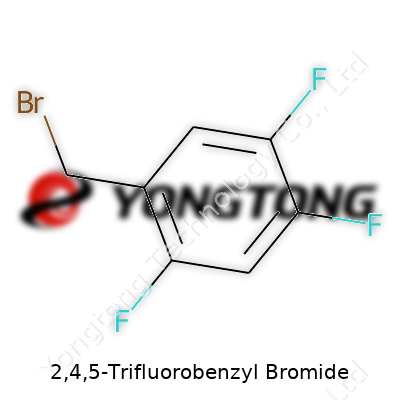

2,4,5-Trifluorobenzyl Bromide: Understanding an Influential Chemical

Historical Development

Chemists have spent decades exploring aromatic halides, searching for ways to add value to industries like pharmaceuticals and agrochemicals. The journey of 2,4,5-trifluorobenzyl bromide traces back to a broader interest in polyfluorinated benzyl compounds. As awareness grew around the benefits of selective fluorination, research teams in the 1970s and 1980s looked for practical ways to introduce trifluorinated groups onto the benzyl skeleton. The resulting substance carved out a niche thanks to a mix of chemical stability and unique reactivity. Over time, the compound gained traction in academic circles and industries hungry for building blocks in advanced synthesis. The rise of targeted pharmaceuticals and crop protection products pulled it further into the limelight, often as a stepping stone in complex molecular design. Generations of synthetic chemists experimented with this chemical, pushing the boundaries of what aromatic fluorides could do.

Product Overview

2,4,5-Trifluorobenzyl bromide stands out because of its halogenated profile. Each fluorine atom affects how the molecule interacts with others, and the bromide at the benzylic position opens the door for nucleophilic substitution. This feature draws interest from labs focused on fine-tuning molecular scaffolds and triggers curiosity from those seeking new drug candidates. The substance usually appears as a clear to slightly yellowish liquid, sometimes defined by a pungent odor typical for benzyl halides. Its uses stretch across chemistry disciplines, but most commonly revolves around its application as an intermediate.

Physical & Chemical Properties

Looking at the numbers helps anyone working with this chemical. The compound weighs in at 241.98 g/mol. Its melting point sits low, often below room temperature, and it boils at roughly 73-75°C at 15 mmHg. Slight water solubility and high solubility in organic solvents like dichloromethane or ether become practical concerns in labs. With a density around 1.65 g/cm³, spills quickly settle toward the bottom of most vessels. The trifluoro pattern attached to the benzene ring helps stabilize the molecule, even when exposed to mild oxidative or reductive environments. Chemists take advantage of the reactivity of the benzyl bromide function; nucleophiles can snap it off, trading bromide for a wide array of groups. Meanwhile, the electron-withdrawing effect of the fluorines makes the aromatic ring less reactive towards electrophilic attack, shifting the molecule’s chemistry in predictable ways.

Technical Specifications & Labeling

Manufacturers usually provide this substance with clear labeling: CAS number, purity (typically above 97%), and physical state. Quality standards expect low moisture content, confirmed by Karl Fischer titration, and impurities—like dibromides or partially fluorinated derivatives—are tightly controlled using NMR and GC analysis. Labels highlight hazards, including phrases like “toxic by inhalation” or “eyes and skin irritant,” with storage guidance set for cool, dry, and well-ventilated places, ideally in amber bottles, to guard against UV degradation. Most suppliers seal the product under inert gas and recommend using it within a set date for best performance.

Preparation Method

Chemists who synthesize 2,4,5-trifluorobenzyl bromide start with the corresponding trifluorobenzyl alcohol. Conversion to the bromide typically requires phosphorus tribromide (PBr3) or hydrobromic acid. Reactions run under controlled temperature, and excess reagents are washed away with water, then the product gets dried over magnesium sulfate. Some labs prefer phase-transfer catalysis, bringing up yields and purity, especially useful on industrial scales. Final purification often takes place via vacuum distillation or column chromatography, depending on the lab’s resources and desired scale.

Chemical Reactions & Modifications

In the lab, this compound often partners with a nucleophile. Common reactions include substitution with amines, thiols, or alkoxides, producing functionally diverse molecules. The aromatic ring, shielded by the fluorines, resists many standard transformations, so chemists often exploit the benzylic position instead. For instance, attaching amino groups by reacting with aniline can give rise to specialized drug scaffolds, while coupling to thioureas leads to bioactive thioethers. Hydrogenation of the benzylic position yields 2,4,5-trifluorotoluene. Sometimes, scientists take advantage of its benzylic reactivity to graft it onto polymers, creating tailor-made materials with controllable characteristics.

