3,4-Difluoroaniline: Story, Structure, Safety, and Scientific Promise

Historical Development

Chemists began paying closer attention to difluorinated anilines in the mid-20th century, with 3,4-difluoroaniline appearing as a natural refinement in the quest for new building blocks in pharmaceutical and agrochemical research. The push for efficient, targeted compounds led researchers to swap hydrogen atoms on the benzene ring for fluorine, creating anilines with a unique balance of reactivity and stability. Pressed by growing interest in fluorinated intermediates, chemical catalogs started listing 3,4-difluoroaniline in the 1970s. At university labs and process chemistry benches, it became a familiar item for those exploring enzyme inhibitors and new pesticides. My own experience working in medicinal chemistry teams marked this chemical as a staple for screening fluorinated analogs, often sought after by those tweaking the activity profile of drug candidates. The compound’s story reflects demand for small molecular changes that spark big advances.

Product Overview

3,4-Difluoroaniline appears as a clear to pale yellow liquid, sometimes with a slight aromatic odor that clings tightly to any spill. Official product names include several synonyms, such as 3,4-DAF, m,p-difluoroaniline, and Aniline, 3,4-difluoro. The catalog and label might list the CAS Number as 367-25-9. Chemists rely on this compound to introduce difluoro substituents to a benzene ring in controlled and scalable ways. Its structure, just one nitrogen atom linking the amino group to the aromatic backbone, lets chemists explore a range of subsequent reactions. The placement of fluorines at the meta and para positions with respect to the amino group means it offers distinctive electronic effects that alter subsequent reactivity, making it very useful for synthesizing enzyme inhibitors, polymer additives, and advanced agrochemical intermediates.

Physical & Chemical Properties

Temperature controls matter when working with 3,4-difluoroaniline. The chemical boils at roughly 191°C and melts around -1°C. Its density falls close to 1.25 g/cm3 at room temperature, and it dissolves easily in organic solvents—ethyl acetate, chloroform, and DMSO among them. Solubility in water stays low, adding to handling challenges for those looking to use it in aqueous reactions. Its moderate basicity stems from the lone pair on nitrogen, but the fluorines pull electron density from the ring, lowering its tendency to act as a nucleophile compared to parent aniline. In the lab, chemists watch for release of toxic fumes on heating, and in my years at the hood, I learned never to let the substance sit exposed to open air for long, as even slight volatilization annoys with its persistent odor and potential for skin and airway irritation.

Technical Specifications & Labeling

Manufacturers provide 3,4-difluoroaniline in varying grades, such as analytical, industrial, or research purity, usually above 97% by GC or HPLC analysis. Containers should display hazard pictograms for acute toxicity and environmental risks. Product data sheets flag the flash point at about 69°C, and they note the dangers if it contacts strong oxidizers or acids. If received in bulk, I always verify the refractive index, assay, and impurity profile before use, since side products like monofluoroanilines can muddy up complex syntheses. Safety data sheets broadly agree on the need for well-ventilated storage and secure closures to prevent evaporation and accidental exposure.

Preparation Method

Industrial synthesis typically starts by selective fluorination of a dihalo precursor, such as 3,4-dichloronitrobenzene, followed by catalytic hydrogenation to yield the amine. Other routes rely on nucleophilic aromatic substitution of 3,4-difluoronitrobenzene, with subsequent reduction of the nitro group. In the lab, I found that using high-pressure hydrogenation with a palladium-on-carbon catalyst produced especially clean amine with minimal risk of over-reduction. For specialty or isotopically labeled material, direct amination of a fluorinated arene armed with an appropriate leaving group sometimes offers higher yields at small scale. Each method has its pros and cons, often balancing raw material cost against purification effort.

