2-Fluoro-3-chlorobenzoic Acid: A Deep Dive into Its Role and Relevance

Historical Development

Chemistry always finds ways to make molecules more interesting, and halogenated benzoic acids have never fallen out of favor. In the 1970s, as synthetic chemists pushed for more selective herbicides and new pharmaceutical building blocks, researchers started running halogen-selective substitutions on benzoic acid rings. 2-Fluoro-3-chlorobenzoic acid came out of this feverish period: it’s a product of careful tweaking for ring activation and control. Original mentions popped up in patent literature as agrochemical intermediates—in those early days, everything with a carboxylic acid group and a couple of halogens had eyes on it. The journey hasn’t been glamorous, but the compound rose in the ranks thanks to its versatility and the way it would fit snugly into the pipeline for both pesticides and pharmaceutical precursors.

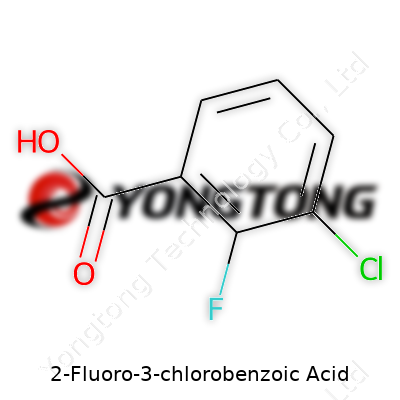

Product Overview

2-Fluoro-3-chlorobenzoic acid blends two halogens—fluorine and chlorine—on a benzene core lined with a carboxylic acid group. People using it care more about what these substitutions do to the ring’s reactivity and solubility. It does not just sit on a warehouse shelf; it serves as a key node for building more complex molecules, especially where selective reactivity matters. In the lab, it can open doors to a suite of derivatives with tailored biological or industrial use. The size, arrangement, and electronegativity of its substituents give this molecule a particular place in the toolbox of organic chemists. Scientists and engineers saw value in having both fluoro and chloro groups available for further reaction or as blocking groups in multistep syntheses.

Physical & Chemical Properties

Looking at 2-Fluoro-3-chlorobenzoic acid on a lab bench, you find a nearly white crystalline solid. It holds up well under standard storage, so stability isn’t a worry. The compound weighs in with a molecular mass just above 174 g/mol. Its melting point hovers around 145-148°C, a useful mid-range that fits most recrystallization work. The acid group ensures moderate solubility in polar organic solvents—think methanol or dimethyl sulfoxide. Fluorine brings high electronegativity to the molecule, while chlorine bumps up the molecular heft. Together, they tune the acidity of the carboxylic group and influence interactions during reactions. Chemists regularly look to its NMR and IR spectra for identification: signals from the aromatic hydrogens, plus characteristic peaks from the halogenated carbons, help with quality control.

Technical Specifications & Labeling

Suppliers define quality using common analytical techniques—purity above 98%, checked by HPLC or GC-MS, usually gets a batch accepted. Most bottles list CAS number 183658-63-7 on the label, plus the molecular formula C7H4ClFO2. MSDS documents address stability, reactivity, and hazard data. Proper labeling—batch numbers, expiration dates, and storage advice—serves all users. Accurate identification avoids confusion, since mistakes with halogenated acids lead to big headaches in the synthesis workflow. Laboratories expect material traceability, and suppliers who skip rigorous documentation lose trust fast in pharmaceutical or crop-protection supply chains.

Preparation Method

Synthesizing 2-Fluoro-3-chlorobenzoic acid starts from a fluorinated or chlorinated benzoic acid or its derivatives. Most common routes depend on directed ortho-lithiation, allowing selective introduction of fluorine or chlorine after a suitable protecting group locks down one side of the aromatic ring. Another method involves halogen exchange or using Sandmeyer-type transformations—tossing a diazonium salt into the mix and trading out functional groups for halides. Reaction conditions must be tuned carefully: too much base or oxidant can rip the ring apart, too little leaves the wrong substitution pattern. Yields rise and fall based on solvent, catalyst choice, and temperature. Downstream purification—either recrystallization or column chromatography—secures the kind of purity needed for downstream chemical processes or research applications. Solvents and reagents require attentive handling to avoid moisture or cross-contamination; those factors can torpedo selectivity and compromise safety.