Synonyms & Product Names

Catalogs and scientific papers list other aliases. Alongside 2,4,5-trifluorobenzyl bromide, names like benzyl bromide, 2,4,5-trifluoro- appear. International Chemical Identifiers (InChI), SMILES notation, and registry numbers have joined CAS entries, smoothing international trade and regulatory checks. Each supplier uses these codes to help researchers check cross-compatibility and trace sources.

Safety & Operational Standards

Anyone using this compound wears gloves, goggles, and works in a fume hood. The risk comes from vapors and skin absorption; benzyl bromides tend to alkylate proteins, which means accidental exposure can lead to nasty burns or systemic toxicity. SDS forms detail procedures for spills and emergencies, and disposal usually goes through halogenated waste streams in compliance with local regulations. Laboratories monitor storage closely, since decomposition can yield corrosive fumes over time. Routine training helps lower the odds of exposure, reminding researchers that a single slipup can lead to days of discomfort or longer-term risk.

Application Area

Pharmaceutical chemists use this reagent to install trifluorobenzyl groups onto molecules in drug discovery projects. This alteration often changes a molecule’s metabolic profile, improving stability or delivering better absorption. Agrochemical developers see similar benefits, as tweaks can boost pest resistance or environmental persistence. Polymer chemists use it to attach halogenated aromatic groups onto backbones, aiming to create resins and coatings that shrug off harsh conditions. Even analytical chemistry teams use it for derivatizing analytes, allowing for easier detection by chromatography or mass spectrometry.

Research & Development

Academic groups continue to report new methods for synthesizing trifluorobenzyl derivatives. Some explore greener protocols, swapping out harsh solvents for benign media or finding ways to recycle catalysts. Industrial R&D teams look for faster, more reliable ways to scale up production with less waste and lower costs. Cutting-edge work explores new transformations of the trifluorobenzyl motif and the impact of these changes on biological targets. Databases of reaction conditions help chemists decide on the best route for their targets, and open-source tools offer predictions on what products might come from a given set of reactants.

Toxicity Research

Toxicology studies flag the compound for its irritancy and alkylating ability. Researchers measure LD50 values in animal models and track metabolic breakdown products using in vivo and in vitro assays. Some focus on understanding if the benzyl or trifluorobenzyl group influences binding to DNA or proteins, raising questions about potential mutagenicity. Environmental teams take a hard look at breakdown, persistence, and the impact of residual material escaping into wastewater. Findings spur improvements in personal protective protocols and often feed back to manufacturers, nudging them to develop safer derivatives.

Future Prospects

The next wave of interest builds on trends in green chemistry and targeted therapeutics. If new synthetic routes carry less environmental burden, adoption across industry could accelerate. Advances in biocatalysis open up potential for milder, more selective transformations, which means higher purity without aggressive reagents. Demand keeps growing for trifluorinated building blocks, not just for new drug candidates, but for high-tech materials in energy, coatings, and electronics. As regulatory scrutiny tightens, companies invest in cleaner processes and comprehensive risk assessments, aiming to balance performance with safety. Research into alternatives keeps pace, buoyed by the promise of fluorinated molecules that are easier to handle and friendlier to ecosystems. The story of 2,4,5-trifluorobenzyl bromide has unfolded across decades but shows no signs of losing relevance, especially where innovation meets need.

Piecing Together the Structure

A lot of folks look at the name 2,4,5-trifluorobenzyl bromide and feel lost right away. Chemistry can seem all smoke and mirrors if you’re not wearing a lab coat, but really, it’s about clarity and details. The chemical formula tells you exactly what’s going on at the molecular level. In this case, we are talking about a benzene ring with three fluorine atoms at positions 2, 4, and 5, along with a bromomethyl group attached to the ring. Put all of that together, and the formula reads C7H4BrF3.

Why These Details Matter

Every atom in a chemical compound plays a part. In research labs, missing or misplacing a simple atom means starting the process from scratch. Speaking from long afternoons hunched over textbooks and reaction flasks, confusion over chemical formulas wastes resources, time, and money. Reliability comes from clear communication, and chemical notation leaves little to guesswork. The three fluorine atoms make this molecule behave in ways that set it apart from other benzyl bromides. Extra fluorination changes reactivity, boiling point, toxicity, and its path through organic synthesis.

Real-World Uses and Why You Should Care

Compounds like 2,4,5-trifluorobenzyl bromide are not just for show in some chemistry olympiad. Their unique characteristics slide naturally into pharmaceutical development and specialty materials. With pharmaceutical chemistry, every functional group affects how a drug molecule latches onto its target in your body. Those fluorines can help make a drug more stable or help it sneak past enzymes that break down compounds too quickly. That’s why folks in drug discovery watch these details closely; one atom off, and a promising compound may become useless.

