2,4-Xylenesulfonic Acid: Roots, Roles, and Real-World Impact

Historical Development

The journey of 2,4-xylenesulfonic acid traces back to late nineteenth-century organic chemistry labs, where sulfonation of aromatic hydrocarbons became a foundational skill for chemists pushing the boundaries of industrial dye and detergent synthesis. Early research into toluene derivatives drew out the potential locked in the methyl groups of xylene, attracting synthetic chemists exploring new sulfonic acids for novel applications. By the mid-1900s, as synthetic pathways matured and industrial scale production of xylene and its derivatives took off, 2,4-xylenesulfonic acid found consistent utility—particularly in textile dye manufacture, surfactant blending, and as a catalyst in organic transformations. Laboratory journals from this period brim with tales of purification challenges and ambitious synthesis modifications, but progress marched forward, turning the once-finicky compound into an industrial mainstay.

Product Overview

2,4-Xylenesulfonic acid steps onto the scene as an aromatic sulfonic acid, built around a xylene molecule with two methyl groups attached in the 2 and 4 positions, and a sulfonic acid group anchoring the activity profile. This acid usually appears as a crystalline solid ranging from off-white to pale yellow, and it displays strong acidic behavior. Chemical manufacturers market it as both a laboratory reagent and a performance chemical for several sectors, where its reactivity, solubility in water, and stability stand out. In practical terms, industrial buyers and lab techs value straightforward handling and predictability.

Physical & Chemical Properties

This compound displays a melting point that depends on its degree of purity and hydration, generally falling between 105°C and 115°C, and features high solubility in water—traits that help in bulk processing and downstream use. The molecule includes two methyl arms, which add hydrophobic character, and a persistent sulfonic acid group, which contributes to powerful acidity and hydrophilicity. These attributes support its role as a useful acid catalyst and a component in surfactant and detergent design. Its molecular weight sits at 186.21, and it carries a strong, sometimes sharp odor typical of sulfonic acids. Handling this material puts one in the company of other mid-weight aromatic acids, prized for performance but still demanding respect in terms of storage stability and reactivity.

Technical Specifications & Labeling

Quality-focused suppliers provide technical grades of 2,4-xylenesulfonic acid with purity levels often above 98%, noting any residual moisture content or organic impurities on the certificate of analysis. Drums or bags carry hazard precaution labeling under GHS, signaling skin and eye irritation risks, alongside clear batch codes and use-by dates for audit trails. In the European Union, REACH registration details accompany consignments, and in the United States, TSCA registration matters to downstream buyers—bolstering E-E-A-T by keeping compliance front and center. Knowledgeable chemists rely on reliable labeling and a comprehensive safety data sheet that matches up with global chemical safety standards.

Preparation Method

Production typically involves direct sulfonation of xylene using concentrated sulfuric acid or oleum. This process introduces the sulfonic acid group at the desired position on the aromatic ring, producing a mixture of isomers unless well-controlled. Selective crystallization and careful temperature management help isolate the 2,4-isomer. The byproducts and waste acids require neutralization, and closed-loop systems support efforts toward safer, cleaner manufacturing to minimize acid mist releases and caustic effluents. Factories scaling up this process install robust fume-handling and process control systems, acknowledging both community and regulatory expectation for responsible stewardship.

Chemical Reactions & Modifications

2,4-Xylenesulfonic acid participates in sulfonation, alkylation, and neutralization reactions. As a strong acid, it catalyzes esterification processes, especially in contexts where mineral acids could disrupt delicate molecules or trigger unwanted side reactions. Its sulfonate group also lends itself to coupling with dyes and surfactants, anchoring the molecule in complex formulations without sacrificing reactivity. Chemists targeting modified surfactants or specialty chemicals often start with 2,4-xylenesulfonic acid, reacting it with amines or metal ions to design new detergents, dispersants, or specialty catalysts. Examples in patents and literature underscore the versatility it brings to the table.

