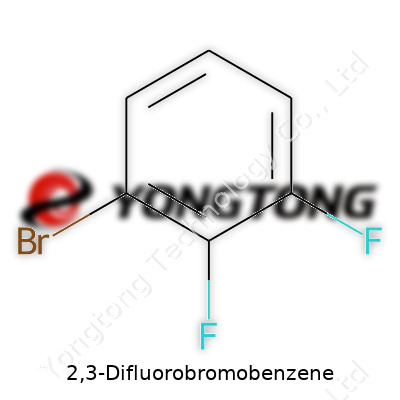

2,3-Difluorobromobenzene: Detailed Perspective

Historical Development of 2,3-Difluorobromobenzene

Chemists have always searched for new building blocks to drive both clinical and industrial synthesis forward. The birth of 2,3-difluorobromobenzene came from advances made during the post-war chemical boom. About midway through the twentieth century, as organofluorine chemistry took center stage in pharmaceuticals and agriculture, laboratories needed new variants of halogenated aromatic compounds. This specific molecule, featuring bromine and two fluorine atoms on a benzene ring, emerged during a time when companies started to realize the value of tailored aromatic scaffolds. Researchers, seeing both its reactivity and the distinctive properties that two fluorines could deliver, made 2,3-difluorobromobenzene more broadly available by the late 1970s, which gave medicinal and agrochemical teams a different angle on halogen-rich aromatic intermediates.

Product Overview

As an aromatic intermediate, 2,3-difluorobromobenzene commands serious interest across process chemistry. Its sharp reactivity, driven by both the electron-withdrawing fluorine atoms and the versatile bromine, offers a platform where targeted substitutions, cross-couplings, and functionalizations become more efficient. Whether you find yourself in a university R&D lab or an active pharmaceutical ingredient (API) production plant, this compound brings flexibility. The simple combination of a benzene ring, two fluorines at the ortho and meta positions, and a bromine at a neighboring position gives chemists an edge in pushing molecules toward their next transformation.

Physical and Chemical Properties

2,3-Difluorobromobenzene usually presents itself as a clear to pale yellow liquid at room temperature. With a molecular formula of C6H3BrF2 and a molar mass of around 192.99 g/mol, it holds a distinctive chemical fingerprint. The boiling point generally ranges close to 170–175°C, which means it fits comfortably into most laboratory distillation setups. It’s slightly denser than water, clocking in at roughly 1.67 g/cm3. The presence of both bromine and fluorine atoms creates a unique electronic environment. Fluorines at the 2 and 3 positions pull electron density from the ring, making it much less reactive toward many electrophilic aromatics, yet that same effect also makes nucleophilic substitution on bromine much more selective and manageable.

Technical Specifications and Labeling

A bottle of 2,3-difluorobromobenzene typically arrives labeled with details that matter to every bench scientist and compliance manager: chemical purity (usually at 98% or better for demanding synthetic work), water content by Karl Fischer, and a clear CAS number, 38572-37-7. Reputable suppliers always add hazard labeling in line with GHS—warning users of harmful vapors, environmental impact, and the need for ventilation or respiratory protection for large-scale use. Crucially, batch traceability, including lot numbers and analysis certificates, keeps every drum or flask tied back to a documented QC process, keeping both audits and downstream processing safe.

Preparation Method

The main synthesis route leverages selective halogen exchange. A typical process starts with 2,3-difluoroaniline, running through diazotization, followed by a Sandmeyer reaction to introduce the bromine atom at the desired site. The method banks on well-controlled temperature and stoichiometry, with copper catalysis helping to steer the reaction cleanly to the target compound. Yields, in skilled hands, typically approach 75–85%, although scale-up always brings new challenges around byproduct management, solvent control, and heat dissipation. A lot of the time, purification rests on fractional distillation or carefully controlled recrystallization from non-reactive organic solvents.

Chemical Reactions and Modifications

The dual halogen pattern makes this molecule a chemical workhorse in cross-coupling reactions, especially Suzuki-Miyaura and Buchwald-Hartwig protocols. Bromine acts as a leaving group under palladium catalysis, opening the door for a vast range of C–C and C–N bond-forming steps. Fluorines tune the aromatic ring’s reactivity, which has allowed researchers to push through selective metalation, directed ortho-lithiation, or nucleophilic aromatic substitution where the rest of the ring resists over-reaction. The result: faster access to diverse substituted aromatics, with the two fluorines often doubling as metabolic blockers or hydrogen bond modifiers in bioactive molecules.

