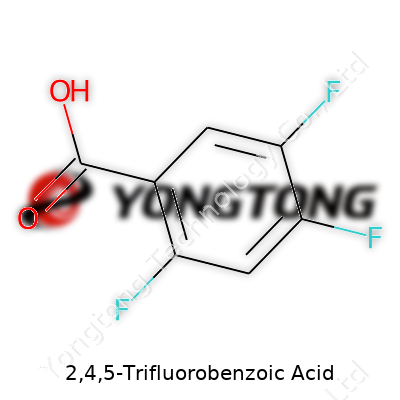

2,4,5-Trifluorobenzoic Acid: Perspective and Practice

Historical Development

Chemists began investigating fluorinated benzoic acids back in the middle of the twentieth century. The hunt for selective agrochemicals and pharmaceuticals in the 1960s lit a fire under synthesis programs. Researchers worked to introduce fluorine atoms into benzoic acid to influence molecular interactions and bioactivity, as fluorine's small size and electronegativity can tweak both the acid's solubility and its ability to resist metabolic breakdown. What started as a narrow research focus—often aimed at pesticide or herbicide development—quickly branched into materials science, as organic fluorine compounds started showing up in liquid crystals, specialty polymers, and even dyes. Over the decades, each advancement built on earlier discoveries, creating a sort of molecular toolkit for other researchers and industries.

Product Overview

2,4,5-Trifluorobenzoic acid stands out due to its unique arrangement of three fluorine atoms on a benzene ring with a carboxylic acid group, offering a perfect reference for those studying how electron-withdrawing groups impact reactivity and physical properties. Chemists favor it for its predictability: it offers good crystallinity, sharp melting points, and demonstrates impressive thermal and chemical resistance. There’s a steady demand in custom synthesis, whether clients need building blocks for drug molecules or reliable standards for analytical testing. Producers usually offer it in pure, microcrystalline powder form, prioritizing solid batch consistency and ease of handling, which is what most lab protocols require.

Physical & Chemical Properties

This compound forms white to off-white crystals and melts around 162 to 166°C. I’ve watched first-hand as even a tiny batch resists environmental stress—exposure to moisture doesn’t lead to clumping, and the powder remains free-flowing after months on the shelf. Solubility reveals the classic trends: poor in water, fair in alcohols like ethanol, very soluble in common organic solvents such as acetone, ether, and DMSO. The acid's pKa hovers near 3.4, thanks to fluorine’s strong electron-withdrawing pull, clearly more acidic than unsubstituted benzoic acid. Volatility stays low under standard conditions, so handling losses tend to be minimal during weighing, transfer, or storage. It doesn’t exude odors, making it much easier to work with compared to volatile carboxylic acids.

Technical Specifications & Labeling

Manufacturers typically specify purity above 98%, alongside detailed chromatographic purity breakdowns—GC or HPLC traces often come with the product for QA transparency. Users appreciate the clear CAS number (446-17-3 for this molecule), molecular formula (C7H3F3O2), and accurate molecular weight (176.09 g/mol) on every label. Containers usually bear batch numbers, hazard pictograms, and recommended storage conditions. Packaging in amber glass vials or high-density polyethylene bottles keeps the compound stable in ambient lab settings since it doesn’t react with glass or most plastics.

Preparation Method

Large-scale synthesis relies on selective fluorination of benzoic acid derivatives, usually via nucleophilic aromatic substitution using KF or CsF on a 2,4,5-halobenzoic acid precursor. Some smaller-scale processes use direct fluorination or even diazotization and Sandmeyer-type fluorination. The choice usually comes down to cost and waste management; nucleophilic routes produce fewer toxic byproducts and tend to deliver higher regioselectivity, which matters if a lab’s handling dozens of trifluoro isomers. Extraction steps pull the crude acid into aqueous alkali and then precipitation follows acidification. Purification often wraps with recrystallization from ethanol or ether to get the bright, clean crystals labs expect.