Chemical Reactions & Modifications

Once you have this acid, modifying it is straightforward thanks to the versatility of the aromatic ring and the carboxyl group. Esterification transforms the acid into a methyl or ethyl ester, letting it slip into more lipophilic environments or evade premature reactions in a synthesis plan. Amide coupling, using EDC or DCC, tacks on side chains—key steps for building drug candidates. Halogen substitutions at ring positions allow for further tuning of electronic properties. Both halogens are reactive but selective chemistry can swap them for aryl-amine, alkoxy, or even hydrogen, opening doors for library synthesis. Using standard Suzuki or Stille couplings, you can plug the core molecule into larger frameworks to test biological or material science properties. Nitration, reduction, or oxidation steps all respond in characteristic ways due to the presence of those halogen groups, so the compound’s position in modular synthetic routes stays secure.

Synonyms & Product Names

In catalogues, this acid appears as 2-Fluoro-3-chlorobenzoic acid, but chemists might call it 3-chloro-2-fluorobenzoic acid as well. Some vendors list it by its systematic IUPAC name or just the shorthand 2F3ClBA. Across research articles, these names are used interchangeably, so a careful cross-check of structure is important to avoid ordering the wrong regioisomer. Awareness of the synonyms prevents both costly procurement errors and mix-ups in experimental records.

Safety & Operational Standards

Direct handling of halogenated benzoic acids brings risks. Eye and skin irritation are frequent issues during weighing and solution prep. It pays off to use a fume hood, gloves, and goggles. Chronic exposure isn’t well-documented for this compound, but general caution carries over from similar carboxylic acids: ingesting, inhaling powder, or fluid splashes can irritate mucous membranes and, in large enough doses, lead to more serious symptoms. Many operations develop SOPs around solvent waste and spill containment. Fresh researchers learn by example that it’s not enough to assume a compound “isn’t that dangerous just because it’s not regulated.” Good laboratory practice, including proper labeling and timely disposal, stops mishaps before they have a chance to snowball.

Application Area

In industry and research, people count on 2-Fluoro-3-chlorobenzoic acid to open synthetic pathways—especially for active pharmaceutical ingredients and custom herbicides. Drug discovery platforms value the halogen pattern for tuning metabolic stability and receptor affinity; molecules built from this scaffold offer opportunities for lead optimization. Agrochemical firms lean in on the halogenated core to create next-gen herbicides and fungicides—modifying the acid for enhanced uptake, shelf life, or target specificity. Material science teams look past biological effects, using the acid as a starting block for specialized polymers and coatings built for chemical resistance. The acid holds its own as a diagnostic probe, fluorescent tag, and intermediate for complex small-molecule libraries. Each group finds room to innovate by starting from this molecule’s particular combination of substituents, driving the development of patents and new intellectual property.

Research & Development

Laboratories push this compound through panels of reactions, testing new routes to compounds with unique pharmacophores or pesticidal properties. Big pharma companies fund early-stage screens, hoping that new analogues built off 2-Fluoro-3-chlorobenzoic acid will outperform old leads in potency, solubility, or selectivity. Universities look for ways to streamline the synthetic steps, cut manufacturing costs, or build green chemistry approaches that sidestep hazardous reagents. This ongoing development reflects changing priorities: as regulatory scrutiny rises, research pivots toward safer processes, renewable feedstocks, and cleaner waste streams. Screening efforts stretch into organofluorine and organochlorine chemistry, trying to understand how those halogens change in vivo behavior, which can affect everything from absorption to long-term persistence in the body or environment.

