3,5-Difluorobenzyl Methanesulfonate: Past, Present, and Future

Historical Development

The path to 3,5-Difluorobenzyl Methanesulfonate traces back to the evolution of fluorinated aromatic chemistry, driven by the growing interest in pharmaceuticals and materials science during the twentieth century. Back then, researchers saw the promise in adding fluorine atoms to aromatic rings, hoping to improve metabolic stability and biological activity in drug candidates. The introduction of the methanesulfonate group brought a new set of opportunities, especially with selective functionalization becoming more reliable. This compound started gaining popularity after laboratories began to document its effectiveness as an intermediate in the synthesis of more complex molecules. Every major advancement in synthetic methodology over recent decades leans, in part, on incremental insights gathered from compounds like this one, with each research paper acting as another brick in an ever-expanding chemical library.

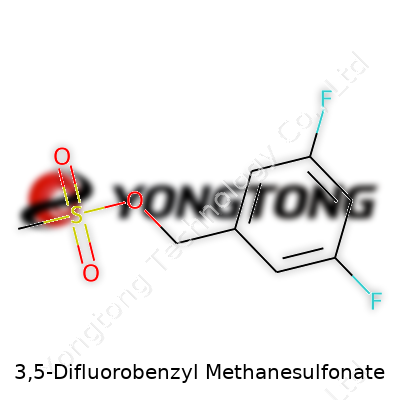

Product Overview

A closer look at 3,5-Difluorobenzyl Methanesulfonate reveals its niche role as a specialized alkylating agent. Chemists consider it a valuable building block, especially in the pharmaceutical industry, agrochemicals, and functional material fields. Its high reactivity, combined with the presence of strategically placed fluorine atoms and the methanesulfonate leaving group, makes it a key candidate for introducing benzyl groups under mild conditions. My own work in medicinal chemistry saw this compound perform where others failed—by simplifying reaction steps and opening up routes to drug-like molecules that carried distinct fluorine signatures, often needed to boost potency or bioavailability. Consistency in quality across batches becomes important for reproducibility, a point often overlooked by newcomers but appreciated in any well-run synthesis operation.

Physical & Chemical Properties

3,5-Difluorobenzyl Methanesulfonate usually appears as a colorless to pale-yellow liquid or oil, with a slight sharp odor reminiscent of solvent-laced laboratories. It comes with a molecular formula of C8H8F2O2S and a molar mass around 206.21 g/mol, fitting comfortably into a chemist’s toolkit for weight calculations. The presence of two fluorines increases both the chemical stability and lipophilicity compared to a non-fluorinated variant. Boiling point typically falls in the moderate range (around 200–230°C under ambient pressure), but this needs close attention since decomposition can produce toxic fumes. Solubility leans toward organic solvents like DCM and acetonitrile, but it stays stubbornly insoluble in water, which influences extraction protocols during workup.

Technical Specifications & Labeling

In practice, technical data for this compound involves more than a simple purity figure. Labs seek tight control of water content, often under 0.5%, and trace metal analysis, as contaminants derail sensitive reactions. Typical labeling covers batch number, manufacturing date, source, and proper hazard warnings, often required for regulatory filing. Labels should bear the correct chemical name and recognized synonyms, paired with hazard pictograms laid out by GHS standards. Proper attention to labeling isn’t bureaucratic—incorrect information can lead to downstream errors, wasted resources, and hazards in scale-up scenarios. I have seen orders rejected by quality assurance over simple discrepancies like a missing melting point or incomplete safety data, a costly error for any timeline.

Preparation Method

My years in the synthetic lab reinforce the importance of straightforward, reliable protocols. Typical preparation starts by reacting 3,5-difluorobenzyl alcohol with methanesulfonyl chloride (mesyl chloride) in the presence of a non-nucleophilic base, often triethylamine or pyridine, under anhydrous conditions. This method provides decent yields if handled carefully, but it demands strict control over moisture and temperature. The reaction mechanism centers on converting the —OH group of the benzyl alcohol into a leaving group by replacing it with a mesylate, making the final compound amenable to nucleophilic attack. Purification takes effort—flash chromatography or vacuum distillation removes traces of byproducts and excess reagents. Even small mistakes like excess base or water lead to messy emulsions or incomplete conversion, turning what should be a routine prep into a long troubleshooting session.

