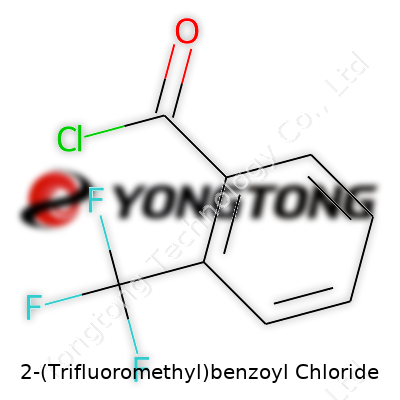

2-(Trifluoromethyl)benzoyl Chloride: An Eye on Its Evolution and Today’s Impact

Origins and Historical Perspective

Chemists didn’t find 2-(Trifluoromethyl)benzoyl chloride by accident. The early fluorine chemistry work in the mid-20th century drew researchers toward adding trifluoromethyl groups to aromatic rings. Early patents discussed halogenated derivatives as potent intermediates in pharmaceuticals and crop protection. Fluoroaromatic systems changed the approach to organic synthesis, and labs grew more interested in the crisp reactivity and added stability these new motifs brought. The drive for progress in the pharmaceutical and agrochemical sectors pushed research further, giving 2-(Trifluoromethyl)benzoyl chloride a permanent seat at the table.

Main Features and Product Walkthrough

This compound stands out in bottles or drums: a clear to pale yellow liquid. Commercial offerings come in different grades, ranging from multigram lots for the lab to hundred-kilo shipments for industrial players. 2-(Trifluoromethyl)benzoyl chloride packs a punch with its electrophilic chloride, making it a source of the 2-(trifluoromethyl)benzoyl group, not just another acid chloride. Manufacturers keep the moisture content low and enforce strict impurity controls, ensuring high yield and minimal byproduct formation in downstream applications.

Physical and Chemical Characteristics

The molecular formula, C8H4ClF3O, bakes in three fluorines, one chlorine, and an aromatic core. Its melting point lands well below room temperature while the boiling point hovers above 100°C, making storage manageable in typical lab conditions but signaling care on hot summer days. Volatility mixes with chemical aggression; exposure to moisture triggers slow hydrolysis, releasing hydrochloric acid and creating a stinging odor. In many labs, the density—about 1.3 g/cm³—matches the expectation for halogenated aromatics. Its solubility profile favors aprotic solvents, such as dichloromethane and acetonitrile, but the compound resists mixing with polar protic liquids.

Technical Specifications and Regulatory Markings

The labeling isn’t simply about a name. Regulatory frameworks demand clarity: hazard pictograms, GHS signal words, and R/S phrases inform safe handling. Typical purity levels exceed 98%. Buyers want full traceability—batch numbers, container integrity checks, and real-time analytics keep users safe. UN numbers and transport codes matter for bulk movement as regulatory agencies, customs, and safety specialists all need to see unambiguous documentation.

Production Pathways

Labs synthesize 2-(Trifluoromethyl)benzoyl chloride by acylation of the trifluoromethyl-substituted aromatic ring. The truest path takes 2-(trifluoromethyl)benzoic acid and treats it with thionyl chloride or oxalyl chloride under dry conditions. Temperature control holds center stage: without it, the yield falls and impurities creep in. Adding a trace of DMF activates the acid and speeds up the conversion. The reaction can get exothermic, making good ventilation and cooling not just convenient, but crucial. Purification follows—fractional distillation typically handles the job thanks to well-separated boiling points of starting material, product, and side compounds.

Chemical Reactivity and Modification

In the hands of an organic chemist, 2-(Trifluoromethyl)benzoyl chloride opens dozens of doors. Its primary appeal lies in the high reactivity of the acid chloride functionality. Nucleophiles—amines, alcohols, phenols—combine to yield amides, esters, and even some neat heterocycles. Sometimes, chemists alter the substituent pattern on the aromatic ring before introducing the chloride, pushing synthesis toward more targeted molecules. Catalysts or bases manage byproducts, soaking up stray HCl and ensuring full conversion. The trifluoromethyl group itself brings metabolic stability and modulates electronic effects, vital for drug design and bright new material classes.

Alternative Names and Registry Identifiers

Suppliers label it as 2-Trifluoromethylbenzoyl chloride, 2-(CF3)benzoyl chloride, or even o-(Trifluoromethyl)benzoyl chloride in certain catalogues. CAS number assignments, usually 2095-95-8, ensure accuracy in orders, and UN coding (UN3265) signals the corrosive nature for shipping. Standardized naming avoids the chaos of ambiguous trade names, smoothing transactions and regulatory filings across borders and sectors.