Chemical Reactions & Modifications

3,4-Difluoroaniline serves as a launch pad for further chemical creativity. The two ortho-fluorines block standard electrophilic aromatic substitution at those positions, so most transformations target the nitrogen, such as acylation to form amides or coupling reactions with activated acids and isocyanates. The compound quickly forms ureas and sulfonamides, prized in drug discovery. Palladium-catalyzed coupling chemistries, like Buchwald-Hartwig amination or Suzuki coupling, allow for the installation of aryl groups ortho or para to the amino group, depending on which positions remain open. In my own hands, the electronic withdrawing power of the fluorines toned down excessive side reactions, letting me push reaction conditions a bit harder without seeing runaway polymerization or intractable tars. This moderation opens numerous doors for those in need of robust intermediates.

Synonyms & Product Names

The labeling of 3,4-difluoroaniline can trip up those outside pure chemistry circles. Names common to chemical supply catalogs include m,p-difluoroaniline, 1-amino-3,4-difluorobenzene, and 3,4-difluorophenylamine. CAS 367-25-9 always uniquely identifies it. Brand listings sometimes shorten it to 3,4-DAF for industrial documentation. Each synonym reflects a slightly different way to look at the molecule’s structure, but all refer to the same essential compound, whether purchased in 25-gram glass bottles or 25-kilogram drums.

Safety & Operational Standards

Working with 3,4-difluoroaniline requires a set routine. The compound bears acute toxicity warnings—prolonged skin or inhalation exposure can burn or sensitize tissue, and liquid contact can sting almost immediately. Standard PPE includes nitrile gloves, goggles, and full lab coats. Engineering controls such as fume hoods become non-negotiable. Spilled material should be absorbed with inert, non-combustible matter, never allowed down the drain. Regulatory bodies classify it as hazardous waste. Disposal routes must pass through approved chemical destruction, typically incineration. After an incident with eye splash many years ago, I stick to a strict policy of double-checking containers before and after use. Training for new lab workers places special stress on safety data sheet review and spill response drills, reflecting best practices outlined by OSHA, NIOSH, and EU equivalent standards.

Application Area

Researchers and industrial chemists view 3,4-difluoroaniline as a flexible intermediate for a host of downstream syntheses. Fluorinated anilines often anchor pharmaceutical programs, particularly in CNS drug discovery, due to the potential for metabolic stability and low off-target effects. Agrochemical development teams use it to build up selective herbicides and insecticides, leveraging unique bioactivity seen in difluoro substituents. Some advanced materials groups incorporate these units for specialty polymers and resins, betting on the altered thermal or electrical properties fluorine brings. One of my projects involved synthesizing difluoro quinolines for tests as enzyme inhibitors, with 3,4-difluoroaniline at the heart of the process. Its chemical backbone survives rough reaction conditions, unlocking a longer list of modifications than simpler analogs.

Research & Development

Development chemists chase after ways to lower the cost, waste, and risk tied to 3,4-difluoroaniline production. New catalytic methods focus on site-selective fluorination, aiming to cut out hazardous byproducts and scale up batch sizes without extra waste streams. Analytical groups push for more robust ways to monitor trace impurities, since off-spec batches can threaten downstream quality in pharma and polymer runs. Structure-activity relationship studies—often pulled from academic journal data—continue to validate the role of difluoroanilines as bioisosteres in drug design. In the competitive world of high-throughput screening, researchers keep looking for more efficient routes to fluorinated building blocks, striving to beat competing labs to patentable leads.

Toxicity Research

Toxicologists map the hazards of 3,4-difluoroaniline by looking at animal models and cell assays, noting data showing oral LD50 values in rats around 300–600 mg/kg. Acute exposure irritates eyes, skin, and respiratory tract, causing symptoms ranging from dermatitis to shortness of breath in unprotected handlers. Some tests hint at possible methemoglobinemia risk, a condition where blood cannot carry oxygen as efficiently, creating special risks for repeated or high-dose settings. Studies continue to examine chronic exposure effects, but so far, evidence on carcinogenicity or mutagenicity remains limited. Regulators call for close compliance with exposure limits and spill protocols. This legacy of safety reminders shapes every step in process design where the chemical plays a role.

