

3,5-Difluorophenol isn’t as obscure in the world of organic chemistry as it might sound to newcomers. Folks use it for research into pharmaceuticals and agrochemicals. Its structure slips in two fluorine atoms on a phenol ring in the 3 and 5 positions, but until you hold a model or scribble it out, that description feels about as lively as tax code. Chemists look at tweaks like these because even a tiny swap, like a fluorine atom in just the right place, can shift a molecule’s whole personality. That’s especially true for drugs or pesticides—the difference between targeting a bacteria’s enzyme or slipping by unnoticed in an animal’s body.

Molecular Formula: Not Just Letters and Numbers

The molecular formula for 3,5-difluorophenol is C6H4F2O. Six carbons stack into a benzene ring, with four hydrogens poking out. Two fluorine atoms perch at opposite sides, kicking out the usual hydrogens, and a single oxygen hangs off as a hydroxyl group. It’s a tight, flat structure—those substitutions push and pull at the system, often making the entire molecule more stable or resistant to breakdown.

Calculating Molecular Weight: A Simple Tally, Big Consequences

The molecular weight matters in chemistry like weight matters in cooking—you won’t get far with vague handfuls. Here’s the tally for 3,5-difluorophenol:

- Carbon (C): 6 atoms × 12.01 g/mol = 72.06 g/mol

- Hydrogen (H): 4 atoms × 1.01 g/mol = 4.04 g/mol

- Fluorine (F): 2 atoms × 18.998 g/mol = 37.996 g/mol

- Oxygen (O): 1 atom × 16.00 g/mol = 16.00 g/mol

Add those up, and you land at 130.10 g/mol for 3,5-difluorophenol. That number pops up everywhere: labeling, safety data sheets, chemical procurement, and lab calculations.

Why This Compound Draws Research Attention

Researchers want molecules with a track record. Fluorinated phenols like this compound don’t just survive a little longer in living systems—they also slip more easily past certain enzymes. That property can strengthen their activity in drugs or help them last out in the field as crop protectants. In my university lab, one postdoc joked that adding fluorine to any ring system is like giving a Porsche an upgraded suspension—the thing just handles better. It can resist acid, hold up to sunlight, and sometimes dodge the usual chemical breakdown routes.

This stubbornness makes 3,5-difluorophenol a useful piece in the toolbelt for medicinal chemistry. Teams building antibiotics or anti-inflammatories might stitch it into larger frameworks to see what perks pop up. Environmental scientists look at its persistence, tracking how quickly it degrades because longevity isn't always a win—substances that don’t break down easily can hang around in waterways or soils. That brings tough conversations about sustainability and health, long after a product leaves the lab.

Building a Safer Future With Smarter Chemistry

The future of chemistry means balancing performance with care—designing molecules that work as intended but don’t stick around longer than welcomed. Regulatory agencies and research teams suggest tracking every data point, from toxicity to breakdown. More transparency is coming; open information on composition, hazard data, and molecular properties helps non-experts gauge risk and reward long before products hit the shelves.

3,5-Difluorophenol stands as a reminder: progress in molecular tweaking comes with responsibility. Smart design leans on precision—like knowing the difference between C6H4F2O and its cousins. Progress means not just building new compounds, but making sure lab benches, factory floors, and wastewater systems handle them smart, safe, and thoughtfully.

The Character of 3,5-Difluorophenol

3,5-Difluorophenol doesn't always make headlines, but it stays present in plenty of labs and chemical warehouses. It’s a clear liquid with a sharp smell, often called into service for making pharmaceutical ingredients and specialty chemicals. I remember my early days in chemical research—bottle after bottle stuffed onto shelves, each with its own quirks. Some drew attention because mistakes wouldn’t just ruin an experiment; they’d put people and workspaces at risk. 3,5-Difluorophenol falls into that group, thanks to its reactivity and potential hazards.

Physical Properties and Hazards

It boasts a low melting point and stays a liquid at normal room temperatures. The vapor carries risk: it irritates the nose and lungs, and skin contact burns quickly. Data from Safety Data Sheets point out class-4 health risks, especially where splashing or spills hit unprotected hands and eyes. Using nitrile gloves, splash goggles, and lab coats can make all the difference, not only to your own safety but to everyone sharing the workspace. I’ve watched colleagues brush aside these steps out of impatience, and more than once, emergency showers and eye washes saved the day. Don’t skip them—no shortcut feels worth a chemical burn or a call to the ER.

