2,4-Dichlorobutyrophenone: A Close Look at Its Role and Impact

Historical Development

Scientists started paying attention to 2,4-Dichlorobutyrophenone decades ago, searching for better intermediates for pharmaceuticals and pesticides. In the mid-20th century, chemists explored ways to use halogenated phenones for their reactivity, and before long, this compound showed promise in synthetic chemistry labs. Companies in Europe patented its use in the 1960s and 1970s, with early development tied closely to rapid advancements in organic synthesis. Researchers saw the value in its stable structure and reactive chlorinated butyryl side chain, setting the stage for widespread adoption in chemical manufacturing.

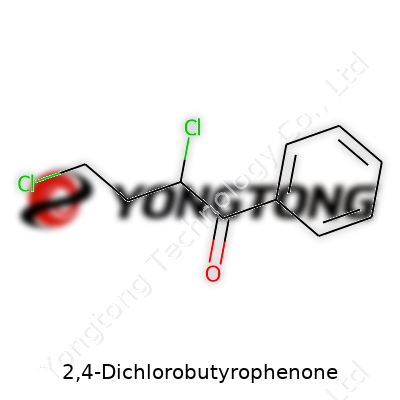

Product Overview

2,4-Dichlorobutyrophenone comes out of the lab as a reliable intermediate for a range of chemical products. Its structure includes a phenone (benzene ring with a ketone) attached to a butyryl group with chlorine atoms at the 2 and 4 positions. This arrangement makes it attractive for synthetic routes in both pharmaceuticals and agrochemicals. Over time, manufacturers have kept an eye on shelf-stability and consistent purity. Chemical suppliers who know their customers' needs make sure the product meets strict quality benchmarks before sending it off to formulators and labs.

Physical & Chemical Properties

In the bottle, 2,4-Dichlorobutyrophenone appears as a solid or sometimes a highly viscous liquid, depending on the batch and purity. The melting point often lands between 38°C and 42°C, and the boiling point stretches past 290°C, with a slight smell that hints at its aromatic backbone. Solubility can throw some users for a loop—water won’t do much to dissolve it, but common organic solvents work just fine. Chemists make use of its low vapor pressure and moderate reactivity, and specific gravity sticks close to what one would expect from a chlorinated aromatic compound.

Technical Specifications & Labeling

Labeling for 2,4-Dichlorobutyrophenone reflects a strong focus on traceability and compliance. Most bottles in commercial circulation carry batch numbers, purity certificates, and hazard statements. A lot of batches push past 98% purity, but industrial customers sometimes accept lower grades for less-critical applications. The labeling includes CAS number 3612-20-2, hazard pictograms for skin and eye irritation, and clear instructions on storage well away from sunlight and moisture. Shelf life can span several years if handled with attention to these storage guidelines, making it a dependable staple in chemical inventories.

Preparation Method

Manufacturers stick with Friedel–Crafts acylation as the gold standard when making 2,4-Dichlorobutyrophenone. This process uses 2,4-dichlorobutyryl chloride with benzene or substituted phenol, and aluminum chloride or other strong Lewis acids as catalysts. The route yields a clean product if workers manage the temperature and stir rate correctly, but trace impurities from unreacted starting materials challenge production on a larger scale. Down the line, purification steps like crystallization and distillation help chemists get to a technical or analytical-grade product, but tight controls over water content and acidity remain crucial.

Chemical Reactions & Modifications

Organic chemists reach for 2,4-Dichlorobutyrophenone because the reactive ketone and dichloro groups open doors to a range of modifications. The ketone can take nucleophilic additions, making it valuable for further functionalization or as a precursor to more complex structures. Chlorine atoms at the 2 and 4 positions offer sites for nucleophilic aromatic substitution or even halogen-metal exchange under the right conditions. With these reactive handles, the compound enables synthetic access to different heterocycles, pharmaceuticals, and specialty polymers. Modifying the butyryl side chain or acyl group can steer reactivity in useful directions, broadening its utility well beyond just one industry.

Synonyms & Product Names

Chemists and suppliers may refer to 2,4-Dichlorobutyrophenone with several names. Beyond the straightforward “2,4-Dichloro-4-phenylbutan-1-one,” others call it “Butyrophenone, 2,4-dichloro.” Some catalogs list it simply by the CAS number, 3612-20-2, or as “Dichloro Butyrophenone” in shorthand. Each name points to the same structure and similar handling protocols, but knowing the aliases helps avoid confusion in international ordering and regulatory submissions.

