2,6-Difluorobenzamide: A Deep Dive into Its Science and Impact

Historical Development

Chemistry has a long love affair with fluorine, and the story of 2,6-difluorobenzamide did not spring up overnight. Scientists first explored difluoro benzenoid compounds in the search for molecules with both biological punch and synthetic flexibility. In the postwar push for new agrochemicals and medicines, tweaking every available aromatic ring seemed a full-time job. Researchers began making benzamides with various substitutions, setting up the foundation for 2,6-difluorobenzamide to step into the spotlight. By the late 20th century, this compound emerged as an intermediate for herbicide and pharmaceutical research, thanks to its unique blend of stability and reactivity. People in the industry wanted something that handled well in the lab, offered precision in industrial synthesis, and met the rising bar for safety and environmental impact. Newer apparatus and purer starting materials helped chemists nail down reliable preparation methods, a real turning point for regular commercial use.

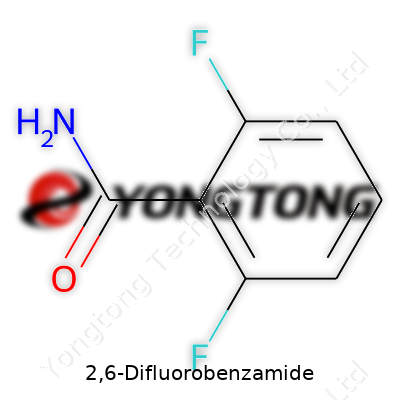

Product Overview

2,6-Difluorobenzamide covers a lot of ground in chemistry. It starts with a benzene ring, drops fluorines at the 2 and 6 slots, and finishes it with a classic amide group. This simple tweak puts a lot of power in one molecule: enough electronegativity to stand up against metabolic breakdown, enough manageability to become a base for further functionalization. This molecule has become a go-to intermediate for chemists who want to build drugs, crop protectants, or specialty chemicals. More than a raw building block, it helps underpin cleaner, more selective reactions—a feature that keeps it in steady demand.

Physical & Chemical Properties

You can spot 2,6-difluorobenzamide in the lab as a white crystalline solid. It doesn’t carry an unpleasant odor, which keeps working environments more tolerable compared with many amides. Its melting point hovers around 131–134 °C, making it robust enough for most handling needs. With a molecular weight of 157.12 g/mol and moderate solubility in both organic solvents and warm water, it plays well in typical synthesis and purification steps. The pair of fluorines bump up its resistance to chemical attack and biological breakdown, so once made, it sticks around longer than many of its non-fluorinated cousins. The amide function can engage in hydrogen bonding, which can influence both solubility and reactivity in downstream transformations.

Technical Specifications & Labeling

Quality standards matter more than ever in today’s manufacturing climate. Purity for research-grade 2,6-difluorobenzamide usually tops 98%, verified by HPLC or NMR, to limit nasty byproducts. Regulations in the US and EU ask for labeling with CAS No. 18063-03-1, hazard symbols, and all necessary details about storage and handling. Labels typically flag eye and skin irritation as well as give clear batch tracking for traceability. Companies supply certificates of analysis and safety data sheets—information that ends up making or breaking trust during audits or international shipments. Packaging ranges from laboratory vials to multi-kilo sealed drums, built to keep product dry, avoid contamination, and survive global transit.

Preparation Method

Synthesizing 2,6-difluorobenzamide generally starts with 2,6-difluorobenzoic acid. Chemists convert this carboxylic acid into its acid chloride using thionyl chloride or oxalyl chloride. The next step is to bubble ammonia into the reaction, forming the amide bond and liberating side products like hydrogen chloride gas, which get scrubbed from the system. This route keeps costs in check, avoids exotic reagents, and scales to multi-kilo lots without exotic engineering. With modern controls, side reactions and impurities have been held to low levels. Some labs push for greener chemistry—using carbodiimide activation instead of acid chlorides or working in water-rich solvents—but the backbone of industry preparation has not strayed far from these original bench-top tactics.

