2,6-Difluorophenol: A Deep Dive

Historical Development

Chemistry rarely spotlights 2,6-Difluorophenol in headlines, but this compound has threaded its way through several decades of synthetic research. Back in the mid-1900s, as organic chemists unlocked the value in halogenated aromatics, they discovered that fluorinating phenol changed its reactivity and behavior in unexpected ways. Laboratories explored various difluorinated patterns, but the 2,6-substitution eventually earned its place due to its nuanced balance—it brings new traits to phenol’s backbone. Over time, as pharmaceutical and material science needs grew more sophisticated, chemists kept returning to the difluorinated motif for inspiration.

Product Overview

At its core, 2,6-Difluorophenol tips the scales as an aromatic compound featuring a phenolic ring with fluorine atoms at the ortho positions. What makes this compound intriguing lies in how those two substituents almost barricade the hydroxy group, changing both acid strength and reactivity compared to the parent phenol. It rarely appears as a finished consumer product, but serves instead as a building block—something like a versatile kit piece in the assembly of bigger, more complex molecules. Chemical suppliers keep it stocked for universities, pharma labs, and research outfits seeking to test new reactions or scaffold drug candidates.

Physical & Chemical Properties

Looking over the bench, 2,6-Difluorophenol often appears as a crystalline solid or a faintly colored liquid. Its melting point typically ranges from 38°C to 41°C, pretty low compared to regular phenol, and it boils near 153°C under reduced pressure. Hydrogen bonding gets hindered by the bulky fluorines, which shifts its solubility toward organic solvents—think ether, dichloromethane, or even toluene. Acidity lands higher than phenol’s thanks to the electron-withdrawing fluorines, nudging the pKa below 8. In practice, the compound endures the kind of tear-down reactions often required for chemical synthesis, showing decent resistance to mild bases but vulnerability to strong oxidizers or reducing agents.

Technical Specifications & Labeling

On a chemical drum or reagent bottle, reputable suppliers mark 2,6-Difluorophenol with clear identifiers: CAS Number 367-30-6, molecular formula C6H4F2O, formula weight near 130.09 g/mol, and purity details that matter most in research—often better than 98% by gas chromatography. Labels should specify lot number, expiration date, and proper hazard warnings. Any shipment must include Safety Data Sheets (SDS) that spell out safe handling and first aid. Trace impurities should stay below 0.5%, especially when fine-tuned for pharmaceutical synthesis or academic studies. A reliable supplier will offer batch-specific certificates, showing results for water content and major residual solvents, plus spectral analysis.

Preparation Method

Getting 2,6-Difluorophenol to the shelf takes a path through selective fluorination and hydrolysis. Early syntheses often started with 2,6-difluoroaniline, which reacts via diazotization, then hydrolysis of the resulting diazonium salt to drop in the hydroxy group. Other routes use nucleophilic aromatic substitution on 2,6-difluorochlorobenzene using sodium hydroxide, typically under high pressure and heat. Modern refinements swap out aggressive conditions for catalytic techniques, sometimes turning to selective electrophilic fluorination of phenol derivatives—a practice that limits unwanted byproducts and aligns better with green chemistry goals. Each method trades off yield, purity, and cost, so process engineers pick based on their priorities and local regulations.

Chemical Reactions & Modifications

Chemists treat 2,6-Difluorophenol as a springboard for further substitutions and cross-couplings. The fluorines pull electron density, making the aromatic ring somewhat less nucleophilic, but the hydroxy group hangs on for etherification and esterification tricks. Suzuki-Miyaura couplings find a familiar partner here, transforming the aromatic ring for new drug candidates or advanced materials. Halogen-lithium exchange unlocks additional substitution, setting up the residue for complex target molecules. In medicinal chemistry, tweaking the ring—by adding side chains to the hydroxy group—can shift bioavailability or metabolic stability of drugs in subtle but measurable ways.

