2,3-Difluoro-5-chloropyridine: Examining Its Development, Chemistry, and Role in Modern Research

Historical Development

Chemists started looking at pyridine derivatives more than a century ago, mainly because these compounds show up everywhere from pharmaceuticals to agriculture. 2,3-Difluoro-5-chloropyridine sits in a corner of this story. Back then, developers chased after molecules they could adapt easily, and this one rose in value the moment folks realized putting fluorine and chlorine on a pyridine ring made it behave quite differently. Early synthesis routes meant harsh reagents and unpredictable yields, but advances in halogenation and directed lithiation in the late 20th century gave chemists more control. The compound’s commercial relevance started climbing as researchers searched for new agrochemical scaffolds and intermediates for active pharmaceutical ingredients. The more that chemists learned about swapping halogens to tune function, the more interest this pyridine attracted.

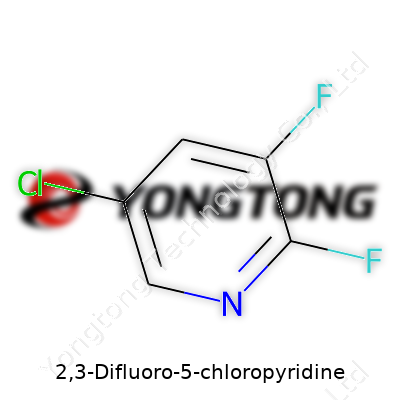

Product Overview

2,3-Difluoro-5-chloropyridine builds on a six-membered heteroaromatic ring, with fluorine atoms at the 2 and 3 positions, and a chlorine at the 5 position. The unique arrangement of halogens changes electron distribution, which in turn shifts both reactivity and biological activity. Suppliers usually offer this compound as a colorless to pale-yellow liquid or low-melting solid, packing it in tightly sealed glass or PTFE-lined bottles to keep out moisture and light. Chemists usually look for it at purities above 98%, since traces of precursors or side-products can kill selectivity in downstream reactions. This pyridine makes regular appearances as a building block for complex molecules, especially where highly specific substitution patterns are needed.

Physical & Chemical Properties

This molecule blends the volatility and basic character of pyridine with the high electronegativity from fluorine and the heavier chlorine atom. 2,3-Difluoro-5-chloropyridine weighs in at about 148 grams per mole, with a boiling point near 180°C. Its density sits close to 1.46 g/cm3, so workers handle it much like they would any heavier halogenated compound. It barely dissolves in water but mixes well with nonpolar and weakly polar organic solvents—think dichloromethane, acetonitrile, and ether. The two fluorine atoms pull electron density, dropping the pKa closer to 3. The chemical feels slick and slightly sharp to the nose; it’s usually bottled under nitrogen because halopyridines break down in prolonged sunlight or humidity. On the bench, it resists many standard oxidation and reduction procedures, but directed halogen-metal exchange and nucleophilic aromatic substitution both unlock new modifications.

Technical Specifications & Labeling

Reputable labs and suppliers attach a clear label that includes batch number, purity assay by GC or NMR, recommended storage conditions (often below 25°C, dark, tightly closed), date of manufacture, and the globally harmonized system (GHS) hazard information. Most sources specify the compound’s CAS number, molecular formula (C5H2ClF2N), and shelf life, which rarely extends beyond two years under best conditions. Clear traceability comes in handy for regulated industries and academic work alike, since minor impurities can show up as side products in complex syntheses. Any responsible facility logs these details digitally and on paper to back up quality assurance, especially if a product ships internationally.

Preparation Method

Industrial routes favor multi-step synthesis starting from pyridine or substituted chloropyridines. Selective halogen exchange or directed ortho-lithiation, followed by electrophilic fluorination, puts fluorines at the 2 and 3 positions. Another approach kicks off with 2,3-dichloropyridine, then swaps one chlorine for fluorine using potassium fluoride under phase transfer catalysis. Process chemistry often demands pure reagents and anhydrous conditions—water spoils the game quickly. Catalysts such as copper(I) salts sometimes improve yields and speed, yet the challenge in batch production comes from rigorous exclusion of air and moisture and tight control of exotherms. Final purification often calls for fractional distillation under reduced pressure or careful chromatography, since the physical properties put it close to common by-products.