Synonyms & Product Names

Across the global supply chain, this compound appears under several names, sometimes as 2,4-dimethylbenzenesulfonic acid or by abbreviations such as 2,4-XS acid. In inventory systems and regulatory filings, names and synonyms cover every base: 2,4-xylene sulfonic acid, 2,4-dimethylbenzene sulfonic acid, and other minor variations. End-users should cross-check these synonyms on procurement paperwork to dodge errors that could compromise production quality or safety.

Safety & Operational Standards

Safe use of 2,4-xylenesulfonic acid calls for respect for its corrosive nature, with personal protective equipment—gloves, goggles, fume hoods—forming the frontline against accidental contact. Good plant management leans into regular ventilation assessments, eye-wash station inspections, and staff training on acid incidents. Chronic exposure carries modest risks, but splashes and inhalation dominate real-world injury reports, making training and vigilance imperative. Employees point to the importance of up-to-date Safety Data Sheets, staged spill kits, and clear rules on acid storage and shelf life. Industry watchdogs look for evidence of compliance with OSHA, REACH, and local EHS codes.

Application Area

2,4-Xylenesulfonic acid matters most in the production of dyes and pigments, helping anchor anionic moieties that stick color to fabric and paper. Beyond textiles, formulators add it to surfactant blends in cleaning agents, seeking its balance of hydrophilic and hydrophobic tendencies. Water treatment specialists use its acid form and salts to influence charge and precipitation, working systems from municipal plants to pharmaceutical fillers. The compound’s catalytic acumen also shines in esterifications, supporting the manufacture of plasticizers and specialty esters. It finds utility in the synthesis of certain pharmaceuticals, linking the world of bulk chemistry to the careful, measured work in drug labs.

Research & Development

Lab teams experimenting with 2,4-xylenesulfonic acid often pursue incremental advances: more selective catalysis, new functional materials, or robust, greener synthesis techniques. Recent studies in polymer science highlight its use as a chain-modifying agent, altering viscosity and physical properties in adhesives and coatings. Industry-funded research places value on recyclability of sulfonic acid catalysts, tight control of sulfonation pathways, and the hunt for alternatives to harsher mineral acids. Partnerships with universities have widened the net, connecting the dots between core chemical properties and real manufacturing needs. Benchmarking performance across a variety of conditions, researchers highlight the acid’s versatility, but also its environmental profile, always in pursuit of better safety and sustainability.

Toxicity Research

Toxicity profiles for 2,4-xylenesulfonic acid remain generally moderate among low molecular weight sulfonic acids. Acute exposure tends to irritate tissues but does not lead to systemic toxicity at typical workplace concentrations. Animal tests reveal the low incidence of chronic or carcinogenic effects, yet real-world handling sometimes leads to overexposure when protections slip. Environmental impact studies urge careful wastewater management, with effluent discharge rules normally enforced stringently in Europe, North America, and East Asia. Researchers eye the residue fate in river systems, knowing that unchecked release could cause long-term effects not yet fully described in the literature.

Future Prospects

The coming era promises shifts for 2,4-xylenesulfonic acid as environmental regulations push chemical industries toward sustainable production and end-of-life management. Special attention turns toward closed-loop systems, minimization of waste, and renewable feedstocks. In formulations, chemists work to craft detergents and surfactants that meet new biodegradability standards without losing cleaning punch. Academic collaborations look to harness the best of catalytic activity for regional industries eager for homegrown inputs. Digitalization in plant management and improved process analytics aim to drive yields up and emissions down. Adoption of stricter hazard labeling and next-generation chemical tracking will give supply chains new transparency. The next generation of researchers and plant managers steps forward understanding both the legacy and the lasting relevance of foundational molecules like 2,4-xylenesulfonic acid.