Industry, too, relies on the specifics. In fields from agriculture to electronics, trifluorinated intermediates like this one get built into everything from pest control agents to advanced plastics. Scientists have published papers showing that trifluorobenzyl groups help produce compounds that resist degradation, last longer on the shelf, or perform better under stress. No sweeping statements here—peer-reviewed data from the last decade show a clear uptick in interest in fluorinated compounds due to these properties.

Keeping Safety in the Conversation

Few people outside the field mull over the safety implications of using more halogenated chemicals. It’s an elephant in the room. Bromides and fluorinated benzenes can be potent and sometimes hazardous. Years ago in the teaching lab, the safety goggles weren’t a fashion statement—they were a necessity. Handling trifluorobenzyl bromide means gloves, eye protection, and a good fume hood. Its higher reactivity compared to plain benzyl bromide means less room for error. Regulatory agencies watch compounds like this, weighing benefits against environmental and health risks. Fact is, responsible use and disposal must be part of anything involving halogenated organics.

Paths Toward Safer Handling and Broader Innovation

As demand grows for trifluorinated building blocks, researchers push for greener, safer methods of making and using these chemicals. New synthetic techniques, tighter regulations, and better monitoring can help keep labs safe and ensure only the intended use reaches the public. Collaboration between chemists, environmental scientists, and manufacturers stands as the most reliable way to balance innovation with safety. The whole conversation boils down to paying attention—one molecule at a time.

A Closer Look at 2,4,5-Trifluorobenzyl Bromide

2,4,5-Trifluorobenzyl bromide isn’t a household name, but in the labs and plants where science meets real-world challenges, this compound finds plenty of work. Chemists use it for its knack for adding fluorine atoms to molecules, a process that changes the behavior of those molecules in powerful ways. This chemical comes with some baggage, as safety and environmental health always play into its handling, but its usefulness is why it keeps showing up on order sheets.

Driving Pharmaceutical Advances

Drug designers often run into roadblocks with bioavailability and metabolic stability. Fluorinated building blocks like 2,4,5-Trifluorobenzyl bromide lend a helping hand here. By attaching it to new candidates, chemists can fine-tune how drugs slip through the body or lock onto a biological target. For drug makers, every new reaction offers a shot at building molecules that break through stubborn diseases. The pharmaceutical field has grown to depend on specialized reagents, and 2,4,5-Trifluorobenzyl bromide is one of the tools reaching for safer, more effective pills.

Power in the World of Agrochemicals

Crops face a long list of threats—fungi, bacteria, and pests that evolve fast and cause billions in losses. Fluorinated chemicals remain a steady piece of modern pesticide labs. Thanks to the particular arrangement of its atoms, 2,4,5-Trifluorobenzyl bromide can be bolted onto larger molecules, boosting their resilience and giving products a better chance against environmental breakdown. The result? Fields stay greener, harvests more stable, and food supplies safer. These benefits matter especially where farming happens on thin margins and weather throws up surprises every year.

Specialized Organic Synthesis

Beyond drugs and crops, synthetic labs need selective reagents for tricky reactions. 2,4,5-Trifluorobenzyl bromide offers a way to slip a fluorine pattern onto chemical frameworks, driving research into new polymers, dyes, and specialty chemicals. Science journals often describe its use as a coupling partner, unlocking options for researchers who track the latest trends in carbon-fluorine chemistry. Personally, I’ve seen graduate students celebrate quietly after pulling off a reaction with this compound, once a stubborn transformation finally yielded those sharp, clean peaks in their spectra.

Chemical Safety and Environmental Impact

No chemical operates in a vacuum. 2,4,5-Trifluorobenzyl bromide has toxic traits, and experienced lab workers do not go easy on personal protective equipment. Failing to respect its hazards can lead to health problems, so industry guidelines shape how it gets stored, moved, and turned into more benign compounds. Disposal calls for even tighter rules, since fluorinated molecules sometimes linger in water or soil. Following best practices lowers these risks, but calls for new, greener syntheses keep growing both in academia and industry. Green chemistry isn’t a buzzword—it’s a real shift, and fluorinated building blocks sit at that crossroads between scientific progress and responsibility to people and planet.