Chemical Reactions & Modifications

Chemists rarely let 2,4,5-trifluorobenzoic acid sit idle as a static building block. Its carboxylic group welcomes standard amide-forming or esterification reactions, pushing the molecule into new classes of specialty compounds. I've worked on library synthesis campaigns that use this acid for block building—its electron-deficient ring enables further substitution reactions, like nucleophilic aromatic substitution at the remaining hydrogen positions. Even Suzuki or Heck couplings can proceed with a suitable halogenated partner, allowing construction of more complex aromatic frameworks. Reduction strategies pull the acid down to the alcohol (benzylic positions invite reduction), or oxidation can nudge it toward trifluorinated benzaldehydes or ketones. Chemists who want to explore SAR (structure–activity relationships) lean heavily on these modifications.

Synonyms & Product Names

Suppliers use several synonyms, such as 2,4,5-trifluorobenzoic acid, Benzoic acid, 2,4,5-trifluoro-, or simply “TFBA, 2,4,5-” in catalog listings. European vendors sometimes shorten it to “TFBA (2,4,5)” on secondary packaging. Trade names aren’t common for this chemical, most likely because its applications stay close to the R&D or custom synthesis market rather than any direct-to-consumer channel. Clarity in labeling helps avoid confusion among the many regioisomeric trifluorobenzoic acids used in industry.

Safety & Operational Standards

Working safely with 2,4,5-trifluorobenzoic acid means taking all the usual precautions around strong acids and fluorinated aromatics. The dust can irritate skin or eyes, so gloves and safety glasses make sense. Even though acute toxicity sits low compared to many halogenated aromatics, long-term exposure data isn’t as thorough as I’d like, so I always stick to fume hoods during weighing or transfer. MSDS documentation covers the key hazards: respiratory irritation from dust, and low but possible risk of mild systemic toxicity on ingestion. Waste disposal heads straight to halogenated organic collection, ensuring nothing sneaks into municipal waste streams. Labs that use this compound for pharma or ag chem development demonstrate compliance with international standards from OSHA, REACH, and ICH on labeling, use, and recordkeeping.

Application Area

Most of the action happens in agrochemical and pharmaceutical development, where the molecule serves as a precursor for more complex active ingredients. Medicinal chemists value its trifluorinated ring as a model to control lipophilicity and metabolic stability in drug candidates. I’ve seen it pop up in the screening of new fungicides, anti-inflammatory compounds, and CNS modulators, thanks to its resistance to oxidation and enzymatic cleavage. Material scientists use 2,4,5-trifluorobenzoic acid derivatives as intermediate steps for high-performance polymers and special resins, hunting for new degrees of chemical inertness and thermal stability. Analytical chemists pick it as a reference standard, especially where high sensitivity fluorine NMR or MS detection methods are in use.

Research & Development

Research teams tap into 2,4,5-trifluorobenzoic acid for both academic and industrial projects. University research leans heavily on its defined structure to model electron-withdrawing effects in aromatic chemistry or probe new catalytic processes for selective halogenation. Industrial groups use high-throughput analytics to screen libraries derived from this acid, aiming for more potent, more selective, or more environmentally friendly compounds. I’ve worked with collaborative projects testing new cross-coupling methodologies, using this molecule’s electron-deficient ring to showcase what happens when traditional Pd or Ni catalysts run into strong inductive effects. Every cycle through the lab generates a little more certainty about how to leverage perfluoroaromatic acids in real applications.

Toxicity Research

Toxicologists approach fluorinated organics like these with caution. Acute toxicity for 2,4,5-trifluorobenzoic acid sits low based on available animal data, no potent mutagenicity or reproductive issues reported in the published literature, but chronic and environmental impact data still lag behind. Breakdowns in soil or waste streams usually move slowly, and environmental chemists track the behavior of such acids in aquatic settings. Risk assessments focus on the impact on beneficial soil flora and possible bioaccumulation, so researchers recommend keeping discharge tightly controlled. Ongoing research into metabolic fate in mammalian and plant systems helps fill in knowledge gaps, though regulators keep an eye out for signs of persistence and bioactivity that could tip the scales away from widespread use.

