2,4,6-Trifluorobenzylamine: In-Depth Overview and Commentary

Historical Development

Research on aromatic amines gained traction during the growth of the chemical industry in the twentieth century, driven by the pharmaceutical and agrochemical sectors. By the late 1970s, attention turned to fluorinated aromatics, as scientists learned that fluorine atoms could improve stability, alter biological activity, and fine-tune the physical traits of molecules. Out of this creative surge, 2,4,6-trifluorobenzylamine took shape as one of the more promising members of the trifluorinated aromatic amine family. Chemical suppliers, particularly in the United States, Germany, and Japan, scaled up research and production after noticing the compound’s utility for creating targeted pharmaceuticals, crop protectants, and specialist polymers. Soon enough, research labs and factories kept it in regular stock, seeing in it both synthetic flexibility and a means to push chemistry forward.

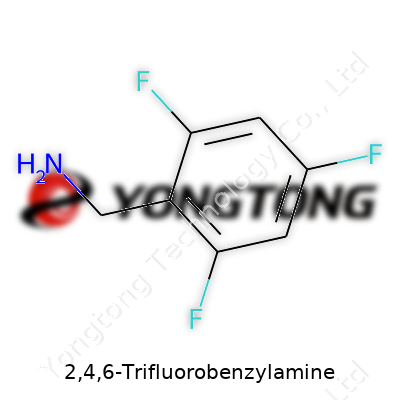

Product Overview

2,4,6-Trifluorobenzylamine sits among the aromatic amines known for unique physical and reactivity profiles. The molecule fits into synthetic plans where one aims for both stability and specific points of reactivity. Chemists working on new compounds, especially those targeting improved resistance to metabolic breakdown, frequently reach for it thanks to the electron-withdrawing power of its three fluorine atoms. They find it useful in medicinal chemistry, materials science, and crop research, relying on its particular amine group and fluorinated ring system for synthetic planning that might baffle less adaptable molecules.

Physical & Chemical Properties

This compound has a molecular formula of C7H6F3N, a molar mass close to 161.1 g/mol, and typically appears as a colorless to pale yellow liquid under ambient conditions. Its boiling point measures around 175–180 °C, so the substance handles moderate heat without excessive volatility. The three fluorines at the 2, 4, and 6 positions of the benzene ring keep the molecule’s character distinct: volatility sits a bit lower than similar benzylamines, yet its solubility in common organic solvents (such as ether, methanol, acetone) allows flexible use in both bench and pilot-scale chemistry. The basic amine shows moderate nucleophilicity, though the electron-withdrawing effect of the ring’s fluorines reduces its reactivity compared to its non-fluorinated cousins.

Technical Specifications & Labeling

Quality chemical suppliers often provide purity at or above 98%, making this standard suitable for research and pilot syntheses. Labels should give CAS number 63703-58-4, molecular details, batch reference, date of manufacture, and hazard statements under GHS. Labs demand tight documentation for transit, storage, and use, linking labeling and certification directly to the requirements of safety and regulatory compliance—an area that grows stricter each year in response to regulatory and corporate responsibility. Analysts recommend verifying exact fluorine content and amine assay before embarking on scale-up or animal testing.

Preparation Method

Historically, chemists start from commercially available 2,4,6-trifluorobenzaldehyde. They reduce the aldehyde group to a primary alcohol, then convert the alcohol to a benzyl halide before nucleophilic substitution with ammonia or a suitable amine. The introduction of fluorines often precedes amine installation, as direct amination of a pre-fluorinated ring avoids harsh or wasteful reaction conditions. Modern process chemistry puts emphasis on step economy and greener reagents, aiming for scalable and low-waste synthesis. Careful purification—especially fractional distillation or flash chromatography—keeps impurities and hydrolyzed by-products out of the final bottle.