Chemical Reactions & Modifications

Reactivity of 2,3-Difluoro-5-chloropyridine runs along the lines of other halogenated aromatics. The pyridine nitrogen pulls in nucleophiles, while the halogens orient further substitution or coupling. Organometallic reagents like Grignard or lithium compounds swap with the halogens under precise conditions, letting synthetic chemists bolt on aryl, alkyl, or other substituents with clear regioselectivity. Directly, the activated ring enables SNAr reactions to replace chlorine or even one fluorine with amines or thiols, yielding key intermediates for pharmaceutical projects. Cross-coupling brings in Suzuki, Stille, or Buchwald-Hartwig conditions, turning this modest-looking pyridine into a launchpad for scaffolds across both combinatorial libraries and targeted lead optimization. Handling and purification draw on experience, because isomer formation and multiple substitutions pop up if conditions wander.

Synonyms & Product Names

Different catalogs and chemical supply houses tag 2,3-Difluoro-5-chloropyridine with names like 5-Chloro-2,3-difluoropyridine, 5-Chlor-2,3-difluorpyridin, and the shorthand CDFP. Some industrial product sheets label it using the CAS Registry Number 96534-34-4. Local language differences and legacy company codes sometimes cause confusion, so experienced chemists keep aliases in a lab notebook for cross-referencing, and always double-check molecular weights and structure if purchasing from less established sources, especially in the global market.

Safety & Operational Standards

Handling 2,3-Difluoro-5-chloropyridine means paying full attention to health and safety protocols. This chemical acts as an irritant to both skin and respiratory tract, with both acute and chronic effects reported in exposed workers. Most labs run fume hoods, gloves (nitrile or better), tight goggles, and dedicated spill plans. MSDS data calls for immediate washing with soap and water upon exposure. Inhalation brings respiratory discomfort or even pulmonary distress, so proper PPE matters—not just for regulator compliance but real health. Disposal means following local hazardous waste rules, usually through incineration or solvent-compatible waste pickup; landfills and sinks stay off-limits. Responsible facilities post hazard codes, keep emergency eyewash and ventilation, and train all crew on accidental exposure response, not just paperwork drills.

Application Area

Medicinal chemists reach for 2,3-Difluoro-5-chloropyridine in the hunt for new APIs and crop protection products. Its pattern of halogenation tunes solubility, permeability, and metabolic stability—features drug developers crave when shaping lead compounds. The ag sector uses it, too: inserting these motifs can produce herbicides and fungicides with longer life in soil without raw increase in toxicity. Polymer manufacturers sometimes bolt it into specialty monomers, coaxing out new material behaviors, as the electron-withdrawing elements twist up reactivity for tailored plastics or coatings. On the academic side, this compound often fills in as both substrate and standard in mechanistic studies, showing up everywhere from new catalyst discovery to process optimization scale-up trials. Each new tweak in its structure can open fresh chemistry that spills directly into commercial and therapeutic innovation.

Research & Development

Researchers bring this compound into labs looking to expand chemical space quickly, since its structure encourages unique vector points for further elaboration. Current work targets not just new substitution reactions, but also biotransformations and green chemistry alternatives. Teams test catalysts—both homogeneous and heterogeneous—that can swap in functional groups under milder conditions, dropping greenhouse gas impact along the way. Combinatorial chemists have screened libraries built on 2,3-Difluoro-5-chloropyridine, often finding hits in kinase inhibitor campaigns, anti-infectives, and probes for receptor mapping. Process researchers lean into optimizing large-scale batches, swapping out toxic or regulated reagents for safer, scalable alternatives. Conducting real-time monitoring with technologies like inline NMR and HPLC allows continuous improvement—in both product quality and environmental footprint. Every year brings fresh patents, usually split between new biological targets and improved synthesis routes.