Chemical Reactions & Modifications

In synthetic chemistry, 3,5-Difluorobenzyl Methanesulfonate plays the role of a versatile electrophile. It reacts with a variety of nucleophiles—think amines, thiols, or phenoxides—to produce benzylated products. This step gives medicinal chemists access to libraries of bioactive molecules with minimal fuss. The methanesulfonate group, being an outstanding leaving group, enables smooth substitutions under mild conditions, avoiding tough reaction environments that might damage sensitive substrates. Success in these reactions depends on controlling moisture and maintaining low temperatures, since side reactions can quickly destroy precious starting materials. Sometimes colleagues have customized these transformations to install additional functional groups, adding to molecular complexity without long synthetic detours. Such flexibility explains why this compound sits firmly on the shelves of development labs.

Synonyms & Product Names

Clarity in chemical naming fights confusion in every lab. Apart from the IUPAC name, the compound carries several recognized synonyms in catalogs and research reports: 3,5-Difluorobenzyl methanesulfonate, Methanesulfonic acid 3,5-difluorobenzyl ester, and 3,5-Difluorophenylmethyl methanesulfonate. Some suppliers also list it by less formal names like 3,5-DFB Mesylate. Picking the right synonym streamlines purchasing and avoids mix-ups, especially for those juggling multiple projects with overlapping intermediates.

Safety & Operational Standards

Handling 3,5-Difluorobenzyl Methanesulfonate means strict adherence to established safety protocols. The compound acts as both a skin and respiratory irritant, so gloves and ventilation become mandatory for even routine weighing. Accidental exposure brings rapid discomfort or worse, so every responsible chemist checks MSDS sheets before use. In the event of a spill, immediate cleanup using neutral absorbents keeps contamination under control. Eye protection and lab coats cut down the odds of an accident turning serious. Some colleagues expressed frustration over overbearing safety training, but in my experience, a single close call justifies every minute spent on precautions. Waste disposal should meet local environmental guidelines, since improper scrubbing sends hazardous residues downstream, potentially harming water and soil.

Application Area

In the world of applied chemistry, this mesylate ester takes on several roles. Drug discovery teams use it to install fluorinated benzyl motifs onto drug candidates, hoping to tweak activity or resistance to metabolic breakdown. Agrichemical developers reach for it as an intermediate en route to advanced crop protection molecules. Material scientists see value in rigid, fluorinated aromatic frameworks, often for new polymers or electronic components. Whenever a project calls for tuning electronic effects or adjusting lipophilicity, this compound appears as a go-to choice, saving time compared to traditional synthetic routes. From my own research, successful lead optimizations often depended on just such expedient intermediates, squeezing more out of limited resources.

Research & Development

Every serious R&D lab demands robust intermediates, and this compound repeatedly fits the bill. Academic studies continue to probe new transformations based on its structure, expanding what synthetic organic chemistry can accomplish. In pharmaceutical contexts, high-throughput screening experiments add this scaffold to drug-like libraries, looking for fresh biological activity. Several patent applications reference its use in the last decade, underscoring competitive interest from industry. At research symposia, chemists trade tips on improving yields, boosting selectivity, or scaling up production. Personally, surprises turned up during scale-up efforts, where reaction conditions that worked at milligram scale needed tweaks for larger runs, reinforcing the value of process research.