Chemical Reactions & Modifications

The chemical strength of 2,6-difluorobenzamide lies in its ring. Those two fluorines add electron-withdrawing character, steering reactivity to new places compared with unmodified benzamides. It stands up well under conditions where hydrogenated benzamides might fall apart or rearrange. Nucleophiles can attack the amide in specific ring transformation reactions, though the fluorines slow the pace, which can be an asset in multistep synthesis. It undergoes N-alkylation or N-acylation to make new analogs for drug or agrochemical development. With the right catalysts, chemists can even swap out one or both fluorines for other groups, opening a door to prepare arrays of analogs for patent-driven industries. Strong bases and electrophilic aromatic substitution remain somewhat limited due to the fluorine effect, but creative teams find workarounds, showing the flexibility that keeps this molecule interesting.

Synonyms & Product Names

On chemical shelves around the world, 2,6-difluorobenzamide doesn’t stick to just one label. Some suppliers call it Benzamide, 2,6-difluoro-, while others refer to it as 2,6-DFBA or DFBA. Depending on the catalog, you might spot the name AI3-51824 or other system-generated variations based on structure. These synonyms can trip up the unwary researcher trying to order the correct precursor—so regular checks between CAS numbers, supplier lists, and internal tracking files remain an essential habit in both R&D and manufacturing.

Safety & Operational Standards

Safety in handling 2,6-difluorobenzamide lands squarely in the camp of good laboratory practice. Skin and eye contact create irritation, though not the burning hazard of more volatile amides. Gloves, goggles, and lab coats should not be skipped—accidents happen fast during high-throughput synthesis or scale-up. Airborne dust rarely reaches concerning levels under proper ventilation, but respiratory masks work as a backup in poor settings. Spillage or accidental exposure calls for quick washing and medical review, but most labs find the risks manageable with current training and facility controls. Waste must route through certified disposal paths, especially in regions tightening down on halogenated organics in water streams. Fire is not a frequent threat, but dry conditions and separation from acids or oxidizers round out the safety basics.

Application Area

Pharmaceutical and agrochemical developers have invested serious resources in 2,6-difluorobenzamide derivatives. Its rigid structure and metabolic resistance find frequent use in preparing new drug candidates targeting inflammation, cancer, or neurological conditions. On the farming side, herbicide chemists reach for this compound to build molecules punishing to weeds but sparing to crops. Even outside commercial chemicals, academic labs run transformations on this benzamide to test new synthetic routes or reaction concepts. Environmental testing firms sometimes use it as an internal standard to calibrate mass spectrometry, due to its stability and traceability. It also acts as a foundation in structure-activity relationship studies—scientists swap those fluorines or the amide backbone to tease out trends that guide future discovery.

Research & Development

Innovation drives new uses and better handling of 2,6-difluorobenzamide. Research groups recently published new catalytic methods to introduce or swap fluorines, further opening the toolbox for medicinal chemists. Some teams use it in probe molecules to study how drugs bind proteins, exploiting its particular electronic effects to reveal new patterns. Stability under oxidative conditions gives formulation scientists a jump on shelf-life improvements. The gold rush for bioactive molecules has expanded to seek fluorinated structures, and 2,6-difluorobenzamide provides a ready scaffold. Startups and corporate labs alike keep filing patents on new uses and modifications, showing that even a “simple” molecule can keep surprising us when paired with today’s tools.

Toxicity Research

No one wants to find out too late that an intermediate poisons test animals or workers, so toxicologists have put 2,6-difluorobenzamide under the microscope. Most standard tests in rats and bacteria show low acute toxicity. It does not bioaccumulate in common model systems at normal levels, and no genotoxicity stands out. Still, chronic exposure or high doses should be avoided, as the long-term interaction of halogenated organics with biological tissues remains an active research field. Eye and skin irritation stand documented, and regulatory bodies push for updated handling recommendations as new studies roll in. The industry keeps evolving on the front of worker health—companies run air and surface tests, invest in training, and prepare for worst-case cleanup even absent major incidents.