Synonyms and Product Names

Buyers and users run into plenty of alternate names—2,3-bromodifluorobenzene, 1-bromo-2,3-difluorobenzene, and their variations pop up depending on the catalog or the language. Chemical Abstracts Service registers it as 38572-37-7. Checking for these synonyms actually matters: ordering under the wrong name has landed more than one project in procurement limbo, leading to confusion or even shipment of entirely the wrong compound.

Safety and Operational Standards

This isn’t a molecule to take lightly. Like all halogenated benzenes, exposure can trigger dermatitis, respiratory distress, and long-term organ risk, especially where vapor builds up. Gloves, splash goggles, industry-rated fume hoods, and careful stock handling make a difference, every single time. On a larger scale—kilo labs and pilot plants—air monitoring and spill management grow in importance, with every production run requiring a clear material safety data sheet on-hand and all waste routed to halogen-specific incineration or solvent recovery. Safety training forms the backbone of working with this family of chemicals; without a strong process culture, even an experienced team can end up facing unnecessary risk.

Application Area

2,3-Difluorobromobenzene finds its strongest role as a synthetic intermediate. Pharmaceutical projects grab it for quick access to difluorinated phenyl fragments, especially when developing kinase inhibitors or agrochemicals that demand metabolic stability. Agrochemical groups lean on the molecule for fungicide backbones or herbicidal compounds that require persistent aromatic systems. Materials science teams use it when they want stable, electron-rich frameworks—think in the design of new functional polymers for electronics or advanced coatings. Over the past decade, the push toward precision medicine and next-gen crop protection has forced labs to revisit the molecule as a springboard for custom-tailored products, rarely as the final product itself.

Research and Development

The most interesting advances today revolve around more sustainable manufacturing. Chemists test greener solvents, lower-energy catalysis, or even non-metal processes for halogen exchange, all designed to ease environmental impact without sacrificing selectivity or yield. Computational teams, helped by new algorithms, analyze the molecule’s reaction profile, mapping out pathways that sidestep traditional bottlenecks. In regulatory research, the unique metabolic stability provided by the two fluorines attracts attention as a way to modify biological half-lives or minimize unwanted byproducts. As drug discovery accelerates, the need for clean, scalable, and cost-effective routes keeps 2,3-difluorobromobenzene firmly in R&D portfolios across the globe.

Toxicity Research

Toxicologists still treat every new halogenated aromatic with suspicion, recalling the long shadow cast by compounds like PCBs. Testing so far points to a moderate risk profile—no acute lethality at low doses in animal studies, but repeat exposures raise red flags around liver and kidney function. Reports indicate potential bioaccumulation, mainly due to the metabolically difficult difluorinated core, although rates run lower than heavier, polyhalogenated species. Chronic exposure above recommended thresholds often produces neurological symptoms and can worsen pre-existing respiratory or dermatological conditions. The upshot is that, despite its chemical versatility, workers need strict environmental and personal protection throughout both lab and plant operations.

Future Prospects

The road forward for 2,3-difluorobromobenzene looks set for both opportunity and scrutiny. On one hand, newer transition-metal catalysis methods promise cheaper, faster, and safer access to a wider array of difluorinated benzene derivatives. The continued rise of fluorine-rich compounds in drug chemistry—particularly for their metabolic tuning and bioactivity benefits—should keep demand healthy in both pharma and agrochemical circles. On the other, increasing global regulation of halogenated aromatics will push suppliers to up their game in traceability, purity, and environmental responsibility. With sharper process analytical tools and a shift toward greener chemistry, the next decade may turn 2,3-difluorobromobenzene from just another building block into an example of how legacy chemicals can earn their place in a more responsible, innovation-driven marketplace.

Understanding the Backbone: Why Structure Means Something

Every time I pick up a chemical name like 2,3-difluorobromobenzene, it does more than just trigger a memory of college chemistry quizzes. It speaks to the careful way scientists organize knowledge, not for the sake of neatness but because a clear name reveals deep information. Here, we are not just playing with a jumble of atoms. Each prefix and position maps out a real, physical architecture—one that shapes reactivity, safety profiles, environmental persistence, and industrial value.

The Formula Unpacked: C6H3BrF2

2,3-Difluorobromobenzene gives away its secrets through its name. The backbone is benzene (C6H6). By substituting a bromine atom and two fluorine atoms at positions 2 and 3 on this ring, you end up with a simpler-sounding formula: C6H3BrF2. This formula distills a set of choices chemists make in synthesizing aromatic compounds. It doesn’t just satisfy a curiosity; it tells chemists what kinds of bonds to expect, how the molecule might react, and even sheds light on its possible byproducts.

