3,5-Difluoroanisole: A Close Look at a Versatile Building Block

Historical Development

Chemists didn’t just stumble across 3,5-difluoroanisole overnight. This compound started turning heads during the late 20th century, when researchers working with fluorinated aromatics began searching for alternatives to common methyl and methoxybenzenes. As pharmaceuticals and high-performance materials leaned more into the unique effects of fluorine, the demand picked up. Large-scale industrial synthesis took shape as folks realized that placing fluorine atoms on the aromatic ring—especially at the 3 and 5 positions—unlocked new biological activities and material properties. Since the 1990s, patent activity drifted steadily upward, with new uses showing up almost every year in agrochemicals, pharmaceutics, and specialty chemistry.

Product Overview

3,5-Difluoroanisole stands out among fluorinated phenyl ethers. It brings a blend of stability and reactivity to both research labs and manufacturing plants. Its methoxy group protects the benzene ring, while the two fluorines tune its electron density, creating a platform for further transformation. The standard grade usually appears as a colorless, transparent liquid, offering good shelf life under the right conditions. Its odor falls somewhere between subtle and slightly sweet, but this scent belies the heavy lifting it can do downstream. Chemists favor it as an intermediate; its structure fits easily into more complex molecules without dramatic side reactions.

Physical & Chemical Properties

Temperature determines much of what 3,5-difluoroanisole can and cannot do. With a boiling point right around 155°C and a melting point that keeps it liquid at room temperature, this chemical handles routine lab conditions well. Its density comes in at about 1.2 g/cm³, heavier than most simple aromatics thanks to those two fluorine atoms. The molecular weight—146.12 g/mol—keeps it solidly in the small molecule camp, so chemists can move between milligrams and kilograms without losing track. Its solubility sits highest in organic solvents like diethyl ether, dichloromethane, or acetone, but it barely cooperates with water. That hydrophobic nature makes it easy to extract or purify during synthesis.

Technical Specifications & Labeling

Suppliers mark out 3,5-difluoroanisole with strict identifiers: CAS number 455-81-8 stands as the universal tag. Purity levels often start at 98% or higher—any less, and the risk of side products goes up. Labels must spell out hazards in bold: "flammable liquid," "may cause skin irritation," and the like. Container sizes range from 25 mL amber-glass bottles for bench work to one-liter drums for process chemistry. Regulatory data usually meets standards set out by bodies like REACH in Europe or TSCA in the US, so buyers know what restrictions apply. GHS pictograms draw attention to flammability and irritant hazards, an added reminder for lab staff.

Preparation Method

Synthesizing 3,5-difluoroanisole usually starts with a phenol backbone, built up with two fluorine atoms using selective halogenation on an anisole precursor. Direct introduction of the methoxy group follows, often using sodium methoxide or methyl iodide in the presence of a metal catalyst. Control plays a key role here: each step may call for low temperatures to lock in regioselectivity and reduce unwanted byproducts. Industrial-scale syntheses sometimes favor nucleophilic aromatic substitution, letting fluoride ions punch into activated sites after the methoxy group goes on. Purification typically relies on vacuum distillation and column chromatography, to ensure every batch leaves the factory as close to specification as possible.

Chemical Reactions & Modifications

Chemists often reach for 3,5-difluoroanisole during multi-step synthesis. It can anchor Suzuki-Miyaura cross-couplings, building up complexity one carbon at a time. The fluorines both activate and block substitution, helping direct new groups to just the right spots. Nitration or halogenation reactions usually proceed cleanly, with product yields holding up even at moderate scale. Its methoxy group sometimes gets swapped out for amines or thiols with the right catalysts, unlocking new applications without tossing the whole scaffold. If you’re building an agrochemical lead or a something for a novel OLED material, this compound becomes a flexible intermediate.

Synonyms & Product Names

Chemists know this compound by more than one name. The IUPAC system spells it out as 1-methoxy-3,5-difluorobenzene. Some catalogs abbreviate it to just "3,5-DFA" or similar variations. In older journal articles, you may find references to "m-difluoroanisole" or "alpha, gamma-difluoroanisole," reflecting its substitution pattern. Specialty suppliers sometimes give it trade names that target a specific application, but for most, the CAS number stays the most important identifier.

Safety & Operational Standards

Every bottle of 3,5-difluoroanisole needs careful handling. Workers protect their eyes, skin, and lungs using basic PPE: nitrile gloves, splash goggles, and lab coats. Spills can generate slippery surfaces, so work atop absorbent pads and inside fume hoods. Fire risk stays elevated around open flames, since vapors catch easily. Waste streams flow into organic disposal bins; no one sends it down the drain. Emergency procedures include eyewash access and spill kits on hand, making sure staff avoid direct contact. Regulatory audits may check labels, storage logs, and safety data sheets for lapses, since human health always comes first.