The Backbone in Dye and Pigment Labs

2,4-Xylenesulfonic Acid works behind the scenes in chemical production floors, but its fingerprints appear on things as common as your notebook covers and kitchen plastics. Dye manufacturers have relied on it for decades because it behaves well as a sulfonating agent, meaning it helps attach “sulfonic” groups onto organic molecules to make colors stick better. Large pigment houses have built their recipes around this acid since it draws out richer, longer-lasting shades in textiles and plastics. Lab technicians once told me, “Without the sulfonic punch of compounds like 2,4-xylene sulfonic, reds fade quicker than you can launder them.” That simple fact keeps demand steady, since nobody wants their school shirts or kids’ toys losing color after a few spins in the wash.

Catalysis in Pharma and Petrochemical Plants

The pharmaceutical sector sees 2,4-Xylenesulfonic Acid as a catalyst for several organic reactions, especially where acid-driven chemistry can boost yields. I watched a pilot run on a factory floor where a sulfonic acid catalyst saved two days in reaction time and shaved off excess solvent waste, which isn’t just efficient—it saves thousands in operational costs. Sometimes, efficiency comes from simple substitutions like switching to a sulfonic acid salt that’s easier to filter out at the end.

Surfactants and Water Treatment

Beyond bright colors and pharmaceuticals, 2,4-Xylenesulfonic Acid plays a surprising role in keeping water systems flowing. Water softener suppliers use sulfonated chemicals in formulations that help keep scale from forming in boilers and pipes. In my household, switching to better-treated water cut back on kettle residue, and folks in industry watch similar chemistry working at much bigger scales. Municipal treatment engineers, always cautious about residual chemicals, prefer additives they can trace and neutralize, so the well-known properties of xylenesulfonic derivatives help them weigh risks and benefits precisely.

Polymers, Resins, and The Glue That Holds Things Together

Adhesive manufacturers want resins that grab and hold but don’t dissolve in the first rainstorm. Xylenesulfonic acid serves as a modifier in certain resin formulations, making them more water-resistant and durable. I once sat through a product demonstration for a new school glue, where the chemist proudly outlined the switch to a sulfonic acid blend that kept glue lines crisp on damp paper projects. Over years, the sticky fingers of school kids and warehouse workers tend to highlight which recipes stand up—and this chemistry regularly makes the cut.

Looking at Safety and Environmental Impact

Any chemical with widespread industrial use needs a hard look at safety and disposal. Long-term workers in dye or resin plants wear gloves and splash shields, since leaking drums or misapplied handling leads to burns or irritation. Regulators value chemicals like 2,4-Xylenesulfonic Acid because safety protocols are well-established from years of use. Still, plenty of room exists for green chemistry alternatives, and newer, less persistent acids are hitting the market. Smart procurement means talking with suppliers, checking recent data, and keeping eyes open for changes in rules and best practices.

Thinking Forward

Communities, both on the plant floor and in the neighborhood, want transparency from chemical producers. Users and factory managers keep asking for environmental scorecards on sulfonated additives. If substitutes come along that perform equally but break down faster after use, they should get a fair shot. The next generation of chemical engineers needs to see life cycle analysis as part of the job. That’s how the supply chain turns a specialty acid—hard to spell, tricky to pronounce—into a safer, more responsible tool for industries old and new.

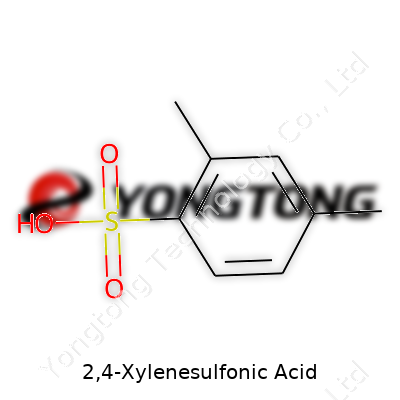

Breaking Down Its Structure

2,4-Xylenesulfonic acid might not sound like something you run into every day, but its core structure builds from familiar chemistry. The molecule starts with a benzene ring — that six-carbon ring is the backbone for many aromatic compounds both in labs and out in industry. On this ring, there are two methyl groups attached at the 2- and 4- positions. Those methyl groups, consisting of a carbon and three hydrogens each, can shift the usual chemical behavior of the ring, making the compound more reactive in some cases.