Toxicity Research

Toxicologists watch halogenated aromatic acids with a cautious eye. 2-Fluoro-3-chlorobenzoic acid, like many in its class, doesn’t see wide use as a final consumer product, so in-depth chronic toxicity studies lag behind more common chemicals. Still, preliminary in vitro and rodent screens point to moderate risk: carboxylic acids can cause local irritation and rare systemic effects in large doses, though the added halogens create concern about long-term environmental impact. Structure-activity relationships suggest the molecule avoids some metabolic pathways that trigger acute toxicity, but questions linger about bioaccumulation and breakdown products, especially when they spread through soil or water. Researchers keep pressing for more data, using this compound as a model for understanding how small changes in structure shift toxicity profiles—not just for humans, but also for the ecosystems that touch industrial waste or runoff.

Future Prospects

As the world demands tighter control over chemicals in the environment and the market asks for faster, cleaner syntheses, 2-Fluoro-3-chlorobenzoic acid stands as both a challenge and an opportunity. On the manufacturing side, process chemists look for routes that maximize selective halogen introduction, cut solvent waste, and improve yields. Regulatory shifts drive interest in alternative reagents and biodegradable derivatives that won’t hang around in soil or waterways. The pharmaceutical industry sees value in expanding the repertoire of halogenated benzoics for early-stage drug design, while agrochemical R&D teams work toward safer, more effective crop protectants that owe their performance to these building blocks. As new analytical techniques come online, researchers will keep pushing for better data on behavior, breakdown, and biological compatibility. This molecule remains at the intersection of classic synthetic chemistry and modern industry demands, serving as a touchstone for new ideas about safer, smarter molecular design.

The Real Stakes in Purity

Anyone who has ever spent time in a lab knows the challenge of tracking down high-purity chemicals. With 2-Fluoro-3-chlorobenzoic acid, purity makes the difference between success and headaches in synthesis and analysis. This compound shows up in pharmaceutical research, agrochemicals work, and materials science. Even small impurities can cause side reactions, odd test results, or even throw a whole production run off balance.

What ‘Purity’ Means Here

Purity isn’t just a number slapped onto a bottle for marketing. For 2-Fluoro-3-chlorobenzoic acid, labs and suppliers usually target a minimum of 98% to 99% purity. Chemical listings from trusted suppliers, like Sigma-Aldrich and Alfa Aesar, mention purity figures in this range. They determine that percentage through analytical techniques such as high-performance liquid chromatography (HPLC), nuclear magnetic resonance (NMR), gas chromatography-mass spectrometry (GC-MS), or melting point analysis. An honest analysis means more trust down the line.

Why High Purity Changes the Game

During a research stint at a mid-sized specialty chemicals firm, I ran into the trouble impurities cause. During scale-up, we tried to save money by buying a slightly cheaper batch, which only guaranteed 95% purity. Yields dropped. Byproducts crept in. Testing time ballooned, along with the budget. Switching back to a batch at >98% purity reduced headaches. Reagents with those extra points of purity don’t just behave better—they save time, money, and a lot of trouble.

How Labs Check and Maintain Purity

No one should take claims on a label at face value. Researchers constantly run spot checks, preparing a sample and running HPLC or NMR before starting larger synthesis projects. Some researchers run thin layer chromatography as a quick check if advanced equipment is tied up. If a batch looks cloudy, clumps, or smells odd, most chemists go back to the drawing board and confirm purity before moving on. Cross-referencing supplier certificates with in-house data weeds out low-quality batches.

Supplier Practices and Transparency

The best vendors provide batch-specific certificates of analysis (COAs). These COAs list both purity percentage and detailed breakdowns of known impurities. Some even include chromatograms or spectra. That level of openness means scientists can make informed decisions, anticipating possible issues long before a project grinds to a halt. A responsible supplier also offers data on shelf life, moisture sensitivity, and recommended storage conditions, so the chemical doesn’t degrade over time.

The Ethics of Purity Disclosure

Regulated industries like pharmaceuticals and crop protection have a low tolerance for impurity. End products require a clean record, so any chemical intermediate—2-Fluoro-3-chlorobenzoic acid included—needs traceability and documentation. Labs play their part by double-checking supplier claims and reporting anomalies. Looking back at past recalls due to contamination, greater transparency can prevent costly setbacks and protect public health.