Application Area

Industries across the map find uses for 3,5-difluoroanisole. Pharmaceutical firms use it to build core motifs for enzyme inhibitors, antiviral drugs, and even diagnostic agents. Agrochemical researchers synthesize herbicides and insecticides, aiming for molecules that break down safely after use, with the difluoro motif increasing selectivity. Electronics companies blend it into liquid crystal and OLED precursors, chasing better display colors and durability. Academic labs chase novel reactivity, using it as a launchpad for anything from conjugated polymers to photoinitiators. Its role as an adaptable intermediate keeps it stocked on shelves worldwide.

Research & Development

R&D teams take a close look at how small changes in the aromatic ring shift yields or tune biological effects. Chemists design new fluorinated scaffolds, hoping to uncover compounds that resist metabolic breakdown or bind more tightly to their protein targets. Funding bodies in the US and EU have backed projects involving 3,5-difluoroanisole, especially in partnership with academic researchers. The publication record continues to build, as scientists look for structure-activity relationships or test new catalytic systems that speed up its functionalization.

Toxicity Research

3,5-Difluoroanisole doesn’t carry an extensive toxicity record, but early findings suggest this compound needs respect. Animal studies indicate moderate oral and dermal toxicity, though no widespread environmental issues have cropped up at typical use levels. Respiratory exposure leads to irritation, but no strong evidence links it with carcinogenicity or chronic disease in humans. Still, exposure limits recommend time under the hood and regular air quality checks, especially in settings where solvents or similar aromatics could accumulate. Waste management matters: improper disposal can lead to bioaccumulation risks, so compliance with local and international guidelines remains critical.

Future Prospects

The next decade looks bright for 3,5-difluoroanisole. Companies keep pushing this compound into new territory, eyeing improved pharmaceuticals, smarter crop protectants, and stronger organic materials. Synthetic chemists dig for new catalysis strategies, chasing greener routes that cut down on waste and energy use. R&D labs collect more data on safety and downstream effects, aiming for workflows that blend innovation with responsibility. As battery chemistry and display technology shift, new applications may yet arise—so anyone working with fine chemicals would do well to keep an eye on this underestimated intermediate.

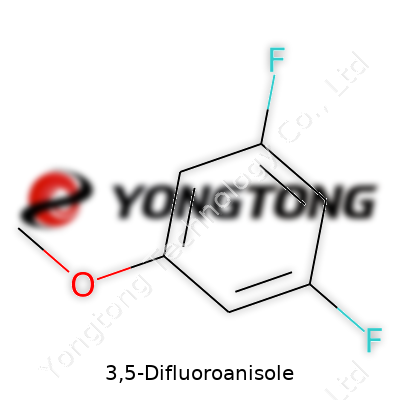

Understanding Chemical Structure: 3,5-Difluoroanisole

If you look at the molecular formula for 3,5-Difluoroanisole, it reads C7H6F2O. In plain terms, it’s a benzene ring loaded with a methoxy group (–OCH3) and two fluorine atoms anchored at the 3rd and 5th positions. Chemists label these positions based on the methoxy group’s location, counting around the ring until reaching the spots that carry the fluorine atoms. This arrangement doesn’t happen by accident; chemists build it with intent, mainly for its specific reactivity and uses in pharmaceuticals or materials science.

The Backbone and Substituents

The compound’s core is a simple aromatic ring. Attach a methoxy group at spot number one for the typical anisole base. Dropping two fluorines at positions three and five isn’t just for the fun of it. Tossing fluorines onto a benzene ring shakes up the way the molecule behaves. Fluorine’s strong pull changes how electrons dance around, shifting the compound’s reactivity profile. This isn’t just lab talk, either. In practical chemistry, those changes draw a line between success and wasted effort, especially when hunting for new drugs or materials.

Why Does Fluorination Matter?

Adding fluorine to organic molecules isn’t a recent fad. Medicinal chemists have leaned on this move for decades. Fluorine atoms often boost metabolic stability, tinker with binding properties, and make molecules more likely to break into the right markets, like drugs or advanced plastics. In the case of 3,5-Difluoroanisole, the two fluorine atoms crank up the molecule’s oil-loving character, or lipophilicity. This change isn’t random—drugs with the right balance here slip through cell walls and last longer in the body. Fluorine can also help nudge compounds into the sweet spot where they block a disease enzyme or sneak past biological barriers.