Seeking Smarter Solutions

Research continues into safer analogs and improved reaction conditions, with some groups turning to catalysts or alternative solvents to drop the overall risk. The search for less toxic fluorination agents runs in parallel with making existing processes cleaner and less wasteful. Investment in worker training and site monitoring also makes a difference, since handling specialty chemicals demands constant attention to detail. Scientists, regulators, and industry partners share the job of keeping chemistry moving forward while respecting environmental and safety limits. The challenge remains—chemistry rarely stands still, and the tools we use shape the society we build.

Why Proper Storage Matters

Imagine picking up a carton of milk stored at room temperature in the summertime. Most folks will check the date and give it a sniff, but even before that, we know it’s risky. Similar rules apply to products that require specific storage and handling conditions. Incorrect storage can ruin not just food, but pharmaceuticals, chemicals, and consumer goods as well.

Key Factors in Storing This Product

Temperature, humidity, and exposure to light stand out as primary concerns. Many products remain stable at cool, dry conditions -- usually between 15°C and 25°C -- and out of direct sunlight. Heat may speed up chemical reactions or cause items to spoil. High humidity can turn powders sticky or cause metal parts to corrode. Light can lead to color changes or even break down vital active ingredients.

From my experience working with temperature-sensitive materials on construction sites, misplaced storage led to lost batches, which not only wasted money but also delayed projects. In one case, a supplier delivered epoxy that had sat in the sun all afternoon. By the time crews started to mix it, the resin had thickened and wouldn’t set right. Storage guidelines aren’t just fine print—they keep both the product and your project on track.

Practical Steps for Safe Storage

Simple routines go a long way. For starters, keep items in the original packaging until just before use. Manufacturers design these containers with chemical or moisture barriers that shield contents from the environment. Closing bags, sealing lids, and keeping containers off dusty or damp floors help stop contamination and unwanted reactions.

Mark storage areas clearly and train staff about any special requirements. Pay close attention to warning labels and expiration dates. Use products in the order they arrive, following the “first in, first out” method. Rotate stock so older supplies leave the shelf first, avoiding unnecessary waste.

Transport and Handling Concerns

Safe transport means more than moving from point A to point B. Sudden bumps or jostling can stress fragile containers. Keep items strapped tightly during transit. Avoid exposure to excessive heat or cold, as temperature swings can damage the item’s structure or affect its ingredients. For some chemicals, even a little moisture in the air can trigger lumps or dangerous reactions, so dry, covered vehicles remain a must.

During handling, encourage gloves, goggles, and protective clothing when needed. Spills or splashes may occur, especially with liquids or fine powders. Maintain cleaning supplies and ensure access to emergency washing stations. Involving workers in safety briefings not only keeps everyone informed but also builds a culture where folks watch out for one another.

Looking Ahead: Solutions for Storage Challenges

Emerging tracking technology now lets managers monitor temperatures, humidity, and entry to storage sites in real time. Alerts flag any unusual activity or changes before a product loses value. Automated shelving and barcode systems make organization easier, reducing human error and helping teams find what they need quickly.

Clear communication between suppliers, managers, and end users cuts down on confusion and mistakes. Updated checklists and digital records save time and let teams review storage conditions and inventory at a glance. Attention to detail in these steps supports both product safety and business success.

What Chemists Look For

Quality becomes a big deal in every lab that uses 2,4,5-trifluorobenzyl bromide. This compound pops up in medicinal chemistry, agrochemical research, and a mix of organic synthesis tasks. As a synthetic building block, even small traces of impurity throw off downstream reactions, sometimes costing teams days or weeks of troubleshooting. High purity isn’t just about technical compliance—getting the expected reaction yield and avoiding side products comes down to how clean each reagent is.

Purity Standards: Numbers That Matter

Suppliers of 2,4,5-trifluorobenzyl bromide will usually certify their material at 97% or higher, often reaching 98% or even 99%. Independent analysis using gas chromatography (GC) or high-performance liquid chromatography (HPLC) backs up these claims. For anyone who’s spent time in a research lab, an accurate GC report means the difference between progress and wasted days chasing a ghost impurity.

Why Even 1% Makes a Difference

Someone unfamiliar with laboratory chemistry might wonder why pure material matters so much. Even without visible contaminants, trace levels of halogenated byproducts or residual starting compounds can slow down or block critical reactions. One project I once helped out on consumed weeks because a batch contained just 2% of unreacted trifluorotoluene. Until we traced it back to reagent quality, each run gave unpredictable results, forcing us through batch retests and off-the-cuff troubleshooting.

Common Impurities and Their Impact

Typical contaminants in a batch of 2,4,5-trifluorobenzyl bromide include related bromides, trifluorotoluenes, or inorganic salts left from synthesis. Water content sneaks in if the chemical sits on a warehouse shelf too long. Each impurity can change the way a product behaves when further modified. In certain pharmaceutical syntheses, unidentified impurities even show up as low-level mutagenic byproducts—one missed contaminant and the FDA halts everything.