Better Results Through Smarter Choices

Investing in the purest material available, running quality checks, and demanding more from suppliers doesn’t just benefit end users—it raises the bar for the entire scientific community. Mistakes carry big costs. A little diligence at the start pays off in cleaner data, safer products, and a smoother journey from lab to market.

Storing Chemicals: Details Matter

Working on research projects, strict protocols around chemical storage quickly become second nature. Storage keeps both the compound and people secure, especially with benzoic acid derivatives like 2-Fluoro-3-chlorobenzoic acid. Mishandling these powders can mean lost samples, ruined experiments, and safety concerns. My early lab days taught me a simple fact: mess up storage, and chemistry bites back.

Main Risks: Moisture, Light, Contamination

2-Fluoro-3-chlorobenzoic acid acts like many benzoic acids. It clumps under damp conditions and can degrade over time if left in sunlight or exposed to the air. The science is straightforward—aromatic acids may not explode on contact with moisture or dust, but hydrolysis and photodegradation don’t need a dramatic moment. Time quietly ruins purity, reducing yield and reliability for anyone depending on that batch.

Standards Shaped by Evidence

Storage goes beyond tossing a bottle on a shelf. The material holds up longest in a tightly sealed container, placed in a dry, cool area. Desiccators work wonders against moisture, and low humidity environments cut down on risk of caking or unexpected reactions. At my university lab, desiccant packs went into every chemical jar, and we checked for solid seals as habit—those small steps made a difference.

The accepted storage temperature lands at room temperature or slightly cooler—20 to 25°C is a good window. Down in a basement store room away from direct light, I noticed far fewer troubles with discoloration or loss of mass over time. Direct sunlight nearly always spells trouble for organic acids. For compounds like this, brown glass helps, but keeping it in a shadowy cabinet gives even better protection.

Labeling: The First Line of Defense

Every researcher hears this line—label properly or prepare for confusion later. I’ve seen wasted bench time simply because someone skipped a date or forgot to add a note about hygroscopicity. A label isn’t just for audits, it helps remind everyone that this chemical doesn’t play well with water or air. Including both the name and expiration, plus basic handling notes, keeps accidents down.

Practical Steps to Cut Down Risks

Splitting stocks, so you aren’t repeatedly opening the main bottle, saves money and product. Aliquoting reduces exposure—simple as that. Training the team to close caps tightly, return the bottle to the right storage area, and avoid touching chemicals with bare hands avoids unnoticed contamination. Powders or crystals can hold invisible fingerprints, and that wears down purity for the next user.

Spills happen, so keeping a spill kit ready nearby is smart. Gloves and goggles are non-negotiable for handling strong acids, even mild-looking ones. If a chemical causes breathing trouble, use a fume hood—most modern labs already have this principle locked down, but reminders never hurt.

Why These Steps Matter

Storing 2-Fluoro-3-chlorobenzoic acid the right way means cleaner results and a safer workspace. It protects both your science and your health. The rules may seem routine, but cutting corners never pays off here. Every good lab I’ve worked in, whether for academic or industry projects, started with strong habits—and storage tops that list for a reason.

A Closer Look at the Makeup

2-Fluoro-3-chlorobenzoic acid doesn’t just appear fascinating on paper — its formula, C7H4ClFO2, highlights a specific mix of carbon, hydrogen, chlorine, fluorine, and oxygen. Each element contributes to the molecule’s behavior, and that behavior shapes outcomes in fields like medicine, agrochemicals, and material sciences. What’s really at stake? Every atom counted matters. The molecular weight tallies up to approximately 174.56 g/mol, offering a useful figure whether preparing a solution in a research lab or designing a step in chemical manufacturing. For those of us who have mixed hundreds of grams or traced spectra for clarity, this information sets the groundwork for reliable results.