Future Prospects

Everything points toward smart integration of 2,4,5-trifluorobenzoic acid derivatives in next-generation pharmaceuticals and specialty chemicals. Drug discovery keeps pushing for molecules that blend potency, selectivity, and metabolic stability, and the trifluorinated benzoic acid scaffold supplies medicinal chemists with just those tools. Green chemistry trends drive synthetic chemists to develop safer, less polluting fluorination methods, often turning to newer catalytic or electrochemical approaches. Analytical labs benefit from new standards and reference materials built on this acid, supporting more accurate testing protocols. While environmental persistence raises a red flag, continuous investment in biodegradability and tailored modification strategies may ensure these molecules remain valuable without becoming long-term hazards. Labs and producers need to keep up with regulatory developments as new data emerges, mixing caution, innovation, and responsible stewardship in every batch.

Getting Familiar with 2,4,5-Trifluorobenzoic Acid

2,4,5-Trifluorobenzoic acid doesn’t pop up often in daily conversation, but in the world of organic chemistry, it’s got a steady role. This compound belongs to a group of chemicals known as benzoic acids, which form the backbone of many important industrial chemicals. The “2,4,5-trifluoro” part signals that three fluorine atoms are attached to the benzene ring, specifically at the 2nd, 4th, and 5th positions. This small shift in structure can create big changes in how the molecule behaves.

Breaking Down Its Chemical Formula

The formula for 2,4,5-Trifluorobenzoic acid is C7H3F3O2. Each part of this formula holds meaning:

- C7: Seven carbon atoms form the aromatic ring structure and the carboxylic acid group.

- H3: Three hydrogen atoms remain after substituting other hydrogens with fluorine atoms.

- F3: Three fluorine atoms bring high electronegativity, changing the molecule’s reactivity and properties.

- O2: Two oxygen atoms create the carboxylic acid group, which often dictates how these compounds interact.

Why Chemical Structure Shapes Its Importance

Dropping fluorine atoms onto a benzene ring is not just a trivia question—it’s a real change in physical and chemical behavior. Carbon-fluorine bonds are super strong because fluorine grabs electrons with unmatched strength. This often makes the resulting molecule more stable and less likely to break down in the environment. From experience reading studies and data sheets, I’ve noticed pharmaceutical and agrochemical laboratories use this stability when designing new drugs and pesticides.

Fluorinated benzoic acids show up in research aimed at finding new medicines, especially ones that hold up against tough conditions or avoid getting broken down too quickly in the body. For farmers and gardeners, these tweaks can lead to herbicides that stick around longer, cutting down on how much needs to be applied.

Challenges That Come with Fluorinated Compounds

Not everything about these molecules is a win. Their stability means they sometimes stick around in nature for a long time. Reports from environmental scientists draw attention to the fact that these compounds, once released, don’t break down easily. This has raised concern about build-up in soils and waterways, echoing worries we already have with PFAS chemicals. In past projects, I’ve seen how difficult it can be to remove persistent pollutants from water systems, and more stable chemistry usually means higher cleanup costs.

Looking Toward Solutions

Awareness stands as the first step. Chemists now try to design molecules that balance performance with biodegradability. Industry and research labs take greater care to capture and recycle their waste streams, using newer filtration and catalysis technologies. Regulation, too, keeps evolving to monitor where these compounds are made and used. Working with colleagues in chemical manufacturing, I’ve seen firsthand the difference strict process controls make in limiting environmental impact.

2,4,5-Trifluorobenzoic acid, with a formula of C7H3F3O2, reminds us that small choices in the lab can ripple out to much bigger effects in the field, factory, and the world around us. Fluorine’s power offers both opportunity and risk—a classic double-edged sword in the chemist’s toolkit.

What is 2,4,5-Trifluorobenzoic Acid?