Storage Recommendations

Keeping this compound on a shelf takes a lot more than screwing a cap on tight. Glass bottles with robust, chemical-resistant seals stand up best against its corrosive bite. Polyethylene and some fluoropolymers also do well, just don’t trust it in thin plastic or soft storage. Humidity doesn’t play nice here: water vapor in the air can turn the liquid darker and less pure, spoiling its usefulness. Airtight seals and storing away from moisture help preserve its punch for later reactions.

Careful temperature control forms a key detail. Most facilities keep it below 25°C (77°F), away from direct sunlight or any space with wide temperature swings. Too much heat and you get pressure that contorts bottles, sometimes popping seals or venting sharp fumes. Dedicated flammable storage cabinets—grounded and vented for safety—give peace of mind if fire hazards ever come into play. I’ve seen old labs stack bottles high in easily accessible corners; all it takes is a careless bump for a bottle to shatter and blanket the room with toxic vapor. Leaving 3,5-Difluorophenol out in plain sight invites trouble.

Safe Handling Practices

Handling doesn’t stop at wearing safety gear. Proper technique calls for careful pouring, using funnels, and keeping absorbent pads on hand for inevitable drips. Don’t pipette by mouth, ever. Fume hoods turn into your closest friend, not just for mixing but for simple bottle transfers too. Label everything, always; mislabeling leads to confusion, and confusion turns into mistakes with real health costs.

Disposing of excess or spilled liquid has to follow federal and local hazardous waste regulations. I once watched a technician pour stray fluids into a basic trash bin—nobody escaped the acrid stink, and a costly cleanup followed. Waste containers marked for halogenated organics save time and prevent cross-contamination.

Practical Solutions in Everyday Labs

Budget cuts can pressure teams to reuse storage containers or stretch out personal protective equipment. Skimping invites risk; a cheap bottle fails sooner, and a worn glove rips right at the wrong time. A strong lab culture helps: peer checks, updated safety posters, and regular drills keep safety habits sharp without relying on one person’s memory. Digital tracking for chemical stocks also flags expiring bottles so no one grabs a risky, degraded sample off the back shelf.

3,5-Difluorophenol brings value but asks for respect. Smart habits, proper containers, and a constant eye on safety make hard work safer and save everyone from the headaches an accident brings.

Understanding the Hazards of 3,5-Difluorophenol

3,5-Difluorophenol often pops up in chemical research labs, popping up in pharmaceutical synthesis and agrochemical development. Like a lot of aromatic compounds, this substance has its hazards. My own run-ins with similar compounds have taught me caution carries real value, especially with anything phenol-based. Even at small volumes, skin gets irritated, respiratory tracts can burn, and eyes sting.

The molecular structure, two fluorines stacked on a phenolic ring, gives extra bite. That ring anchors toxicity, while the fluorine atoms hike up volatility. Exposure usually spells out two main risk areas: contact with skin or eyes and inhalation. You smell it, you’re already late to the party. Phenols, even without the fluorines, damage tissue on contact. Think red, burning skin, and escalating discomfort.

Short-Term and Long-Term Effects You Should Know

Short bursts of exposure can blister, itch, or damage eyes. But deeper trouble sometimes creeps in. Some colleagues reported headaches and dizziness after one spill. I remember seeing an intern deal with nausea and confusion after handling phenols with poor ventilation one summer. Organ health can take a hit—a bad enough dose, and you drag liver or kidney trouble into the equation. Repeated hits may even tangle up your blood cells or nervous system over time.

It’s not uncommon to see faint coughs turn into something worse, even hospital visits in rare cases. Nobody wants a fainting spell in the lab or lingering tremors weeks later. The worry isn’t only acute symptoms but what happens with repeated low exposures. Some research flags possible links to long-term systemic toxicity if left unchecked.

Proper Precautions Matter

Respecting 3,5-Difluorophenol starts with basic protection. Forgetting gloves, mask, or goggles is asking for trouble. Nitrile gloves stand up better than latex against small molecules like this. Full goggles stop splash from reaching eyes. A splash to the face can burn, so extra gear goes a long way. I keep a face shield handy whenever I bust open a new bottle of anything phenolic. Clothing layers help, especially if anything tips or spills—bare ankles can burn just from a dropped beaker’s contents bouncing off the floor.

Ventilation plays a bigger role than people think. Fume hoods beat fans or open windows every time. Work dry, work slow, and keep windows closed. Once I saw a cloud escape because a hood was shut off for maintenance—a small mistake but a real lesson. Wash hands before touching your phone, keys, or face. Store bottles tightly sealed, away from high temps or sunlight, to prevent breakdown or leaking vapors into shared lab space.