Synonyms & Product Names

The chemical literature doesn’t limit itself to a single label for this compound. Besides 2,6-Difluorophenol, researchers reference it as 2,6-DFP, 2,6-Difluoro-1-hydroxybenzene, and in older texts, even 1-Hydroxy-2,6-difluorobenzene. Suppliers may list stock under any of these, which can trip up new bench chemists scanning catalogs. Many online databases like PubChem, ChemSpider, and drug discovery collections track synonyms, smoothing out confusion for procurement teams.

Safety & Operational Standards

Labs treat 2,6-Difluorophenol with the same respect they give to other reactive phenols. Gloves and splash-proof goggles rank as required gear. The fumes still trigger discomfort, irritating mucous membranes and skin, so fume hoods get steady use. Inhalation can irritate airways, and the hydroxy group helps the compound cross membranes, intensifying toxicity. Any waste goes straight into appropriate halogenated organic disposal, never down the drain. Regulatory authorities have mapped out exposure limits, even if the thresholds vary: US OSHA tends to track overall phenolic content, while European agencies flag both acute and chronic risks tied to fluorinated aromatic compounds. Emergency showers and eyewashes shouldn’t stay optional wherever the compound gets handled.

Application Area

2,6-Difluorophenol rarely stands alone; it walks into the limelight as a supporting actor in chemical synthesis. Agrochemical developers look at it as an intermediate to craft more potent herbicides and insecticides—the two ortho fluorines improve metabolic resistance in plants and animals. Enzyme inhibitors in the pharmaceutical sector often start with this scaffold, favoring its rigidity and electron distribution for better receptor matching. Material scientists tap 2,6-Difluorophenol to build specialty fluoropolymers with heightened thermal and chemical resistance. For the most part, it doesn’t end up in final products consumers would recognize, but its fingerprints spread through drug libraries and industrial materials around the world.

Research & Development

Over the last decade, research into 2,6-Difluorophenol gained new momentum due to advances in organofluorine chemistry and high-throughput screening. Medicinal chemists probing kinase inhibitors or CNS-active molecules often reach for difluorophenols as starting points—fine-tuning metabolic profiles while reducing off-target toxicity. University research groups turn their attention to sustainable synthesis, trying to swap out toxic fluorinating reagents or develop catalysts that work at room temperature. Analytical chemists track metabolite formation, using mass spectrometry or NMR to map out precise biotransformations in cells. Funding from public agencies and private industry increasingly flows to any research that finds safer, cheaper, or less wasteful ways to make or modify this building block for larger applications.

Toxicity Research

Toxicologists don’t turn a blind eye to 2,6-Difluorophenol. Early tests flagged phenol’s toxicity long ago, and difluorination tends to amplify the risks, thanks to increased membrane penetration and slower breakdown in organisms. Rodent studies have shown acute toxicity at relatively low exposure levels, nailing down the need for strict handling protocols. In aquatic systems, the compound doesn’t break down easily—raising concerns over persistent pollutant buildup if waste streams aren’t contained. Regulators, noting both chronic and reproductive toxicity warnings from phenolic halides, keep pushing for better regulations and alternative disposal practices. Labs now track exposure with blood and urine tests, especially where workers spend all day handling the chemicals.

Future Prospects

The road ahead for 2,6-Difluorophenol looks set to expand as demand rises for fluorinated building blocks in pharma, agrochemicals, and materials science. Synthetic chemists continue chasing milder, cleaner methods to put these molecules within reach for industries chasing green labels and improved safety. Researchers investigating metabolic fate and environmental breakdown hold keys to ensuring these compounds don’t turn into invisible hazards over time. As AI-driven modeling streamlines drug and material design, the need for precise, reliable sources of specialized intermediates like 2,6-Difluorophenol grows more pressing. The companies and labs that invest in smart processes, responsible stewardship, and clear data on toxicity will likely set the pace for what responsible, advanced chemical manufacturing really means.