Safety & Operational Standards

Anyone handling this compound deals with a clear set of risks. Skin contact can lead to irritation, and the solid or vapors may cause eye redness or discomfort. Best practice calls for gloves, goggles, and ventilated workspaces at a minimum. Inhaling dust or vapors poses a risk to mucous membranes, so good ventilation or a fume hood makes a big difference. Disposal takes extra care, since chlorinated organics often end up regulated as hazardous waste. Proper training and adherence to material safety data sheets reduce the danger, and frequent safety audits keep operations on the right track.

Application Area

The reach of 2,4-Dichlorobutyrophenone stretches across multiple fields. Pharmaceutical makers use it as a building block when assembling active pharmaceutical ingredients. In agrochemicals, it serves as a precursor to certain herbicides and plant growth regulators. Polymer and specialty chemical manufacturers use it for the synthesis of custom materials. Research labs rely on this compound when testing routes to novel molecular structures, making it a familiar face on chemical inventory lists at universities and R&D-focused companies.

Research & Development

Research groups keep finding fresh ways to use 2,4-Dichlorobutyrophenone as a synthetic intermediate. Teams working in medicinal chemistry value its potential to bring in reactive sites for drug candidates, while others focus on developing greener synthesis routes that minimize hazardous byproducts. Innovation in this area often comes from tweaking reaction conditions or catalysts to boost yield, lower waste, or get to more complex targets in fewer steps. Some university labs look at new applications in catalysis, while industrial researchers think about how changing regulations around chlorinated organics might affect future sourcing and disposal.

Toxicity Research

Toxicologists take the hazards of 2,4-Dichlorobutyrophenone seriously. Animal studies show that ingestion or exposure above certain thresholds can impact liver and kidney function. Reports in journal literature point to moderate acute toxicity, especially in rodents, but less is known outside of controlled research settings. Human data remains limited, as routine workplace exposure tends to be well-controlled in regulated environments. For environmental toxicity, the compound breaks down slowly, raising concerns about persistence if not managed correctly. Ongoing research addresses what breakdown products form under various conditions and how these impact water and soil health near manufacturing sites.

Future Prospects

Shifts in green chemistry push manufacturers to explore alternatives to conventional halogenated intermediates, but demand for 2,4-Dichlorobutyrophenone holds steady where regulatory compliance is clear and the compound performs as needed. Emerging pharmaceutical targets and novel agrochemicals could benefit from refinements in synthesis and purification. As sustainability grows in importance, companies test lower-waste pathways, cleaner catalysts, or biobased feedstocks. Regulatory changes around hazardous organics may reshape sourcing and disposal, nudging industry down different production paths. Chemists who keep up with changes in policy and technology will likely shape its future more than anyone else, but for now, this compound stays rooted in chemical manufacturing, research, and product development.

Chemistry as a Foundation

Most people don’t run into 2,4-Dichlorobutyrophenone on a daily basis unless they hang out in a chemistry lab. The name itself sounds like something straight out of advanced textbooks, but the truth is, this compound fits into industrial and pharmaceutical fields. Anyone who’s mixed or measured chemicals knows just how purposeful each one must be.

Role in Pharmaceutical Synthesis

Pharmaceutical researchers use 2,4-Dichlorobutyrophenone as a building block. It helps piece together bigger, more complicated molecules that shape the active parts of some drugs. A solid example: in the early development stages for certain anticonvulsant and antipsychotic treatments, scientists rely on intermediates like these. Compounds built from phenone derivatives act as scaffolding, so researchers can attach new groups and test for promising medicines.

The process may sound routine but getting intermediates just right makes or breaks the whole chain. Even a slight impurity in a phenone derivative can derail everything downstream. Practically speaking, careful sourcing and inspection of 2,4-Dichlorobutyrophenone keep pharmaceutical products consistent. Without trustworthy intermediate chemicals, no one in the industry can guarantee drug safety.

Use Across Chemical Manufacturing

Quality matters just as much for chemical manufacturing as it does in pharma. 2,4-Dichlorobutyrophenone contributes to the production of agrochemicals and other specialty compounds. Agrochemical companies need precise precursors to develop herbicides, pesticides, and regulators for crop science. Years of trial and error go into picking compounds that balance effects on plants and minimize unintended harm.

Experience has shown that making and handling these chemicals offers no room for shortcuts. The synthesis demands tight temperature and reaction controls, which keeps risks in check. I’ve seen teams sweat over purification because even traces of leftover contaminant spoil an entire batch. So, folks working in chemical plants put a lot of effort into using the right instruments and methods.