The real standout group in this molecule is the sulfonic acid group (-SO3H) at the 1-position. This group turns the whole molecule into a strong acid, and it ramps up the water solubility in a big way. So, the full name — 2,4-xylenesulfonic acid — tracks with what’s on the ring: a sulfonic acid group, and two methyl groups, spaced apart.

Looking at its formula, C8H10O3S, these elements tell a lot about its function and reactivity. My experience handling aromatic sulfonic acids in the lab showed how quickly they dissolve due to the sulfonic group, contrasted with more stubborn hydrocarbons. The added methyl groups only slightly change this behavior, but they do impact how the molecule interacts with other chemicals.

Why Its Structure Matters in the Real World

This structure isn’t just a drawing on paper; it sets the stage for how the acid reacts and works in industrial processes. Companies in the dye and detergent industries have used aromatic sulfonic acids like this one for a long time. Its water solubility, stemming from that sulfonic acid group, makes it useful in water-based chemical processes. Little details — like the spacing between methyl groups — can tweak solubility and reactivity, guiding how manufacturers push reactions in one direction or another.

Chemists and process engineers have long favored sulfonic acids in the formation of specialty chemicals and as catalysts. The acidic hydrogen is much stronger than what you get with carboxylic acids, so it works well where strong acidity is needed without drifting into hazards brought by mineral acids. My experience in synthesis highlighted how having more control over acid strength matters, especially when downstream safety and waste handling become bigger concerns.

Health and Safety — Handling Aromatic Sulfonic Acids

Working with 2,4-xylenesulfonic acid calls for attention to safe handling practices. Sulfonic acids, including this one, irritate skin and eyes and can damage mucous membranes. Proper gloves, goggles, and fume hoods all become part of the regular rhythm in the lab. The sulfonic group brings some benefits — it's less volatile than strong mineral acids — but no one gets careless around these compounds. Regulations, like those from OSHA or the European Chemicals Agency, highlight risks and set exposure limits.

Disposal of xylenesulfonic acids needs consideration too. Neutralization, often with a basic solution, ensures the acid no longer poses a risk downstream. Wastewater treatment plants monitor these chemicals closely because of their ability to alter water pH and their persistence. Environmental chemists keep pressing for greener substitutes or methods that break down the sulfonic ring once industrial use ends, aiming to prevent soil and water buildup.

Building Better Chemistry with Structure in Mind

Structure introduces opportunity and responsibility. Having those methyl groups on the benzene ring offers chemical flexibility, but it also calls chemists to pay attention to each functional group’s influence. Advances in green chemistry keep pushing for ways to harness the best aspects of chemicals like 2,4-xylenesulfonic acid while dialing back the risks. The more deeply we understand these molecules, the better we can create products that serve society and respect the environment.

Why We Should Pay Attention to 2,4-Xylenesulfonic Acid

Anyone who has spent time in a lab or at a chemical warehouse learns early that some chemicals just demand more respect than others. 2,4-Xylenesulfonic acid falls into that category. Its sharp smell lingers in the air, and it never seems to let you forget you’re working with something that can bite back. The stuff can eat through metals, burn skin, and choke up your lungs. These aren’t just textbook warnings—they are the kinds of risks that can send someone home from work or worse.

Personal Experience: Mistakes Stick With You

Years ago, I watched a coworker mix 2,4-xylenesulfonic acid without any face shield. The splash wasn’t dramatic, just a drop on his arm. That single mistake led to weeks of irritation and a tough call to the safety manager. This isn’t a chemical that gives second chances. Many industrial acids leave lasting burns, but aryl sulfonic acids like this one can slip through gloves if you aren’t using the right material. Regular latex gloves won’t cut it; heavy-duty nitrile or neoprene keeps hands safer.