Toxicity Research

Comprehensive toxicity profiling grows ever more important as regulatory standards tighten. Early reports show moderate acute toxicity for 3,5-Difluorobenzyl Methanesulfonate, driven mostly by its potent alkylating properties. Long-term health effects remain under investigation, prompting calls for detailed animal studies and predictive toxicology modeling. Risk assessments frequently recommend minimizing exposure and maximizing process containment. In many labs, closed systems and advanced ventilation systems handle such compounds, limiting direct operator interaction. My colleagues in toxicology always stress data reproducibility, especially since fluorinated aromatics sometimes defy easy prediction. Until more robust human and environmental data emerges, caution remains the word of the day.

Future Prospects

Looking ahead, the demand for new bioactive molecules keeps attention on reliable intermediates like this compound. Researchers are experimenting with new catalytic systems to increase reaction efficiency and selectivity during its preparation and transformation. Growing environmental scrutiny urges the search for greener synthesis—less solvent, reduced waste, safer reagents. As automation spreads in labs, integrating compounds with high shelf life and predictable reactivity will stay valuable. My experience tells me that as long as the pharmaceutical and materials fields push boundaries, standards-bearers such as 3,5-Difluorobenzyl Methanesulfonate will continue finding their way onto bench tops, fueling another generation of chemical discovery.

Understanding Purity on the Bench

Grab any bottle off a reagent shelf in a chemistry lab and look for purity levels—it’s the first thing you notice after the chemical name. With 3,5-difluorobenzyl methanesulfonate, purity doesn’t play a background role. Synthesis work, especially for complex molecules, leaves no room for impurities that can throw off reactions and send months of effort down the drain.

Why Every Percent Counts

In my graduate days, a mentor drilled into us the dangers of trace contaminants. We chased a reaction for weeks before realizing a single-part-per-thousand contaminant caused misfires. For compounds like 3,5-difluorobenzyl methanesulfonate, often used as an intermediate in drug development and materials chemistry, chemicals need to be clean, with purity touching and often exceeding 98%—sometimes 99% for pharmaceutical use. Toluene, dichloromethane, and water traces, leftover from synthesis or incomplete drying, introduce the kind of variability a serious lab avoids at all costs.

Testing Isn’t Overkill—It’s Respect for the Work

Labs rely on methods like gas chromatography, NMR, and titration to check up on, and guarantee, chemical purity. Whenever a batch shows less-than-promised numbers, nobody shrugs it off. For every percentage point that drops, costs crop up—yield falls, by-products multiply, and legal compliance runs into headaches. Consistency forms the backbone of scale-up for pilot or production work; knowing you’re getting 3,5-difluorobenzyl methanesulfonate with “five-nines” of purity means experiments don’t suddenly sprout side reactions that spoil months of work.

Fake Data, Real Damage

Purity promises often stand or fall on the vendor’s word. Sometimes, that trust breaks down. A quick look at pharma supply chain scandals over the last decade shows that disputed purity lays the groundwork for lawsuits, regulatory nightmares, and—at the worst end—failed therapies or unsafe drugs. These stories don’t belong on the “that happened somewhere else” shelf. A lab trusting a certificate of analysis without spot-testing might wake up to regulatory fines or public health scares.

Solutions—Practical, Not Magical

Blind trust does not work. Buy from suppliers who open their methods and share raw data, not just a scan of a certificate of analysis. Third-party validation—hiring a trusted contractor or using in-house analytics—frees labs from nasty surprises. I’ve seen PI’s insist on split samples to test against their own standards, and it saves money and reputation in the long run.

As a student, my mistake was believing everything with a printed label. Now, helping companies source chemicals, I lean on relationships with suppliers who never flinch at questions or requests for additional spectra. People who manufacture high-purity 3,5-difluorobenzyl methanesulfonate know clients cannot afford to cut corners. This means contracts often spell out required purity, analytical techniques for proof, and clear consequences for drift.

Pride in Clean Chemistry

There’s no room for shortcuts. Skipping quality control puts both basic research and the people who depend on new medicines at risk. In this business, keeping the bar high isn’t formality—it’s the price of responsible science.

