2,6-Difluoroaniline: A Deep Dive into Its Journey and Role in Modern Chemistry

Historical Development

2,6-Difluoroaniline didn’t get noticed until chemists in the mid-20th century started digging deeper into halogenated aromatics. In those days, most manufacturers relied on simple anilines for their dyes and pharmaceutical precursors, but as researchers probed the influence of substituents on reactivity and function, the difluoro derivatives rose in importance. Fluorination turned out to have a big impact on the chemical and biological behavior of aromatic rings. Laboratories working in agrochemical and pharmaceutical discovery broadened their focus to these compounds by synthesizing new analogs, tweaking physical properties, and generating patentable drug scaffolds. The journey of this compound mirrors the broader trend—the hunger for structural variation as science pushed forward.

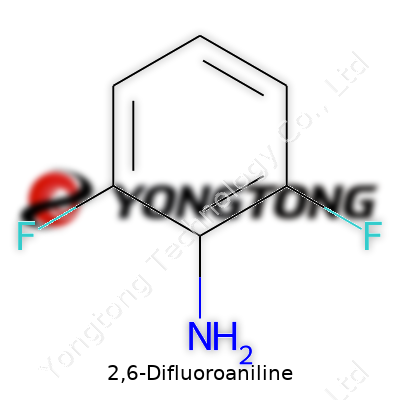

Product Overview

At a glance, 2,6-Difluoroaniline looks like a simple fine chemical, but the story goes well beyond the bottle. Most manufacturers provide it as a colorless to pale yellow liquid, lightly aromatic, with a sharp, chemical odor. The main buyers come from companies active in pharmaceutical intermediates, crop protection, and specialty polymers. Today’s synthetic chemists count on building blocks like 2,6-Difluoroaniline for creating complex molecules, because the fluorine atoms change reactivity in a predictable way. It’s not just another aniline; it’s a key part of modern chemical libraries.

Physical & Chemical Properties

As someone who has spent hours in front of a lab bench, I appreciate how small structural tweaks can dramatically alter a compound. 2,6-Difluoroaniline has a boiling point around 180–185°C, reflecting the two electron-withdrawing fluorines on the ring. The density falls near 1.3 g/cm³, and it dissolves in typical organic solvents such as dichloromethane and ethanol. The two fluorine atoms at the ortho positions activate the ring toward nucleophilic addition and stabilize the molecule against oxidative breakdown. Unlike plain aniline, the electron deficit at the ortho positions shifts reactivity, opening up new routes for selective functionalization.

Technical Specifications & Labeling

Producers in Europe, America, and Asia stamp their labels with batch numbers, assay purity often greater than 98%, and closely track water and impurity content via advanced techniques like GC-MS. GHS labeling rules require clear hazard pictograms—skull-and-crossbones for toxicity, exclamation marks for irritancy. Most shipments travel in amber glass or tightly sealed steel containers, always marked with UN numbers and safety data references. Even in small research labs, staff must log each bottle and store it separately from oxidants and acids. Chemical traceability runs from production site to end-user, a necessary step for both safety and patent defense.

Preparation Method

Getting to 2,6-Difluoroaniline from scratch typically starts with 2,6-difluoronitrobenzene. Industrial chemists use catalytic hydrogenation—often on palladium-on-carbon—at moderate temperatures and pressures. Some labs choose iron or tin with hydrochloric acid in smaller setups. This route avoids over-reduction or dehalogenation, as those valuable fluorines must stay untouched. Sourcing and waste management stand out as the main challenges: nitrobenzenes and reducing metals both raise environmental red flags, so process controls and solvent recovery need tight attention. As stricter emissions rules come into force worldwide, synthetic routes shift toward hydrogen gas and reusable catalysts to reduce the environmental footprint.

Chemical Reactions & Modifications

2,6-Difluoroaniline gives organic chemists a flexible platform for derivatization. Those two fluorines set off a domino effect: activating certain positions for nucleophilic substitution, deactivating others, and enabling complex cyclizations. Typical reactions include acylations, sulfonations, and diazotization for making azo dyes or complex heterocycles. Medicinal chemistry teams introduce new substituents on the nitrogen atom for testing pharmacological effects, or use the aromatic amine to create ureas and sulfonamides. At each stage, the balance between reactivity and stability hinges on those two small fluorine atoms—without them, none of the downstream chemistries would behave in quite the same way.