Future Prospects

The next decade will shape 2,6-difluorobenzamide’s legacy far beyond its current uses. New computational models point to even more biological targets waiting for exploration, and the pressure for green chemistry will keep the industry searching for production routes with lower waste and energy use. Upgrades in purification equipment should drive purity higher and costs lower, pushing the compound into niches that demand clean intermediates. Universities and startups will keep expanding the roster of physical and medicinal transformations, possibly uncovering applications no one sees today. Some see it as a stable workhorse for building more complex molecules, others as a chemical probe to illuminate underexplored biological spaces. Science never stands still, and neither does the role of building blocks like 2,6-difluorobenzamide.

Understanding a Key Chemical Ingredient

It’s easy to overlook the small chemicals that keep big industries running. 2,6-Difluorobenzamide falls right into this category. Most people have never seen it on a store shelf or in a product label, yet it plays a behind-the-scenes role in areas like pharmaceuticals, agriculture, and advanced materials.

The Backbone of New Compounds

My background in pharmaceutical research taught me that the search for better drugs often starts with chemicals known as “intermediates.” 2,6-Difluorobenzamide serves as one of these building blocks. Drug development teams use it to create new compounds with targeted properties. Its molecular structure, featuring two fluorine atoms, gives chemists opportunities to design medicines that last longer in the body or resist breakdown. Research has shown that adding fluorine to a molecule often increases its stability and activity, making medicines more effective or helping reduce side effects.

Agriculture’s Quiet Helper

People in farming communities rarely hear about chemicals like this, but their impact reaches the food we eat. Some herbicides get their power from base chemicals much like 2,6-Difluorobenzamide. When I worked on a project evaluating crop yields in Midwest farmland, I realized how critical it was for fields to stay clear of invasive weeds. Herbicides built with these intermediates can provide strong weed control and longer-lasting results, helping farmers produce more consistent harvests. No one wants unproven substances used on their food, so crop protection products face heavy scrutiny; companies use intermediates like 2,6-Difluorobenzamide only after confirming they break down safely and don’t build up in the environment.

Supporting Advanced Materials

The tech industry relies on specialty polymers for everything from water-resistant coatings to parts found inside electronics. Chemists often use 2,6-Difluorobenzamide as a step in making new high-performance plastics. Its unique structure leads to polymers that can handle extreme conditions—heat, solvents, or repeated mechanical strain. Materials scientists looking to create more reliable, longer-lasting products keep an eye out for chemical intermediates that offer stability, and this molecule consistently shows up in their formulas.

Addressing Concerns and Moving Forward

Using synthetic chemicals raises reasonable concerns about worker safety, consumer health, and environmental protection. Over the years, tighter controls on production and waste disposal have helped limit exposure and pollution. Chemical plants now follow stricter international regulations. Whenever a new drug or material begins with 2,6-Difluorobenzamide, companies must provide data on toxicity, environmental breakdown, and the ways people could be exposed down the line. Analysts and regulators pore over these records, and products that don’t meet modern safety standards rarely reach the market.

Cost has always shaped how widely used these processes become. As more facilities refine their manufacturing, price barriers tend to drop. At the same time, institutions press for transparency on sourcing and safeguard development from lab to shelf. This improves quality and builds trust. Walking through these changes firsthand, I’ve seen the industry shift from secrecy toward greater openness—both in research and communication with the public.

Paving a Transparent Path

Innovation brings excitement, but vigilance remains essential. With every new chemical, companies face a balancing act between breakthrough and responsibility. In the case of 2,6-Difluorobenzamide, the story plays out not only in factories and labs but also in daily products and public health policies. As research deepens, responsible use shapes a future that benefits more people—without the trade-offs of the past.

The Structure Under the Microscope

2,6-Difluorobenzamide carries the chemical formula C7H5F2NO. This structure lies at the intersection between benzene chemistry and pharmaceutical innovation. The benzene ring, which forms the backbone of countless organic molecules, gets two fluorine atoms attached at the 2 and 6 positions. Swapping hydrogen atoms for fluorines packs a serious punch, both in stability and in bioactivity. The amide group—made by bonding an amine to a carboxylic acid—hangs off the ring, shaping not only how this molecule interacts in a lab but also how it behaves inside living systems.