Future Prospects

Looking ahead, research promises new low-waste, regioselective methods for preparing fluorinated aromatic amines like 3,4-difluoroaniline. Collaborative projects between academia and industry chase sustainable, high-yielding processes that sidestep harsh reagents and cut cost per kilogram. Discovery chemists experiment with analogs to open new application windows in regulatory-compliant agrochemicals and blockbuster drugs. Advanced catalysis, digital reaction optimization, and AI-guided retrosynthesis point toward faster routes from bench to market. The ever-tightening focus on sustainability, worker safety, and environmental compliance keeps pushing manufacturers and end-users to raise production and operational standards. The blend of safety, chemistry, and innovation keeps 3,4-difluoroaniline in the toolkit of labs and mills exploring the frontiers of chemical science.

3,4-Difluoroaniline: What Sets It Apart?

3,4-Difluoroaniline stands out among aniline derivatives mostly due to those two fluorine atoms carefully sitting on its benzene ring. This sort of chemical “tinkering” gives the molecule a different reactivity than its single-fluorine or non-fluorinated cousins. Working in a chemistry lab for a few years, I learned firsthand how just one subtle difference in a molecule can open doors to entirely new fields.

Core Role in Pharmaceutical Research

One of the most important uses for 3,4-Difluoroaniline shows up in drug discovery. Medicinal chemists rely on small building blocks like this to piece together experimental molecules. That double fluorination does more than just change the name—it can subtly shift how a molecule handles itself in the body, making compounds last longer, bind more tightly, or sidestep dangerous side effects. Drugs for cancer, infections, and brain conditions often start as a drawing on a whiteboard, and building blocks like 3,4-Difluoroaniline give researchers a shot at solving real health problems. If you check the background of a new kinase inhibitor or a next-generation anti-inflammatory, you often find fluorinated anilines in its lineage.

Moving Chemical Innovation Forward

This isn’t just about medicine. Agrochemical researchers reach for molecules like 3,4-Difluoroaniline to build new pesticides or herbicides. Farmers battle weeds and pests each season, and chemical innovation can tip the balance, protecting crops and keeping the food supply steady. Synthetic chemists in large companies use these kinds of building blocks to test how different substitutions affect the potency and environmental profile of plant protectants. This helps get more out of every drop sprayed on a field, while working to reduce runoff and soil impact. I’ve read case studies where tweaks like fluorine substitutions made all the difference between a product failing or transforming agricultural practices.

Specialty Material Applications

Material science doesn’t always grab the headlines, but it changes lives in the background. 3,4-Difluoroaniline features in the process of creating certain dyes, liquid crystals, and advanced polymers. Imagine the color on your monitor, the anti-smudge coating on your glasses, or the insulation around delicate electronics. Some of those improvements trace back to clever chemical work involving fluorinated anilines. That’s not just academic chemistry either. My time volunteering with a school science club made me appreciate how often innovations in simple materials lead to stronger, longer-lasting, and more efficient devices.

Facing Responsible Use and Safety

With all this promise comes responsibility. 3,4-Difluoroaniline, like many synthetic chemicals, requires careful handling. Improper disposal or exposure can threaten water supplies and worker safety. Safety training forms a key part of daily lab life. Industry regulations push for lower emissions, safer packaging, and better tracking. Progress in green chemistry offers hope: newer synthetic strategies aim to cut waste, use recyclable solvents, and trim down toxic byproducts. Chemists, regulators, and manufacturers have a shared duty here.

Staying Ahead With Knowledge and Cooperation

Those working with chemicals like 3,4-Difluoroaniline rely on deep training, clear data sheets, and smart lab routines. Strong oversight and a culture of safety protect workers and whole communities. Sharing research across industry, health care, and agriculture helps translate lab breakthroughs into real-world improvements. By applying strict standards and honest reporting, we keep building a safer, stronger chain from chemistry to consumer.