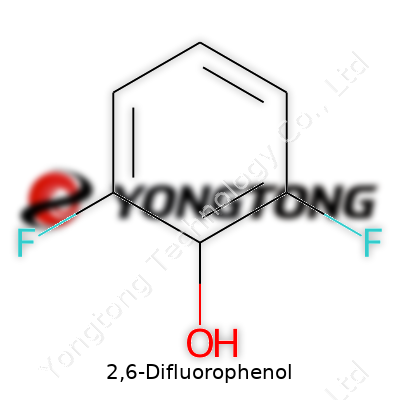

The Heart of the Matter: Chemical Structure

2,6-Difluorophenol stands apart with a simple yet striking chemical formula: C6H4F2O. Here’s what that means. Inside every molecule, we find a benzene ring—six carbons shaped like a hexagon—each bonded to hydrogen atoms. With 2,6-difluorophenol, two hydrogens on that ring make way for two fluorine atoms, and one spot holds a hydroxyl (–OH) group. The “2,6-” points straight to the positions on the benzene ring where those fluorine atoms sit, flanking the –OH on opposite sides. This formula sums up the tiniest physical detail that gives the compound its chemical identity.

Why Get to Know 2,6-Difluorophenol?

Chemistry isn’t just one long cake recipe; every detail matters when safety and performance hang in the balance. I remember working with fluorinated aromatics in a materials science lab, where even slight shifts in the atomic arrangement changed everything—solubility, boil points, toxicity. 2,6-Difluorophenol holds special value for medicinal chemists who look to harness the special reactivity that comes from having two electronegative fluorine atoms hugging the benzene core. That duo nudges electrons in a way that makes this version of phenol more stable against oxidation and shifts its hydrogen-bonding pattern, which matters when drugs interact with our bodies.

There’s also an environmental angle. Phenols naturally resist breaking down in nature, so swapping in fluorine atoms makes them even more persistent. Factories that make, use, or process this compound need strict controls so it doesn’t wind up in water or soil. I’ve seen how these substances, used carelessly, can linger for years and sneak into food chains. That makes knowing the formula, and what it stands for, crucial for anyone involved—from a high school chemist to an industrial supplier.

What the Formula Tells Us About Potential Hazards

The world of chemical safety runs on details. One atom here or there means the difference between a disinfectant and a poison. The presence of two fluorine atoms in 2,6-difluorophenol does more than change the name; it changes reactivity and how our bodies process it. Fluorinated phenols can act as enzyme inhibitors, so labs use them with plenty of respect and shields. Occupational guidelines call out personal protection and proper ventilation, a direct result of knowing which atoms sit where in a compound like C6H4F2O.

That vigilance has roots in lab practice, not policy. I’ve handled compounds with similar formulas and learned to watch for volatile fumes and skin exposure. Clear labeling and up-to-date safety protocols keep risks in check, while chemists and engineers seek greener alternatives with less environmental persistence.

Solutions and Responsibility

So what steps actually make a difference? Start with up-to-date storage and handling guidelines in workplaces. Routine training goes a long way, as does keeping comprehensive Material Safety Data Sheets (MSDS) easily accessible, not locked in some back office. At the policy level, regulatory agencies such as EPA and OSHA keep close watch on fluorinated organics, often updating standards as health data evolves.

For researchers and industries, searching for alternatives that break down faster in nature can pay off down the road. Green chemistry groups now explore ways to swap out fluorinated aromatics for less persistent options, or design molecules that keep key properties without lingering in the environment. Care and transparency at every level, from formula knowledge to disposal, help keep chemistry a tool for good rather than trouble.

What is 2,6-Difluorophenol?

2,6-Difluorophenol stands out among the smaller fluorinated chemicals getting real work done in research labs and industry. It’s a chemical compound made up of a benzene ring with two fluorine atoms stuck at the 2 and 6 positions and a hydroxyl group sitting at the 1 position. Its properties—high reactivity and stability—make it a favorite with chemists focused on creating new molecules.