Why Structure and Weight Shape Real Outcomes

Details about molecular formulas and weights don’t just satisfy curiosity. Anyone who’s struggled with a scale in a lab or watched a reaction fail after picking the wrong compound knows: accuracy here reduces costly errors. The specific arrangement of fluorine and chlorine rings a bell for chemists searching for selectivity. These halogens swap out hydrogen atoms, tweaking both physical and biological properties dramatically. Maybe it’s about increased resistance to breakdown, maybe it means a new spectrum in NMR studies. Fluorinated and chlorinated benzoic acids have often served as building blocks for innovative products, from crop protection to pharmaceuticals that resist breakdown in the body.

Cutting Through to Real-World Use

I’ve watched teams burn days problem-solving after a small mix-up in chemical nomenclature. Listing the exact formula, C7H4ClFO2, and molecular weight, 174.56 g/mol, clears confusion, speeds up procurement, and sharpens accuracy on the bench. Research isn’t cheap, and no one likes backtracking because the wrong acid landed in the synthesis step or an assay gave skewed results.

The Importance Leaves the Classroom

Clarity in reporting a compound’s stats lifts quality everywhere. Real-world stories feature mistakes in gram-scale synthesis, or supply chain hiccups when two “close enough” acids on a spec sheet aren’t close at all. Academia, industry, and regulatory bodies alike build trust on accurate naming. This isn’t about trivia — it’s the avoidable errors that don’t get caught until late-stage steps or worse, market release. Bench chemists, formulation scientists, and environmental analysts all rely on these details to protect users and the public. I’ve seen it play out: accurate labeling shields a project from recall or a study from retraction.

Pushing Toward Fewer Mix-Ups and Cleaner Data

Better reporting and more reliable communication prevent many headaches. Training newcomers on proper chemical notation and reinforcing why the molecular profile matters sidesteps costly messes. Taking time to confirm identities of compounds — not just skipping over the halogen pattern or atomic math — pays dividends. Databases get more robust when researchers contribute verified molecular weights and formulas, not guesses. This all ties back to smoother operations, safer products, and science that holds water when it matters most. People working hands-on with chemicals win, as do end-users and communities downstream.

Chemistry in the Real World

Some chemicals earn a spot on the bench because they help solve problems in ways other compounds can’t. 2-Fluoro-3-chlorobenzoic acid, with its distinctive mix of a fluorine and chlorine atom attached to a benzene ring, is one of those specialty molecules. Chemists value it for what it lets them build, not just for what it is.

Building Block for Pharmaceuticals

Drug research often resembles a series of experiments with molecular Legos. Aromatic acids like this one give scientists a strong starting point. Medicinal chemists make small tweaks to molecules, adding pieces or substituting atoms, to nudge a drug’s performance toward targets like improved absorption or reduced side effects. Halogenated benzoic acids show up in plenty of “hit” molecules at the discovery stage. The chlorine and fluorine atoms each offer something extra—stability, biological activity, or resistance to breakdown in the body. Researchers can connect this molecule to amines or alcohols, producing new drug candidates for testing against cancer, infection, or autoimmune disorders.

Agricultural Chemicals and Plant Protection

Folks working on ways to protect crops also turn to compounds with tailored structures. Adding both fluorine and chlorine can discourage bacteria, fungi, or pests from breaking down the chemical, which helps it remain active in the field longer. When chemists design new herbicides or pesticides, they use 2-Fluoro-3-chlorobenzoic acid as a core for building up larger molecules. Companies blend these pieces into formulas for controlling weeds, insects, or blight—not just because the chemicals kill outright, but because resistance develops more slowly with these newer, less familiar scaffolds.

Raw Material for Specialty Materials

Beyond labs and farms, specialty acids like this turn up in the preparation of performance materials—think dyes, advanced polymers, and liquid crystals. In producing colorants, the arrangement of halogens on the benzene ring changes how the final dye behaves—shades shift, fade resistance goes up, or the material works better for photolithography. Electronic materials, especially those needed for display screens or advanced sensors, demand fine-tuned starting points; aromatic acids with both electronic “pushers” and “pullers” shape performance better than simpler alternatives.

