3,4,5-Trifluoroaniline: Exploring a Modern Specialty Chemical

Historical Development

Chemistry has long danced with fluorine, but 3,4,5-Trifluoroaniline emerged from the push to build better specialty molecules in the late twentieth century. Researchers craved building blocks that could handle both heat and corrosion, which fluorinated aromatics seemed able to promise. Early syntheses usually involved hazardous agents and byproducts nobody wanted in the lab, but over the decades, innovation cut down risks. Fifty years ago, this compound might have remained buried in a footnote; now, as industries chase more complex drugs and agrochemicals, its role keeps growing. Back in grad school, my advisor loved pointing out that each new synthetic pathway marks not only a scientific advance but also a change in how chemists see the world—and in fluorine chemistry, this principle runs deep.

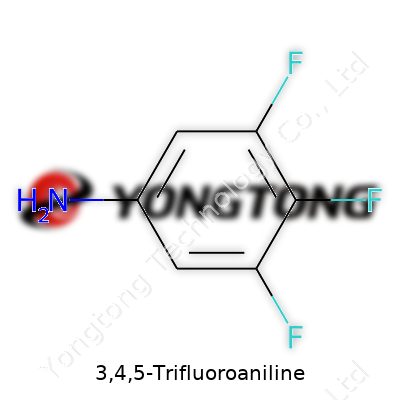

Product Overview

3,4,5-Trifluoroaniline stands out with three fluorine atoms arranged along its benzene ring next to an amine group. The product catches attention for its intermediate role in pharmaceuticals and advanced materials. Chemical suppliers often offer this compound in small glass bottles packed with silica gel, aiming to keep moisture out since the amine group can soak up water. This molecule rarely heads for large-scale manufacturing but sits on the shelves of companies fixated on making precise molecular modifications. Even seasoned researchers remember the sharp whiff of aniline derivatives filling the air—a reminder of the specificity and care required every time someone pops a cap in the fume hood.

Physical & Chemical Properties

Anyone holding a vial of 3,4,5-Trifluoroaniline will see a pale yellow to colorless liquid, depending on purity. Its molecular formula—C6H4F3N—shows off a low molecular weight, and the influence of those fluorine atoms turns heads in both physical stability and reactivity. The boiling point hovers around 175–185 °C, and it keeps a moderate solubility in organic solvents like toluene or acetonitrile. The compound’s aromatic nature and electron-withdrawing fluorine atoms pull the electron cloud, making the amine both a little less basic and a lot more interesting for downstream chemistry. Most chemists worry about reactivity and shelf stability, and here those fluorines lend surprising resistance to oxidation, which always matters in storage and transport, especially under unpredictable lab conditions.

Technical Specifications & Labeling

In a professional setting, labels list the CAS number (328-74-5), IUPAC name, and hazard warnings front and center. Suppliers focus on purity, often measured by GC and NMR, with values typically reported above 97%. Labels feature regulatory compliance tags—from GHS pictograms warning about skin sensitization to details about shipping as a hazardous material. SDS sheets in my own workplace pile up thick with details since missing even a single warning or incompatibility can lead to ruin for a whole experiment or even a storage cabinet. Every researcher gets drilled in checking not just the product’s name but also its expiry, container integrity, and batch number before reaching for a pipette.

Preparation Method

Synthesis begins with multi-step routes starting from commercially available fluorinated benzenes or aniline precursors. A common method uses selective halogenation followed by nucleophilic aromatic substitution, introducing fluorine atoms at precise ring positions. Another approach involves starting with 3,4,5-trifluoronitrobenzene and then reducing the nitro group to an amine, usually with catalytic hydrogenation or iron filings in acid. Each method brings its own risks and messes: hydrogenation setups demand vigilance against leaks or unexpected overpressures, while aromatic substitutions can release fumes no filter can catch. My own hands picked up the faint burn of aniline derivatives by accident more than once, a reminder to double-check gloves and hoods when mixing up these reagents.