Importance in the Real World: Not Just Another Molecule

I’ve worked with fluorinated aromatics before, and bumps in the lab show how substitution patterns control the outcome more than most students realize. Adding fluorine at two spots, plus bromine, totally shifts how the compound behaves. It might suddenly repel water, break down more slowly in the environment, or unlock a pathway for a new drug or pesticide. Regulators look at these details to assess hazards—and these are not academic questions if you’re thinking about safety sheets or waste streams in a manufacturing plant.

Science and industry count on these formulas. A mistake or misunderstanding somewhere along the line can mean wasted resources or even serious health consequences. I’ve seen whole batches written off because the wrong isomer got added during a critical step. It's tough to overstate how much clear, accurate naming supports research, quality assurance, and regulatory compliance. The chemical formula is more than paperwork; it's a keystone for reproducible science and responsible handling.

Facts Driving Safer, Smarter Use

Statistics show that correct identification and traceability cut lab accidents. The Chemical Abstracts Service (CAS) assigns every unique compound a number, which helps track global use and regulation. There’s a reason regulatory agencies, from the EPA to REACH in Europe, require absolute clarity in how chemicals are labeled, stored, and moved around the world—it keeps communities safer and improves transparency in the supply chain. A seemingly simple formula like C6H3BrF2 lets researchers anticipate whether the molecule might persist in the environment or pose toxic risks, especially since halogenated benzenes can linger and cause real harm if mishandled.

Better Systems, Fewer Mistakes

What works in my experience is building checklists and standardized digital systems for recording and verifying chemical data. Cross-verifying with spectral data or supplier documentation is key. Open-access databases can tighten verification, reducing human error and supporting better decision-making for everyone—researchers, regulators, and everyday workers who handle these substances. If you want safer chemistry, the foundation starts with following and double-checking what’s inside every bottle and beaker, starting from a precise formula like C6H3BrF2.

A Look at an Overlooked Building Block

Most people haven’t heard much about 2,3-Difluorobromobenzene. It doesn’t show up in mainstream news or casual small talk, but chemists and materials scientists lean on compounds like this every day. With its unique mix of fluorine and bromine on a benzene ring, it serves as so much more than an academic curiosity.

Pharmaceutical Development Rides on Strong Chemistry

Doctors rely on better medicines, and drug designers rely on strong chemical building blocks. 2,3-Difluorobromobenzene provides just that. Its unique structure makes it a sturdy starting point for complex drug candidates. The bromine atom can swap places with other groups under the right lab conditions, making possible a whole family of new compounds.

Fluorine might seem a small tweak, but in drug chemistry, it flips the switch on stability and effectiveness. Fluorinated rings often help drugs survive inside the body, improving how long and how well they do their job. Major pharmaceutical pipelines look for such structural pieces because they fend off breakdown and add precision to targeting disease pathways.

Agrochemical Breakthroughs Depend on Smart Ingredients

Feeding the world isn’t just about land and water. It’s also about chemistry. Farmers count on crop protection products to keep yields strong and pest pressures low. Some of today’s most effective herbicides and fungicides started as small tweaks to familiar benzene rings. Add a touch of fluorine and bromine at just the right spots, and you might improve performance or safety.

2,3-Difluorobromobenzene packages these elements in a way that’s easy for research chemists to modify. Laboratories use it to shape the next generation of agrochemicals—an edge for both food producers and consumers.

Materials Science and Custom Polymers

Engineers are demanding more than ever from plastics, coatings, and films. Modern materials need to handle harsh environments, conduct electricity, or resist wear. The presence of fluorine often helps. Chemists have found ways to build specialty polymers and coatings starting from molecules like 2,3-Difluorobromobenzene. Once in the lab, its chemical handles create room for innovation: new adhesives, specialty electronics, and films that hold up when others fail.

Better Chemistry Means Safer, Cleaner Synthesis

Old-school chemistry sometimes produced too much waste or struggled to scale safely. Newer paths often rely on clean, predictable reactions involving fluoro- and bromo-benzenes. When chemists start with 2,3-Difluorobromobenzene, they can control where and how they add new groups. Less waste, fewer toxic byproducts, and simpler purification mean less environmental headache for everyone.

Challenges and Solutions

Working with fluorinated aromatics isn’t always easy. These compounds can cost more, and handling them in bulk brings safety demands. The production of fluorinated chemicals also raises questions about sustainability and responsible sourcing.

Research continues in greener methods for fluorination, including electrochemical approaches and selective catalysts. Resource-sharing among manufacturers, regulatory review, and third-party auditing all contribute to a safer marketplace. Ongoing education on lab safety makes a difference, too—something I remember well from my own days in the research lab, gloves and goggles on, double-checking procedures.

