2,4-Difluoroaniline: Insights and Impact

Historical Development

Chemists began examining fluorinated anilines in the early half of the twentieth century, driven by the search for new synthetic building blocks. The introduction of fluorine atoms brought notable shifts in chemical reactivity, so 2,4-Difluoroaniline didn’t take long to pique the curiosity of those working on pharmaceuticals and agrochemicals. Over the years, researchers pushed forward in both academic and industrial labs, establishing clear routes for its synthesis and documenting its unique traits. As knowledge of aromatic fluorination grew, so did applications, laying today's foundations for specialty chemicals based on small aromatic rings with selective fluorination spots.

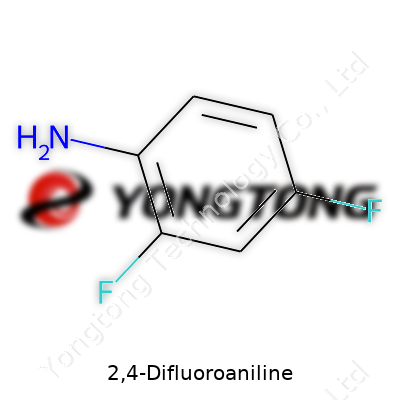

Product Overview

2,4-Difluoroaniline sits as a small yet important piece in the larger puzzle of fine chemical building blocks. This compound features an aniline ring substituted with two fluorine atoms at the 2 and 4 positions, giving it a fingerprint different from both aniline and other difluoro analogs. Used frequently in the synthesis of advanced organic molecules, its popularity stems from the way fluorine atoms alter both reactivity and biological properties. Industrially, precise batches of this aromatic amine appear in catalogs from multiple specialty suppliers, often showing up in quality control labs ready for derivatization or polymerization work.

Physical & Chemical Properties

2,4-Difluoroaniline appears as a clear to pale yellow liquid at room temperature, and it gives off a bit of a sharp, ammonia-like odor familiar to those handling aromatic amines. Its boiling point clocks in around 174–176°C, which keeps it convenient for vacuum distillation or solvent extractions. The molecule dissolves well in common organic solvents — diethyl ether, ethanol, dichloromethane — and maintains stability under typical storage conditions if kept away from strong oxidizers or extreme heat. Both fluorine substituents substantially lower its pKa compared to aniline, making the amino group less basic, a trait chemists use in planning selective transformations.

Technical Specifications & Labeling

Reliable batches of 2,4-Difluoroaniline carry purity levels above 98%, often validated by NMR and GC-MS to rule out problematic side-products. Specifications communicate precise density, refractive index, and appearance alongside expected limits for water, heavy metals, and residual solvents. Safe handling relies on clear GHS-compliant labeling: pictograms warn of potential acute toxicity, the supplier includes batch numbers for traceability, and a comprehensive Safety Data Sheet accompanies every container. While basic, those upfront standards form a backbone for confidence among researchers and manufacturers working downstream, where non-compliance could risk reactions or product recalls.

Preparation Method

Most synthesis approaches draw from aniline functionalization or selective nucleophilic aromatic substitution. One common route involves starting from 2,4-difluoronitrobenzene and reducing the nitro group to an amine, often with catalytic hydrogenation over palladium on carbon, or by treatment with iron and acid. Some routes use fluorinated precursors with halide exchanges or metal-catalyzed amination, offering flexibility in scale and cost. These methods allow fine-tuned quality control to favor high-purity product, although aggressive reagents and exotherms can crop up during large-scale work, reminding one that small changes in process translate into big concerns for plant operators.

Chemical Reactions & Modifications

One key advantage of 2,4-Difluoroaniline lies in the unique electronic influence its two fluorines exert on the aromatic system. Chemists leverage these properties in cross-coupling chemistry, such as Suzuki or Buchwald-Hartwig reactions, taking advantage of altered reactivity at specific positions. Amide formation with acid chlorides, urea synthesis, and diazotization further broaden its potential. In pharmaceutical contexts, these modifications help create drug candidates with improved metabolic stability, while agrochemical research seeks derivatives possessing environmental persistence and target specificity. Each modification taps into the balance between the amino and fluorine functionalities, producing compounds with real-world impact.

Synonyms & Product Names

This molecule commonly answers to several industry names. Besides 2,4-Difluoroaniline, suppliers list it as 2,4-DAF, 2,4-DFA, or 2,4-difluorophenylamine. CAS number 367-25-9 provides a global reference, with trade names varying between catalogues but always referring back to the same core structure. Knowing these synonyms prevents costly mix-ups in ordering or shipment — nearly every large-scale buyer double-checks both structural diagrams and registry numbers before confirming a purchase order.