My Take from the Lab Bench

Working with difluorinated aromatic compounds brings a few challenges and surprises. I’ve made similar molecules in grad school—taking simple anisoles, pronouncing a wish, then flipping on the fume hood and starting the slow slog of reactions, purifications, and NMR checks. Every tweak on the ring means temperature changes, new solvents, and different isolation steps. Sometimes, the two fluorines stubbornly resist attaching where you want them. It takes some grit and more than a little patience.

The payoff shows in the data. Those difluoro tweaks adjust melting points, boiling points, and how the molecule interacts with enzymes. Some compounds leap in potency, others stall. That hands-on work teaches the limits and gives a healthy respect for why pharmaceutical companies hire so many smart chemists to work out these puzzles. 3,5-Difluoroanisole isn’t just a chemical curiosity. Every new tweak opens up a shot at better medicines or tougher materials.

What Stands in the Way—and Steps Forward

Chemists run into bottlenecks during synthesis and scale-up. The presence of fluorine means some reactions run slow or chew through expensive reagents. Waste treatment also raises red flags—fluorinated byproducts can hang around in water long after the lab work is done. The world’s push for greener chemistry means labs now work on cleaner ways to add fluorine, recycle solvents, and scrub up waste streams. With each new study, researchers keep asking if smarter routes can be found, using milder reagents or renewable feedstocks. Investment in sustainable chemistry isn’t just the right thing; it’s the only route forward in a world that counts every atom and every drop of solvent.

Final Thoughts on Its Relevance

3,5-Difluoroanisole stands as more than a chemical structure on paper. Its pattern brings something special to the table—stability, selectivity, and potential new uses in health and materials technology. To anyone working at the intersection of chemistry and human need, every substitution on that aromatic ring holds a story of challenge, discovery, and progress.

Why Chemists Value 3,5-Difluoroanisole

Walk through any modern chemical research lab and ask a synthetic chemist about useful building blocks, and you’ll likely see 3,5-difluoroanisole on their shelf. This compound uses its unique structure to open up several paths for creating advanced molecules. Over the years, I’ve seen it play a quiet supporting role in research projects focused on fine-tuning molecular performance. It makes sense, since the two fluorines on the aromatic ring do more than tweak a scent or alter solubility—they guide reactivity, making new reactions possible.

Pharmaceutical Innovation Gets a Boost

Drug discovery teams keep a close eye on how molecules interact with enzymes and receptors, right down to how tiny modifications affect function. 3,5-difluoroanisole often shows up in medicinal chemistry because the pair of fluorine atoms can help introduce metabolic stability, improve binding profiles, and even reduce side effects. There’s a long trail of patents and published articles on compounds that rely on its core structure to tweak inflammation, target cancer cells, or block an enzyme. Of course, chemists always look for safer, more effective therapies, and this molecule serves as a stepping stone in the search.

Material Science and Electronics

Material chemists work with more than just plastics and metals. Molecules like 3,5-difluoroanisole lend themselves to crafting organic semiconductors and liquid crystals. I’ve sat in conference rooms where researchers describe how subtle differences in molecular geometry lead to new screen technologies or faster sensors. The anisole core resists breakdown during processing and the dual fluorines fine-tune electronic properties, which is why this compound is so attractive when researchers design new displays or solar cells.

Agrochemical Research: Improving Crops and Yields

Crops battle fungi, insects, and weeds every growing season. Scientists in agrochemical development have looked to 3,5-difluoroanisole for inspiration when making new crop protection agents. Adding fluorines not only changes the activity of these agents but also controls how long they stick around in soils or on leaves. These are choices that matter for the environment and for farmers who rely on safer, more targeted treatments.

The Fragrance and Flavor Factor

Not every application comes from the sterile world of pharmaceutical and industrial labs. The fragrance industry often explores new aroma ingredients to shape how we experience perfume or candles. The anisole backbone brings a sweet, slightly spicy character, which perfumers appreciate. By swapping in fluorines, creators can adjust how long the scent lingers in the air, add a modern twist, or ramp up scent stability. As someone who’s wandered through fragrance trade shows, it’s clear that new molecules with such fine-tuned features can set trends.

Looking Ahead: Responsible Chemistry

Across research settings, the best results come from open discussion about risk, waste, and responsibility. Every chemist knows that introducing new molecules into the world calls for steady testing and transparency. 3,5-difluoroanisole’s track record comes from years of study and plenty of collaboration between chemists, toxicologists, and regulators. The next chapter will focus on minimizing waste, sourcing responsibly, and continuing the search for greener ways to make and use essential molecules like this one.