With the right controls and responsible sourcing, 2,3-Difluorobromobenzene stands out as more than a lab oddity. From medicine to agriculture to new types of plastics, its utility bridges gaps between cutting-edge science and the needs of daily life.

Learning from Years in the Lab

Nothing teaches respect for a chemical quite like seeing what happens when storage guidelines get ignored. 2,3-Difluorobromobenzene holds its own as an organobromide—manageable with care, yet ready to cause problems if left in the wrong environment. Having worked with halogenated benzenes, I’ve watched more than one researcher scramble due to leaky vials and unlabelled samples. People who treat it lightly rarely make that mistake twice.

The Heart of Safe Storage

Letting any halogenated aromatic sit out in the open leads to headaches, sometimes literally. 2,3-Difluorobromobenzene should wait out its time in tightly sealed amber glass bottles, away from moisture and light. Air and sunlight nudge these compounds toward slow decomposition. You want to keep it dry, cool, and well shielded from light sources. Storing with desiccant helps keep water out, since moisture can gradually affect purity and reliability in synthesis. Regular fridges work, but a designated chemical refrigerator with explosion-proof features keeps things safer.

Leaving flammable solvents with reactive halides in a standard break room fridge—a rookie mistake—risks more than spoiled experiments. A chemical refrigerator cuts down on the risk of dangerous buildup from invisible vapors. For extra protection, double containment doesn’t hurt: secondary containment trays pick up accidents before they have a chance to creep across the shelf.

Handling with Focus and Foresight

Work with gloves, goggles, and a solid lab coat forms the baseline. Any chemical that brings a bromine atom into the mix can irritate quickly, both on the skin and in the lungs. Using a fume hood isn’t just a recommendation; it’s the kind of advice that should get followed every time. Volatile organics like this one spread their fumes readily if left open during transfer. Minimizing exposure time cuts down on headaches and long-term health risks.

Label everything, even if the bottle only spends one week out of its original box. Human error steps in far sooner than we like to admit. Clear marking of date opened, lot number, and person responsible adds accountability and helps with tracking any purity issues that pop up later.

Risks and Real-World Problems

Costly mistakes happen when teams take shortcuts. Leaky containers, poorly ventilated storage areas, or mixing with incompatible materials snowball into dangerous spills or surprise reactions. 2,3-Difluorobromobenzene may not combust like more notorious chemicals, but pairing it up with strong bases or metals ramps up the chance for unwanted reactions.

Getting rid of waste responsibly sits high on the list. Pouring it down the drain or tossing it out with regular trash brings trouble. Waste contractors that handle halogenated organics safely keep accidents away from the broader community.

A Path Forward: Building Everyday Safety

Well-ventilated storage, clear separation of different chemical families, and up-to-date chemical inventories support a responsible lab culture. Training new staff on the quirks of halogenated aromatics pays off in the long haul. Replace old or worn bottles before leaks start, and remind everyone that small cracks in handling add up to big problems if left unchecked.

Over years spent handling these compounds, I find that careful habits save both time and peace of mind. 2,3-Difluorobromobenzene responds well to this approach. Safe storage and thoughtful handling help make every research project run smoother and let teams focus on discovery instead of damage control.

Unpacking the Significance of a CAS Number

The term CAS number gets tossed around in chemistry labs, regulatory meetings, and procurement offices like folks toss salt over their shoulders. It’s not just a number—it’s a global passport for every chemical out there. Ask a supplier or a regulator about 2,3-Difluorobromobenzene, and they won’t flinch: CAS number 64248-58-6. This label lets chemists grab the right substance from a warehouse shelf, check for hazards, or track records across continents. The CAS Registry, built by the Chemical Abstracts Service, pulls the scientific world onto the same page, no matter what name or synonym you might find in the literature.

Why Exact Identification Matters

One day, I stood under buzzing fluorescents in a stockroom, fingers crossed, hoping we'd pulled the right bottle. Too many close calls come from confusion between isomers or subtle naming mismatches. A wrong compound seeping into a reaction isn’t just frustrating—it can trigger failed research, lost money, or safety scares. The CAS number for 2,3-Difluorobromobenzene, 64248-58-6, draws a line in the sand. There’s no trading digits or confusion. Once that number is stamped onto paperwork, labels, databases, it chases away error.

Industry and Research Rely on This Number

Whether building blocks head toward pharmaceuticals or agrochemicals, nearly every chemist I know pulls the CAS number before reaching for a substance. 2,3-Difluorobromobenzene, with its specific positioning of fluorine and bromine atoms, offers unique properties for organic synthesis. If a research team tries to replicate a procedure without confirming the exact compound through its CAS number, months can disappear into the void. I've watched this play out—a missed detail in labeling led a graduate student to spend a whole semester on reactions that never panned out. Consistency, traceability, and reproducibility hang from the thread of those nine digits: 64248-58-6.