Safety and Environmental Attention

Anyone involved with these compounds gets a real lesson in chemical safety. Contact with 2,4-Dichlorobutyrophenone can irritate the skin, eyes, or airways. Workers suit up in gloves, goggles, and masks; they rely on proper training instead of just warning signs. Poorly handled disposal could seep into local water or soil—a risk that stays on managers’ minds.

Strict storage rules and closed-system processes keep most issues from popping up in modern facilities. Still, not every country holds companies to the same standards. There’s ongoing work to bring global regulations into tighter alignment. Substituting safer, less toxic intermediates makes sense wherever possible, but practical chemistry doesn’t always allow an easy switch.

Where To Go From Here

Long-term, it pays off to invest in safer manufacturing and cleaner alternatives. Engineers and chemists continue building better processes for intermediates, testing new compounds that break down faster and leave fewer byproducts. The push toward greener chemistry brings both challenges and opportunities. The right technical improvements don’t just protect people in the lab but help the rest of us too—especially when these compounds show up, however indirectly, in the fields and pharmacies we rely on each day.

Breaking Down the Name

Chemistry lingo can throw off even lifelong science buffs, but once you crack open the name “2,4-Dichlorobutyrophenone,” the pieces fit together with purpose. The backbone is phenone—a reference to phenyl ketones. In this case, that means a benzene ring tied directly to a carbonyl group (C=O). Add “butyro”—which refers to a four-carbon chain—and you’ve set up a structure: phenyl ring with a butyrophenone side chain. The “2,4-dichloro” twist drops in two chlorine atoms onto the benzene at the second and fourth positions, shifting the molecule’s behavior and properties.

The Structure in Close-Up

Lay it out on a page, and 2,4-Dichlorobutyrophenone comes to life as 1-(2,4-dichlorophenyl)butan-1-one. One end holds that familiar benzene ring, with chlorines glued to the carbon at position 2 and position 4. The carbonyl group (C=O) branches off the benzene, and from the carbonyl exists a four-carbon chain. Drawing it out, you’d count: chlorine at carbon number 2, another at 4, carbonyl group attached at position 1, then three more carbons making up the straight aliphatic chain.

Visual learners might imagine a fork: the base is the benzene ring, each chlorine an extra prong—one to the left, one to the right—while the butyrophenone chain trails away. Chemical shorthand brings it as C10H10Cl2O, emphasizing two chlorine atoms, ten carbons in total, and a single oxygen stirring up reactivity.

Why the Structure Matters

Molecular quirks shift more than just textbook details. Chlorine atoms don’t just sit still—they amplify the molecule’s ability to interact with other materials, from solvents to enzymes. Folks working in labs or factories notice these chlorinated phenones behaving far differently from parent butyrophenones. You tend to see higher toxicity and greater activity in chemical reactions. Not every version of the molecule will trigger a dramatic difference, but these chlorines boost both chemical durability and the ability to bind to biological sites.

This compound often appears in stories about organic synthesis. Chemists chase down molecules with specific substitutions to create new drugs, materials, and testing reagents. Changes in the structure mean changes in legal handling and environmental safety, too. Persistent molecules—especially chlorinated ones—can stick around in water, soil, and living creatures. That’s why many countries regulate them closely.

Responsible Handling and Looking Forward

There’s always a bigger picture than diagrams or line formulas. Manufacturing and handling 2,4-Dichlorobutyrophenone means suiting up for safety, managing waste streams, and considering long-term impact. At my own research bench, I learned that a small tweak in a molecule—like popping on a chlorine—can turn a sleepy precursor into a biologically potent compound. Gloves, goggles, and well-labeled containers move from suggestions to hard rules.

Solutions start before problems show up. Careful tracking of chlorinated chemicals, routine safety training, and pushing for greener alternatives clear a path for both innovation and responsibility. Chemists now design “safer” molecules right from square one, avoiding persistent pollutants or toxic breakdown products. Thinking about structure goes beyond the lab; it shapes health and policy decisions long after someone sketches that benzene ring on a napkin.

What Is 2,4-Dichlorobutyrophenone?

2,4-Dichlorobutyrophenone often finds its way into chemical synthesis, especially in pharmaceuticals and laboratory settings. It’s a clear, oil-like substance with a sharp smell. The chemical structure, with two chlorine atoms and a butyrophenone backbone, gives it the ability to produce strong reactions—with both compounds and people.