Weighing In on 3,5-Difluoroanisole

Walking through the maze of chemical names, 3,5-Difluoroanisole might look intimidating to most people, but beneath the jargon is a simple story about atoms and math. This compound, with two fluorine atoms attached to the benzene ring and a methoxy group rounding out its structure, packs a precise punch in terms of molecular weight—a value that chemists, pharmacists, and researchers check before anything else. Why does it matter that this number comes out to 146.12 g/mol? Because in science, numbers like this often mean the difference between an experiment that clicks and one that fizzles.

The Math Is Real—So Are Its Effects

Calculating the molecular weight isn’t smoke and mirrors; it’s about counting the atoms that make up the molecule. Here’s how it breaks down for 3,5-Difluoroanisole (C7H6F2O): you’ve got seven carbons (7 x 12.01), six hydrogens (6 x 1.01), two fluorines (2 x 19.00), and one oxygen (16.00). Chemists don’t estimate these numbers—they use precise measurements because a single miscalculation can trip up everything from dosage in a lab to the way a reaction behaves. Over the years, I’ve watched more than one project get held up because folks skipped this step or went with rough numbers.

Real-World Stakes: Why Precision Matters

Everyday chemistry routines, from formulating new drugs to materials testing, depend on knowing exact weights. Take drug development. If the team skips out on checking the molecular weight, someone down the line could end up with a product where the active ingredient falls short (or overshoots), rendering a pill either useless or dangerous. One wrong atom here or there, and the margin for error closes in quickly. I’ve seen colleagues go back to the drawing board more than once due to a botched calculation like this.

Molecular weight also shapes how compounds move in the body, dissolve, or react with others. It tells you how much of the substance you have by just weighing it out. Scale up to manufacturing, and that one number controls batch yields, shipping weights, and how customs classifies the shipment crossing a border.

Clear Steps to Accuracy

Nobody enjoys double-checking figures, but chemistry punishes the careless. My advice to anyone handling new compounds is simple: don’t rely on memory or hasty lookups. There are databases—like PubChem or ChemSpider—that confirm molecular weights quickly. Calculators help but understanding atomic weights and being able to tally up the numbers always pays off. One of my past mentors insisted on running these by hand at least once before trusting any software—those habits save time and face in the long run.

If a team or researcher feels pressed for time, investing in standard digital tools helps reduce mistakes. Setting up a lab with easy-to-use reference materials and checklists makes this less of a chore. Sharing responsibility across team members strengthens checks and builds a cooperative environment; no one person carries all the risk of error.

Learning from the Details

A single value like the molecular weight of 3,5-Difluoroanisole ripples through every part of a chemical workflow, from theory to the finished product. It’s not glamorous, but it’s a foundation I trust more than promises or shortcuts. If one thing keeps researchers out of trouble, it’s starting with the numbers that don’t lie.

Why 3,5-Difluoroanisole Deserves Special Attention

Every lab tech has a story about handling chemicals that look harmless but demand respect. 3,5-Difluoroanisole, a clear, organic liquid with two fluorine atoms, falls right into that camp. It doesn’t appear dramatic in a bottle, but its volatility separates it from substances you just toss in a cabinet and forget. Looking at its material safety data, you spot immediate red flags: strong odor, potential toxicity, and low flash point.

Storing with a Mindset for Safety

Anyone who’s stored flammable organics knows space matters. Always park 3,5-Difluoroanisole in a flammables cabinet away from sunlight, open flames, or heat sources. This chemical reacts poorly to temperature changes, so a cool, dry spot makes a difference. Even small leaks can risk inhalation exposure or cause vapors to build up in closed quarters. Every safety manual worth its salt spells out the value of tight containers—metal cans or amber glass work, as long as the seals fight off air and moisture. And don’t stash acids, strong oxidizers, or bases nearby. Accelerating a chemical reaction in storage will ruin a good day.

Personal Experience: The Power of Good Labeling

I’ve seen what happens when someone relies on memory instead of a marker. Always label the container with the date received, hazard class, and your chemical’s identity. Once, a missing label forced an afternoon of detective work—dozens of potential hazards, all because someone skipped this step. Good organization saves hours and keeps everyone healthy. Digital inventory can help, but nothing beats eyes and clarity in the storage room.