Chemical Reactions & Modifications

The compound offers a responsive amine group just off a ring locked into a high electron-deficiency state by three strong fluorines. Chemists reach for it in reductive aminations, acylations, and urea or sulfonamide syntheses. In medicinal chemistry, the benzylamine group can be connected through amide linkages to build peptide mimics, or coupled with isocyanates to add urea fragments. Catalytic coupling reactions—like Buchwald-Hartwig amination—find 2,4,6-trifluorobenzylamine highly useful, with its electron-deficient ring often steering selectivity in remarkable ways. Halogen exchange and cross-coupling can extend the fluorinated benzyl unit into new molecular architectures for agrochemicals or materials.

Synonyms & Product Names

Literature and supplier catalogs include quite a roster of alternative designations: 2,4,6-trifluoro-phenylmethylamine, α-(2,4,6-Trifluorophenyl)methanamine, and 2,4,6-trifluorobenzyl amine feature prominently. The CAS registry number 63703-58-4 stands as a reliable point of reference for those seeking to distinguish it from other trifluorinated derivatives. In industry shorthand, some synthetic chemists refer to it simply as TFBA, but full nomenclature stays in play for certification and import.

Safety & Operational Standards

Stringent global regulations guide the handling of aromatic amines, demanding well-ventilated workspaces, chemical-resistant gloves, goggles, and procedures for careful waste collection. 2,4,6-Trifluorobenzylamine releases fumes that irritate skin, eyes, and respiratory passages; short-term spill or skin contact prompts immediate washing, and longer exposure may impact liver and kidney function—though evidence remains fragmentary. Labels direct that storage occurs below 30 °C in sealed containers, away from oxidants or acids. Labs track their stocks carefully, reporting loss or breakage to meet local health and environment rules.

Application Area

Medicinal chemists see major value in this trifluorinated benzylamine, often weaving it into drug candidates where blocking metabolic oxidation means longer-lasting pills. Pesticide researchers combine it with heterocycles or sulfonyl moieties for better bug- and weed-fighting power. Polymer developers and materials scientists find the compound helpful for synthesizing specialty resins, liquid crystals, or advanced coatings. They often cite the role of the fluorine atoms in tuning low surface energy, UV stability, and chemical resistance. I’ve seen colleagues use 2,4,6-trifluorobenzylamine for assembling unique molecular probes, too, where specific fluorination helps boost NMR signal and tailor biological response.

Research & Development

Development labs and university researchers probe new derivatives with each passing year. Projects span searching for anti-tumor properties, building enzyme inhibitors, and looking for new materials to resist fire or degrade less in strong sunlight. Academics report that the sharp electronegativity from the trifluorinated core alters hydrogen bonding and aromatic stacking, nudging properties in directions that older, non-fluorinated scaffolds can’t match. Pharmaceutical industry attention gradually rises as computational chemistry links ring fluorination to better drug performance in blood and tissue.

Toxicity Research

Toxicologists pay close scrutiny to the subtle hazards of fluorinated aromatics. Bench-scale studies suggest 2,4,6-trifluorobenzylamine can generate intermediates that stress mammalian liver cells, with the size of exposure acting as the key risk factor. Animal tests point to moderate oral and dermal toxicity at high doses, similar to related benzylamines. Attention falls on laboratory waste: persistent fluorinated fragments sometimes resist easy breakdown, so chemical waste programs move quickly to contain and neutralize traces before discharge. Researchers in Europe and North America keep a close eye on regulatory shifts, since the larger environmental concerns around some per- and polyfluorinated substances threaten tighter future controls.

Future Prospects

Outlook for 2,4,6-trifluorobenzylamine tracks the path of synthetic and applied chemistry trends. Stable fluorinated groups grow more popular as drug companies look for ways to cut dosage size and expand bioavailability. Environmental regulations keep pushing toward safer, cleaner production—not only for this compound but also for every intermediate and by-product. I expect further breakthroughs in “green” synthesis, and wider adoption in advanced materials, especially if regulatory barriers can be matched by clever waste management. Chemists who unlock new applications, or who design pathways to recycle or safely degrade fluorinated residues, stand to shape the next stage of this compound’s role in industry and science.