Challenges and Responsible Use

Every good tool carries some responsibility. Strong halogenated compounds, while useful, also raise red flags about environmental and safety risks. Chlorinated and fluorinated chemicals sometimes linger in nature. Developing greener synthetic routes and exploring biodegradable alternatives matter just as much as clever discovery work. Many teams have started switching to solvent-free conditions, recycling acids, or choosing less toxic reagents as part of a broader shift to sustainable chemistry.

Looking Forward in the Lab

Years of working in research shows how a single new compound can jumpstart innovation across fields. 2-Fluoro-3-chlorobenzoic acid has already played its part in pharmaceuticals, agriculture, and advanced materials. As demand grows for more selective drugs and environmentally safer agrochemicals, this little molecule’s profile will likely grow—pushing chemists to think even harder about how to balance effectiveness with stewardship. Chemistry that balances power with responsibility usually brings the most lasting results.

What is the CAS Number?

In chemistry, every substance that finds its way into a lab, a pharmaceutical formula, or even an industrial process gets stamped with a special number—something called a CAS number. For 2-Fluoro-3-chlorobenzoic acid, this is 3861-63-4. That string means a chemist, a researcher, or someone handling regulatory paperwork can’t confuse this compound with another. Accuracy keeps projects running and labs out of trouble, so that number is more than a label. It’s a passport, a universal ID for one unique molecule.

Why Do Scientists Care About the Right Numbers?

Plenty of chemical names sound almost identical. Take benzoic acid derivatives—switch a chlorine for a fluorine, bump an atom over by one carbon, and you get a different substance. In my university research days, I saw how one typo could unravel a whole experiment. With accurate CAS numbers, suppliers avoid costly shipping mistakes. Researchers can verify they’re working with the right material. Inventory stays clear. Chemicals with nearly the same name but slight structural changes can act in very different ways, making these numbers the line between success and a repeat trip to the lab.

Regulations: Not Just Red Tape

Governments don’t joke about chemical safety. Regulatory bodies such as the European Chemicals Agency and the United States Environmental Protection Agency use CAS numbers to track substances moving across borders. A wrong number on a manifest spells trouble—not just in lost merchandise, but also in potentially hazardous outcomes. Accurate CAS data protects workers, helps emergency crews respond during spills, and keeps sensitive compounds out of the wrong hands.

In the pharmaceutical world, regulatory submissions hinge on precise identification. Without a correct CAS, approval for research or clinical trials stalls. The number lets auditors trace raw material all the way back to its source, catching contamination before it reaches patients. Sometimes, a missing or wrong number can delay entire production lines or trigger costly recalls.

Challenges in Chemical Databases

These days, it seems digital databases should solve everything. Databases still rely on human input, and even big platforms contain errors or duplications. That’s why a lot of us cross-check numbers and search more than one database before placing an order or filing a compliance report.

Imagine shipping a ton of chemical to a production plant, everything riding on one entry being right. No one rewrites a process because of a typo, but someone has to pay for a shipment mistake or a regulatory fine. In my own work, I’ve seen companies standardize their procurement around CAS numbers, posting them on storage shelves, and even requiring double-verification on orders.

Keeping the Process Honest and Safe

From academic research to multinational industry, trust begins with details. CAS numbers offer that peace of mind. Standard operating procedures should include routine checks—especially as teams grow or new members rotate into the lab. Staff training, barcode systems linked to CAS data, and regular database audits close as many gaps as possible. Those steps let teams stay productive and build reputations for safety and efficiency, all with help from seven digits and a couple of dashes.

Final Thoughts

2-Fluoro-3-chlorobenzoic acid’s CAS number 3861-63-4 holds more weight than a line item on a spreadsheet, acting as an anchor for accuracy and reliability. The way teams use it—checking, cross-referencing, and sharing—shapes how safely and efficiently that compound changes hands or makes its way into new applications.