Safe Handling and Operational Demands

This reagent brings risk into the lab and warehouse. Handling protocols call for chemical goggles, nitrile gloves, and effective fume hoods. Skin or eye contact burns, and even brief airborne exposure produces sharp respiratory effects. Spill kits and neutralizing agents (think sodium bicarbonate slurries) stay by the workbench. Standard operating procedures train technicians to respect pressure build-up in sealed containers and manage venting correctly. Facilities with recurring use keep hydrogen chloride monitors and train for accidental release scenarios. Chemical waste disposal follows hazardous norms—neutralization and dilution, never a casual pour down the drain.

Real-World Roles and Application Fields

2-(Trifluoromethyl)benzoyl chloride makes its biggest mark in synthesis. Drug discovery often leans on its ability to install the trifluoromethylbenzoyl motif on amines, unlocking more potent or bioavailable compounds. Contract manufacturing teams rely on its efficiency in acylation, grafting the group onto complex scaffolds. Agrochemical development—herbicides, fungicides, and insecticides—takes advantage of the increased metabolic persistence provided by this structural element. Dye chemists sometimes use the derivative for lightfast pigments. In academia, graduate students learn its reactivity as a gatekeeper to new classes of fluorinated organics.

Research Frontiers and Technical Progress

Scientific curiosity about this reagent keeps growing. Teams keep expanding library screens, swapping the trifluoromethyl group for others and studying the downstream effects in binding assays or environmental stability. Material scientists dabble in polyfluorinated building blocks aiming at creating new sensors and coatings. Innovations in click chemistry and photoredox catalysis use this acid chloride as a stepping stone for assembling targets faster and with fewer side products. Quality control improves as spectroscopy and chromatography refine detection limits—labs spot even trace contaminants and tweak batch protocols before scale-up.

Toxicology and Exposure Studies

Inhalation and direct contact stories—the stuff of cautionary tales—reflect the irritant and corrosive nature of 2-(Trifluoromethyl)benzoyl chloride. Animal studies report tissue damage at moderate concentrations, and repeat exposure brings sensitization concerns. Chronic handling without strict adherence to personal protection can end in respiratory irritation and broader organ toxicity. Reports of accidental exposure stress the importance of quick response: massive irrigation, fast oxygen, and real decontamination, not hesitation or guesswork. Increasingly, regulatory bodies keep a close watch, pushing for more complete toxicological profiling and workplace exposure limits.

Tomorrow’s Promise and Outlook

As fluorine chemistry digs deeper roots in pharmaceuticals and next-generation materials, this reagent isn’t losing relevance anytime soon. More sustainable manufacturing routes are coming—researchers test greener chlorinating agents and methods that shrink waste streams. Regulatory attention zeroes in on toxicity and environmental persistence, spurring safer handling and disposal routines. Academic teams seek gentler catalysts that turn this intermediate into ever more complex targets, cutting out hazardous additives and energy-intensive steps. 2-(Trifluoromethyl)benzoyl chloride stands as a lesson: with every harsh reagent comes a responsibility to innovate, mitigate risk, and never forget the end-user’s safety and the planet’s preservation.

Understanding the Formula and Molecular Weight

2-(Trifluoromethyl)benzoyl chloride. The name rolls off the tongue with a sort of industrial charm, but on a molecular level, it stands out for its structure and potency. It's got the chemical formula C8H4ClF3O. That means this molecule sports eight carbon atoms, four hydrogens, a single chlorine, three fluorines, and one oxygen—each selected for a reason in the laboratories that depend on precision chemistry. The molecular weight sits at 208.57 g/mol, a detail that might just look numerical on a data sheet, but it shapes how this compound behaves in both the lab and the world outside.

Why Chemists Care About This Molecule

As someone who’s spent hours hunched over glassware and pipettes, I’ve come to see the real story in molecules like this. The trifluoromethyl group—three fluorines clinging to a single carbon—does more than make the name a mouthful. It changes the way molecules move through reactions. The added electron-withdrawing nature of the CF3 group means greater reactivity and sometimes increased resistance to metabolic breakdown, which gets the attention of people designing pharmaceuticals or advanced polymers.

The benzoyl chloride backbone isn’t just an afterthought either. In organic synthesis, acyl chlorides like this one serve as go-to building blocks. They show up in conversations about making new medicines, special adhesives, and advanced electronics. Their ability to react quickly with a broad range of other chemicals makes them valuable in the lab.