Building Block for Pharmaceuticals

Pharmaceutical researchers like using 2,6-Difluorophenol when they need to cook up fresh drug candidates. This compound often helps in the synthesis of active pharmaceutical ingredients (APIs). It’s not just about adding the fluorine atoms; the compound brings in improved chemical stability and can tweak how drugs behave in the body. Drug developers value this because swapping a hydrogen for fluorine can increase a medicine’s half-life, make it work better, or help it dodge enzymes that try to break it down too quickly. Several antiviral, antibacterial, and anti-inflammatory drugs grew out of chemistry that started with simple molecules like 2,6-Difluorophenol.

Flavor Chemicals and Agriculture

Some flavor chemists have turned to 2,6-Difluorophenol as a starting material for synthetic flavors. The compound helps construct scent and taste molecules that can go into everything from chewing gum to perfume. Small tweaks in its structure can lead to big changes in the final smell or taste. On top of that, researchers in crop science have found use for 2,6-Difluorophenol in making agrochemicals like herbicides and fungicides. The fluorine atoms help these chemicals stick around long enough in fields to do their job without breaking down too quickly, which matters when you want to save money and reduce chemical runoff.

Materials Science and Electronics

Making advanced materials often begins with compounds like this one. 2,6-Difluorophenol anchors the production of specialty polymers, coatings, and adhesives. These engineering materials see use in devices that need tough, heat-resistant packaging and electronics where insulation counts. Adding special chemicals like this into a polymer can give plastics new electrical or thermal qualities. It helps designers build lighter, more rugged electronics that can survive tough industrial environments or last a long time in vehicles. This kind of chemical engineering isn’t flashy but it’s behind many products we count on every day.

Research and Problem Solving

The importance of 2,6-Difluorophenol often ties back to lab research. Scientists searching for new reaction pathways—maybe in the hunt for efficient green chemistry—regularly test chemicals like this as both a reactant and as a tool for modifying other molecules. The compound offers predictable reactivity, which saves time and money for research teams and helps minimize hazardous waste. University labs see value in using it as a teaching tool too. By working with a reliable fluorinated phenol, chemistry students learn key skills for the next generation of discovery.

Challenges and Responsible Use

Despite its strengths, making and handling 2,6-Difluorophenol comes with caution. Fluorinated chemicals don’t always break down in nature, raising environmental questions. The solution starts with tightening up production standards, improving chemical recycling, and tracking industrial waste streams closely. Chemical engineers continue to look for safer synthesis methods—like using less harsh reagents or recycling solvents. It’s on both manufacturers and researchers to keep risk low for workers and the planet without slowing down scientific progress.

What Makes 2,6-Difluorophenol Worrying?

A lot of folks haven’t heard of 2,6-Difluorophenol, but it’s a chemical that pops up in labs and some industrial settings. Its structure is simple: a phenol ring hanging onto two fluorine atoms. This might not sound impressive, but what’s packed into those molecules can cause some damage, especially if handled carelessly.

One thing learned from working in research labs is to never underestimate even the smallest vials of clear liquid. 2,6-Difluorophenol isn’t famous like mercury or lead, but stories from chemists point to strong health risks. The American Chemical Society warns about its toxicity. A splash on skin leads to redness and pain, sometimes even chemical burns. Just sniffing the open bottle lets out a sharp, stinging odor, not unlike stronger cleaning agents, but with a bitter edge that hints at danger. Inhalation can trigger headaches, dizziness, or worse respiratory trouble.

Looking at Toxicity and Exposure Risks

Toxicology data, which many scientists and regulatory agencies trust, lays out the numbers: low LD50 values in animals, meaning a small dose can prove pretty harmful. 2,6-Difluorophenol doesn’t evaporate as quickly as some solvents, but that doesn’t reduce its risk. Spills linger. Residue sneaks into the air or sticks to gloves and bench tops, hitching rides on unsuspecting hands. Chronic exposure amplifies health problems. In research sites where staff worked with halogenated phenols, colleagues complained about sore eyes, nose bleeds, and strange skin rashes.