Certificates of Analysis: Trust, but Verify

Relying on vendor paperwork alone can betray anyone who needs consistent performance. The top-tier labs ask for a Certificate of Analysis but then double-check by running their own GC or NMR on received samples. Each shipment can fluctuate, so monthly checks make more sense than one-time verification. For any pharmaceutical or regulatory-bound environment, this practice isn’t an option—it’s essential.

Managing Supply Chain and Handling Risks

Quality begins long before material arrives at the loading dock. Responsible chemical manufacturers control their synthesis carefully and batch-test every drum. During my time working with purchasing teams, price wasn’t the only negotiation point—supply consistency and full transparency with analytical data always topped the list. Training staff to spot color changes or unexpected odors catches problems before opening a container costs hours. In the rare event of a “bad lot,” trusted suppliers will recall or replace stock quickly, smoothing out any workflow disruptions.

Best Steps for Reliability

To guarantee success with 2,4,5-trifluorobenzyl bromide, organizations should source from reputable providers who offer full analytics with every order. Internal double-checking with available analytical tools catches minor issues before they disrupt larger campaigns. Building a habit of transparency and documentation keeps projects moving smoothly and reputations out of trouble.

Why Paying Attention Matters

Whenever a compound crops up in headlines, safety questions never stay far behind. People want to know if they can breathe it, touch it, or drink from tap water if traces sneak in. Nobody likes risking their health at work or home. I’ve spent enough time in labs and factories to see firsthand how easily a small oversight can snowball into real danger. Stories from OSHA inspection reports don't exist to scare anybody—they serve as grim reminders that safety isn’t a box to check. It’s a way of working.

What Makes a Compound Risky?

Most hazards come down to a few things—how people get exposed, how much somebody gets, and how tough it is to shake off the effects. Sometimes, dusts cause asthma or strong odors lead to headaches and dizziness. Skin rashes pop up after touching liquids people barely noticed. Certain gases displace oxygen or build up in small spaces, leaving no warning until it’s too late. Cancer risks don’t come up from one quick spill, but repeat exposure turns low numbers into big problems.

Ask any industrial hygienist: simple mistakes, like skipping gloves or cracking a window, can mark the difference between safe handling and a trip to the ER. Folks in research settings might handle milligrams, but production workers push tons of the same material every day. A safe process for one person may pose big risks for another.

Lessons from Accidents

Chemical accidents stick in memory, especially those that spilled into communities. Chemical leaks, fires, even mislabeled bottles—you see the pattern. The Bhopal gas tragedy changed safety standards worldwide. More recently, mishaps in storage rooms closed entire schools and highways. Even careful operations trip up. Simple things—ignoring a whiff, skipping a step, guessing missing labels. These don’t seem like headline-making moves, but in my experience, most incidents start precisely with those.

What the Science Says

Regulatory agencies, like the EPA, OSHA, and international health organizations, use animal studies, workplace health reports, and long-term surveys to guide rules. Chemical safety data sheets don’t just come from review committees—they rely on decades of real medical cases, emergency room data, and long-haul worker studies. For instance, benzene’s leukemia link didn’t jump out at the first sign—it trickled in from years of records.

Some compounds break down fast; others stick around long after their job ends. That matters, whether it’s in a landfill, water supply, or dust on protective clothing brought home to families. My own hands have itched more than a few times after a shift, and friends have needed lung checks for jobs they left years earlier.

Practical Answers and Smarter Choices

Solving safety challenges takes more than writing rules—it calls for honest feedback and respect for limits. Simple reminders work: check labels, wear gear, and don’t trust your nose. Managers set better examples by encouraging people to slow down and report concerns, even if that means pausing production. Companies with strong track records usually welcome questions, run regular training, and pay attention to low-level signals—like rising absenteeism or unusual smells in the building.

Better engineering controls, like improved ventilation or substitution with less toxic alternatives, often bring the biggest payoffs. Tighten up storage, use spill kits, and schedule regular audits. Workers talk to each other; if somebody says, “This thing doesn’t feel right,” it’s worth listening. No process runs too smoothly to forego a second look at safety.

Toward Fewer Hazards, Stronger Trust

Living safely with chemicals won’t mean avoiding them entirely, but it should always mean understanding the risks and treating them seriously. Respect for safety starts at the top and grows every time somebody decides to use a fresh pair of gloves or closes a bottle immediately after pouring. Small habits build trust—both in the workplace and at home.