Hazards of Handling

I work in a university lab where chemical safety sits high on everyone’s list, so I’ve seen firsthand what improper handling looks like. A bottle of this compound left uncapped can fill the air with a harsh odor. The main issues arise because 2,4-Dichlorobutyrophenone irritates the eyes, skin, and respiratory tract. If someone splashes a bit on their hand, redness and a burning sensation set in quickly. Vapors lead to coughing or choking, especially in small, unventilated spaces. Contact with the eyes or swallowed droplets pose an even greater risk—pain, vision problems, nausea, and, in some cases, lasting tissue damage.

Long-Term Risks

The concern stretches well beyond short-term irritation. Chlorinated organics, like this compound, have a long track record of causing trouble. Animal studies often find that repeated exposure causes liver problems or disrupts the central nervous system. Sometimes workers complain of dizziness, confusion, or headaches after breathing certain vapors for too long. There’s also the worry about carcinogenicity, though no broad human evidence exists at this point. Still, other compounds in its class make doctors and researchers cautious. Over the years, the EPA and OSHA have flagged related chemicals for strict handling guidelines, so nobody in my line of work takes shortcuts.

Environmental Impact

Beyond the lab or factory floor, runoff or spills head straight to local waterways. Chlorinated organics resist breaking down, which means that once 2,4-Dichlorobutyrophenone leaks out, it lingers for a long time. Fish and small organisms in creeks and rivers buckle under the weight of such contamination. Many regulatory agencies require reporting even small spills because lasting build-up feeds its way up the food chain, threatening local wildlife and endangering drinking water.

Reducing the Risk

Risk reduction boils down to solid routines. Gloves, goggles, and chemical splash aprons stay on as long as the container’s open. Every student or lab worker needs training before handling compounds like this. Fume hoods and closed systems cut the odds of breathing in vapors. Anyone storing 2,4-Dichlorobutyrophenone keeps it in a secure, cool place, away from acids or other reactive chemicals. Quick access to spill kits, plenty of ventilation, and easy communication play big roles in staying safe. Some companies run regular safety drills and insist on written protocols, which makes a difference when something goes wrong.

Potential Solutions

Moving forward, industry and research groups push for less toxic alternatives wherever possible. Quick-reference safety datasheets, color-coded labeling, and barcode tracking can stop a small mistake from snowballing into a disaster. Engineering controls, such as vented cabinets and automated transfer systems, take workers further out of harm’s way. Community education, responsible disposal, and reporting transparent accident records encourage trust and improve practices. In my experience, leadership that takes regular safety audits seriously and budgets for protective gear will always have better outcomes. Small steps add up, pushing dangerous chemicals out of the shadows and into the spotlight where risks can be managed—and minimized.

Taking Chemical Safety Seriously

Anyone who works around chemicals knows there’s no cutting corners when it comes to safety. 2,4-Dichlorobutyrophenone might not ring a bell for everyone, but this compound, often used as an intermediate in pharmaceutical and fine chemical production, deserves some respect in the storage room. Years spent in research labs have shown me that most accidents start not from ignorance, but from thinking "that won’t happen here." It does, and one small mistake can cause a world of hurt.

Understanding the Risks

This substance isn’t particularly famous for being explosive or extremely reactive. Still, it causes real health hazards: skin and eye irritation, breathing difficulties if inhaled, and potential harm with long-term exposure. The way you handle and store it isn’t just about keeping shelves tidy—it’s about protecting everyone working nearby. The compound's powder can become airborne, and mishandling spreads contamination quickly.

Smart Storage: What Works

Shelves need more than strength—they need a plan. 2,4-Dichlorobutyrophenone should sit in a cool, dry area, out of direct sunlight and far from sources of ignition. Moisture harms the container and the contents, so climate control helps here. Some old labs, like ones I’ve worked in, put incompatible substances together out of convenience, then paid the price. Don't store with acids, oxidizers, or strong bases. Dedicated, labeled cabinets with secondary containment trays can mean the difference between a quick clean-up and a health incident.

Store only the amount needed in the working area. Large containers stay locked up in the chemical storeroom. Overcrowding increases spills and confusion. Everyone who comes near must know what’s inside those bottles; labeling should be clear and checked often. Faded markers or missing hazard signs have tripped up more than one busy worker.