Safety & Operational Standards

Working with 2,4-Difluoroaniline means paying close attention to hazard statements and workplace guidelines. The compound shows toxicity through ingestion, inhalation, and skin contact, and it may cause skin sensitization or respiratory irritation at higher concentrations. Proper ventilation, nitrile gloves, eye protection, and fume hood containment rank as basic lab safeguards. Regulatory limits for exposure sit in line with other aromatic amines, reflecting both acute and chronic toxicity concerns. Spills and accidental releases on the plant floor demand immediate cleanup using absorbent material, and containers must stay tightly closed in well-ventilated places. In my experience, regular training makes the difference: careless handling rarely results from ignorance of the substance but more from everyday shortcuts. Emphasizing safety culture at all levels — from graduate students to seasoned operators — keeps accident reports to a minimum.

Application Area

The chemical provides a foundation for several technology sectors. In pharmaceuticals, it’s used to construct anti-infective compounds and specialty fragments for kinase inhibitors, taking advantage of fluorine's impact on binding and metabolic resistance. Agrochemical developers employ 2,4-Difluoroaniline as a key intermediate in novel herbicides and fungicides, pushing for new molecules that address resistant weed populations and lower environmental drift. Dyes, pigments, and polymers round out the applications, where the molecule imparts both colorfastness and chemical resistance. Technically demanding industries prefer it for these unique physical and electronic effects, which aren’t achievable with non-fluorinated anilines.

Research & Development

Labs continue chasing after new ways to shape fluorinated aromatic amines. Improvements in catalytic processes, greener solvents, and automated reactor control dominate recent literature, all reflecting the pressure to cut both cost and environmental impact. Researchers explore advanced functionalization strategies, including late-stage modifications and regioselective coupling. Pharmaceutical lead optimization work depends on rapid access to difluoroaniline variants for structure-activity relationship studies, while high-throughput methodologies speed up synthesis and purification. My own work once required custom analogues for enzyme inhibition studies — the adoption of improved batch processes saved weeks of wait time and cut down hazardous solvent consumption dramatically.

Toxicity Research

Traditional toxicity studies of 2,4-Difluoroaniline focus on acute exposure risks and potential for mutagenicity. In rodent models, repeated dose studies show organ involvement typical for aromatic amines, including liver and kidney concerns. In vitro assays suggest moderate cytotoxicity, with particular attention paid to the possibility of DNA adduct formation. Environmental impact studies look at persistence and breakdown products, since fluorinated aromatics can stick around in soil and water. Risk assessments inform production and handling guidelines, and regulatory agencies keep an eye on both workplace exposure and environmental release. Analytical chemists continue to monitor both in-plant and downstream distribution, as detection sensitivity for aromatic amines improves year after year.

Future Prospects

Interest in 2,4-Difluoroaniline will likely advance alongside fields seeking more selective or robust molecular scaffolds. The push for sustainable chemistry — greener fluorination, solvent recycling, and energy-saving syntheses — intersects directly with its production. The pharmaceutical and agrochemical industries will keep pressing forward, demanding more analogues that meet evolving regulatory or biological targets. Emerging uses in electronic materials, including OLEDs and specialty polymers, promise new directions as fluorinated aromatics make up unique niches for high-performance technologies. Sustainable routes to 2,4-Difluoroaniline, using bio-based feedstocks or recyclable fluorination reagents, should gain traction, possibly shifting the production landscape. As more gets uncovered about its long-term safety and subtle reactivity, this small molecule will keep impacting synthetic strategies and product pipelines for years to come.

What’s the Real Deal With 2,4-Difluoroaniline?

Many folks don’t pay much attention to the names on chemical labels, yet 2,4-Difluoroaniline plays a big role behind the scenes. This compound carries two fluorine atoms on its benzene ring, and that changes how it behaves and what you can do with it in a lab. My early exposure to chemistry taught me how a tweak in molecular structure opens up new doors. Here, those tiny fluorine atoms make all the difference in the world for a variety of products.

Why Chemists Look for It

If you ask anyone working in drug discovery or agricultural science, 2,4-Difluoroaniline usually pops up early in their discussions. Pharmaceutical research teams use it as a key building block. Manufacturers grab it to make other complex molecules. 2,4-Difluoroaniline gives scientists a way to insert fluorine atoms into substances, so you end up with medicines that last longer in the body or pesticides that break down slower in the soil, giving crops better protection.