Ventilation and Containment: Best Friends in the Lab

Vapor from organofluorine compounds spreads easily. Adequate ventilation keeps concentrations far below dangerous levels. I always check the exhaust before opening a bottle. Storage areas work best with ventilation systems that sweep out fumes and never let gases hover above ground. Spills can soak into absorbent surfaces if left unchecked. Any cabinet holding these kinds of chemicals should come with spill trays and a plan for quick neutralization. Practice makes all the difference; a dry run through the spill kit builds muscle memory and confidence.

PPE Can’t Be an Afterthought

Even the neatest operation faces splashes and drips from time to time. I learned early that gloves rated for organic solvents and safety goggles matter more than lab coats. Latex barely slows down the molecules in 3,5-Difluoroanisole; nitrile or thicker are the way to go. Proper PPE means full coverage. On one long day, a sleeve slip led to skin contact. Immediate washing prevented major problems, but that moment stuck with me: shortcuts put people at risk.

Disposal: Not a Trash Chute Matter

Every hazardous waste bin counts. Pouring leftovers down the drain creates long-term headaches for water systems and violates regulations. Always put spent 3,5-Difluoroanisole in sealed, labeled containers designed for organic waste. My team gets yearly training on local disposal rules, and updates matter—one year’s acceptable practice may change the next. Working alongside the environmental safety office avoids surprises during an inspection and keeps the workplace in good standing.

Room for Improvement: Culture of Communication

Chemical safety works best in a community. Sharing close calls, near misses, and tips around storage and handling shapes a team that watches out for one another. An open-door policy on reporting hazards or unclear instructions means even the newest tech can raise a hand if something seems off. Recognizing patterns in these reports highlights risks before they turn into incidents. Strong documentation and peer training build resilience, and prevent hard-earned lessons from slipping through the cracks.

Sorting Through Purity Options

Ask any chemist or researcher: not all chemicals are created equal. 3,5-Difluoroanisole shows up on order forms and lab benches in several different purity grades. This isn’t just some academic subtlety—it shapes how people use it, how reliable results turn out, and even whether a project succeeds or fizzles out.

Why Purity Affects Everything

A bottle marked “98%” will not behave the same as one that says “99.9%.” Tiny traces of impurities sometimes undermine catalysts, change physical properties, or show up as ghost peaks on a chromatogram. In fragrance chemistry, a flyspeck of the wrong impurity can ruin the whole batch for perfumers or create off-notes in a consumer product. A pharmaceutical team working on a new active ingredient can’t afford to guess what minor contaminants might be present, since regulators take a hard look at every molecule in the final product.

In my time working with analytical labs, trace contaminants often proved to be the difference between passing a QC check and tossing a day’s work down the drain. These aren’t abstract horror stories—wasted raw materials and delayed projects cost real money. Take a researcher at a university: if they order the lowest grade to save a few bucks, that tiny margin might turn out to be a steep price if a key reaction suddenly doesn’t reproduce.

Applications Drive the Choice

Someone blending standard solutions for calibration in analytical chemistry usually springs for “analytical grade” or “HPLC grade” levels. These products undergo extra purification and testing, so users see cleaner backgrounds on sensitive instruments. On the other side, a synthesis scaled for chemical intermediates in plastics may take a less expensive, technical-grade batch where a little extra impurity won’t hurt.

Not every buyer understands that difference. Sometimes, logistics or budgets push labs to take what’s available, figuring “good enough” will do. But ask a process engineer hit with a contaminated intermediate and they’ll describe how difficult it can be to troubleshoot problems caused by sub-par ingredients.

Documentation Tells the Story

Reputable chemical suppliers spell out the specs. Purity is usually listed as a percent—sometimes also with known limits of water, heavy metals, or organic residues thrown in. Providers who value transparency post full Certificates of Analysis (COA) and batch numbers for traceability. Over the years, I’ve found that the extra ten minutes reviewing those details saves hours in the long run. Spotty documentation often hints at cutting corners.

How To Pick the Right Grade

Anyone ordering chemicals faces a choice. It pays to talk to technical reps and read supplier data. For an industrial run with aggressive downstream purification, tech-grade may be more than enough. In situations where every part-per-million matters, only the purest reagent passes muster.

For labs with complex quality demands, it makes sense to keep tighter control. Establish standards for which grades are suitable for each application and stick with suppliers who stand behind their material. Stay alert to price swings that don’t match the usual purity differences—sometimes a “deal” masks a compromise.

Better Practices Build Trust

As a habit, insist on documentation every step—from ordering to delivery and use. Make purity a routine talking point in the lab, not just a footnote after-the-fact. Willpower and discipline keep experiments reproducible and products safe. Clean chemistry grows from clear standards, not just clean glassware.