2,4,5-Trifluorobenzoic acid looks like a mouthful, but folks who spend a lot of time in chemical labs or manufacturing plants have seen it crop up again and again. This chemical carries three fluorine atoms attached to a benzoic acid ring, which cranks up its value for certain jobs. If you’ve studied organic chemistry or worked in a research lab, you’ve probably run into its distinct, sharp-smelling crystals. Depending on what project I was tackling, seeing that trifluoro group in a molecule meant something was getting real in the synthesis.

Powerhouse Ingredient for Pharmaceutical Research

Modern drug discovery constantly chases tweaks that improve how medicines work inside the body. 2,4,5-Trifluorobenzoic acid steps onto the scene as a go-to building block for crafting more complex molecules in this race. Medicinal chemists turn to it for its ability to change a drug molecule's metabolic stability or solubility. Adding trifluoro patterns can make a medicine last longer in the body or resist breaking down too fast. I’ve watched researchers thrive on these small atomic tweaks, sometimes goose-bumping at the improvement in drug action from a smartly placed fluorine. It’s used to construct active pharmaceutical ingredients, often as a stepping-stone that then gets built out into something bigger and targeted.

Key Role in Agrochemical Production

Modern agriculture has been feeding more people with less land, thanks in part to specialty agrochemicals. 2,4,5-Trifluorobenzoic acid often finds itself worked into new pesticides and herbicides. These molecules need to hang tough against sunlight, microbes, or the first rainstorm, otherwise they’re wasted. The flourine-rich benzoic acids pump up the resilience of active crop-protection agents. Out in the field, this translates to products that stick around longer and need fewer applications. This isn’t just efficiency — it means less chemical runoff, and fewer truckloads shipped across the country.

Materials and Advanced Chemistry

Everyone expects high-performance plastics and specialty coatings to work under harsh conditions, but not a lot of people think about what makes them possible. 2,4,5-Trifluorobenzoic acid plays a role in manufacturing polymers that stand up to heat, UV light, and strong cleaning agents. In research settings, chemists use it to make fluorinated copolymers and advanced materials that go into medical devices or electronics. From weather-resistant films for solar panels to sleek, fingerprint-proof device cases, this chemical’s fingerprints are everywhere. Working with these materials up close, I’ve learned that adding just a dash of a trifluorinated building block can shift performance benchmarks.

Roadblocks and Responsible Use

All this usefulness comes with responsibility. Creating and using fluorinated chemicals raises questions. Persistent organic pollutants—perfluorinated substances among them—have popped up in water systems. Chemists now have to design with care, tracking both safety in the lab and downstream impact on the environment. We need greener routes to make these acids, closed-loop reactions that don’t spill out byproducts, and stronger standards for waste handling. In my own experience in the lab, it’s clear that the field needs more push for clean chemistry and monitoring over the long haul. Regulatory frameworks are catching up, but industry and academic researchers have to keep leading the way, seeking substitutes and better disposal practices where possible.

Why Purity Numbers Carry Real Weight

I’ve spent years picking apart the fine print on chemical specs, especially for laboratory work where trace impurities can skew whole studies. With 2,4,5-Trifluorobenzoic Acid, you notice most suppliers focus on offering purity grades above 98%. Labs rarely settle for less. Even for routine sample prep or synthesis, scientists hold fast to that “98% and up” figure like a safety harness. The difference between 96% and 99% purity doesn’t just show up on paper; it shows up in the ability to reproduce results, the clarity of NMR spectra, and the confidence people can have in downstream reactions.

Who Sets These Purity Benchmarks?

The pharmaceutical and material science industries push for these high standards. Regulatory authorities, journals, and in-house quality control teams demand it. National and international guidelines like those from the United States Pharmacopeia or European Pharmacopoeia aren’t involved for every compound, but their influence lingers—researchers have grown to expect documentation and reliable testing (moisture, residue on ignition, heavy metals, NMR, and HPLC profiles). Major lab suppliers like Sigma-Aldrich and TCI list 2,4,5-Trifluorobenzoic Acid typically in the 98-99% range, and occasionally someone will advertise 99.5% or “analytical grade.” Lower grades tend to land with a warning—more like “for industrial use only” or for situations where uncharacterized impurities won’t undermine a process.