What Happens After You Buy It?

Shops selling research chemicals see a steady demand for 2,4-Difluoroaniline. Labs run experiments to turn it into antibiotics, anti-inflammatory agents, or cancer treatments. The fluorine atoms let chemists fine-tune how drugs interact with the body. Look back at years of research from journals—adding fluorine often increases a drug’s potency and stability. That improves treatment results.

But scientists outside medicine find it useful too. The same properties help in making dyes and specialty materials. Changing the ring structure of aniline shifts color and reactivity, so everything from pigments used in electronics to materials for coatings can rely on this molecule. I remember seeing it pop up during a project aimed at designing brighter OLED screens for handheld devices.

The Worry List: Health and Safety

Everything useful comes with a tradeoff. Direct exposure to 2,4-Difluoroaniline carries serious health risks. Workers need to handle it in well-ventilated labs, with gloves, face shields, and real-time monitors for any leaks. It’s classified as a hazardous material in most regulatory guidelines. Repeated skin contact or inhalation can cause irritation and, if someone ignores protocols, deeper problems over time.

Paying Attention to Regulation

Producers need to keep a close eye on compliance. Strict reporting rules keep tabs on who uses how much. Inspections by environmental and workplace safety authorities look for proper storage, labeling, and disposal protocols. In the past decade, regulatory fines have gone up for companies ignoring chemical waste standards. Responsible handling protects employees and keeps the community’s water and air cleaner, and companies that keep a public list of materials often set the gold standard for transparency.

A Path Forward: Safer and Smarter

Innovators in the chemical industry search for safer substitutes every year, but the unique properties of 2,4-Difluoroaniline hold a strong spot for the time being. More companies are investing in enclosed systems that limit exposures and cut waste. Some research teams study ways to recycle what’s left after manufacturing, pushing for greener chemistry practices. As raw material prices and environmental demands rise, that focus on health and sustainability keeps growing. The future points toward better protection and smarter solutions for using chemicals like this.

What’s Behind a Chemical’s Name?

You don’t need a lab coat to untangle the name “2,4-Difluoroaniline.” Strip away the jargon, and you’ll see it has a backbone called aniline—a benzene ring holding onto an amino group. Scientists love to tweak molecules, so this one has picked up two fluorine atoms at the second and fourth spots. Now, talk to anyone in a synthesis lab who’s worked through aromatic chemistry, and they’ll say just how much one letter or digit tossed into a formula changes how a substance behaves.

The Formula: C6H5F2N

Here it is—C6H5F2N. This isn’t just a riddle for a chemistry student; each piece says something. There are six carbon atoms joined in that classic aromatic ring. Five hydrogens hold their places. Two fluorines stick out at just the right spots. Toss in one nitrogen—that’s the amine group waving hello. I remember in college, flipping through molecular models and feeling the frustration of missing one little substituent. Never fun. But every element counts, and even one atom out of place means a totally different compound.

What the Formula Tells Us

C6H5F2N doesn’t only describe composition. It shapes safety, reactivity, and how that molecule interacts with others—a lesson I learned quick after a safety mishap during undergraduate research. Forgetting a fluorine in the formula meant missing critical toxicity data. Anyone working with fluorinated organics knows some combinations become more toxic, stubbornly stable, or surprisingly useful. That’s why accuracy in chemical identification isn’t just academic.

Molecular formulas like this play a central role in regulations and manufacturing. Drug companies use them to dodge cross-contamination. Environmental scientists track how molecules with fluorine accumulate or break down in landfills and water. The smallest structural change, such as swapping a fluorine from one carbon to another, could be the difference between a useful cancer treatment and a pollutant that won’t degrade. Companies lean on these details so they don’t blow a budget chasing impurities, and so environmental health doesn’t take a backseat.

Addressing the Issues with Clarity

There are plenty of times researchers and students misreport compounds, leading to miscommunication or, worse, accidents. I’ve seen journals print errata over misplaced numbers or atoms. A solution starts with better education—training young chemists to double-and triple-check formulas and to tailor safety protocols specifically for the correct compound. Technology helps, too. Chemical inventory software can cross-check structural information against logged formulas. Industries committed to cleaner chemistry invest in safer fluorine alternatives and make those substitutions routine, not afterthoughts.