Short-Term Exposure: No Room for Carelessness

I’ve learned from talking to industrial hygienists that breathing in the dust or fumes brings more trouble than most expect. People usually notice the acid taste in the air right away, but the real damage happens as it settles in the lungs. Consistent exposure could mean coughing, wheezing, and trouble breathing. Handling powders or granules, it’s easy to see how spills float into the air unless local ventilation draws it away. Respirators rated for acid gases make a difference here.

Clothing and Clean-Up: Protect and Isolate Yourself

Spills happen, and the cleanup always tests your training. I remember wiping up a small spill and noticing my boots starting to bubble from the acid. Never skip the step of checking your protective gear for leaks or soft spots before heading to the area. Acid-resistant aprons and boots make a difference. Clothing made from cotton melts right through if splashed, so switching to chemically resistant suits helps keep you whole.

Sensible Storage: Avoid Metal, Watch for Leaks

Storing this chemical in any metal drum invites corrosion. Polyethylene containers shut down that risk. Don’t stash acids near caustics or materials that give off chlorine. Mixing those by accident leads to ugly reactions. Regular checks for leaks, ventilation, and labeled storage make a huge difference in keeping people and property safe.

Disposal Isn’t Guesswork

I speak from experience—never dump leftover acid down the drain. Local waste programs require special paperwork for acids like this, and improper disposal corrodes pipes, damages wastewater systems, and risks legal trouble. Neutralizing with a basic solution under a fume hood, using spill kits, and following environmental guidelines keeps communities safer.

Training Makes the Difference

Most accidents happen because someone didn’t know the risks or skipped a step. Real training, not just reading a manual, helps people remember these hazards. Teaching new hires by showing them the scars chemicals leave, not just slide decks, makes the lessons stick. Chemical safety grows out of habits, attention, and a bit of healthy fear—things that anyone, from seasoned chemists to new warehouse hands, picks up by working smart and not cutting corners.

Why Storage Matters for 2,4-Xylenesulfonic Acid

If you’ve handled chemicals for any length of time, you know some of them ask for more respect than others. 2,4-Xylenesulfonic acid falls into that camp. The stuff is strong—both in what it can do and how it can go wrong if left sitting around somewhere it shouldn’t. Keeping chemicals like this safe isn’t just ticking boxes. Ignoring basic safety has burned plenty of folks, both in the lab and on the plant floor.

Give It a Real Home—Not Just a Shelf

I’ve worked in storerooms where acids ended up jammed against boxes of food containers, and the air always had a bite to it. No surprise, safety slips away when acids get stashed wherever there’s space. 2,4-Xylenesulfonic acid belongs in a sealed, corrosion-resistant container. Metal lids can sometimes spell trouble, so plastic or glass with tight seals keeps the fuming down and the risk lower. Leaks love loose-fitting caps—check more than once before walking away.

Keep It Away From Heat and Sun

Heat speeds up degradation, warping containers and building up pressure inside. I once watched a sunny window with a few careless bottles become a sticky, dangerous mess. Always choose a cool, shaded cupboard or specialized acid cabinet, far from any source of ignition or intense sunlight. A climate-controlled storage space beats an open rack in a stuffy room every time. Signs warning about chemical storage help keep passersby out, so proper labeling belongs on every door and bin.

Separation From Incompatible Substances

Mix-ups come fast in busy workspaces. On one shift, I caught a crate of acids stacked on a pallet with oxidizers—every safety training manual warns against this. You can’t risk cross-contamination with strong bases or oxidizers, since those can spell disaster. Keep the chemicals set apart, and always read storage labels, not just color codes. Segregation shelves offer peace of mind and make checks simpler. After all, the wrong mix in a spill can lead to toxic gases or even an explosion.