Bumps in the Road: Contaminants and Real-World Issues

Even high-purity batches can bring in the odd hitch. Any chemical that travels through multiple hands before showing up in a bottle runs the risk of cross-contamination, especially if factories handle other fluoroaromatics in the same lines. Plus, poorly-sealed packaging lets in humidity or ambient particles. Once, I got a batch that was 97% pure, but contained an unexpected trace of a related benzoic acid derivative because the drums weren’t cleaned properly during transfer. Even at these low levels, contaminants trip up custom synthesis or studies relying on ultra-sensitive detection.

Techniques like melting point analysis or spectroscopy tell a big piece of the story, but today, reliable chromatographic purity data (HPLC or GC) and sometimes mass spectrometry matter, too. For a teaching lab, crystals pulled from the bottle might be just fine, but for a pharmaceutical QA lab or anyone chasing a patent, every “point-nine” after the decimal counts.

Getting and Keeping High Purity

Sourcing from reputable suppliers helps. They document certificates of analysis (CoA), batch tests, and impurity profiles. But after you’ve got that shiny bottle, storage steps into the spotlight. Airtight containers, dry conditions, minimal handling—these simple actions keep that 98-99% purity from drifting down. I’ve watched well-meant exposures to ambient air push batches to collect enough moisture in weeks to disrupt weighing and cause partial hydrolysis.

If purity slips below target, re-crystallization or column chromatography can sometimes clean things up, but the trade-off is cost and time. Lately, some labs automate routine purity checks, linking data directly into inventory systems to flag old or at-risk chemicals before they see use.

The Big Picture: Why Care About the Last Percent?

For anyone using 2,4,5-Trifluorobenzoic Acid, precision builds trust—between colleagues, between labs, between industry partners and regulators. That extra half-percent keeps controls tight, avoids costly reruns, and steers research away from dead ends. The story of chemical purity isn’t just numbers on a label; it’s woven through every successful experiment and discovery that leans on pure, predictable ingredients.

Why This Chemical Deserves Careful Handling

Anyone who has spent time in a lab knows that not all chemicals act the same. Some puff away in the breeze, others cling to moisture, and a few seem to cause trouble just from the label. 2,4,5-Trifluorobenzoic Acid falls into the category that rewards respect. Used in research settings or in some manufacturing processes, it’s not a household name, but those of us in the science world need to know how to keep it stable and safe.

Understanding Its Risks and Sensitivities

This compound isn’t among the most hazardous you’ll encounter, but ignoring basic storage principles leads to spills, decomposition, or worse, accidental exposure. From years of handling similar aromatic acids, I’ve seen what happens when someone shrugs off the advice and leaves a jar open or doesn’t watch the temperature.

2,4,5-Trifluorobenzoic Acid tends to stay stable under ordinary room conditions, yet fluctuating temperatures or exposure to moisture encourage it to break down or clump. As with other acidic powders, direct sunlight speeds degradation. Inhaling fine acid dust isn’t anyone’s idea of a good day. Getting proper ventilation and containment stops those problems before they begin.

Choosing the Right Container

Glass bottles with tight plastic screw caps handle this material well. Store suppliers recommend these because the acid doesn’t react with glass or polyethylene the way it can with metals. From personal habit, I avoid old or cracked containers, no matter how convenient they seem. Label containers by name and date. Don’t trust makeshift stickers—a solid, waterproof label pays for itself the first time a shelf gets crowded.

Avoiding Temperature and Moisture Surprises

I’ve kept similar chemicals on both bustling stockroom shelves and in climate-controlled cabinets. Humidity causes powders to cake or attract clumps of dirt from open air. Almost every standard lab stores acids in a cool, dry location. For this acid, a standard chemical storage cabinet away from sunlight does the trick. If the lab runs hot in summer, extra insulation or a monitored environment helps prevent breakdown.