Synonyms & Product Names

I’ve seen this compound called several things, depending on country and catalog: 2,6-Difluoroaniline, Benzenamine, 2,6-difluoro-, and 1-Amino-2,6-difluorobenzene. Larger distributors often assign proprietary codes for quick inventory checks. In regulatory documents, the CAS number 5509-65-9 secures universal recognition, preventing confusion with isomers or related halogenated anilines. This patchwork of names really proves the importance of careful chemical tracking—especially as trade and research spread across borders.

Safety & Operational Standards

2,6-Difluoroaniline ranks as hazardous: skin, eye, and respiratory irritant, with potential systemic toxicity after exposure. Workers in a production facility wear gloves, splash goggles, and filtered respirators, particularly during large-scale synthesis or packaging. Strict ventilation, closed systems, and emergency showers form part of the operational checklist. Spillage response drills mark the difference between a routine accident and a major incident. All waste streams, whether aqueous or organic, require neutralization and incineration under seasoned supervision. For research users, training makes a difference—knowing how not to become a statistic, learning from industry’s long list of near-misses and lessons written in technical bulletins.

Application Area

You’ll find 2,6-Difluoroaniline woven into molecular scaffolds for drugs and agrochemicals, especially as a key ingredient in advanced herbicides and insecticides where specific biological targets respond well to ring-fluorinated structures. Drug discovery teams value it for synthesizing kinase inhibitors, antivirals, and experimental CNS treatments, since fluorine atoms can enhance membrane permeability and tweak metabolic stability. Polymer chemists tap into this building block for engineering heat-resistant and chemically stable films. Several dye manufacturers use difluoro-substituted anilines as their anchor for new hues. It’s a true workhorse in the world of specialty chemicals, even if most people outside a laboratory never hear its name.

Research & Development

Inside advanced R&D labs, chemists look for fresh synthetic routes to make the process greener and cheaper—lowering energy use, swapping out toxic solvents, and capturing side-streams for recycling. Ongoing work investigates new coupling reactions and late-stage functionalization, allowing one-pot multistep syntheses. As pressure grows from customers and regulators, the most successful labs publish route optimizations that cut waste and shorten time to market. Meanwhile, computational chemists delve into fluorine’s effect on receptor-ligand interactions, mining data for next-generation bioactive compounds built from the 2,6-difluoroaniline skeleton. Industry-academia collaborations have picked up speed, with universities publishing new reaction pathways that filter into industrial scale-up campaigns just a few years later.

Toxicity Research

Toxicologists and environmental scientists have spent years tracking the persistence and health risks of difluoroaniline derivatives. Laboratory studies on rats and mice show that high doses can trigger central nervous system depression, liver changes, and potential genotoxic effects. Aquatic toxicity catches attention too, especially given the compound’s slow biodegradation in surface waters. That raises real-world questions about safety standards in both manufacturing and end-use environments. European and Asian regulators regularly tighten exposure limits, requiring industrial dischargers to adopt advanced filtration or closed-loop systems. Science keeps pressing for less hazardous replacements, but there’s still heavy demand for proven fluoroaniline derivatives—so occupational monitoring and PPE remain frontline defenses.

Future Prospects

Much of the next chapter for 2,6-Difluoroaniline focuses on sustainability and new field applications. Startups and research arms at chemical giants are testing bio-based routes and electrochemical fluorination methods. Green chemistry principles drive the search for catalysts and reaction media that leave a lighter environmental mark, pressing beyond batch reactors to continuous processes. In the life sciences arena, scientists hope for more selective and effective drugs built on difluoroaniline frameworks. Artificial intelligence models now predict new biological targets and synthesis options, accelerating timelines. I suspect the fluorinated aniline—once niche, now mainstream—will keep finding novel uses, especially as climate policy and chemical regulation ramp up demand for more sustainable solutions in every corner of modern industry.

Why Small Changes in Molecules Matter

Even a simple tweak in a chemical structure can lead to a big difference in how a compound behaves or gets used. 2,6-Difluoroaniline really shows how chemistry works at a fine level. Take aniline, slip in two fluorine atoms at the right spots, and you get something that can interact very differently in chemical reactions. The formula for 2,6-Difluoroaniline is C6H5F2N. This means its benzene ring carries two fluorine atoms at the second and sixth positions, leaving a single amine group attached. The rearrangement of just two atoms gives new properties, which tells a lot about how chemistry shapes technology and medicine.

Why Knowing the Formula Matters

It’s not just academics who need to get the formula right. In real-world labs and factories, one wrong digit in a formula can send a project off the rails. The position of those two fluorine atoms brings new opportunities for synthesis. Pharmaceuticals, agricultural chemicals, and dyes draw on a deep understanding of structure. Subtle changes in atomic arrangement shift boiling points, reactivity, and toxicity.