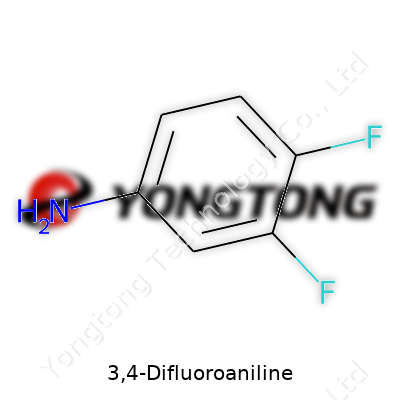

Understanding the Structure Behind the Name

Chemical names can look intimidating, but they often tell a story about a compound’s shape and function. Take 3,4-Difluoroaniline. At its heart, this compound traces back to aniline, a simple aromatic amine that’s found its way into medicines, dyes, and many more facets of daily life. The “3,4-difluoro” part reveals the tweaks made to the core structure—two fluorine atoms attached to an aromatic benzene ring at positions 3 and 4, counting from the nitrogen end. One amino group (NH2) sits at position 1. Every change in structure can force a property shift, and for researchers, these shifts hold a world of opportunity.

Why the Molecular Formula Matters

The molecular formula provides the basic chemical fingerprint of a substance. Break 3,4-Difluoroaniline down and you get C6H5F2N. That stands for six carbon atoms, five hydrogens, two fluorines, and one nitrogen. While this looks simple, it’s packed with meaning. Knowing the formula guarantees accuracy in synthesis, purity checks, and risk assessments. I still remember my first time running a reaction using a halogenated aromatic amine in the lab — one slip in the stoichiometry, and things didn’t add up. Confirming the molecular formula kept me from wasting precious hours and expensive reagents.

Practical Impact

Chemists and chemical engineers take the molecular formula and use it as a toolkit staple. Let’s say you’re working with pharmaceuticals, trying to tweak a compound’s biological activity. Fluorine atoms sit in many modern drugs, not just for show but for critical changes in solubility and metabolic stability. The specific arrangement in 3,4-Difluoroaniline adds layers of complexity. Patterns like these have helped shape everything from antibacterial drugs to agrochemicals. Robust data—like an accurate molecular formula—anchors solid research, reproducible results, and regulatory compliance.

Safety and Environmental Considerations

Halogenated aromatics, even those that seem harmless, require careful handling. Chemistry doesn’t happen in a vacuum. Working with substances like 3,4-Difluoroaniline, I’ve always checked safety sheets. Slight tweaks in a formula, like swapping a hydrogen for a fluorine, can vastly change toxicity or environmental persistence. Factoring in the exact composition helps chemists decide on safe handling, storage, and disposal. Industry standards and health regulations rely on this information. Ignoring it courts disaster.

Getting the Most from Chemical Data

Accurate molecular formulas support everything from large-scale manufacturing to classroom education. Every industry veteran I know stresses the importance of robust communication across teams—research, quality control, and regulation all benefit from clarity. An incorrect formula sows confusion, wastes time, and could even spark safety incidents. Precision earns trust and credibility.

Stepping Toward Smarter Chemistry

Challenges push scientists to keep learning. Navigating the rising tide of chemical innovation takes reliable data and a strong foundation in the basics. In my experience, pulling the molecular formula out of a name like 3,4-Difluoroaniline isn’t just an academic exercise; it shapes the way projects unfold from conception to production. It unlocks information buried in safety protocols and intellectual property filings, and underpins ethical stewardship of chemical technology. As more people take an interest in green chemistry and sustainable design, foundation skills—starting with decoding formulas—deserve a spotlight.

Why Safety Matters

Anybody who spends time around chemicals knows that a small lapse in judgment can lead to bigger problems than anybody bargained for. 3,4-Difluoroaniline falls into this tricky category. The stakes feel even higher with compounds like this because they carry potential dangers: toxicity, fire risk, and harmful effects after just a short exposure. My years in the lab taught me to never get comfortable around hazardous substances, and this one demands real respect.

Personal Protection Comes First

Chemists learn early that protective gear should feel like a second skin. For this compound, don’t even think of skipping goggles or a face shield. Splashing this stuff in your eyes can mean serious damage, fast. Gloves need to go on before opening the bottle, and not the cheap disposable sort either. Nitrile or neoprene stays strong against aromatic amines. Always throw away gloves after handling, even for a short time. A lab coat and closed shoes stay on at all times, and working in a fume hood is a must. Even seasoned chemists keep the sash low, because inhaling vapors might hurt your lungs or make you sick, and in a cramped work room, fumes collect quickly.