Takeaway

Memorizing C6H5F2N doesn’t make anyone a better chemist, but respecting how these numbers and letters translate to real-world impact does. From personal experience, starting with a clear, correct formula saves a lot of headaches and keeps discovery on track. Matters of accuracy with molecules like 2,4-Difluoroaniline echo through labs and beyond, shaping the safety, impact, and potential of the chemicals we create.

What 2,4-Difluoroaniline Actually Is

2,4-Difluoroaniline pops up in labs and factories producing advanced materials, dyes, and pharmaceuticals. At first glance, it seems just another aniline derivative in the world of organic chemistry. Its molecular structure—an aniline ring with two fluorine atoms—gives it unique properties, but also raises a few red flags for those handling it.

Hazards That Deserve Attention

Acute toxicity studies have flagged this compound for several concerning effects. Short-term exposure can bring on irritation in the eyes, skin, and respiratory system. Accidental splashes may leave red, burning sensations, and the fumes sting your throat instantly. Skin absorption isn’t just a theoretical risk. Many who skipped gloves in rush jobs paid for it with headaches, dizziness, and nausea lasting hours. Chronic low-level exposure doesn’t shout loudly, but it wears down the body over months, sometimes showing up later as liver or kidney issues. These facts aren’t pulled from thin air—SDS documents and toxicological profiles back them up.

What Science Says

Peer-reviewed studies add context: rodents exposed to high doses of 2,4-Difluoroaniline show evidence of organ toxicity over time. The compound doesn’t just vanish harmlessly. It lingers in the environment, potentially contaminating soil and water through improper disposal. Manufacturing plants handle hundreds of kilos yearly. Accidents may be rare, but they do happen—firm numbers on occupational exposure show some workers getting sick after breaches in safety protocol.

Why People Should Care

Chemicals like this are easy to ignore if you’re not working with them daily, yet their footprint extends farther than the factory gates. Lack of awareness can lead to mishandling, leaks, or careless disposal. Once in the environment, persistent chemicals don’t just pack up and leave. Communities near chemical plants sometimes learn the consequences much later, through groundwater tests or rising health complaints.

Better Ways Forward

Companies already have strict safety measures on paper—ventilation, double gloves, face shields—yet workplace complacency often sets in after the first few uneventful months. Routine training helps. So does investing in safer containment, like sealed transfer systems that cut down on spill risks. Audits led by third parties shake things up and encourage staff to spot tiny lapses before they snowball.

Disposal shouldn’t be an afterthought. Incineration at high temperatures remains the best disposal method, breaking the molecule into harmless bits. Dumping into drains may save a few minutes, but the long-term costs land on everyone else. More facilities switching to green chemistry alternatives eventually lowers risk, and some companies are pushing researchers to develop less volatile substitutes.

Takeaway—Stay Informed, Stay Safe

People working with or around chemicals like 2,4-Difluoroaniline owe it to themselves and their neighbors to treat it seriously. Health matters more than cutting corners. With clear facts, practical precautions, and open communication between all levels of staff, these hazards can be handled without drama. Solid information, reliable habits, and better technology keep everyone out of harm’s way—both now and years down the line.

Why Safe Storage Matters with 2,4-Difluoroaniline

Handling chemicals like 2,4-Difluoroaniline always calls for attention. This organic compound, mainly found in research labs, comes with its hazards — think of health risks like irritation of the skin, eyes, and respiratory system. I’ve seen people learn this lesson the hard way, discovering just how quickly a carelessly stored drum can turn dangerous. This compound doesn’t forgive laziness.

Watch Out for Light, Heat, and Moisture

Chemical stability keeps everyone in the building safe. 2,4-Difluoroaniline holds up best at room temperature, away from heat sources that could speed up chemical reactions. A cool, well-ventilated storage room reduces the chances of vapor buildup. Some labs let the temperature sneak up or condensation build — a risky move. Moisture and heat bring unpredictable reactions, so dry and constant conditions work best.

Separation from Incompatibles

Strong oxidizers and acids love to make trouble when paired with organic intermediates like this one. I once worked at a place that ignored segregation rules, cramming everything onto the same shelf. Sooner or later someone dropped a bottle, and the cleanup wasn’t pretty. Always choose a separate storage cabinet for substances like 2,4-Difluoroaniline. Flammable materials and incompatible chemicals need their own dedicated spaces. Fire-resistant cabinets pay for themselves the first time they stop a spill from becoming a disaster.

Count on Containment and Ventilation

Volatile aromatics release fumes that build up in an unventilated cabinet. You hardly notice it at first, but headaches, nausea, and worse can sneak up if air sits stagnant. Install exhausts and make sure fresh air keeps flowing through storage areas. Spill trays and secondary containers help contain leaks. I’ve seen well-designed labs avoid big headaches just by setting up simple barriers and air movement.