There’s a good example in drug development. Many modern medicines get their advantages from fluorine atoms slipped into very specific spots on a molecule. These tweaks improve stability in the body, make absorption easier, or stop the compound from breaking down too fast. 2,6-Difluoroaniline forms a building block in these processes, providing a starting point for more complex chemistry. Someone working at the bench uses structures like this every day; it’s not just an academic point, it’s a step toward the next cancer drug or another pesticide that needs to last longer in the field.

Why Fluorine Atoms Get a Lot of Attention

Fluorine’s almost unmatched in its ability to change a molecule’s character with only a small addition. With 2,6-Difluoroaniline, those two extra fluorines make the whole molecule less likely to react in certain ways, but they also create a pattern that’s easier to recognize in analysis like NMR or chromatography. Cheaper manufacturing processes have opened up the supply of difluorinated compounds, which matters for research and industry.

Personal experience in the lab confirms it—sometimes, after hours or days of synthesis, just one wrong formula will waste an entire batch. Double-checking the chemical formula, especially for tricky aromatic amines like this one, becomes routine. Safety information, storage advice, and predictions for chemical behavior all hang on those few letters and numbers.

Handling Challenges With Chemical Information

Inaccurate descriptions, especially online, pose risks to students and professionals alike. Misinformation leads to failed experiments and, worse, safety hazards. Trusted resources—peer-reviewed journals, chemical supplier datasheets, and established databases—help keep everyone on the right track. In classrooms and on the job, clear notation avoids confusion and saves time.

Promoting chemical literacy means more than memorizing formulas; it involves understanding why a formula points to certain hazards or uses. The right knowledge supports not only innovation but also robust safety practices. Chemical formulas carry weight—they serve as a bridge from the periodic table to practical results in medicine, agriculture, and materials science.

Small Molecule, Big Impact

Most people outside of chemistry classrooms don’t spend time thinking about 2,6-Difluoroaniline. Yet, this compound finds its way into products and processes that many rely on every day. The backbone of its value comes from the two fluorine atoms locked into an aniline ring, a structure that offers both chemical stability and unique reactivity—a powerful mix for modern industries.

Driving Innovation in Pharmaceuticals

Researchers in drug development often count on small changes to deliver big results. Swap a hydrogen for a fluorine atom, and you can change everything from metabolic stability to receptor selectivity. That’s one of the reasons why 2,6-Difluoroaniline keeps showing up in pharmaceutical research. It acts as a starter material—or intermediate—helpful for building more complicated drug molecules. Such small changes help create drugs that last longer in the body and break down more slowly, which can mean fewer pills and a smoother experience for patients.

A few years ago, while working on a small R&D team, I saw firsthand how a difluoro-substituted aniline sped up our discovery work. One day, we struggled with an experimental antiviral synthesis until we tried using 2,6-Difluoroaniline. The fluorines blocked unwanted side reactions, giving us a cleaner pathway and more time to focus on testing the drug’s effects. This sort of result gets repeated across labs worldwide—making this simple molecule an unsung hero in new medicine development.

A Key Player in Crop Protection

There’s another side of the story on the farm. Protecting crops from disease isn’t just about chemistry; it’s about finding the right balance between safety and efficiency. For years, chemical producers have turned to 2,6-Difluoroaniline to build safer, more effective agrochemicals. The unique shape and properties brought by the fluorine atoms let chemists create molecules that harm pests but leave crops untouched. This selectivity cuts down on waste and reduces environmental impact, which matters to both growers and consumers.

A vivid example came up during a project with a crop science group working to tackle fungicides that stick around in soil too long. Using 2,6-Difluoroaniline as a core, their team synthesized a fungicide that broke down quicker after the harvest, lowering residue in food. Solutions like this show real-world benefits when people think through both growth and safety together.

Fuelling Materials Science

Beyond fields and pharmacies, 2,6-Difluoroaniline also finds its way into labs looking for specialty materials. Polymers based on this chemical gain extra toughness and resistance to heat and solvents, which makes them attractive for electronics and coatings. For example, some display screens use materials built on difluoroaniline foundations, providing durability for daily use and better performance under stress. Electronics engineers aim for longer-lasting gadgets, and adding fluorinated aromatics like this one is a step toward those goals.