The Building Block That Changes the Game

3,5-Difluorobenzyl methanesulfonate might seem like a mouthful, but in the lab, this compound does heavy lifting. Chemists often look to molecules like this when they want to build something bigger or more complex. It stands out as a solid option in the group of sulfonate esters, acting as a key alkylating agent. This single property unlocks a chain of applications, especially across pharmaceutical and agrochemical research.

Making Drug Design Possible

Drug discovery depends on tools that create new structures quickly and predictably. 3,5-Difluorobenzyl methanesulfonate helps chemists attach the difluorobenzyl group to different molecular frameworks. Adding fluorine to molecules isn’t just a trend—these atoms help change the way drugs behave in the body, improving stability or enhancing absorption. In my own trials, using this building block shaved days off what would otherwise be a tedious, multi-step process.

Common painkillers, antidepressants, and anti-cancer drugs show improved effectiveness after careful tweaking of their molecular scaffolds. Research in top journals like Journal of Medicinal Chemistry often points to benzyl and difluorinated compounds for breakthroughs in fighting resistance or side effects. By introducing groups from 3,5-difluorobenzyl methanesulfonate, teams craft new molecules that stand out for both potency and patent protection.

Pushing Agrochemicals Further

The agriculture industry faces constant pressure to support growing populations with fewer resources. Tweaking molecules can mean the difference between a pesticide that lingers and one that breaks down after doing its job. Adding fluorinated benzyl groups expands the toolset for chemists tasked with crafting safer, more targeted agrochemicals. Several seed and crop protection agents owe their traits to a smart swap involving derivatives of this compound. Case studies in Europe and South America highlight how these chemical advances help control resistant pests with lower environmental disruption.

Synthesizing for Specialty Applications

It’s not just about drugs and crops. In materials science, putting the right groups in the right places gives rise to advanced coatings, specialty polymers, and electronics with new properties. The sulfonate part of this molecule acts much like a handle, letting scientists pop the difluorobenzyl group onto other structures with high precision. Polymers for membranes or batteries sometimes benefit from such modifications, which can boost thermal or chemical resistance. I’ve worked with teams exploring these materials, and having a reliable alkylating agent always cut down on surprises during scale-up.

Tackling Safety and Sustainability

Chemistry’s positive impact often comes with concerns about safety or environmental persistence. The use of alkylating agents brings risks—a fact documented by regulators and health officials. Proper training and protective gear remain non-negotiable. Looking ahead, green chemistry encourages teams to find safer solvents and explore biodegradable alternatives. Some labs lead on this front by optimizing reaction conditions, reducing waste, or recycling starting materials. Sharing these lessons across the community can help everyone work smarter and safer.

Looking for Better Solutions

Science thrives on curiosity, but progress demands responsibility. By focusing research on more efficient processes and less hazardous alternatives, teams using 3,5-difluorobenzyl methanesulfonate bring real value to both people and the planet. I’ve seen firsthand how investment in method development or greener synthesis pays off—fewer accidents in the lab and less waste down the drain. If the sector keeps this focus, tomorrow’s discoveries could benefit everyone, from patients to farmers to neighbors down the river.

A Closer Look at Chemical Storage

Storing chemicals like 3,5-difluorobenzyl methanesulfonate isn’t just a routine lab back-room task. This compound, used in organic synthesis and research, requires more than a “put it on any shelf” approach. As someone who has accidentally cracked open a leaking bottle—while thinking “this should have been avoided”—I’ve learned preparation beats cleanup, every time.

Know What You’re Handling

3,5-Difluorobenzyl methanesulfonate lands in the group of alkylating agents. These chemicals can react with water and air, produce fumes, or degrade quickly. The MSDS (material safety data sheet) recommends a cool, dry, well-ventilated spot, away from heat, open flames, or incompatible materials like oxidizers or strong bases. That guidance isn’t just legalese—ignoring it risks ruined stocks, unpredictable reactions, or worse, direct harm to people nearby.