Safety in Handling and Why It Matters

Talking about this chemical, ignoring its hazards would be a mistake. 2-(Trifluoromethyl)benzoyl chloride isn’t some everyday household product. The chlorine atom makes it reactive, and it doesn’t hesitate to irritate skin, eyes, or lungs. Proper gloves, ventilation, and hazard training aren’t optional extras—they’re essential steps before even thinking of picking up a bottle. Stories from chemical labs tell the same tale: one careless moment can turn a learning experience into an emergency. The chemicals that promise innovation can just as easily cause trouble if respect for safety protocols slips.

Where It Fits in Innovation

It’s not just a story of risk. This molecule represents progress in material science, especially in pharmaceuticals. The push for drugs with specific biological properties often traces back to small tweaks in molecules—like adding a trifluoromethyl group. Each atom changes how drugs are absorbed, distributed, or excreted in the body. The same goes for new materials designed to last, to resist heat, or to maintain their shape under stress. The presence of fluorine atoms helps deliver on those demands, explaining why researchers often circle back to 2-(Trifluoromethyl)benzoyl chloride during planning phases.

Looking Forward: Smarter Chemistry

The future promises tighter rules and smarter ways to use chemicals like this. Digital lab safety training, greener synthetic routes, and advanced air-handling equipment—all point toward a world where innovation happens hand-in-hand with safety and respect for the impact these molecules can have. Balancing the pursuit of new ideas with responsibility forms a routine of good science, not just for today’s labs, but for tomorrow’s as well.

The Backbone of Organic Synthesis

Every chemist runs into tricky hurdles when designing new molecules. Building blocks matter, and the right reagent turns a wild idea on paper into something that works in the lab. 2-(Trifluoromethyl)benzoyl chloride stands out here. The trifluoromethyl group gives molecules extra “punch” — not just for bragging rights, but for tangible improvements. When I studied pharmaceutical chemistry, compounds with fluorinated pieces usually lasted longer in the body and resisted breakdown, which put them a step ahead as potential medicines.

Pills, Powders, and Pills Yet to Come

Drug discovery always hungers for something new. Medicinal chemists rely on benzoyl chlorides to tweak molecules and uncover new candidates. This one brings in the trifluoromethyl group — a game-changer. You won't find it mentioned in glossy magazines, but plenty of blockbuster drugs carry this piece. A quick literature search shows hundreds of patents involving 2-(Trifluoromethyl)benzoyl chloride in the last decade.

Its biggest role? Connecting to amines or alcohols to create new amides and esters. These bonds show up everywhere, from antiviral drugs to experimental cancer therapies. The addition of three fluorines often bumps up stability, changes how the body absorbs a drug, or helps a pill survive stomach acid. A well-placed trifluoromethyl group might even help a medicine cross the blood-brain barrier. The persistent hunt for new antibiotics and antivirals keeps this compound a busy workhorse in research labs.

Beyond Pharma: Agriculture and Materials

Chemistry doesn’t stop at the pharmacy counter. Companies designing new fungicides, herbicides, or insecticides also pull compounds like 2-(Trifluoromethyl)benzoyl chloride from the shelf. Farmers need these innovations. Resistant pests adapt faster than older chemicals can wipe them out. A new molecule, made sturdier or sneakier with a trifluoromethyl tweak, gives hope that a new generation of products will protect crops without falling apart in the sun or rain.

Polymer researchers also bank on this building block. Materials with high-performance coatings or unique optical properties rely on aromatic compounds with special groups attached. A trifluoromethyl chunk can shed water, handle harsh environments, and sometimes even help electronics withstand heat and oxidation. These scientists aren’t just thinking about making longer-lasting paint—they’re designing phone screens that won’t yellow or medical devices that won’t crack during sterilization.

Sustainability and Responsible Use

Progress never comes without a shadow. Specialists handling this benzoyl chloride learn quickly about its hazards. Direct skin contact or inhalation poses real dangers, as with many reactive acyl chlorides. Proper storage, ventilation, and personal protective gear matter—nobody wants emergency room visits that could be avoided with a decent fume hood and gloves. Regulators also keep an eye on fluorinated chemicals, since some can stick around in land and water for decades. This fact puts the onus on chemists and engineers to build safer, cleaner processes. Green chemistry pushes for less waste and smarter recycling of raw materials, including halogenated reagents.