Municipal water planners, always keeping an eye on chemical spills, flag phenolic compounds as serious troublemakers in drinking water. Even small concentrations turn water foul and toxic to aquatic life. Two fluorines boost its chemical punch, making it even less friendly to both natural environments and human bodies.

Safeguards and Solutions

Training and supervision make up the first line of defense. New chemists learn pretty quickly from seniors: always put on goggles, gloves, and a lab coat—then double-check ventilation before pouring a drop. Anyone cutting corners faces consequences, and not just from bosses; skin reactions remind people fast.

It helps to have up-to-date chemical safety data sheets (SDS) in grabbing distance. The latest recommendations suggest storing 2,6-Difluorophenol away from heat and light, and using chemical fume hoods every single time the bottle opens. Anyone in contact should wash up immediately and toss single-use gloves in a dedicated hazardous waste bin, not a regular trash can.

Lab safety cultures sharpen up through experience and honest conversations. I watched a coworker’s quick reflexes save a spill from turning into an emergency. Emergency showers, eyewash stations, and spill kits are just as important as fire alarms. Everyone, from green students to seasoned researchers, keeps an eye out for unsafe habits.

For those outside the lab—people living near industrial parks or water sources downstream from chemical plants—the best shield comes from public awareness and regulatory oversight. Environmental agencies must monitor waste streams, enforce limits, and require company transparency about what leaves the plant. The Environmental Protection Agency in the United States lists phenolic compounds for rigorous review in effluent streams. Public pressure led to those checks and should keep them going strong.

Taking Safety Seriously

2,6-Difluorophenol deserves respect, not just from researchers but from companies and the communities that could feel its impact. Every workplace handling chemicals should focus on better training, clear labeling, thorough cleanup routines, and a willingness to speak up about unsafe practices. Small habits and strong oversight keep dangerous substances from creating bigger stories in headlines and hospitals.

The Importance of Knowing Molecular Weight

Chemists and researchers lean on molecular weight for nearly every calculation in the lab. Think about mixing chemicals for a new material or figuring out the right dose in medicine—if that molecular weight is off, everything ends up skewed. I remember working through an undergraduate organic chemistry lab, and my first thought always pointed to the periodic table. You build molecules piece by piece, carbon by carbon, atom by atom.

2,6-Difluorophenol draws some attention in organic synthesis and pharmaceutical research. The structure might sound complicated, but it boils down to a benzene ring holding two fluorine atoms at the 2 and 6 positions along with a hydroxyl group. Simple substitutions at key spots on a ring have a way of tweaking a molecule’s character.

Crunching the Numbers: How Chemists Calculate It

Let’s break down the chemistry: the molecular formula for 2,6-Difluorophenol is C6H4F2O. Pulling up the standard atomic weights:

- Carbon (C) weighs in at about 12.01

- Hydrogen (H) comes to 1.01

- Fluorine (F) hits 18.998

- Oxygen (O) measures 16.00

Stack them up: (6 x 12.01) + (4 x 1.01) + (2 x 18.998) + (1 x 16.00). That brings the total right around 130.09 g/mol. Seeing those numbers click together always brings back the energy of working through assignments or prepping reaction mixtures. It’s one of those core skills you never stop using. Miss a single decimal, and the entire recipe falls out of line.

Why This Number Matters

Knowing the molecular weight means everything in chemistry circles. If you want to weigh out a sample, you grab that number to convert grams to moles. If you need to track how much product a reaction makes, you lean on precise molar amounts. I’ve seen too many reactions go sideways in classrooms just because someone skipped a decimal or misread the formula. Safety nets in industry depend on these calculations—hazard assessments, drug formulations, pollution tracking—each starts with nailing the numbers.

From personal experience, even tiny molecules like 2,6-Difluorophenol leave a big footprint in research. Academic labs keep records with detailed molecular weights, down to two decimal places, so that colleagues worldwide speak the same language.