Smart Storage Means Fewer Accidents

Once I watched a co-worker toss a bottle of aniline derivative onto a crowded shelf. The cap was loose, and soon the air in the room had that biting, chemical smell. Nobody needs those emergencies. To avoid them, keep every container tightly closed. Store 3,4-Difluoroaniline in a cool, dry place, away from any heat sources or open flames. This compound isn’t shy about starting fires. Keeping it isolated from oxidizers and acids reduces the risk of dangerous reactions. Label every container clearly. It helps everyone stay out of trouble.

Cleaning Up Right

Spills turn a normal day into a scramble if nobody knows what to do. I remember grabbing the wrong absorbent material and making a problem even worse. Now I know to use inert absorbents like vermiculite or sand for spills, never just paper towels. Soak up the spill, seal it in a bag, and get it into hazardous waste as soon as possible. Air out the room and use proper ventilation to clear any lingering fumes. Let coworkers know about the spill right away. Nobody wants to walk into a contaminated work space by mistake.

Emergency Moves

Getting exposed to a chemical like 3,4-Difluoroaniline sends adrenaline racing. If it touches your skin, get under running water for at least fifteen minutes. Don’t wait, don’t think about it, just go. It’s distracting and sometimes scary, but it always beats a hospital visit. If it gets in the eyes, rinse right away and get medical help. Breathing fumes means moving to fresh air immediately. Colleagues can help arrange medical attention—never try to tough it out alone.

Training, Habits, and a Respectful Mindset

Over time, safety stops feeling like a checklist and becomes a habit. Training makes all the difference, not just for people new to the lab but for old hands growing complacent. It helps to stop once in a while, look over protocols, and run through emergency plans. Regular safety drills bring out flaws in old routines, and they keep the right response fresh in everyone’s mind. After years working with chemicals, I came to respect even the routine. Each small step protects lab workers, and that’s experience speaking.

Storage Risks Too Many Ignore

I’ve seen plenty of laboratories and workshops cut corners with chemical storage, thinking a tightly closed door or a simple warning sign is all it takes. That approach just invites trouble, especially with specialty chemicals like 3,4-difluoroaniline. This compound shows up in a lot of synthetic work, especially in pharmaceuticals and advanced materials. It brings some serious risks to the table, mainly because of its toxicity and flammability.

Direct Experience with Handling Makes a Difference

My years on the bench drilled in a basic lesson: respect the containers. I remember colleagues getting skin and eye irritation from trace exposures that would sneak out because a bottle cap wasn’t sealed right or was stored in the wrong place. 3,4-difluoroaniline gives off toxic fumes, and you smell them fast if you don’t take care. So keeping its container tightly sealed, using materials that won’t react with the chemical (think glass with a Teflon-lined cap), prevents vapor leaks and chemical attacks.

Shelving Choices Are Not Just About Space

Flammable liquids belong away from heat sources. I never treat those warning labels as afterthoughts. 3,4-difluoroaniline catches fire quite easily, so it sits far from open flames, heaters, hot plates, and even direct sunlight. Flammable storage cabinets, ideally with spark-proof latches, give another layer of security. I've seen fires start in places where folks thought "nothing could go wrong." Humidity can corrode some containers, so moisture-free shelves matter, and keeping the temperature cool—below 30°C—keeps pressure from building in the bottle.

Contamination: The Quiet Trouble-Maker

The tiniest amount of water, acid, or base can react with 3,4-difluoroaniline and turn a batch into hazardous waste or ignite it. I learned early on to keep incompatible substances far apart. Acids and oxidizers never share a shelf with this chemical, because accidental mixing can cause dangerous reactions. Using a separate storage area, with a clear label and a spill tray, avoids a lot of headaches.