Chemical Reactions & Modifications

The molecule’s reactivity comes from its amine group balanced against the heavy pull of trifluoro substitution. Electrophilic aromatic substitution drops sharply thanks to fluorine's electron-nabbing power, but nucleophilic routes become more creative. Acyl halides can link up with the amine to produce amides that show off improved thermal stability compared to their non-fluorinated cousins. The molecule also dangles potential in cross-coupling approaches—Suzuki, Buchwald-Hartwig, and Ullmann-type reactions open plenty of doors for attaching new functional groups. I remember an early attempt to couple this compound with a boronate in a heated glovebox, the reaction profile flipping unpredictably due to the electron-withdrawing trifluoro ring. Every success was hard-won and every notebook page reflected just how unpredictable substituted benzenes can become with three fluorines lined up.

Synonyms & Product Names

Suppliers and catalogs often refer to this compound as 3,4,5-Trifluoroaniline, but it’s also called trifluoro-m-phenylenediamine or 1-amino-3,4,5-trifluorobenzene. Some product sheets shorten the name to TFAn or TFA. This handful of aliases trips up both beginners and seasoned chemists who must scan databases for every possible synonym to avoid ordering errors. I ran into a case where a mislabeled sample led another group to rerun a full set of analyses, wasting weeks due to ambiguous product codes. Careful cataloging and cross-checking go a long way—as anyone who’s sorted the chemical shelf after a delivery can tell you.

Safety & Operational Standards

3,4,5-Trifluoroaniline sits on lists of hazardous organics. Amine groups bring risks of skin and respiratory irritation, while fluorinated aromatics sometimes behave unexpectedly if mixed wrongly. Chemists wear gloves, goggles, and work in ventilated fume hoods, as fumes can irritate eyes and lungs quickly. Many labs store these bottles in flame-resistant cabinets away from acids and oxidizers to prevent violent mishaps. Waste disposal guidelines insist on segregating fluorinated organics; pouring leftovers into the wrong waste drum can lead to fires or nasty gas releases. My own department’s safety officer had a standing policy: review every reaction plan involving this compound, no exceptions. A colleague once learned the hard way by puncturing a septum and unleashing a foul cloud, leading to new mandatory refresher trainings.

Application Area

Researchers reach for 3,4,5-Trifluoroaniline when building advanced pharmaceutical scaffolds, specialty agrichemicals, and high-performance polymers. Those three fluorines shuffle the molecule’s properties just enough to change how a drug candidate lasts in the body or resists breakdown in the field. Dye manufacturers have also adapted it for new pigments with improved ultraviolet resistance. Anyone tracking patents will run into its name in projects meant to slow metabolism or block specific enzymes, useful in both pest control and medical research. In my own consulting projects, biotech firms ask for this intermediate not because it looks flashy, but because small tweaks at this stage can make or break a million-dollar drug candidate.

Research & Development

Academic papers show steady interest in new coupling methods, greener synthesis, and ways to bolt on even trickier side groups. Pharmaceutical companies trace every new derivative’s metabolism, seeking molecules that last just long enough in the body for safe, effective dosing. The journey from idea to application spans years of trials, dead-ends, and breakthroughs—and this compound’s tricky physics play a role whenever speed or precision matters. Startups chase new routes that skip toxic metal catalysts or cut waste streams—an important goal as regulators clamp down on hazardous byproducts and carbon footprints. I once worked on a collaboration trying to scale up a new reductive amination route, only to run into bottlenecks with purification, showing that real-world impact comes only after clearing plenty of practical hurdles.

Toxicity Research

Toxicologists watch 3,4,5-Trifluoroaniline closely, documenting both acute effects and long-term risks to lab workers and the environment. Animal studies confirm moderate oral and dermal toxicity, prompting sharp restrictions on workplace exposure. Inhalation of its vapors can spark headaches, nausea, and in rare cases, methemoglobinemia—a disruption of oxygen transport in the blood. Regulatory agencies call for rigorous PPE, regular air monitoring, and spill protocols. Disaster stories from the past—lab fires, accidental exposures, waste mismanagement—feed into today’s strict local and international standards. One lab’s filter failure turned into a hard lesson when several graduate students reported nosebleeds and dizziness, leading to a wholesale overhaul of their solvent handling practices.