Handling That Doesn’t Cut Corners

You’ll rarely see me in the lab without gloves and a lab coat. Nitrile gloves, splash-proof goggles, and closed shoes feel like a hassle at 7 a.m., but they stay on. If you skip protective wear—even “just for a sec”—you open the door to trouble. Spills on bare skin mean immediate irritation, and chemical odors can linger.

Use dust masks or respirators if handling powders in anything beyond tiny amounts. I’ve met folks who swore off proper ventilation, trusting the room’s old fan. In reality, fume hoods make a big difference and offer real protection if things go sideways. After every use, wipe down surfaces and change gloves. Don’t carry the mess throughout the building.

Training and Emergency Planning

No one gets a free pass with chemical safety. Ongoing safety training makes core knowledge stick. Everyone—from students to senior staff—should know the toxicological risks, spill procedures, and emergency cleanup. Practice makes fast action reflexive. In labs I’ve managed, annual drills trimmed spill response from minutes to seconds.

Emergency showers, eye-wash stations, and spill kits need to remain accessible and marked—never blocked by boxes or furniture. Everyone on site should be able to name the nearest one without thinking. That awareness turns dangerous accidents into minor hiccups. Consulting the safety data sheet (SDS) for the latest guidelines keeps everyone sharp and up to date with best practices.

Raising the Bar Together

Mistakes come from assuming bad things only happen somewhere else. A culture built on vigilance, respect, and teamwork keeps people safe around chemicals like 2,4-Dichlorobutyrophenone. Each small habit—closing bottles, labeling clearly, suiting up for protection—matters more than any clever shortcut. One person's diligence today means fewer emergencies and better health tomorrow.

What It Does in the Lab and Beyond

A lot of folks outside chemistry circles don’t think much about what goes on inside research labs until a new material, medicine, or cleaner shows up on store shelves. In fact, most of these breakthroughs come from testing the building blocks of more complicated materials. 2,4-Dichlorobutyrophenone is one of those pieces. You won’t see it as a finished product, but it works behind the scenes.

Behind Every Modern Medicine Cabinet

This compound pops up most frequently in drug research. Researchers use it as a starting material when they try to build molecules for new drugs, especially those that need a particular arrangement of atoms for the medicine to work safely. The structure of 2,4-Dichlorobutyrophenone makes it useful for making a certain kind of chemical bond — the sort that pops up in anti-inflammatory drugs, anti-seizure medications, and treatments for conditions like high blood pressure.

Researchers lean on this compound because it lets them add small tweaks to a molecule without completely changing its core structure. From my own days in a chemistry lab, those little tweaks could mean the difference between a promising lead and a dead end. Without handy reagents like 2,4-Dichlorobutyrophenone, making adjustments could drag on for weeks instead of days.

Creating Pesticides and Specialty Chemicals

Big farming operations and home gardens share the same enemy: weeds. The active ingredients in some weed killers start from molecules like 2,4-Dichlorobutyrophenone. Its chemical backbone lets manufacturers build up the weed-blocking ingredients step by step. You end up with more targeted action in the field, which means fewer chemicals drifting into the water or soil where they don’t belong.

Manufacturers also value this compound when designing specialty coatings or plastic additives. Their chemists break it down and put it back together in new ways to produce chemical mixtures for paints, resins, or adhesives that last longer or hold up better against heat and sunlight.

Helping Out in Biological Research

A lot of research labs use this compound to make molecules that probe what’s happening inside cells. Chemical tools built from 2,4-Dichlorobutyrophenone help scientists label proteins in order to watch them move or turn off genes in specific tissues. I remember working on a project that needed to map how certain proteins shifted inside cancer cells after treatment. We wouldn’t have made any headway if not for reliable building blocks like this one.

Dealing With Safety and Environmental Concerns

Every time scientists pick up a bottle of 2,4-Dichlorobutyrophenone, they know they’re handling something that has to be treated with care. Spills or improper storage can hurt workers or spread chemicals beyond the lab. Labs need good safety training and air handling to deal with the fumes. Manufacturers and universities keep close records to track who’s buying, storing, or disposing of it.

A newer approach focuses on greener chemistry. Some labs look for alternatives that cut down on waste or reduce the number of potentially harmful byproducts. Others recycle leftover material, turning an old batch into new reagents for another set of experiments.

Looking Ahead

Scientists continue to find new ways to use and handle 2,4-Dichlorobutyrophenone responsibly. As regulations change or new risks come to light, chemical suppliers work closely with researchers and safety experts to update guidelines and recommend safer substitutes where possible. Staying on top of these changes makes a difference not just for people working with the chemical, but for everyone living downstream of its impact.