Toxicity Research

Toxicologists have put 2,3-Difluoro-5-chloropyridine under close scrutiny. Both acute and chronic dosing in small animal models inform regulatory limits for workplace and environmental exposure. Animal studies identify dose-dependent respiratory, hepatic, and dermal effects. In vitro testing of the molecule and its breakdown products probes genotoxicity and effects on common metabolic enzymes—most often CYP450 isoforms. There’s particular interest among environmental scientists regarding persistence and mobility, given its use in agrochemical manufacturing. Stable halogenation means this molecule sticks around longer in soil and groundwater, which spurs additional work on containment, neutralization, and monitoring. Real safety comes from blend of preclinical testing, exposure simulation, and real-world worker studies. Regulators in Europe, North America, and parts of Asia all demand deep data packs before approvals for widespread commercial use.

Future Prospects

Chemists keep reaching for 2,3-Difluoro-5-chloropyridine, not just because of its direct uses but because it opens doors for next-generation molecules. Biotechnology is starting to nibble at approaches for selective modification, hoping enzymes one day match the selectivity of textbook organometallic chemistry. Green chemistry stands poised to make a bigger mark, with new electrochemical and catalytic methods cropping up in academic journals and pilot plants. Demand from pharma for halogenated heterocycles looks set to keep climbing, driven by the growing need for finely tuned drugs that can dodge resistance and metabolic breakdown. Sustainable manufacturing and safer processing—helped along by automation and in-line analysis—may ease some of the environmental and safety headaches historically tied to these materials. The story of this compound links up with a much wider drive for smarter, responsible chemistry, not just faster or cheaper production.

Understanding 2,3-Difluoro-5-chloropyridine in Everyday Chemistry

Getting to know chemical compounds often feels daunting, but learning about formulas can unlock a better sense of what makes up everyday materials and the ingredients used in major industries. Take 2,3-Difluoro-5-chloropyridine as an example. Stripping away mystery, this compound boils down to a simple chemical formula: C5H2ClF2N. Each part stands for a piece of its structure—five carbons, two hydrogens, one chlorine, two fluorines, and one nitrogen atom—all woven into the framework of a pyridine ring.

Why This Particular Compound Draws Interest

Chemists use molecules like 2,3-Difluoro-5-chloropyridine as building blocks. In my lab days, I saw how just a small swap from fluorine to chlorine on a ring could alter the reactivity and the overall function of a molecule. The impact shows up in many fields, especially pharmaceuticals and agrochemicals. Substituted pyridines, particularly those decked out with halogens like fluorine and chlorine, often end up as stepping-stones for new medicines or crop protection agents. They offer more than just their base structure: their electronic tweaks influence how the finished product behaves, whether it interacts with enzymes in the body or targets pests in the field.

Safety and Handling: A Real-World Necessity

Getting to know this formula also means handling with care. Fluorinated and chlorinated pyridines don’t play nice with untrained hands. Toxicity and volatility often tag along. During my time handling materials like this, proper ventilation and gloves became essential. It’s not fear-mongering—flushing away the risk of burns or inhalation exposure matters. For anyone working with such chemicals, double-checking the MSDS (Material Safety Data Sheet) saves a lot of hassle—and possibly health.

Environmental Considerations

Moving hazardous materials always brings up the question of what happens after they get used. Persistent organic pollutants stem from poorly managed disposal. Compounds like this, while valuable, can drift into groundwater or soil. Seeing what unchecked discharge did to a research site during audits drives this home. Solutions invite more than just regulatory compliance. Chemical engineers now push for greener syntheses—routes that cut down on solvent waste or use milder reagents. Adopting closed systems stops leaks and emissions before they reach the outside world.

Ethics and Responsibility in Chemistry

Building molecules like 2,3-Difluoro-5-chloropyridine shouldn’t happen in isolation. Knowledge isn’t enough; actions around safety, waste, and application often distinguish a responsible scientist from a careless one. Communities expect transparency and stewardship. In practical terms, this means regular environmental reviews and open channels for reporting unsafe practices. I’ve learned that fostering a culture of responsibility pays dividends in the trust from colleagues and the surrounding community. No single chemical formula captures that fully, but keeping it in mind on every project can make a difference.

A Small Molecule, Big Impacts

C5H2ClF2N represents more than just atoms bonded together. This formula echoes the impact of chemistry across medicine, food security, and the environment. Using it wisely calls for solid training, smart regulation, and continuous commitment to safety and ethical progress. The story behind each chemical goes beyond the numbers—it’s written by everyone handling, transforming, or learning from it.