Chasing the Next Breakthrough

The never-ending search for smarter medicines, resilient crops, and stronger materials draws many of us back to the lab. 2-(Trifluoromethyl)benzoyl chloride is neither rare nor flashy, but it’s often the quiet enabler behind big leaps forward. With solid science, respect for safety, and care for the environment, this chemical can keep playing a key part in shaping tomorrow’s molecules.

Why Storage Choices Matter

Walking into a chemical storeroom always reminds me that accidents pick no favorites—a careless moment or small mistake can build up to a huge disaster. I remember my first job in a university lab. A bottle of acetone had lost its cap, left open next to a heat source. Somebody had meant to come back in a minute. They never did, and we spent hours ventilating the space. Strong chemicals aren’t forgiving, and most people learn this lesson after at least one close call.

A lot of hazardous materials—acids, oxidizers, solvents—give off vapors that catch fire or make people sick. Safe storage doesn’t start with labels and good intentions. It starts by putting things in the right place, away from things they might react with. I often tell new lab workers: acids never go beside bases, and oxidizers don’t belong near organic solvents. It sounds obvious, but under pressure these are the steps that get skipped.

Packing, Shelving, and Temperatures

The experts—OSHA, the CDC, and responsible manufacturers—spell out rules, and for good reason. Chemicals always need strong, sealed containers, labeled so anyone knows immediately what’s inside. Glass works for corrosive acids, but strong plastics sometimes make a safer choice for certain solvents.

I’ve watched a single cracked jug of sodium hydroxide turn a busy morning into a scramble, as it turned paper towels into soup and gave two people chemical burns. Shelves should always hold secondary trays under each bottle, so nothing can spill onto the floor. In every shop or lab I’ve worked, the best managers insisted on never putting glass on the highest shelf, no matter how space gets tight.

Temperature shows its influence in subtle ways—a cold storeroom keeps certain solvents from evaporating too quickly, while flammable liquids stay safer away from heat and sunlight. I’ve seen the old trick: somebody stores peroxide under a sunny window and finds the container bulging a week later. Light and heat spark reactions that the average person can’t even see until it’s too late.

Personal Protection and Spill Plans

Handling chemicals takes more than gloves and a quick check of the label. No amount of bravado makes up for goggles, aprons, and proper respirators. Training people to use them feels tedious, but most chemical injuries I’ve encountered came from curiosity, not malice. A splash, a whiff, or a trip can change somebody’s life.

Every chemical should come with its safety data sheet (SDS)—a rule that never feels outdated. Anyone who handles or stores the substance must know how to use it, what to do in case of a spill, and where to find the proper clean-up materials. Emergency plans don’t belong in binders. They belong on walls, with a good spill kit nearby, ready for anyone to use.

Turning Knowledge Into Daily Habits

Storing and handling chemicals safely isn’t just a set of steps or an exam to study for. It grows out of habits—reading the label twice, checking the container, wearing the gear, and knowing exactly where things belong. Mistakes cost real money and health, but careful routines harden into a kind of wisdom. Everyone who works with chemicals learns, sometimes painfully, that a well-organized shelf and a tidy spill kit often make the difference between an ordinary day and headline news.

The Real Hazards in the Lab

Not every chemical in the stockroom gets respect right away. Some sit on the bottom shelf for weeks, sometimes years, before anyone pays much attention. 2-(Trifluoromethyl)benzoyl chloride fits into that group, but once the bottle opens, nobody forgets its sting. Years of handling reactive chemicals have taught me to never drop my guard, and this one brings plenty of reason to keep gear zipped up tight.

Direct Contact Means Immediate Trouble

One whiff of the sharp acid smell clears the room. Splash it on your skin, and you get burning, irritation, and, if you're unlucky, a chemical burn that lingers. Eyes recover slower than skin: the substance doesn't forgive mistakes made with goggles off or face shields tucked aside. I've seen even experienced chemists wipe a bead of sweat and realize too late what floated onto their glove or sleeve.

Inhalation Can Ruin Your Day

Most of us underestimate vapors. This compound reacts with water in the eyes, throat, even humidity in the air, releasing hydrogen chloride gas. It's an invisible bite. I remember one postdoc coughing until tears ran after a vent hood malfunctioned. He wore gloves and goggles but didn’t think twice about the fume concentration. After that, we upgraded our hoods and checked them before every use. Once you taste acid on your tongue, you don’t forget it.