The Ripple Effects—for Health, Trade, and Environment

Safety teams check the CAS number before creating material safety data sheets or assigning storage protocols. Regulatory agencies, like the EPA or ECHA, use these numbers to track which compounds move in and out of countries, or appear on restricted lists. Environmental health depends on unambiguous identification. If a spill happens, responders use the CAS number to determine how to clean it up and what risks to look for. Even for disposal, waste handlers rely more on that number than the chemical's common name.

Improving Clarity in Chemical Commerce

Mixing up chemicals sounds funny until it isn’t. Improving clarity starts with training shoulders at every level—from ordering to disposal—on the value of the CAS system. Encouraging suppliers, labs, and regulatory bodies to always lead with the CAS number cuts across language barriers and nicknames. New digital inventory tools and barcode systems can print these numbers right onto labels and manifests, avoiding greasy handwriting or typos on tubes and jars.

Looking Forward: Embracing Precision

Chemistry stays grounded in precision, not just in the lab, but in every link of the supply chain. As more compounds hit the market every year, old habits of shorthand or sloppy cataloging only slow down progress. I always double-check the digits, because that tiny investment saves time, money, and a fair share of headaches. For anybody handling 2,3-Difluorobromobenzene, using CAS number 64248-58-6 means no mistakes—just sharp science, done right.

What 2,3-Difluorobromobenzene Is

Ask any chemist about 2,3-Difluorobromobenzene and they’ll likely mention its place as an intermediate in pharmaceuticals, agrochemicals, or specialty chemicals. With two fluorines and a bromine attached to a benzene ring, the compound gets a lot of interest in the lab. But flashy formulas don’t always tell you if something is dangerous. The only real way to handle risks is to sweat the details and look closely at what science says.

Health Hazards and Why They Matter

Here’s what matters most to me: whether those using 2,3-Difluorobromobenzene face genuine short- or long-term dangers. The MSDS for similar halogenated benzenes signals risk of irritation to eyes, skin, and lungs. With small molecules like this, rapid absorption through skin or inhalation can happen unnoticed. Symptoms—skin redness, coughing, watery eyes—may not seem serious at first. But repeated exposure, especially in a poorly ventilated lab, adds up.

Compounds with both bromine and fluorine catch extra scrutiny. Several difluorobenzene variants show toxicity in animal tests, causing liver and kidney issues at large doses. Researchers reported that some difluoro compounds disrupt enzymes involved in metabolism. No one has published large-scale studies about 2,3-Difluorobromobenzene in particular, but every part of its structure holds risk: the fluorines make it persistent, and the bromine can promote bioaccumulation. That’s a cocktail that keeps toxicologists busy.

Environmental Concerns

Spilling a bromofluorinated benzene outdoors doesn’t go unnoticed either. Persistence is one problem—fluorinated organics stay put in soil and water for years. Most treatment plants struggle to break them down. Animals exposed to persistent organics can build up the compound in tissues over time, even if exposures are small. Brominated chemicals often raise alarms due to links to wildlife disruption, including thyroid function changes and developmental effects.

No one wants to see another case where a lab chemical slips into the water table and stays there. That makes industrial users and researchers responsible not only for protecting people, but also the planet that absorbs whatever gets dumped.

Managing the Risks

You don’t need to hit panic buttons to respect potential harm. Gloves, splash goggles, and fume hoods are non-negotiables when working with bromofluoro benzenes. Anyone opening a bottle should know what to do if there’s a spill or splash. In labs I’ve worked in, every new chemical got treated like it could be the next big hazard, at least until proven safer by solid evidence.

Disposal is where most people get lazy. Pouring small amounts down the drain may seem harmless, but that’s exactly how persistent compounds end up in drinking water. Trained hazardous-waste handlers make sure that chemicals like this end up incinerated at high temperatures, which breaks them down before they have a chance to cause wider harm.

Clear, Responsible Handling Wins Every Time

Experience says clear procedures, not guesswork, keep people safe. Every time a new halogenated compound hits the shelf, someone must read the newest data, check regulations, and err on the side of caution. Until independent studies settle open questions, handling 2,3-Difluorobromobenzene with respect, not fear, gives everyone the best shot at staying healthy.

It’s not about panicking. It’s about reading the data, following best practices, and speaking up if something doesn’t look right. That’s how real safety happens, both for the people in the room and for everyone down the line.