Clearly Label and Control Access

Labels matter more than people think. In a busy storeroom, identical bottles stack up, and mistakes happen fast. Keep every bottle labeled with its name, hazard symbols, and date received. Logs track usage and flag expired stock that shouldn’t sit on the shelf. Lock up hazardous chemicals and hand out access only to trained workers. Unlocked cabinets and poor supervision have led to some of the worst accidents I’ve encountered in my career.

Personal Protective Equipment and Emergency Readiness

Gloves, lab coats, goggles — always use them when moving or pouring 2,4-Difluoroaniline. Skin exposure or accidental inhalation can send people to the hospital. Keep spill kits, eyewash stations, and emergency showers nearby. During one late night shift, that equipment turned a near-miss into a safe lesson rather than a tragedy.

Keeping Records and Reviewing Storage Practices

Good organizations document every step, from storage to disposal. Regular inspections reveal leaks, missing labels, or expired material before they turn into emergencies. Training sessions, review meetings, and walkthroughs make a difference. People remember what they practice. Well-trained staff know how to act if something slips through the cracks.

Final Thoughts: Safe Storage Avoids Trouble

2,4-Difluoroaniline rewards careful handling. Respecting guidelines around temperature, incompatibility, labeling, and protective equipment protects people and property. Forgetting the rules costs a lot more than the time it takes to follow them. Every careful practice I’ve learned in the lab started with a story of what happens when you cut corners. Better to store chemicals right from the start.

Understanding Chemical Identity

Chemistry gives us a language for the building blocks of our world. Every material, from medicine cabinet staples to the electronics that light up our daily life, leans on precision in identification. For researchers, the ability to nail down a chemical with a unique key – like the CAS number – makes all the difference. The CAS number for 2,4-Difluoroaniline is 367-25-9. This number isn’t just a label. It unlocks safety data, handling guidelines, supply chain consistency, and scientific literature from across the globe.

The Role of 2,4-Difluoroaniline

People working in chemical labs or pharmaceutical companies will have seen chemicals such as 2,4-Difluoroaniline named by different systems – IUPAC names, trade names, sometimes even just “the stuff in that bottle over there.” Without a clear standard, all sorts of mistakes can creep in. Mislabel one bottle and you put safety at risk. Pick the wrong substrate for a reaction, results go haywire and time gets wasted.

2,4-Difluoroaniline stands as a starting material for a range of fine chemicals. Think about agrochemicals, dyes, pharmaceuticals — this molecule has shown up in the patent literature for new drug candidates as well. Each shift in its structure can make a dramatic difference in biological activity. Precision defines modern chemistry, not just as a buzzword but as hard necessity, especially for anything entering the food chain or used in medical research.

The Value of Reliable Identification

Daily work in chemistry doesn’t run on trust alone; traceability counts. Having a universal reference like CAS numbers, developed and managed by Chemical Abstracts Service, helps researchers pull the right data without confusion or delay. The number 367-25-9 points directly and only to 2,4-Difluoroaniline — not its cousins, not another isomer, just this compound. A mistake in sourcing or ordering can look trivial, but even a tiny difference in molecular structure might ruin a batch or trigger compliance violations.

Health, Safety, and Supply Chain

Safety professionals rely on this clarity, too. Material Safety Data Sheets (MSDS) use CAS numbers to spell out handling precautions, toxicity, personal protective gear, and emergency steps. This brings peace of mind: if the number matches, the data match. As logistics teams source or ship chemicals, having a reliable identifier reduces costly hold-ups at customs or in transit.

Markets for chemicals like 2,4-Difluoroaniline span continents. Synthetic chemists, suppliers, labs, and regulatory authorities all need to “speak” the same language. A mix-up can have ripple effects, from lost batches to regulatory fines or risk to human health. The discipline around tracking with a CAS number becomes a daily practice, not an afterthought.

Better Practices, Fewer Mistakes

No one finds chasing errors or untangling near misses productive. Building habits around precise identification makes room for innovation, safety, and speed. The trust earned through getting the details right pays off in reputable products, solid research, and regulatory confidence.

As the pace of discovery increases, keeping identification tightly controlled will help steer clear of setbacks. Clarity, accountability, and safety all rely on simple numbers like 367-25-9 being used with intent. In a world built from atoms, that kind of rigor matters.