Paths Forward: Green Chemistry and Safer Processes

As more people grow concerned about the footprint of specialty chemicals, the pressure rises to make 2,6-Difluoroaniline production cleaner and safer. Startups and large firms alike experiment with greener ways to make this compound, cutting back on waste and shifting toward renewable feedstocks. These efforts take time, but public and industry support keeps the momentum going.

With tighter safety standards and smarter guidelines, chemical plants can minimize worker exposure and environmental risk. Tracking supply chains, recycling solvents, and choosing energy-efficient methods all add up. While no single approach solves every issue overnight, it’s clear that progress lies in paying closer attention—every step from lab bench to finished product matters.

Understanding the Risks

The first time I handled 2,6-Difluoroaniline, the caution signs in the lab hit differently. This chemical, clear as water but loaded with danger, packs both toxicity and volatility. Exposure can irritate skin, eyes, and lungs. Even a small spill can create problems nobody wants to deal with. Years working in labs taught me that respect for chemicals isn’t just a guideline. It’s survival.

Personal Protection Always Comes First

Start with the basics—never touch this stuff without the right gear. Nitrile gloves, a lab coat, fully covered arms, and tight goggles are the line between safety and regret. I still remember my mentor showing me scars from a careless splash years ago. Vapors from 2,6-Difluoroaniline can irritate the respiratory tract, so a well-fitted N95 respirator or a fume hood become nonnegotiable.

Ventilation Is Your Best Friend

Labs with strong chemical flow always set up local ventilation or keep work inside a certified fume hood. I’ve seen folks think a cracked window helps, but vapors quickly spread. Even tiny concentrations can make breathing rough and spark headaches. Running experiments in a hood with proper airflow reduces risk, not just to you but to coworkers next door.

Careful Storage Saves Lives

Storing 2,6-Difluoroaniline isn’t just about a label on a shelf. Keep it away from acids, oxidizers, and sources of heat or sparks. One time, a coworker’s bottle leaked because it wasn’t sealed right. The smell seeped through four rooms before anyone noticed. Always double-check container integrity. Security cabinets set aside for toxic organics, made of chemical-resistant material, also protect against accidental mixing and fire.

Clean Up with Confidence

For small spills, absorbent pads and neutralizing agents work. But confidence doesn’t mean carelessness. Never reach for paper towels or your bare hands. If your skin touches even a drop, go to the emergency shower and rinse for at least 15 minutes. Don’t waste time weighing options. For larger spills, evacuate and call emergency response. In my time overseeing lab safety training, panic often set in faster than the chemical spread. Procedures practiced in drills took over and minimized damage.

Medical Attention & Continual Training

Exposure symptoms sometimes appear slowly. I once watched a lab tech downplay a tiny splash on her glove. Hours later, burning and blisters showed up. Don't wait—have a medical professional assess even minor contact. Regular safety briefings keep everyone sharp. Reviewing the safety data sheet isn’t just paperwork; it’s real-time prep for the unexpected.

Practice Makes Safety Real

Every safe chemist I’ve met rehearsed safety daily. No shortcut replaces muscle memory. Spill drills, first aid reviews, PPE inspections—all matter when working with chemicals like 2,6-Difluoroaniline. Geography and experience don’t change the rules—straightforward precautions save health, careers, and sometimes lives.

Melting and Boiling Points: Key Figures

2,6-Difluoroaniline, a colorless to pale yellow organic compound often found in research labs, comes with notable physical characteristics. In practical terms, this compound solidifies at about 16°C. Its boiling point sits near 179°C under typical atmospheric pressure. These numbers might seem like straightforward data, but for anyone working in synthesis or handling specialty chemicals, they matter much more than simple milestones in a day’s work.

Why Melting and Boiling Points Matter

These thermal limits shape exactly how the chemical gets stored, shipped, and integrated into countless reactions. A melting point of 16°C means that in a room that's just a bit chilly, 2,6-Difluoroaniline will stay solid. Researchers moving between lab benches might discover it frozen in a bottle—difficult to pour or dissolve. The boiling point, higher than the boiling point of water, allows greater control over heating processes. It won’t evaporate at low temperatures, which can reduce risks in open systems or accidental spills, but once a reaction climbs above 179°C, lab workers have to consider vapor control.

Personal Experience in the Lab

As someone who’s spent years transferring, weighing, and re-crystallizing chemicals like 2,6-Difluoroaniline, I’ve learned firsthand how these physical parameters dictate workflow. Once, an entire batch solidified in storage on a winter morning, grinding a synthetic sequence to a halt. Time and energy went into warming the bottle gently, not to compromise purity, so work could continue. This isn’t just a minor hassle—a blocked process line can mean ruined samples or delayed research targets.