Hazards Are Real, Not Just Labels

Anyone who's spent time working with chemicals understands how easy it can be to underestimate the danger of a small bottle in the corner. 2,3-Difluoro-5-chloropyridine fits right into that category: a name that doesn’t get much attention, but if left unchecked, the problems stack up quickly. People have gotten too comfortable around unfamiliar reagents, missing gloves, skipping full ventilation just once, and then facing the consequences. It only takes one spill or a splash for things to go south.

This chemical gives off fumes that nobody wants anywhere near their lungs or eyes. People who’ve worked with similar halogen-substituted compounds talk about nasty headaches and sore throats after just a whiff. Even though the liquid looks plain, it hides a real punch toward skin and eyes. That’s a good enough reason to always grab those chemical-resistant gloves, eye protection, and a sturdy lab coat. Quick story—one guy I know learned the hard way after forgetting goggles: a split second, a splash, and the ER visits started. It taught our whole group to never skip the basics, ever.

Sensible Storage for 2,3-Difluoro-5-chloropyridine

Putting it on just any shelf, especially next to acids, bases, or anything that reacts fast, makes zero sense. In my own lab, we only let this bottle live in a tightly-sealed container, away from sunlight and moisture. Dry conditions mean less chance for hydrolysis, which not only helps keep the chemical pure but also keeps dangerous gases from creeping into the air. Folks I talk to in industrial settings all agree: young techs need reminding that stacking bottles, using cracked lids, or ignoring leaks usually brings trouble. Even subtle leaks can taint whole cabinets and foul up other materials.

Temperature swings make some people overlook what’s going on top shelves or in hot rooms. High heat bumps up vapor pressure, and suddenly you’ve got fumes leaking you never planned for. Repeated opening and closing of containers in humid spaces only invites moisture in. My own rule: always double-check o-rings and sealers before walking away for the night and never reuse containers from other chemicals—cross-contamination, especially here, is real.

Transportation: Planning Beats Regret

No one likes paperwork, but proper labeling can mean the difference between routine work and a costly accident. Even for short trips across campus, using secondary containment—think sturdy bags or bins—keeps spills from spreading. I’ve seen people carry bottles as if they were hauling milk; it’s sloppy and risks more than just a floor cleanup. Even in cars or vans, sudden stops or bumps can crack containers, so strapping cargo and keeping spill kits nearby helps.

Waste Isn’t Just "Throw-Away"

It’s tempting to pour leftover 2,3-Difluoro-5-chloropyridine down the drain or toss it in the regular trash. This habit lingers in old labs, often from days when regulations were looser. These halogenated compounds pose serious risks to water sources and garbage handlers. Eco-conscious labs and companies opt for specialized waste streams. For us, working with our local hazardous waste service costs more time—but seeing clean up crews at other labs handle toxic leaks or site contamination tells me it’s worth it. Getting staff comfortable discussing and reporting near-misses almost always improves overall safety culture.

Staying Smart Pays Off

Some people call these precautions overkill until they watch an emergency team suit up for a preventable spill. Operating with a little extra care, using good storage, and handling protocols, doesn’t just protect equipment; it protects all of us who rely on a clean, safe workplace. There’s no shortcut—for 2,3-Difluoro-5-chloropyridine or anything else that ticks the boxes for toxicity, flammability, or reactivity—other than respect for the hazards and a willingness to learn from what’s gone wrong in the past.

Purity Makes or Breaks Chemical Value

I’ve worked with specialty chemicals long enough to know that details around purity determine real-world outcomes in a project. The chemical 2,3-Difluoro-5-chloropyridine turns into something valuable or problematic depending on the grade delivered. Labs, manufacturers, and researchers all count on getting accurate specifications because any slip-ups at the purity level show up as downstream headaches—whether in pharma syntheses, agrochemical pipelines, or advanced materials R&D.

Most of the conversations I’ve had with buyers revolve around one tough question: “Is it actually as pure as your spec says?” The number that shows up on the cert matters for a reason. For this compound, professional suppliers provide a purity grade sitting at or above 98% by GC or HPLC, and a typical certificate of analysis shows not just the overall purity but also singles out key related impurities. Chasing these details isn’t rehearsed bureaucracy; it’s the only way anyone can lock down reproducibility batch after batch.