Why Chemical Precision Matters

Chemical research never settles for just a name; it looks for certainty in numbers and atoms. Knowing exactly what makes up 2,6-Difluorobenzamide makes a difference beyond the laboratory. Chemists won’t waste time second-guessing how a fluoro substituent changes reactivity or stability. Each alteration to a benzene ring means new possibilities for drug design, crop protection, and advanced materials. Fact is, the presence of fluorine atoms on aromatic molecules like this one does more than tweak the weight; it transforms solubility, metabolic resistance, and how enzymes in the body grab hold of the molecule.

Real Impact in the Real World

Many modern medications and agrochemicals build on these chemical tweaks. More than once, a simple substitution on a benzene ring meant the difference between a passing fad and a blockbuster drug. In pharmaceuticals, adding fluorine at precise spots blocks unwanted metabolic breakdown, lengthens how long the drug sticks around in the bloodstream, and sometimes sidesteps toxicity. Companies rely on this class of compounds to shape everything from antifungals to anti-inflammatories. Knowing the chemical formula lets researchers predict how the molecule behaves, whether that’s dissolving in water or withstanding stomach acid.

Why Fluorine Changes Everything

I have seen how tiny changes in molecular structure bring big results in the lab. Swapping out hydrogens for fluorines on a benzamide can mean a shift in melting point or a boost in shelf life. Fluorinated compounds often slip through membranes in a way non-fluorinated relatives cannot, swinging the door open for new medicines that target hard-to-reach tissues. This isn’t just academic; it turns up in cancer treatments, antibiotics, and pain relievers on pharmacy shelves worldwide.

Seeking Better and Safer Compounds

The hunt for safer, more effective chemicals keeps pushing scientists to study exact formulas and structures. Knowing the formula of 2,6-Difluorobenzamide matters in risk assessment and regulation. It’s easier to judge environmental persistence or toxicity if you have a solid grasp of what’s inside the compound. In some labs, researchers use predictive software based on this molecular identity to anticipate how new derivatives might bind to proteins or break down in the environment.

Building Tomorrow’s Science

Every detail, from the arrangement of fluorines to the presence of an amide group, fuels innovation in both industry and academia. C7H5F2NO is more than a formula—it’s a cue for creative thinking and careful responsibility in research. With each new variant, chemists carve paths to safer drugs, better crop-protecting agents, and materials tough enough to handle the future’s demands.

What Science Says About 2,6-Difluorobenzamide

2,6-Difluorobenzamide pops up in labs and manufacturing as a building block in chemistry, most often as an intermediate. Plenty of people without a background in chemical safety might wonder if this white powder poses risks for workers or communities around those facilities. I’ve worked in research settings that dealt with all sorts of chemicals, and every time a new name hit my desk, the first stop was reliable safety data sheets and trusted resources like the European Chemicals Agency (ECHA) or the U.S. Environmental Protection Agency (EPA). These places gather studies and flag substances that pose clear threats to health or the environment.

With 2,6-Difluorobenzamide, technical literature points to relatively sparse toxicity data. The compound hasn’t landed on major international hazard lists, and so far, researchers have not found large-scale incidents involving worker illness or widespread contamination. Still, it doesn’t make sense to treat it lightly. Its molecular structure carries two fluorine atoms on a benzamide ring. Organofluorine compounds sometimes behave unpredictably, and even minor benzamide derivatives can slip under the regulatory radar if few people study them.

Practical Exposure and Handling Risks

Factories and research labs are often the only places you’d find regular contact with 2,6-Difluorobenzamide. If you step inside a chemical plant, the sharp scent of solvents and an array of gloves, goggles, and hoods signals that even ‘unremarkable’ chemicals can irritate skin or eyes, or cause breathing trouble if mishandled. Workers in these environments follow strict hygiene and handling rules. The smart move is to store this compound in airtight containers, keep it away from food, and avoid inhaling any dust or vapors.