Everyone should check cap tightness after each use. Loose lids let in humid air fast. Once, someone left a cap half on and a week later, what had been a fine powder turned patchy and damp. That leads to chemical waste and headaches for whoever has to clean it up.

Keeping Out of Reach and Limiting Exposure

Lock chemical cabinets. New staff sometimes underestimate that rule until they see minor skin or eye irritation from an accidental splash. Safety protocols pay off in the long run, both for health and for preserving the quality of laboratory stocks. Eye wash stations and nitrile gloves already line every modern bench, but a reminder on storage protocols never hurts.

Documentation and Best Practice

Everyone benefits from accessible records. Keep a material safety data sheet near the storage area, printed in a readable font for emergencies. Regularly inventory stored quantities. Over time, supplies get old or unlabeled, and expired materials bring accidental risk. My own routine involves reviewing chemicals quarterly, looking for signs of degradation or improper capping.

By treating 2,4,5-Trifluorobenzoic Acid as an asset—and a potential hazard—storage becomes second nature. Safe habits built early become the invisible foundation to any responsible lab or workplace.

Working Safely With 2,4,5-Trifluorobenzoic Acid

I’ve spent a decent chunk of my laboratory time around aromatic acids. 2,4,5-Trifluorobenzoic acid stands out mostly because of those three fluorine atoms on the ring. Now, that doesn’t make it as wild as some fluorinated chemicals, but it still deserves solid respect. Sometimes people assume every benzoic acid derivative will behave nicely, but this one needs a little extra caution because that fluorination can kick up the reactivity under certain conditions.

Handling Hazards and Precautions

If you ever open a bottle of this compound, don’t go by its appearance — many white powders hide surprises. Even without a nasty odor, the dust can be irritating to your nose, throat, or eyes. On the skin, it can cause redness or a rash, especially if you forget your gloves or the ventilation is poor. Like with many fine powders, the big worry with inhalation comes from dust that sticks in the air. You might not see it, but your lungs notice.

Spilling a bit on the bench isn’t the end of the world. Still, those invisible grains drift, attach to gloves, and follow you. It’s always best to clean up right away and toss any contaminated items. Never underestimate the trouble of a small exposure — some people get sensitized over time, meaning a reaction that gets worse each time they touch the compound. Even if a data sheet lists “may cause irritation,” that’s a fair warning from anyone who has pushed clean-up duties a little too late.

Personal Experience and Lab Practice

In my own lab, I treat 2,4,5-trifluorobenzoic acid like any fine organic acid. Lab coat, nitrile gloves, and goggles go on — no shortcuts, since contact with eyes or skin leaves you with more than just a tingle. Dust masks might not be standard in some workplaces, but if you’re weighing out a bunch, don’t skip them. A fume hood means you’ll have less to worry about — good airflow keeps the dust out of your lungs and off your clothes.

I once worked in a space where the ventilation system failed. Within a half hour, you could tell who got careless: eyes watering, skin itchy, a cough that didn’t go away. That day reminded all of us why basic lab safety exists not just for rules' sake, but for everyone’s health.

Environmental and Waste Issues

Like other fluorinated organics, this acid doesn’t break down easily outside the lab. You can’t pour residues down the sink or toss the waste in the regular trash. Always use sealed containers for any scraps, filter papers, or gloves that touched the acid. Hazardous waste bins are your friend. Anyone who’s dealt with persistent environmental pollutants recognizes how little it takes to create a problem for wildlife or water systems.

If a spill happens, sticky gloves and paper towels might seem fast, but you want a dustpan or vacuum certified for chemical use. Avoid spreading it around — once the powder scatters, nobody in the lab gets a clean floor. Keep safety data sheets close, so you know what kind of absorbents or neutralizers work best for your material.

Better Practices Moving Forward

It never hurts to remind colleagues that trouble comes not just from big emergencies, but everyday contact. Simple steps like good ventilation, proper PPE, and waste segregation go a long way. I always say: think ahead, stay tidy, and never get casual about even a familiar-looking bottle.