Why the Benchmark Isn’t Just a Marketing Game

It’s tempting to look for bargains when ordering intermediates, and sometimes lower-priced batches claim decent purity at 95% or below. From what I’ve seen, these cheaper lots come with ghost peaks, harder purification, and unreliable chemistry. People hit problems that waste both time and money—yield drops, failed analysis, and out-of-spec byproducts. High-purity stocks, independently checked for water, residual solvents, and single-digit ppm for metallics, actually save effort down the line.

Lab mistakes sting because they usually trace back to small things overlooked or questions dodged early in the buying process. For example, I’ve dealt with more than one researcher who trusted a low-cost purchase, only to discover that a seemingly small impurity shifted the reactivity in a key coupling step, forcing rushed troubleshooting and reordering. The stress ripple hits everyone—the junior chemist to the funding manager overseeing costs.

Digging Beyond the COA

One habit I picked up is making suppliers tell me exactly which analytical methods back up their numbers. Just seeing a COA with HPLC at 254 nm means little unless the method development caught all expected impurities. I’m also cautious when I see “on dry basis only” without moisture data, because certain applications—like sensitive active pharmaceutical ingredients—get completely derailed by traces of water or solvents.

From my time working alongside QA teams, I learned that purity specs get real teeth with supporting spectral data. NMR, MS, and even FTIR give a fuller picture, and reputable producers share raw data or at least full traceable batch records. Anything less deserves pushback from buyers. Relying on word-of-mouth or past experience alone doesn’t hold up when audits start asking tough questions.

What the Industry Owes Buyers

The people making and selling 2,3-Difluoro-5-chloropyridine need to get comfortable with transparency. Disclosing not just the number but how it’s reached builds trust. Offering third-party batch validation and making it easy to review data helps buyers—many dealing with thin margins and tight timelines—sleep a bit easier. Upstream honesty saves resources. Buyers should reward producers who keep standards high, even if it means paying a bit more. I’ve seen good chemistry projects bloom or fail because of this one detail. Not every lab or organization can afford to discover the difference the hard way.

A Closer Look at 2,3-Difluoro-5-chloropyridine

Chemists and formulators have a way of getting attached to molecules that pack a punch, even in small doses. I’ve found that 2,3-Difluoro-5-chloropyridine shows up time and time again at the heart of research and development projects, mostly thanks to what those fluorine and chlorine atoms bring to the table. Test tubes lined up on any synthetic chemist’s bench, and you’re almost sure to see pyridines in the mix—especially ones that blend electron-withdrawing groups for unique reactivity. From my experience, that means you get more leeway in making complex molecules, which helps out in several parts of the chemical industry.

Driving Pharmaceutical Discoveries

Drug companies haven’t just stumbled upon this compound by accident. Fluorinated pyridines pop up in conversations about optimizing new medicines because coating a molecule with fluorine often dials up its stability, improves how it behaves in the body, and sometimes even keeps unwanted metabolic products at bay. I remember sitting in a seminar where a researcher walked us through how they relied on 2,3-Difluoro-5-chloropyridine as a building block for a new antiviral candidate, all because of its ability to add resilience and improve bioavailability.

Moving a molecule from the lab bench to clinical use doesn’t just take one clever trick. Structurally, putting both fluorine and chlorine in a pyridine ring opens up several transformation routes. Medicinal chemists have used this compound to build libraries of potential drugs, testing which tweaks make the best disease fighters. Published studies and pharmaceutical databases back this up—fluorinated heterocycles, including this one, frequently star in early lead optimization and the rounds of modifications that follow.

Opening Doors in Crop Protection

Modern farming leans heavily on better weed and pest controls that don’t damage the food we eat. Agrochemical companies put a premium on ingredients that resist breakdown and avoid the pitfalls of previous generations. I’ve met colleagues who use 2,3-Difluoro-5-chloropyridine in their search for active agents in new herbicides and fungicides. Here, that unique structure makes a difference. Those halogen atoms block rapid degradation in the field, so you don’t need as many repeat applications. Some of the problem-solving that happens in the ag space borrows directly from pharmaceutical chemistry, and molecules like this one often form a bridge between the two sectors.