Looking Inside the Structure

Most folks who spend time in a lab know that chemical names can feel like puzzles. You look at “2,4,6-Trifluorobenzylamine” and you might see a mouthful, but there’s a clear story within that string of numbers and letters. Strip it back: you’ve got a benzene ring—think six carbons bound in a ring, with alternating double bonds—then you toss on three fluorine atoms at the second, fourth, and sixth positions. One carbon steps out with a CH2 group, tied to an amino group (NH2). That’s the original benzylamine frame, newly decorated with fluorine. Organizing it all, you get C7H6F3N. It’s clean, logical, and direct.

Why Chemistry Buffs Care

This chemical picks up attention in medicinal chemistry, agrochemical research, and materials science. Researchers seek molecules like this because swapping just a few atoms can influence potency, selectivity, or how a substance stays stable. Fluorine plays a major role here. Drop a fluorine atom into a molecule, and you often change its reactivity, how it dissolves, even how it’s processed in the body. Three fluorines mean this compound acts differently from its plain benzylamine cousin. This kind of tweaking is how new medicines or crop treatments get their jump in performance.My own late nights in the lab involved synthesizing fluoroaromatic amines for drug projects. Adding fluorine tended to boost metabolic stability—keeping the compounds from breaking down before they reached their target. Work like that matters when you’re looking for smaller doses, or trying to avoid toxic breakdown products.

Connecting Formula and Function

C7H6F3N—on paper, that looks simple. Each atom has its role. Fluorine attracts attention since it pushes electron density and stirs up how the entire ring behaves. Medicinal chemists like using trifluoro groups around a benzene ring because it shields parts of the molecule from enzymes, can improve crossing through cell membranes, and may even change how a drug interacts with its target.It’s not just about medicine, either. Scientists build new materials—like high-performance plastics, resins, or electronic components—using trifluorinated pieces to block water and prevent decay.

Tackling the Downside

Working with fluorinated compounds isn’t trouble-free. Some are tough on the environment. They can stick around for years without breaking down—known as persistence. This means researchers have to balance the benefits of chemical stability with long-term impacts. Labs now try finding greener ways to attach fluorine, limit waste, and design molecules that break down after use. Regulatory bodies look closely at these chemicals, since some older fluorinated products have built up in air, water, and even wildlife.It’s on all of us in science to push for safe handling, proper disposal, and smarter design—so 2,4,6-Trifluorobenzylamine and its relatives solve big problems without causing new ones.

What’s Next

The chemical formula C7H6F3N isn’t just numbers and letters for experts—it’s a recipe. If you’re curious or working in a lab, knowing how to break down such formulas and connect the structure to real results opens the door to understanding new treatments, advanced materials, or even the impact on the world outside the beaker. That’s the kind of chemistry that touches lives, one ring and one atom at a time.

What 2,4,6-Trifluorobenzylamine Brings to Chemistry Bench

Anyone familiar with organic synthesis knows the push for unique building blocks. 2,4,6-Trifluorobenzylamine offers a twist on standard aromatic amines. Fluorine atoms at the 2, 4, and 6 positions mark a key difference from more common analogs. Fluorine isn’t just another element; it changes electron distribution across the benzene ring, which chemists use to control reactivity and product outcome in synthetic routes. In my experience at the lab, swapping in fluorinated amines often means better selectivity or different reaction speed, which can make all the difference in challenging multi-step syntheses.

Driving Medicinal Chemistry Innovation

Pharmaceutical research has been reshaped by what small fluorine atoms can do when dropped into drug molecules. 2,4,6-Trifluorobenzylamine finds a real home in creating new leads for medicinal chemistry. Medicinal chemists have added trifluorobenzyl groups to molecules looking for deeper binding in enzyme pockets or searching for new ways to block protein–protein interactions. This modification often leads to higher metabolic stability or shifts in biological activity profiles. Data from published studies point to an increase in drug candidates containing trifluorinated aromatics in discovery pipelines—some major cancer and CNS drugs spring from such roots.