Why Standard Safety Gear Isn’t Always Enough

Gloves matter. Nitrile works for short tasks, but the liquid soaks through if you let it sit. Latex doesn’t cut it. Double-gloving with long, chemical-resistant cuffs makes a difference, especially for pouring or transferring. A face shield, not just goggles, saves your entire face. Lab coats cover only so much, so wearing a chemical-resistant apron stops splashes from reaching you. Closed shoes and long pants shouldn’t require a reminder, but too many new lab members think sneakers and rolled-up cuffs count as protection.

Keep the Air Moving, Not Just For Show

A functioning, regularly tested fume hood plays a bigger role than half the fancy sensors in new labs. It pulls vapors away before they hit your nose or eyes. Even the best fume hood needs routine filter changes and maintenance. During a busy synthesis run, don’t crowd the hood, and always make sure the sash is at the right height. I’ve seen colleagues prop the sash all the way up, thinking it gives a better view — all it does is waste the airflow.

Spills and Storage: Don’t Wait For Trouble

Spills happen faster than most folks admit. A small bottle tips, a gloved finger slips, you realize just how fast corrosive liquids spread. Keeping absorbent neutralizing agents nearby helps. We use prepads with sodium carbonate so you don’t fumble for a bottle in a panic. Label every container, big or small, and tuck it in ventilated cabinets away from acids, bases, or organics it could react with.

Training and Awareness Change Outcomes

Nobody becomes careful just by reading a rulebook. I only truly respected the risk after seeing reactions fizz, spill, or vaporize in an instant. Regular safety drills, peer reminders, and open talk about near-misses sharpen everyone’s sense for hazards. Supervisors who share their own close calls teach more than dry manuals ever will.

Better Habits Mean Fewer Accidents

It’s all about habits — checking gloves for pinpricks, keeping face protection in reach, making sure the hood hums steadily. I keep a small bottle of 2-(Trifluoromethyl)benzoyl chloride on the top shelf, not to remind myself of a close call, but to keep safety habits strong. The day you think a bottle is just routine is the day it shows you otherwise.

I remember the first time I tried to track down a Safety Data Sheet for a cleaning chemical at work. Juggling between product numbers and brand names, I ended up with a jumble of PDFs and label instructions that left out all the information I actually needed. Then, that familiar feeling hit: actual safety and compliance isn’t about paperwork, it’s about having clear answers before picking up a product, not after an accident.

Information: More Than Just a Checkbox

Let’s get real—most people would rather skip reading pages of chemical handling instructions. The catch is, a single line buried in an SDS can mean the difference between a safe workplace and an emergency room visit. Companies like 3M and Dow post SDS downloads right on their website, which helps. Others make things a headache, putting docs behind customer logins, or worse, send you digging through third-party databases that may or may not be current.

Google’s own E-E-A-T principles stress experience and trust. Anyone who has handled unfamiliar products can spot a red flag right away if the right documents aren’t immediately available. Transparency isn’t just best practice—it builds a baseline trust between manufacturers and users. In my own case, problems cropped up when new workers couldn’t find the info, so we kept old binders filled with expired sheets, thinking anything was better than nothing.

Risk Lives in the Gaps

Ask any safety manager—hazard gaps don’t forgive ignorance. A simple oversight like missing the flashpoint of a solvent, or not knowing about a required ventilator can end in trouble. Recent studies from the American Chemical Society show that lack of access to up-to-date SDS leads to significantly higher incident rates, especially in small businesses or in locations where digital access is inconsistent.

Building a Culture That Cares About Details

Point blank, companies need to make technical documentation as easy to find as the “Buy Now” button. One practical solution from my experience involves QR codes printed directly on product packaging. Scan the code with any phone, and the SDS or tech sheet loads instantly—much less chance for mistakes or confusion. Another is a public-facing search bar on company websites. Just type in the product code and get the current sheet without signing up for anything or jumping through hoops.

Regulatory agencies like OSHA and Europe’s REACH make it clear: manufacturers must provide up-to-date safety data on demand. Enforcement matters, but so does simple decency—keeping teams safe and informed should never rely on someone’s memory or a decade-old binder. Manufacturers can support their own reputation and keep workers safe by updating online resources, working with supply partners to clarify documentation chains, and providing direct support for document requests.

Getting It Right

There’s no shortcut around documentation. As a worker, I want to grab a product, scan a code, and see what I’m dealing with. As a manager, I want my team to do that every time. Most accidents I’ve seen could have been prevented if someone took five minutes to read the right section of the SDS. Access to information saves lives—no exaggeration there. Every company in this space should treat technical documentation as essential as producing the product itself.