Don’t Forget Ventilation and Safety Gear

I once helped clean up after a minor spill that turned into hours of work because the room had poor air flow. Ventilated storage keeps vapor concentrations low and helps manage any accidental releases. Every decent chemical storage setup includes this. And PPE counts for a lot: gloves made of nitrile or neoprene, tight goggles, and lab coats protect against splashes or spills. Too many people learn this lesson the hard way.

Training and Documentation Beat Panic

New staff in every lab I’ve worked in had to walk through the chemical storage protocols, and with good reason. Mishaps with 3,4-difluoroaniline are no joke, and knowing what to do in an emergency saves time, money, and health. Safety data sheets need a place on the wall, not tucked away where nobody reads them. Quick access to information, and regular practice with spill kits and fire extinguishers, stays in muscle memory.

Practical Steps Work

Careful labeling, sealed containers, cool cabinets, and dedicated spaces work best. The basics may sound simple, but they offer real protection against costly and sometimes irreversible mistakes. Chemical stewardship depends less on high-tech solutions and more on not getting complacent about the small stuff.

Why Purity Matters in Chemical Supply

Lab work rarely throws up surprises as much as suppliers who can’t get purity right. In my years running reactions that leaned on 3,4-Difluoroaniline, there’s little room for error. Purity specifications become something you check before everything else—because the smallest side product can start a cascade of problems. Unwanted impurities show up in chromatography, eat into yields, and can even poison catalysts. Lab budgets aren't huge, so repeating reactions just because a starting material missed the spec burns both time and money.

Industry Standards: What “Assay” Really Means

Manufacturers who know their business usually post an assay spec in the range of 98% and above for a compound like 3,4-Difluoroaniline. The assay usually relies on carefully validated methods like HPLC or GC, with results double-checked to calm the nerves of research chemists and quality managers alike. In most cases, you’ll see an assay listed as “≥98%,” and that’s not about perfection—just a guarantee the bottle isn’t full of mystery compounds. It’s common for catalogs to say “for synthesis,” which gives a hint that trace contaminants might exist, but nothing that should trip up a standard organic reaction.

Risks Hidden in Lower Grade Materials

I’ve opened drums that were supposed to meet the spec, only to see off-color liquid or pick up a strange whiff. Sometimes it’s water; sometimes it’s left-over solvents. If you’ve tried working with aniline traces in a rigorous process, you know what headaches contaminated supplies cause. Analytical chemists have called me, worried because a starting material sample failed their checks. That wastes weeks of planning, with everyone involved losing patience.

Lowering specifications, even “just for trials,” often boomerangs. One project I remember used a technical grade building block to save on cost. The entire batch failed QC. We had to go back, order the high purity version, and start again. The final cost was double. So, when comparing assay specs, it pays to ask how the assessment was done and to check supporting CoA (Certificate of Analysis) documents.

How Suppliers Demonstrate Trustworthiness

Quality-focused suppliers don’t just throw assay numbers on a data sheet. They communicate the detection methods and limits, list major impurities, and give buyers a direct contact for technical questions. Sometimes that earns a little more trust than any certificate does. If suppliers offer “Pharma grade” options, they include information about substances like heavy metals and residual solvents. Companies that pass their materials through additional purification—using distillation, recrystallization, or high-end chromatography—build a following among pharmaceutical outfits and academic labs alike.

The Role of Independent Third-Party Testing

There’s a growing habit among bigger firms to run their own third-party checks before a big purchase. Labs sending out incoming shipments for verification by a neutral group can sleep better knowing their supply chain isn’t about to let them down. I recall a time a batch sailed through the supplier’s checks, but our own controls found a low but critical contaminant. That’s when it hit me that relying on supplier specs alone isn’t enough—confirmation saves projects and reputations.

Moving Toward Transparent Sourcing

Scientists and purchasing teams benefit most from suppliers willing to open up about their synthesis route and routine checks. Real transparency looks like: updated assay numbers, defined impurity profile, batch-specific certificates, and support that doesn't dodge tough questions. Research teams sharing such experiences in online forums are helping push the industry forward, toward more reliable chemical sourcing and fewer ruined experiments.