Crop Protection and Agrochemical Research

Pest resistance keeps farmers awake at night, and agrochemical companies keep hunting for new active compounds. The use of 2,4,6-Trifluorobenzylamine in agrochemical research plays into this hunt. Introducing trifluorobenzyl scaffolds into candidate molecules sometimes boosts their power against pests or tough weeds by changing how active ingredients interact with biological targets. Some patents suggest that using this amine can also make the chemicals more resistant to breakdown when exposed to sunlight or soil microbes, which means longer-lasting field protection.

Materials Science: From Polymers to Specialty Chemicals

High-tech materials often demand ingredients with special properties. The presence of three fluorines in 2,4,6-Trifluorobenzylamine brings strong thermal stability and chemical resistance, both big deals in modern polymer science. Manufacturers in the coatings and plastics world have found that incorporating this amine leads to tougher end-products, often suitable for harsh or extreme environments. I’ve seen first-hand how a polymer batch containing a trifluorinated building block handles acid better and resists aging compared to traditional materials.

Alternative Energy and Electronics

Demand for reliable materials in batteries and electronics keeps growing. 2,4,6-Trifluorobenzylamine sometimes takes part in creating novel electrolytes, especially in research labs testing new battery chemistries. The inclusion of fluorinated aromatic moieties can mean safer operation at higher voltages, lower degradation, and more stable performance. Companies focused on OLEDs and other smart materials also use these molecules for their strong electron-withdrawing power, helping fine-tune conductivity or stability in devices.

Safe Handling and the Importance of Knowledge

Working with 2,4,6-Trifluorobenzylamine takes discipline. With all the benefits of trifluorinated compounds, proper safety becomes non-negotiable. My years in the lab remind me: gloves and eye protection come first. Read SDS sheets, follow proper disposal rules, and respect the impact that specialty chemicals can have, both on personal safety and the environment. Continued research and responsible manufacturing support meaningful advances in medicine, agriculture, and materials, while staying in line with evolving regulatory frameworks.

Numbers, Names, and the Chemistry That Connects Them

2,4,6-Trifluorobenzylamine stands out as one of those chemical names that grab your attention, especially if you’ve ever spent time squinting at lab bottles. Many in science or industry will tell you — tracking a compound by name gets confusing. That's where the CAS number comes in: 328-81-0 belongs to 2,4,6-Trifluorobenzylamine.

As someone who’s worked with research teams in university labs and also seen the messiness of buying from chemical suppliers, I know the relief a small set of numbers can bring. Common names shift. Hyphens sneak in. Regional differences show up. The CAS registry number cuts through this by giving each compound a single, unique code that everyone worldwide can agree on.

Why Bother With a Registry?

Imagine a lab searching for a compound for an important synthesis. Listings could say trifluorobenzylamine, or maybe use a different abbreviation. Picking the wrong bottle could mean wasted weeks and lost grant money. The CAS number removes the guesswork, and confirms you’re holding 2,4,6-Trifluorobenzylamine, not a cousin with a shifted fluorine.

Mistakes from misidentification hurt more than timelines. In pharmaceuticals, the slightest difference in starting materials often brings a world of trouble down the road. A chemist might think they bought what they needed, only to find that the impurity profile isn’t what they expected. Physicists working with new materials for electronics know the pain of spending months trying to explain data, later realizing a supplier’s labeling choice tanked the whole project.

Digging Deeper: CAS Numbers as an Anchor for Information

Looking up 328-81-0 doesn't just bring up a supplier's listing; it unlocks a flood of reliable, standardized information. Peer-reviewed papers, patents, environmental data — everything lines up under the same identifier, cutting down the hours spent cross-checking alternative spellings or local catalog numbers.