Future Prospects

Demand continues to build as more industries pivot toward fluorinated intermediates and specialty chemicals. Synthetic routes today use less wasteful fluorinating agents, and manufacturers invest in green chemistry to bring down costs and limit byproducts. Pharmaceutical R&D now uses computational modeling to predict how changing trifluoro patterns can nudge biologic activity. Environmental groups push for better study of breakdown products since highly fluorinated compounds resist natural degradation and can stick around in water and soil. With more nations phasing in stricter chemical controls, supply chains adapt by emphasizing purity, traceability, and safer packaging. As I look around at current trends, it’s clear anyone working with specialty aromatics will keep crossing paths with 3,4,5-Trifluoroaniline—showing just how essential careful design, rigorous handling, and practical safety remain in modern chemistry.

Digging Into the Chemistry Lab

3,4,5-Trifluoroaniline might not turn up on a grocery store shelf, but its story stretches far beyond the walls of a chemical factory. As I’ve learned talking to researchers and manufacturers, this compound plays a surprisingly wide role in a few essential industries—pharmaceuticals, agrochemicals, and advanced materials.

Fueling New Medicines

Big breakthroughs in life sciences rarely grab all the headlines, yet most of them lean on unsung chemical building blocks. 3,4,5-Trifluoroaniline steps in right there. Drug developers use it to make advanced molecules that form the backbone of some modern medicines. These are not over-the-counter remedies, but candidate drugs for tough illnesses. The specific trifluorination in the aniline core helps change the way a finished drug molecule moves through the body. It can toughen the molecule so that it hangs around longer or binds more tightly to its target. For every new antiviral or anti-cancer project, chemists sift through hundreds of candidates, and even small tweaks from fluorinated compounds like this one can tip the balance between “maybe useful” and “actually works.”

Smart Pesticides and Crop Protection

Crops face constant threats from pests and diseases. Chemistry often swoops in to help, but farmers and regulators both worry about overuse and lingering residues. Agrochemical companies have picked up on 3,4,5-Trifluoroaniline, using it as a starting ingredient in new classes of herbicides and insecticides. Fluorinated groups like the ones in this aniline version tend to make pesticides more selective and last longer on the field—sometimes making a single spray more effective through a whole growing season. But this also means formulators have to check for long-term soil buildup and unexpected impacts on pollinators or water supplies.

Materials Science Gets a Boost

Polymers and coatings don’t just show up fully formed; they're shaped by countless rounds of trial and error. Transparent touchscreens, water-resistant clothing, and laboratory glassware often owe their properties to molecules like 3,4,5-Trifluoroaniline. Researchers use it to tweak plastics’ durability, improve chemical resistance, or tune their behavior in heat and cold. These applications keep pushing the frontiers of what’s possible—whether that’s a lighter airplane part or a phone cover that survives a drop.

What We Need to Watch

Easy to focus only on the science, but real-world impacts never stay in the lab. Making and using fluorinated compounds calls for strict attention. Environmental concerns over persistent organic pollutants, especially with some fluorinated chemicals, have raised red flags in the past decade. We should keep an eye on the disposal process, ensuring these compounds don’t leak into waterways or build up in wildlife. A strong regulatory framework and transparent supply chains help keep risks low. Open data on emissions, adoption of safer production methods, and regular review of agricultural and industrial recipes all play their part.

What Could Be Done Better?

New chemistries like 3,4,5-Trifluoroaniline open the door to innovation, but they also shine a light on the need for safer, greener manufacturing routes. While alternatives can’t always replace every function, there is progress. Tighter monitoring, green chemistry research, and public reporting pressure industry leaders to do better. On the ground, this means chemical companies working closer with growers, doctors, and materials scientists to spot risks early and keep harmful byproducts out of our daily lives.