Supporting Reliable Knowledge and Safety

Accurate molecular weights support safe science and clear communication. Transparency in data builds confidence—no one wants to guess if a drug batch or an industrial process made the grade. Any misstep in calculation can cost a business or research group dearly. As we move deeper into precision medicine and advanced materials, expectations for rock-solid chemistry only go up.

Reliable, well-documented molecular weight data connects research across borders, and that drives better science in every field. Careful calculation, peer-reviewed sources, and transparent reporting back up every claim. That’s a standard every researcher, whether in a teaching lab or a commercial research hub, learns to respect early on.

Potential Solutions for Better Accuracy

To keep mistakes off the radar, teams need regular calibration of equipment and routine checks of reference materials. Digital tools and up-to-date chemical databases simplify everything, cutting out the room for expensive errors. In my experience, double-checking even well-known compounds keeps operations smooth—nobody wants to gamble a whole project on a miscalculation. Connecting theory with practice, leaning on standards and reputable databases, and building a habit of attention to detail matter more than ever.

Why You Can't Treat Every Chemical the Same

Spending years in the lab, I’ve watched plenty of bottles line the shelves. Some draw more respect than others. 2,6-Difluorophenol stands out as one of those chemicals that demand a little extra care. This isn’t just another brown liquid—it's got a pungent smell, can irritate your skin, and comes with real hazards if you let things slide. It’s pretty easy to see why people ask about the right way to store it. Once, someone left a bottle out with the stopper loose, and the air in the whole room turned sharp and harsh. We couldn’t go back in for hours.

Understanding Its Risks

This compound—known for use in some pharmaceutical work—brings risks that you just can’t ignore. Because its vapors can irritate your nose, throat, and lungs, you never want to breathe it in or let it soak into your hands. Long-term exposure to vapors has been linked to headaches and breathing trouble. If it leaks, it’ll stain your work area and leave a smell that takes forever to clear. I always felt frustrated cleaning up after someone who didn’t tighten a cap.

How to Store 2,6-Difluorophenol Smartly

A bottle of 2,6-Difluorophenol shouldn’t live with the rest of the run-of-the-mill solvents. For starters, you need a cool, dry spot—nothing fancy, just somewhere below room temperature that doesn’t swing up and down with the weather. People often tuck their flammable organics into a vented chemical cabinet. That’s the right call. The storage spot has to sit far away from any heat source. Even setting a bottle on a sunbathed shelf can spell disaster.

This liquid reacts with strong oxidizers, so always keep it far from acids, peroxides, or anything reactive. In our lab, we kept the hazardous bottles labeled using a bold color, stashed on a lower shelf. Accidents happen a lot less if you treat strong-smelling organics with a bit of suspicion. I’ve had close calls—one quick grab in a rush could turn into a broken bottle on the floor if someone placed it up high.

Keep the People and the Planet Safe

Air-tight containers remain your best bet—glass with a proper cap holds up well, but plastic resists corrosion from fumes better over the years. Double-check the seals and keep bottles in a tray that’ll catch drips. Trust me, it's worth wiping down bottles every time you use them. Chemical-resistant gloves, goggles, and a splash-proof lab coat never feel like overkill after you’ve dealt with a spill.

Good storage also means you label dates and run regular checks. I remember pulling out a crusted bottle during an audit; nobody had logged it in years. Responsibility falls on everyone in the lab. If you see something sketchy—a leaking cap, mystery residue—say something before it becomes a bigger deal.

Ideas for Doing Better

Most labs could use more regular training and clear signage about where each class of compound goes. Rules help, but habits matter more. Regular reminders—simple as a note over the cabinet—keep safety in mind. Maybe you work in a place with young techs just learning the ropes. Take a minute to show them what goes where and why. It’s quicker than cleaning up chemical burns later.

Storing chemicals with respect doesn’t come from fear, it comes from hard-earned experience. Handle 2,6-Difluorophenol with the attention you’d want from the next person down the line. It pays off in a cleaner, safer lab, and no one loses a day’s work to a lingering odor or a rash.