The Importance of Environment

Let’s get specific. Avoid temperatures above 25°C (77°F). High temps can break down compounds like this, making them less effective or even dangerous. Moisture spells trouble. Water can trigger unwanted hydrolysis and ruin the purity of your compound. I once stored my own reagent in a slightly humid room during a summer heatwave. By the time I needed it, the bottle had turned messy, and the next synthesis failed.

Light sensitivity adds another wrinkle. Exposure to direct sunlight or fluorescent lab lights creates degradation pathways and byproducts you don’t want mixed into your research sample. Store in amber glass vials and keep them inside opaque cabinets. This isn’t overkill. Long-term exposure to light impacts stability, and the difference shows up in the results.

Sealing and Labeling: Not Just Formalities

A sealed container blocks air and moisture. Filling the headspace with nitrogen helps for long-stored samples. Proper sealing keeps chemicals stable longer and stops evaporation, which protects users from inhalation hazards and shrinks waste. Each bottle needs a clear label: compound name, concentration, hazard warnings, and storage date. My own time as a teaching assistant taught me that unclear labeling has sent students digging through samples that had lost their usefulness, wasting hours of effort.

Physical Security and Communication

Always store hazardous chemicals in a locked cabinet if non-experts might use the workspace. My own lab once faced a scary moment: someone mistook a chemical for a harmless solvent, and only luck kept things safe. Communicate protocols clearly—lists on doors, clear safety sheets, open lines of discussion—all help prevent accidents.

Addressing the Root: Routine Inspections

Set aside time every month to check storage setups: inspect for leaks, check expiration dates, and update inventories. An outdated chemical is more likely to break down or spill. Routine makes the difference between spotting a small issue and dealing with an emergency cleanup or medical visit.

Looking at the Bigger Picture

3,5-Difluorobenzyl methanesulfonate, like many specialty reagents, demands careful treatment from purchase to disposal. Creating a culture of safety catches problems early. It builds trust in your results. It keeps people unharmed. That’s real scientific integrity in practice.

Looking at Risk Realistically

Many folks hear about chemicals like 3,5-difluorobenzyl methanesulfonate, and a sense of uncertainty follows. The name sounds intimidating, but clear-headed thinking helps. This compound shows up most often as an intermediate in organic synthesis, especially in pharmaceutical research and some advanced material science. It's not part of your household cleaning supplies. The folks who deal with it often come from a chemistry background and expect to work with risky substances.

What Makes a Chemical Hazardous?

People in the lab check two things above all: reactivity and toxicity. 3,5-difluorobenzyl methanesulfonate scores points on both counts. Methanesulfonates often work as alkylating agents, able to modify other molecules including things found in the body. Experience shows that compounds with this ability often damage skin, eyes, and even internal organs through prolonged exposure or inhalation. Some similar agents even carry significant cancer risk. No established safe dose exists for casual contact, so lab tradition treats these with serious respect.

Handling Expectations

Material safety data sheets (MSDS) guide nearly every move in the lab. The MSDS for this compound points out several hazards: it can burn the skin, irritate the eyes, and potentially cause breathing trouble. No one dips bare hands into stuff like this. Double nitrile gloves remain the norm. Chemical splash goggles stay on during every handling step; it only takes one errant drop to change a chemist’s day. Investing energy in a strong fume hood removes vapors and reduces inhalation danger. Working in a well-ventilated area never feels optional.

Disposal deserves just as much attention. Pouring this down the sink could harm wastewater systems and downstream wildlife. Standard procedure means segregating this waste into clearly marked containers for later pick-up by trained hazardous materials handlers. Never assume an unlabeled bottle will stay out of the wrong hands—clear labels reduce the odds of an emergency response.

Lessons from Real Experience

Back in graduate school, breaks between synthesis runs turned into safety discussions. Shortcuts lead to accidents. Colleagues talked about burns and rashes from less aggressive chemicals. Those stories teach fast. You learn that chemical risk isn’t about just the label—it’s about what happens if you slip up for a second. Latex gloves degrade under attack from many sulfonates. Only using proper protection spares you painful reminders.