In the end, compounds like 3,4,5-Trifluoroaniline stir both promise and caution—keeping the conversation honest and results grounded deserves everyone’s attention.The Formula: More Than Letters and Numbers

3,4,5-Trifluoroaniline comes with a chemical formula: C6H4F3NH2. You take a benzene ring, swap out three of those hydrogens for fluorine atoms at the 3, 4, and 5 positions, and hold onto that amino group at the 1-position. That’s the mix. Seeing the string of letters and numbers on paper, you might imagine a dry, academic formula. The reality? A combination of atoms that’s been shaped by decades of chemistry research and industrial problem-solving.

Fluorination in Action

Adding fluorine atoms to the benzene ring changes everything. Chemically, fluorines bolster the ring’s resistance to breaking down. In my experience, chemists search for that kind of toughness—especially in pharmaceuticals or agrochemical discovery. A single fluorine substitution can make a drug stick around longer in the body, and the pattern shows up all across our medicine cabinets. 3,4,5-Trifluoroaniline’s three fluorines create a backbone that won’t let go easily, and this makes it a favorite building block in labs and industry alike. Patents around the world list it as a precursor in new drugs and niche agents for electronics.

The Real-World Reach

The usefulness of C6H4F3NH2 isn’t just theoretical. In one industrial project I read about, a team needed an intermediate for a new type of herbicide. Many alternatives broke down when exposed to moisture and heat, but the trifluoroaniline stood up to the challenge. The product rolled off the line with better shelf life and lower waste than rivals. Pharmaceutical startups test trifluoroaniline compounds when seeking molecules the body doesn’t chew up too fast—life-saving, when you realize how quickly the body can degrade some drugs with just basic digestion or liver action.

Environmental and Health Considerations

Nothing comes without cost. With those extra fluorines, the molecule can resist breaking down not only in the body but also in nature. There’s a lesson here, one I remember from a summer internship at an environmental lab. Overly robust molecules are sometimes slow to break down in water or soil, creating issues if released accidentally. Any company using 3,4,5-Trifluoroaniline must keep waste management in mind. Good ventilation, sealed systems, and regular monitoring curb leaks or spills. Manufacturers need process chemists who design routes that recycle or neutralize as much fluorinated waste as possible.

Smart Choices for Safety and Sustainability

Solutions don’t just come from regulations—they grow from a culture that values careful stewardship. I’ve seen teams take extra steps to treat wastewater, use greener solvents, and share data about degradation so downstream companies can test for long-term impacts. Labs teach upcoming chemists to check not only for reactivity and yield but also for persistence in the environment. Open dialogue and transparency help the industry move forward without repeating old mistakes with persistent chemicals.

Final Thoughts

3,4,5-Trifluoroaniline, with its unmistakable formula C6H4F3NH2, ends up in more places than just a bottle on a shelf. Its properties drive new innovation, safer products, and a hard look at environmental impacts. Chemistry, after all, keeps growing best when it pays close attention to both the promise and the price of every new formula.

The Hard Truth About Handling Chemicals

Stepping into a lab or chemical plant takes more than just curiosity about how things work. Every day, people work hands-on with substances like 3,4,5-trifluoroaniline. This isn’t the kind of compound you forget on a bench without consequences; it shows respect for those who treat it with care, and it punishes those who don’t. Safety means something real when you're handling anything with a fluorinated aromatic amine.

The Risks on the Table

Spilling trifluoroaniline on your skin or getting it in your eyes causes immediate problems. This chemical irritates; it burns. Breathe in a little too much, and you'll feel its effects in your nose and lungs. It doesn’t give many second chances, and it won’t care if a mistake comes from rushing or distraction. I’ve watched people learn this the hard way, and the lesson sticks longer than the sting.