Most toxicology profiles of similar benzamide compounds suggest the biggest risks come from inhaling dust or dust getting on the skin, though there haven’t been red flags for cancer, lasting reproductive harm, or environmental persistence at the levels produced so far. Accidental spills get cleaned up with special absorbents and lots of ventilation. A big part of why chemical injuries stay rare is because plant managers and safety officers act like every powder could bite back. That kind of caution pays off.

Why Vigilance Remains Essential

Respect for chemicals comes from experience, not just from reading alarming stories. Fluorinated organics deserve attention because some can build up in the environment or affect wildlife, even if each compound in the category behaves differently. Some of the worst offenders, like PFAS, show up in the news for widespread water contamination. There’s no public evidence 2,6-Difluorobenzamide causes the same mess, but chemical companies rely on updated safety assessments to avoid future surprises.

Moving Toward Smarter Safety

Better labeling, transparent sharing of research, and quick reporting of accidental exposures or spills give both workers and communities peace of mind. Occupational safety depends on following best practices: clear signage, precise containers, regular air monitoring, and updated personal protective equipment. On-site training helps everyone understand where risks live and what to do if something goes sideways.

Public agencies like the EPA and OSHA need strong reporting requirements, so new chemicals like this don’t fall through the cracks. Producers also have a role to fund more toxicity testing. In my time around research teams, questions about safety drove many practical changes—from swapping in less hazardous alternatives to stepping up spill-response drills.

The bottom line comes down to practical respect: no sense downplaying risks until long-term data arrives, and no reason to panic without evidence. Stay cautious, stay informed, and keep lines of communication open between industry, regulators, and communities.

Understanding the Substance

2,6-Difluorobenzamide draws interest from labs working on agrochemicals, pharmaceuticals, and specialty chemical research. As a benzamide derivative, it carries the kinds of health and stability risks that highlight why proper storage goes beyond a checkbox on a safety document. People who handle these chemicals can face real issues if basic precautions get overlooked.

Temperature and Humidity Considerations

Many chemicals don’t react well to dramatic temperature swings. 2,6-Difluorobenzamide comes with a standard recommendation: store it at room temperature, ideally around 20–25°C. Warm storerooms can kickstart decomposition. Cold isn’t always safe either, since condensation on bottles promotes hydrolysis or clumping. I’ve seen labs lose sample purity in humid climates where air conditioning falters or containers stay open longer than intended. For those battling hot, humid summers, silica gel packs in cabinets prove their value quickly.

Dealing with Light and Air

Some compounds turn unstable if kept in bright light. 2,6-Difluorobenzamide, with its aromatic ring, places in the “safer in the dark” category. Translucent jars or doors seem harmless, but shelf-life drops with UV exposure, and—unchecked—photo-degradation can create unexpected side-products. Best practice is amber glass bottles in opaque cabinets. Lid discipline matters. I once tracked a mystery contaminant in a project sample, only to discover the real culprit: a loose cap on an otherwise clean bottle.

Importance of Labeling and Segregation

Stockpiling different powders or liquids on one shelf sometimes tempts those in a hurry. It’s a mistake. 2,6-Difluorobenzamide, despite being relatively stable, shouldn’t sit with acids, oxidizers, or moisture-loving substances. Cross-contamination isn’t rare in busy research spaces where hands juggle pipettes and flasks. I recommend labeling every bottle with the opening date, the chemical’s full name, and a hazard warning—even if everyone thinks the system stays organized. This habit limits confusion, and it proves critical if an inspection or emergency hits.

Personal Safety and Emergency Prep

Direct skin or eye contact leads to irritation. Wearing nitrile gloves, goggles, and lab coats cuts the risk. Ventilation matters. Volatile chemical fumes gather in closed rooms, especially where storage space stays cramped. Dedicated safety cabinets with exhaust vents provide long-term protection from accidental inhalation. Absorbent spill kits must sit close by, not hidden in a closet at the building’s far end. I’ve known teams forced to improvise with paper towels—never ideal during a chemical spill.