This isn’t academic nitpicking. In chemical safety, the certainty of what you’re using means real protection. Safety datasheets tied to CAS numbers spell out hazards and handling info, based on the precise molecular structure. Anyone who’s been handed only a vague “consult your supervisor” for a mystery reagent can appreciate how that feels.

Trust, Transparency, and Honesty in the Supply Chain

CAS numbers help power transparency. Auditors, regulators, and even the end-user in a high school classroom all gain from tracking what’s in a bottle or on a manifest. Big scandals—illegal dumping, lab disasters, or import busts—often break open because a CAS number clears up who had what, where, and why. Trust grows as buyers and sellers speak the same language.

Problems crop up when registries get out of sync, or rogue suppliers use made-up numbers. Those of us who’ve surfed supplier catalogs know dodgy listings waste time and create safety risks. Sticking to official CAS numbers gives buyers the confidence that they’re getting what they ordered, especially for lesser-known compounds like 2,4,6-Trifluorobenzylamine.

How to Sharpen the System

Tighter supplier verification, better training for new lab staff, and public access to up-to-date registry info would help weed out errors. Crowdsourcing error reports and rewarding suppliers for transparent practices also make sense. People deserve clear, accurate chemical information, whether they’re deep in research or starting a new manufacturing process.

At the end of the day, a CAS number like 328-81-0 serves as a small but crucial lock on a huge toolbox. In the details, big risks get managed and strong science moves forward.

Realities of 2,4,6-Trifluorobenzylamine Safety

Storing chemicals sounds straightforward until a strong-smelling bottle cracks open, and nobody can pinpoint where things went wrong. Fluorinated amines like 2,4,6-Trifluorobenzylamine don’t offer much forgiveness if ignored, so setting up a safe spot for them always takes priority. Plenty of labs have learned the hard way that some compounds turn dangerous without proper attention. Eyes water, storage cabinets corrode, entire shelves become contaminated, and all it takes is ignoring a warning label or moving too quickly at the end of a long day. Experience leaves a mark—both on memory and sometimes on the floor.

What Safety Data Sheets Make Clear

Reviewing a chemical’s SDS stops problems before they start. For 2,4,6-Trifluorobenzylamine, the paperwork points out a handful of musts: a cool, dry location, sealed containers, and strong ventilation. Temperature matters. A climate-controlled cabinet set below 25°C usually keeps the liquid stable, sidestepping worries about pressure inside bottles or unexpected leaks. Sunlight triggers unforgiving reactions with lots of amines, so blocks of shade with zero exposure give peace of mind. Moisture also causes havoc, breaking down active ingredients into unknown byproducts. After seeing contaminated samples ruin months of research, most chemists trade convenience for vigilance, using desiccants and checking seals on containers by hand.

Containment and Cross-Contamination

I’ve watched shelves packed too tightly with incompatible chemicals, and the risks multiply with every shortcut. Amines with strong bases or oxidizers push the limits of luck. One spill forms a toxic soup that no janitor wants to approach. Segregating 2,4,6-Trifluorobenzylamine from acids and incompatible solvents keeps reactions predictable. Polyethylene and PTFE containers block out unwanted interactions, avoiding the sorts of micro-cracks that glass sometimes allows. Labels need to stay legible after years of handling—no sharpies that fade or stickers that peel off with time.

Few things irritate lab workers more than finding their personal protective equipment locked away, so the best storage setups put gloves, safety goggles, and face shields right by the chemicals. It turns that quick impulse grab into a brief safety pause, and habits stick that way.

Maintaining Accountability

Rules don’t help if nobody tracks what comes in or out. Keeping a notebook or digital log means that people know which bottle saw daylight last and who last ordered more. The 2018 UCLA lab fire shows what happens when accountability takes a backseat. Strong policies keep chemicals from lingering past their shelf life, which matters for unstable compounds more prone to degrade. Regular inventory stops waste and cuts down on expired material heading to landfill or incinerators—safer for everyone.