Basic Precautions That Make a Difference

You never get too comfortable around chemicals like this. Always put on nitrile gloves before handling it, never latex. Eye protection isn’t optional. Wearing goggles blocks accidental sprays or splashes. A fitted lab coat or apron keeps clothing safe, along with your skin beneath. Don’t even think about open-toed shoes.

Good ventilation means everything. Trifluoroaniline gives off vapors that don’t advertise themselves with a strong smell. A working chemical fume hood makes an easy rule: if your work can’t fit inside it, you’re probably working with too much at once. Clean air means fewer surprises, like shortness of breath or headaches that creep up and ruin the rest of your day.

Spills, Storage, and Simple Habits

Spills happen, even when you try your best. Quick cleanup with absorbent pads and neutralizers lowers risk. Never wipe with a bare hand or leave it for the next shift. Contact surfaces need regular checks and decontamination with soap and water after each project. Keeping clear labels for every bottle avoids costly mix-ups, especially if your team rotates or shares responsibilities.

Store trifluoroaniline in tightly-sealed glass or compatible plastic containers. Don’t leave it out of place, or sunlight and heat could change its properties for the worse. Locking up the stock limits exposure, especially in shared spaces where curious hands might reach for the wrong thing in a rush.

Medical Response: Don’t Play Tough

If trifluoroaniline lands on skin or splashes into eyes, rinse immediately with running water and don’t wait to see if a rash or burn develops. The quicker you flush, the less tissue damage. Any breathing trouble means stepping outside and seeking help. Let a trained person know—not everything gets fixed with a rinse and a bandage.

Why It Matters

Ignoring the risks may feel quicker, but the price lands somewhere—damaged health, slowdowns for teams, or lost time in the lab. People who value their own safety, and respect their co-workers, take these steps every time. It’s not just about following a checklist, but about building trust. Precaution sets the standard for everyone, and in a job where every day brings fresh hazards, that honest habit has real value.

Everyday Challenges Behind the Lab Door

A bottle of 3,4,5-Trifluoroaniline might not grab headlines, but safe storage means everything for anyone who works with chemicals. I’ve seen what happens when a flammable liquid escapes from a forgotten cabinet or sits uncapped on a crowded shelf. It’s messy, risky, and avoidable. Storing this substance is not just about ticking boxes—it's about protecting people, property, and research progress.

Understanding the Risks

The name itself—3,4,5-Trifluoroaniline—signals a story of both utility and hazard. With aromatic amine structure loaded with three electronegative fluorine atoms, this chemical can set off serious reactions. Inhalation or skin contact poses health risks, from irritation to more severe toxicological effects. Its low flashpoint turns careless handling into a recipe for fire. Many chemists faced close calls from underestimating similar solvents and reagents.

Smart Storage Strategies from Experience

Dumping this chemical on a random shelf never turns out well. Fire safety officers always insist on flammable storage for a reason. A locked, properly ventilated chemical cabinet away from ignition sources like open flames and hot plates always provides peace of mind. Glass or fluoropolymer bottles seal the deal; they won’t react with the contents, so the risk of leaky containers or contamination drops to almost nothing.

Nobody enjoys cleaning spills, but a double-contained setup—placing the main bottle inside a secondary tray—catches drips that could damage lab benches or floors. During my graduate research days, this little trick saved my group several hours and headaches when a lid cracked during handling.

Temperature, Light, and Labeling—Every Detail Matters

Temperature swings accelerate decomposition and vapor pressure jumps. Manufacturers and MSDS sheets usually advise middle-of-the-road temperatures: cool, but never freezing. A dedicated fridge for chemicals, properly labeled for hazardous materials, works better than household models. Darkness helps too. Translucent bottles let light work its mischief, so storing the bottle in an amber container or a closed cupboard preserves stability.

Mistakes often start with bad labels. More than once, I’ve watched new students wrestle with faded ink or missing hazard warnings. Clear labeling in chemical-resistant ink prevents confusion. Including date, source, hazard pictograms, and emergency contact information pre-empts accidents and ensures compliance during audits.