Boosting Chemical Synthesis

Beyond medicines and crop solutions, this compound gets plenty of play as a key intermediate. Labs rely on its distinct pattern of atoms to introduce novel features into dyes, electronic materials, and advanced plastics. I’ve handled small vials ordered for custom synthesis jobs, watching the way reactions run smoother due to the electronic effects brought by its fluorine and chlorine neighbors on the ring. Academic chemists and industrial process designers lean on these pyridine derivatives when they need to link, substitute, or protect parts of larger molecules with precision.

Improving the Way Forward

Challenges still show up. Some pathways to make advanced intermediates from 2,3-Difluoro-5-chloropyridine produce a fair amount of chemical waste. Teams are looking for greener, more efficient routes. Research groups swap ideas on safer solvents and recyclable catalysts. I see promise in how newer continuous flow techniques cut down on hazardous byproducts and energy use, which matters for labs and production plants alike.

Whenever a molecule steps up to help make better drugs, secure food supplies, or shape next-gen chemical products, its value goes well beyond what the eyes can see in a flask. From my own workups to big industry trends, there’s no doubt that 2,3-Difluoro-5-chloropyridine deserves its place on the shelf.

Building Up Chemical Know-How

Lab workers and people on production lines sometimes work with chemicals they can’t even pronounce, let alone understand. I’ve seen eyes glaze over when new hires got handed their first safety data sheet (SDS)—pages of hazards that sometimes read like legalese, not plain advice. Take a compound like 2,3-Difluoro-5-chloropyridine. It’s a specialty piece in pharmaceutical syntheses and research. On paper, its hazards don’t sound as dramatic as some classics, but that false sense of security leaves folks vulnerable. One time, a co-worker with years in the industry brushed off gloves. Redness on skin turned to blistering by lunch. That day, trust in the SDS changed for good.

Unpacking the Real Dangers

Sometimes, people think only the “big” chemicals, like old-school solvents and acids, demand respect. In reality, compounds like 2,3-Difluoro-5-chloropyridine pack a punch in subtler ways. This one causes irritation if it gets on your skin or into your eyes. Breathing it in? Expect coughing, maybe worse. Chronic exposure facts don’t get top billing in training sessions, but researchers have enough proof: repetitive low-level hits can compromise lung function and increase hypersensitivity. The stuff isn’t easy to wash out. It clings to fabric. I remember an incident at a facility: a spill migrated to a shared break space. No major injuries, but the supervisor spent the next week re-explaining why protective clothing goes everywhere, not just where the process happens.

Regulations and Genuine Employer Responsibility

Regulatory agencies give guidelines for a reason. OSHA and the European Chemicals Agency both stress hazard communication and workplace controls. Some managers tick off training as a box on a checklist, but companies who prioritize clear, practical planning cut accidents drastically. At one site, leadership insisted on weekly ten-minute refreshers on real events, both good and bad. Accident rates fell over a year by one third. Safety culture beats paperwork when push comes to shove.

Solutions for Safer Handling

Step one: protective equipment. Gloves that resist halogenated agents, goggles, and lab coats that seal at the wrist make a major difference. Ventilation more than pays for itself, whether fume hoods or full-room extraction. Storage matters too—airtight containers in well-marked cabinets, separated from acids and flammables. It’s tempting to skip the label, especially on busy days, but that shortcut has hurt me and folks I know.

Another fix I recommend is hands-on practice with mock spills or accidental exposures. Real scenarios beat reading incident summaries. I’ve taken part in a drill where dyed water represented a spill, and people had to suit up and follow the protocol. The lesson stuck.

Final Thoughts—From Paper to Practice

An SDS for 2,3-Difluoro-5-chloropyridine isn’t just paperwork. It’s a living set of instructions that protect people’s health, livelihoods, and confidence in their work. A safe work environment rests on more than a file on a shared drive—it depends on clear habits, equipment upkeep, and a commitment to speaking up if something looks off. Trust builds through direct action and shared responsibility, not by simply reciting the rules.

References:- OSHA Hazard Communication Standard (29 CFR 1910.1200)

- European Chemicals Agency – Guidance on the compilation of safety data sheets

- Personal experience in chemical laboratory and manufacturing settings