First Aid and Emergency Focus

If things go south—exposure or spill—no hesitation helps. For skin, rinse immediately with flowing water. Eyes need at least fifteen solid minutes at the eyewash station, eyelids pried open. Remove contaminated clothes, toss them for proper decon. Anyone feeling dizzy or sick should get into open air. Bring emergency info to the attending physician—quick answers can save the day. Don’t wait for symptoms to adjust plans; acting fast matters most.

Improving Safety Beyond Basics

Equipment alone doesn’t replace good habits. Double-checking labels, clear handoff logs, and posting up rules in plain sight all help. Run regular training drills for spills and accidental contact, because panicked reactions lead to mistakes. Reporting near misses sharpens company memory—someone else’s mistake today can stop your accident tomorrow.

Easy access to material safety data sheets helps answer questions on the fly. Employers who invest in sturdy fume hoods and keep spill kits stocked reduce real harm. Culture makes the biggest difference—people watch for each other, habits rub off, and the next generation builds on our caution. Safety isn’t a box-ticker, it works as a living process that takes everyone to make it stick.

Background and Laboratory Experience

3,5-Difluorophenol shows up in labs across pharmaceutical, chemical, and agrochemical research. Over years spent around benchtops and analytical instruments, I’ve seen how even small differences in material quality affect downstream work. The industry cares deeply about purity and the look of reagents, particularly for fine chemicals like 3,5-Difluorophenol, because tiny impurities can spoil reactions, push yields down, or complicate analysis.

Purity: Why It Matters and Typical Ranges

Synthesizing and using 3,5-Difluorophenol practically hinges on purity. Buyers often ask for purity levels above 98%. This standard appears everywhere in technical sheets and catalogs. It’s not only about hitting a number; it’s about avoiding side products that can sneak in during synthesis. Nitrophenol, chlorophenol, or monofluorinated traces wreck the confidence in certain analytical results. Analytical tools like high-performance liquid chromatography (HPLC), gas chromatography (GC), and nuclear magnetic resonance (NMR) shine a light on tiny amounts of contamination that can derail sensitive reactions.

Some suppliers deliver grades labeled 98%, 99%, or higher. In-house, I often saw chemists picking the 99%-plus options for critical projects, especially in API synthesis or biological screening. The difference between 98% and 99% may sound small, but trace metals or solvent residues below the surface can cause headaches. Rigorous purification—distillation, recrystallization, or silica filtration—pushes grade higher, but adds to cost and procurement time.

Visual Characteristics: What Chemists Expect to See

3,5-Difluorophenol is an aromatic compound recognizable by its white, off-white, or sometimes faintly beige solid appearance. Most chemists expect crystals or a powdery substance, sometimes with clumps after shipment. Moisture, temperature, and the specific handling in warehouses can nudge the color off-white, but a sharp brown or yellow tone always triggers suspicion. In my experience, if a batch arrives with an unexpected hue, people send it straight to QC labs for verification—it’s that serious.

Physical state changes with temperature. The melting point of this compound hovers around 40-44 °C, so under warm storage or shipping conditions, containers may show a liquefied residue or solid chunks re-solidified at the bottom. If I left a bottle near a sunlit window or in a warm storeroom, it could go from powder to gooey and back to powder again by the next morning. This property frustrates chemists who want a neat, dry powder without fuss.

Addressing Common Challenges

Batches sometimes turn up with trace moisture or solvent trapped inside, clouding the substance or making it clumpy. Silica gel packets and tight seals make a difference, and many labs store it in desiccators to keep the look and performance consistent. Over time, my labmates and I learned to check suppliers’ batch records and ask for recent purity analysis. A reliable certificate of analysis (COA) with spectral readouts gave us a baseline for trusting the material in high-stakes synthesis.

Safer sourcing practices mean going beyond the supplier’s word. Reputable producers maintain up-to-date safety data sheets and reveal all contaminants above 0.1%. Open communication with vendors helps smooth out supply hiccups, like batches with the wrong appearance or purity. Pointed feedback also nudges suppliers to tighten purification or tweak their documentation.

Improving Quality and Transparency

Increasing purity and keeping a consistent look requires vigilance from both producers and users. Labs that actively test each new delivery, document handling conditions, and work with established suppliers keep surprises to a minimum. Building supplier relationships and requesting detailed batch histories forms better habits in the industry. As demand for 3,5-Difluorophenol in advanced research rises, clearer sourcing and transparency standards will keep experiments running paid and results more reliable.