Emergency Readiness

No preparation blocks every accident. Spills still sneak up, containers fall, and fumes surprise even seasoned hands. A well-placed fume hood makes all the difference, drawing away vapors before eyes or lungs get hit. I keep spill kits stocked with absorbents, neutralizers, and bags tough enough to contain fluorinated waste. Training keeps responses automatic—no panic, only practiced steps. Local fire codes guide ventilation, so checking exhaust fans or doors for blockages becomes as natural as tying shoes. Getting all users on board means no one’s left guessing during a real mess.

Keeping 2,4,6-Trifluorobenzylamine safe doesn’t take fancy gear, just routine attention and respect. It becomes a cycle: read, prepare, check, train. Safe storage and handling build trust, both in the lab and in the wider supply chain.

Respect What’s on the Label

Some chemicals just demand respect, and 2,4,6-Trifluorobenzylamine fits that bill. It’s a building block in a lot of research labs and chemical manufacturing, but it’s far from friendly. Toxic by inhalation, hazardous to skin, rough on the eyes — that label with skulls and exclamation points isn’t just paperwork. Relying on legends and what coworkers say puts everyone at risk. Material Safety Data Sheets offer clear details about symptoms like headaches, nausea, or skin irritation, and anyone handling it benefits by reviewing those regularly.

Control Every Contact

The smell may not hit until it’s too late, and most symptoms don’t warn you soon enough. So it makes sense to suit up: nitrile gloves keep hands safe, and goggles stop fumes or a careless splash from causing eye damage. I’ve talked with chemists who mentioned cases of handwashing failing because the wrong gloves were used. Splash-proof lab coats and, for some jobs, full-face shields cut down on the “what ifs.” Respirators with organic vapor cartridges give a clear layer of defense when the air feels questionable.

Good Habits Keep Accidents Out

Anyone who tries to save time by skipping simple measures learns the hard way. Good habits start with regular equipment checks. Glove boxes, fume hoods, and air handling units don’t keep you safe if they’re out of date or leaking. Testing for airflow with a strip of tissue attached to the hood reveals more about its health than a sticker ever could. The best bosses encourage everyone to double-check before mixing or transferring, and to step back and ask questions. Leaving containers open or unlabeled gives trouble a chance to sneak up, whether through spills, evaporation, or confusion.

What If Something Goes Wrong?

Spills can spread fast. Lab floors aren’t forgiving, and a few drops on the counter can endanger colleagues. Absorbent pads soaked in a strong base or special spill kits mop things up, but speed matters. After cleanup, disposal takes priority: waste bins marked for hazardous chemicals keep it off the regular garbage route and protect custodial teams. Showers and eye wash stations need to work — walking past them every day is pointless if no one’s checked the water flow in months. Trainers say it plain: practice using them. Muscle memory and clear signage beat panic and confusion any day.

Routine: The Real Defense

Rushing never helps with these chemicals. Routines, from labeling to personal monitoring, create a safety blanket across the lab. Many people develop a gut feeling for trouble after a few months, but relying only on instinct misses smaller risks. Electronic logs, checklists, and open conversations about near-misses bring new eyes to old problems. Physical and mental presence both matter — fatigue and distraction lead to mistakes as easily as inexperience does.

Seeking Improvement Matters

No single rulebook covers every chemical or scenario, but solid training and staying current with updates improve results for everyone on the team. Changing procedures after someone nearly gets hurt, or following advice sent out by chemical suppliers or safety regulators, keeps the whole group learning. Sharing mistakes may feel uncomfortable, but real progress grows out of honest talk about what isn’t working. The point isn’t to scare people, but to leave fear behind by following smart routines. Each time someone adds a sensible shortcut or replaces worn-out gear, the workplace becomes safer for all.