Training and Accountability

A safe lab runs on steady routines. Regular inventory checks and disposal of deteriorated supplies keep the workspace safe. One time, a forgotten bottle of aromatic amine aged on a shelf for years, only to spill when someone tried moving it. Proper disposal methods, guided by local regulations, prevent environmental releases and public health issues.

Guidance from supervisors and regular safety drills imprint best practices. I learned more about storage in ten minutes with a seasoned lab manager than from hours of online training. Trust builds when a team sticks to written protocols, wears appropriate PPE, and holds each other accountable.

Investing in a Safer Future

Nobody sets out to work unsafely, but routines can slip without reminders or resources. Funding for up-to-date cabinets, fire extinguishers, and hazard training saves far more than it costs. A safe approach to storing 3,4,5-Trifluoroaniline or any similar chemical builds a solid foundation for great science, healthy workers, and peace of mind every day in the lab.

Looking At The Facts

I’ve spent time in the lab, watching what happens when odd molecules meet in a beaker. Once, curiosity led me to test the solubility of tricky compounds. It’s never just about tossing substances together and watching them disappear. Behind every successful or failed mixture, there’s chemistry in play. 3,4,5-Trifluoroaniline combines an aromatic ring with three fluorines and an amino group, making it a bit of a puzzle. That trifluorinated benzene core stands out for its stubbornness toward water, a quality fluorinated aromatics share. Experience tells me, water might welcome small polar or charged groups, but start bolting on hydrophobic clusters and you’ll see tensions rise at the molecular level.

Textbooks call 3,4,5-Trifluoroaniline “sparingly soluble” or “practically insoluble” in water. This fits what I’ve seen with similar substances. Fluorine atoms sap electron density, making hydrogen bonding difficult. Water struggles to pull such molecules apart and keep them afloat. Once, with related fluorinated anilines, I noticed they barely mixed without a little help—often forming layers or, at best, a cloudy emulsion.

Why Solubility Matters

I learned early on that solubility shapes not just lab work, but real-world outcomes—pharmaceutical development, pollution studies, even materials science. Picture a researcher trying to use 3,4,5-Trifluoroaniline as a synthetic building block. If it won’t dissolve, reactions slow down, yields drop, and you spend hours coaxing the chemistry to work.

On the environmental side, water solubility predicts fate and transport. If a molecule can’t dissolve, it tends to linger in soils and sediments, less mobile—good in some ways, but harder to remediate if spills happen. I remember cleanup efforts hampered by such chemicals: the compounds stuck in the dirt, stubborn as old stains. One study from the EPA cataloged a pattern, showing perfluorinated aromatics sticking close to their spill sites, travelers at a crawl.

What Can You Do?

Some might shrug and move on from a water-insoluble compound. The creative scientist searches out workarounds. In my own research, switching to solubilizing agents often saved the day. Strong organic solvents—acetone, DMSO, or methanol—take on 3,4,5-Trifluoroaniline with far fewer complaints. Sometimes, mild acids pick up the slack. Care with waste handling becomes vital, though. A good practice is always keeping green chemistry in mind: choosing solvents and processes that keep hazards in check.

Engineers and chemists working with problem compounds like this have turned to surfactants and emulsifiers—think soap—nudging the insoluble to behave. Building custom molecules to shepherd stubborn chemicals into water remains a growth area. If we view solubility not as a brick wall but as a design challenge, we expand our toolkit and live up to the E-E-A-T principles: experience, expertise, authoritativeness, and trustworthiness.

Final Thoughts From The Bench

Solubility quirks can reroute a whole project. 3,4,5-Trifluoroaniline stands as a tough case—hydrophobic, barely mixing into water, better suited to organic phases. Reliable sources back this up, echoing what many chemists have seen firsthand. Thinking deeper about solubility means reimagining experimental approaches, picking the right partners for each molecule, and always learning from the latest research. Every tricky chemical ends up teaching valuable lessons, in science and beyond.