Handling Spills and Leaks

Few things get your heart racing like seeing a puddle near a drum that should have stayed dry. With 2,4-xylenesulfonic acid, even a small leak creates hazards. Always set up spill containment trays under containers. If you spot crystals or residue, treat them as a warning sign—wiping down the outside before storage goes a long way. Store emergency neutralizers and personal protective gear nearby, so if something happens, you won’t have to hunt for help. I’ve seen a good spill kit turn a near-disaster into a quick cleanup.

Ventilation Saves Lungs and Floors

I remember a poorly ventilated storeroom where fumes left coworkers coughing every morning. Sulfonic acids have a kick, and vapor buildup can corrode both lungs and concrete. Dedicated vent hoods or chemical storage cabinets with air filtration keep breathing easy. Never store open containers or let acid pools dry—both release harmful vapors. Frequent air changes in the storage area reduce buildup fast. If you smell a sharp tang once the door opens, it’s time to improve the system.

Training and Vigilance Pay Off

Even the best storage plan falls flat if folks don’t know the risks or how to act fast. Regular safety walkthroughs help spot bad habits before they cause real harm. Any changes in color, container shape, or labeling need reporting and immediate attention. Hands-on training trumps online videos—all staff should practice handling, storage, and emergency steps. In the end, safe chemical storage comes down to respect, attention, and shared responsibility on every shift.

The Science Behind Solubility

Anyone who's spent time with organic chemistry textbooks might remember that simple aromatic compounds often shy away from water. Once you bolt on the right functional groups, everything changes. Sulfonic acids flip that switch. Their nature makes them forget their aromatic roots for a moment and embrace water quite easily. 2,4-Xylenesulfonic acid joins that group. Add a sulfonic acid group to a xylene molecule, and suddenly you’ve got something eager to greet water molecules, not hide from them.

Why This Compound Matters

I worked in a lab where every reagent told a story. 2,4-Xylenesulfonic acid found its way onto our shelves for a reason—it likes to dissolve. Chemists started using it because its water solubility opens doors for reactions where non-polar solvents would get in the way. This isn't about filling a beaker. Water brings out the best in its ionic form. That acid group, with its hunger for protons, leaves the xylene aromatic ring behind and makes salt-like structures comfortable in water. The math backs it up: most sulfonic acids push their limits far past grams per 100 milliliters, even at room temperature.

Environmental Baseline

Think about the big picture. Lab chemicals shouldn’t only be safe inside their bottles. Once they touch the sink or soil, what happens next? Many organic pollutants stick around because they can’t mix with water. 2,4-Xylenesulfonic acid’s solubility changes the rules. Once it enters water, it doesn’t just hang out in a sediment layer. Treatment plants can target it, and nature’s own dilution game gets to work faster. That’s not a license to pour it down the drain, but it gives regulators one less molecule to worry about sticking around for decades.

Problems and Real Solutions

Soluble doesn’t always mean safe. High solubility means easier dispersion but also makes tracing contamination trickier. I remember troubleshooting a water sample tainted with organics—the soluble ones find their way to unexpected places quicker than anyone expects. Facilities have to keep a close eye on their waste-stream analytics, and regulatory bodies need to set limits that recognize how easily these compounds can move. Rapid dispersal can be both blessing and curse.

Cleanup technology steps in here. Activated carbon filtration helps pull even these charged organics from water, and advanced oxidation methods keep improving every year. Education remains the core piece—students and staff need to know what makes these molecules mobile and why proper disposal always beats “out of sight, out of mind.” Labs and factories that switch to greener processes often look for ways to work around these soluble additives, picking replacements that break down faster or lock up in safer forms.

Looking Ahead

As chemistry evolves, I’m watching how industries adapt to these problems. Efforts to develop better monitoring tools in water systems can spot these soluble molecules before they drift too far. Policymakers listen not only to chemists but to environmental engineers focused on wastewater. It took seeing a simple compound transform a reaction in the lab for me to appreciate the balancing act. Water solubility isn’t just a textbook fact. It’s an open door for both innovation and responsibility, and this acid only reminds us how close those two are connected.