Worker Health and Safety

Sensible temperature controls reduce accidental inhalation. If a staffer heats aniline derivatives beyond boiling, vapors form rapidly, which can lead to acute exposure if there’s not good ventilation. Regulatory agencies, including the Occupational Safety and Health Administration (OSHA), recognize risks tied to many aromatic amines. While 2,6-Difluoroaniline isn’t the most notorious, strict processes and accurate temperature monitoring protect both product quality and worker well-being.

Broader Impacts and Potential Solutions

Supply chains can break down if materials solidify in transit or cases arrive partially melted. Warehouses without active temperature monitoring might see bottles cracking or labels peeling, spreading confusion over chemical quality. Investment in basic infrastructure, simple heated storage units, and clear training for staff handling specialty chemicals make a difference. Some facilities add real-time temperature tracking to log storage conditions—this approach costs more up front but avoids expensive waste and safety incidents down the line.

Reliable Data: The Role of Trustworthy References

In a world crowded with online data sheets, scientists can’t just grab numbers from random sites. Credible sources like the Merck Index, PubChem, and peer-reviewed journals keep researchers aligned with proven figures. A difference of just a few degrees can spell disaster in sensitive syntheses or analytical work. Relying on trustworthy data doesn’t just help with one bottle of 2,6-Difluoroaniline—it anchors safety, efficiency, and reliability across any chemical operation.

The Range of Choices and Why Purity Matters

Walk through the storage shelves of any midsize chemical warehouse and you’ll spot a handful of drums labeled with purity percentages that can make or break an experiment. Anyone who has worked in a university research lab or in a pharmaceutical company knows what it means to pick the wrong grade for their synthesis. With 2,6-Difluoroaniline, buyers aren’t picking up just “aniline with some fluorines on it” — they’re choosing between different purity levels, each carrying very different risks, reliability, and prices.

It’s easy to overlook purity labels if you haven’t seen an experiment fizzle just because impurities poisoned a catalyst. Yet this happens more than it should. In some shops, you can find grades aimed at industrial uses, where minor side-products get shrugged off as irrelevant. Some places stick to “technical grade” or “industrial grade” for customers making bulk polymers, coatings, or dyes. Minor contamination may not matter when manufacturing things like specialty plastics. But if 2,6-Difluoroaniline is heading toward medicinal chemistry, especially early drug screening, stakes shoot up.

Analytical and reagent-grade versions fill shelves in academic and biotech labs. Here, less than one percent impurity can mean hours of wasted work and data that can’t be trusted. I’ve experienced the panic of seeing GC-MS readouts confirming more contaminants than expected, triggering an urgent hunt for a cleaner batch. Pharmaceutical companies, especially those working under Good Manufacturing Practices (GMP), invest in material that often comes with certificates of analysis attached and detailed impurity profiles. For regulatory filings, using ill-defined material can block trials or pull a regulatory red flag.

Impact on Cost, Results, and Reputation

The purer the grade, the higher the cost. Technical grades tend to run cheaper, but there’s trade-off in consistency and traceability. Multinational suppliers send out safety data sheets that look much the same, whether for reagent or pharma-grade. That comfort doesn’t extend to smaller manufacturers, many of whom ship products that defy easy classification. I’ve called suppliers in the past to ask for trace organic impurity data, only to be told that information wasn’t available, or that “everyone else is fine with this material.” This response never satisfies anyone running sensitive experiments.

Sometimes, somebody tries to save money by buying a technical grade sample, hoping filtration or distillation at their facility will bump up the purity. This can work, but often it proves more expensive in the long run, especially if labor and loss of material pile on. On the flip side, it’s hard to justify buying high-purity, expensive grades for pilot studies or routine testing of plastics if end-use performance won’t change.

The Demand for Transparency and Clearer Labeling

Labs and factories would benefit from greater clarity around what each grade truly contains. Labeling should not just list “>98%” with no context. Sharing exact levels of key impurities — water, heavy metals, residual solvents — would support better, safer decisions. This transparency could help new researchers learn which purity grade matters for their work, and avoid repeating the mistakes others have made. As regulations tighten, especially in pharma, chemical makers ought to prepare for more questions from buyers who expect a trail of documentation.

Whether you’re buying for advanced R&D or a pilot manufacturing run, asking for up-to-date safety and impurity data matters. Relying on good communication with suppliers, and resisting the temptation to cut corners on critical reagents, pays off in the long run. Clean results start with clean ingredients, and 2,6-Difluoroaniline is no exception.