Waste, Expiry, and Inventory

Old chemicals often turn overlooked hazards. Set a review schedule. Disposing of expired 2,6-Difluorobenzamide in compliance with local waste rules keeps labs safer and cleaner. Inventory audits tighten up purchasing and encourage swapping out older stocks for freshly received material. Digital records, updated by everyone involved, stop repeats of “mystery white powders” sitting on back shelves.

Building Safer Habits

New team members benefit from hands-on training. People forget written protocols if stress or deadlines kick in. Showing real-life stories about chemical mishaps, both minor and major, builds respect for routine safety checks. In my own experience, simple steps—closing lids, updating logs, wearing gloves—cut chemical headaches that nobody wants.

Understanding the Substance and Its Uses

2,6-Difluorobenzamide doesn’t show up on most people’s shopping lists, but researchers, chemists, and specialty manufacturers know it as a vital ingredient in a handful of chemical processes. It’s plain to see that anyone searching for this specific molecule is probably trying to craft something with precision—maybe developing pharmaceuticals, agricultural compounds, or advanced materials. Getting a reliable source is no small task, and the stakes are high when purity and traceability can't be compromised.

Why You Don’t Find it on the Usual Shelves

Unlike aspirin or bleach, chemicals like 2,6-Difluorobenzamide aren’t found in general stores. There’s strong regulatory oversight for substance sales, especially for laboratory and industrial materials. Many countries enforce registration, licensing, and documentation before purchase, rooted in safety and accountability. From personal experience as someone who’s worked in a university setting, you always had to show credentials and explain the project before any supplier would talk about price or shipping.

The Trust Factor: E-E-A-T in Chemical Purchases

Google’s concept of Experience, Expertise, Authoritativeness, and Trustworthiness (E-E-A-T) might sound like something built for websites, but it fits research chemicals just as tightly. Top suppliers display verifiable credentials—think ISO certifications, detailed lab reports, and clear safety procedures. As a scientist who’s ordered specialty chemicals, you quickly learn that rushed, shadowy offers can end a project or trigger safety inspections. Reliable distributors share full product specifications and batch analysis.

Finding the Right Suppliers

Reputable laboratory suppliers stand out. Thermo Fisher Scientific, Sigma-Aldrich, and TCI are names that often pop up in labs and published studies. Smaller, region-specific suppliers like Alfa Aesar also come recommended by colleagues. These companies list chemicals with catalog numbers, purity levels, and data sheets. Try searching through their websites first—each order usually involves account verification and a few hoops to prove legitimate use.

Any buyer should look for key indicators: Clear address and contact details, product documentation, and transparent shipping policies. Some even allow buyers to view past safety recalls and certificates of analysis for added reassurance. Before opening a company account, it’s smart to talk directly with sales reps and ask about origin, handling, and shipping. If there’s ever a hesitation or vague answer, move along.

Tackling Barriers in Availability

A common challenge is crossing borders. Regulatory blocks on chemical imports can cause major headaches. Once, our lab lost months when customs flagged an incoming package. The solution involved tightening paperwork, listing intended use, and paying close attention to import restrictions. U.S. and EU chemical controls are tough but workable for documented research and industrial use. Collaborating with licensed domestic distributors sometimes helps.

Safe Handling: Nothing Optional Here

Handling 2,6-Difluorobenzamide or any lab-grade chemical means detailed attention to storage, disposal, and incident planning. Suppliers share hazard and safety sheets—don’t skip them. Having worked with both new and veteran researchers, it’s clear that understanding and respecting chemical risks keeps everyone safe. Good habits, not shortcuts, make the difference.

Moving Forward: Building Trust and Skill

Buying specialty chemicals calls for preparation, paperwork, and patience. Whether sourcing for a business, a university, or a startup, seek out suppliers with strong track records, thorough documentation, and open customer service. Smart buyers compare multiple vendors, ask pointed questions, and treat every purchase as a step in building a reliable supply chain.