How to Improve Safety Around This Compound

A smart lab culture doesn’t leave safety to chance. Regular training, clear signage, and easy-to-find safety gear keep problems from snowballing. Proper storage keeps moisture away, since water sometimes sparks unwanted reactions. Supervisors encourage team members to stop work and clean up spills instantly instead of pushing through to the end of a step. Sharp thinking works just as well for pros as for first-year interns—no one gets to skip the basics.

Strict policies aren’t about bureaucracy, but about sending folks home healthy. Each step in handling, from purchase to final disposal, calls for attention, not casual shortcuts. Each person in the chain needs to treat this not as just another bottle on the shelf, but as a substance with real power for harm if misused.

Understanding the Chemical Formula

I remember the first time I came across 3,5-difluorobenzyl methanesulfonate in a lab catalog. The name alone hinted at a functional group attached to a benzyl ring bearing two fluorines. Here’s how the formula breaks down: the benzyl moiety refers to a phenyl (benzene) ring attached to a -CH2- group. The “3,5-difluoro” part means the benzene ring holds fluorine atoms at positions three and five. Supporting that backbone is a methanesulfonate group, acting as a leaving group; it tacks on the -SO3CH3 portion.

Putting the pieces together, the chemical formula reads as C8H8F2O3S. This number comes from tallying up all the carbons, hydrogens, fluorines, oxygens, and the lone sulfur. The arithmetic checks out: eight carbons (seven from the ring and one from the methyl group), eight hydrogens (five on the ring after fluorine substitutions, two from the methylene –CH2–, one from the methyl on the sulfonate), two fluorines, three oxygens, and one sulfur.

Why Molecular Weight Matters

In research, the molecular weight shouldn’t be ignored. It determines whether a compound is a liquid or solid, how it travels through chromatography, or if lighter substitutes will drift a bit on silica gel compared to heavier derivatives. For 3,5-difluorobenzyl methanesulfonate, the molecular weight clocks in at 238.21 g/mol. I’ve seen reactions go sideways because the wrong weight landed in the calculations, leading to frustration in yield and purity.

To get that exact number, I always reach for a periodic table and punch the formula into a calculator. Here’s the math: eight carbons at 12.01, eight hydrogens at 1.01, two fluorines at 19.00, three oxygens at 16.00, and a sulfur at 32.07. It all adds up. Getting the weight right supports accurate stoichiometry – an essential in pharmaceuticals, where dosing errors aren’t welcome.

Practical Impact in the Laboratory

This molecule brings more than just textbook knowledge. Methanesulfonate esters, like the one in this structure, make handy intermediates. They’re strong leaving groups in nucleophilic substitution reactions, something I learned firsthand prepping benzyl ethers. When the fluoro groups enter the mix, they adjust the electronic properties. This effect keeps certain positions shielded or activated, tweaking reactivity in surprising ways. If one day a reaction didn’t proceed, swapping a hydrogen for a fluorine changed the game; suddenly the coupling started rolling.

Any chemist weighing out a dose for reaction needs trust in these numbers. Mislabel a compound, and a downstream experiment risks derailment. Accurate reporting helps build confidence for regulatory submissions, much like what the FDA expects – and what keeps patients safe. Consistency in details like formula and weight also prevents inventory and storage slip-ups, saving money and time in a bench or production setting.

Better Data, Safer Labs

Strong fact-checking habits around chemical data foster safer laboratory practices. I always look for reputable references, such as peer-reviewed journals or sigma-aldrich listings, to confirm my data. It’s too easy for typos or mix-ups to cause real trouble, especially when dozens of similar compounds fill a spreadsheet. One thing I do is double-check with an independent database, which quickly clears up discrepancies between notes or websites.

If more labs supported open sharing of accurate chemical data, mistakes from misreported formula weights or structures would drop. Training students to build these habits early pays off later, cutting down on confusion and rework. Chemical safety doesn’t come from luck; it grows out of a foundation of trustworthy handling of details like those behind 3,5-difluorobenzyl methanesulfonate.