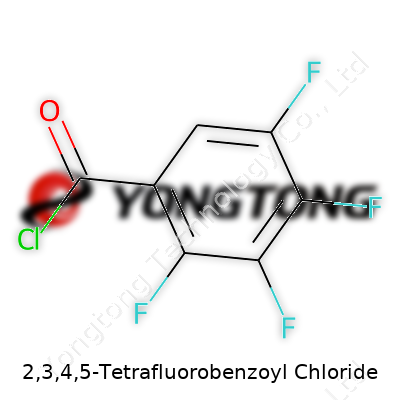

2,3,4,5-Tetrafluorobenzoyl Chloride: A Comprehensive Commentary

Historical Development

Organic fluorine compounds never happen by accident; their development traces back to some of the most dedicated woodshedding in organic chemistry. When chemists first synthesized 2,3,4,5-tetrafluorobenzoyl chloride in the late 20th century, the research didn’t blow up headlines, but it quietly reshaped entire branches of pharmaceuticals and agrochemicals. Unlike standard benzoyl chlorides, which had enabled generations of exploratory synthetic work, fluorinated derivatives chipped away at the old rules, altering reactivity, stability, and—just as crucial—the economics of functional group chemistry. During my years in the lab, labs always chased these compounds for both their resistance to metabolic breakdown and their ability to unlock new functional landscapes, especially for developing active pharmaceutical ingredients.

Product Overview

2,3,4,5-Tetrafluorobenzoyl chloride brings more than its intimidating name to the table. Its formula, C7HClF4O, makes it sound niche, but once chemists started working with it, the applications ranged from crafting new pesticide backbones to custom assembling fluorinated aromatic polyamides. This specialty acyl chloride has become a workhorse for introducing tetrafluoroaroyl groups to diverse bioactive and performance materials. I’ve watched demand rise as major industries embraced the modification potential—usually in response to the push for more robust, environmentally resilient materials.

Physical & Chemical Properties

Handling this compound reminds you that fluorinated aromatics do not mess around with their volatility or reactivity. This colorless to pale yellow liquid boils at about 76 to 78°C under reduced pressure, with a melting range dipping slightly below room temperature. The low viscosity invites easy pipetting, but the pungent, acrid fumes remind every chemist in the room that respiratory equipment is not just a suggestion. In my own experience, this fluid reacts instantly with water—spitting out HCl vapors and forming the corresponding acid—so moisture management becomes a daily ritual.

Technical Specifications & Labeling

Every sample comes with a suite of quality checks: 98% or greater purity by GC, trace moisture below 0.1%, minimal acid chloride hydrolysis. Documentation flags the batch’s origin and purity, providing the all-important chain of custody—crucial for both workplace safety and regulatory compliance. Anhydrous handling usually gets the red-light treatment, with secondary containment and puncture-proof packaging to prevent accidental leaks. I’ve often spent longer poring over shipment logs and hazard labels than actually unsealing the bottle, but proper labeling keeps downstream applications (and operators) on track.

Preparation Method

Manufacturing 2,3,4,5-tetrafluorobenzoyl chloride typically leans on the selective chlorination of its parent tetrafluorobenzoic acid, using reagents like thionyl chloride (SOCl2) or oxalyl chloride. These reactions generate sulfur dioxide and hydrogen chloride as byproducts, so you can’t avoid a fume hood. Scaled-up batches mean you also run up against issues of exothermicity and pressure build-up, pushing engineers to fine-tune agitation rates and quenching protocols. My early roles in process chemistry drove home how a few missed details—improper venting, old glassware—risk runaway reactions.

Chemical Reactions & Modifications

As a reactive acyl chloride, this molecule couples easily with alcohols and amines to form the corresponding esters and amides, especially when people want to install a perfluoroarene motif in a targeted way. The high electron-withdrawing fluorine atoms crank up the carbonyl’s reactivity and stability—less nucleophilic funk than non-fluorinated analogues, but enhanced thermal profile for finished materials. In my own research, the resulting amides proved less prone to hydrolysis and oxidation, making them staples for projects focused on drug stability and polymer lifetimes.

Synonyms & Product Names

Catalogues and papers sometimes call this compound Tetrafluorobenzoyl chloride, 2,3,4,5-TFBCl, or by its systematic IUPAC name. In chemical supply circles, more cryptic labels like "TFB-Cl" show up, but regulatory paperwork always circles back to the full chemical description. One thing worth remembering: confusion between isomeric tetrafluorinated benzoyl chlorides leads to wasted product and paperwork headaches if not cross-checked.

Safety & Operational Standards

Practical safety guidelines for this compound center on wearing proper PPE: goggles, nitrile gloves, and a lab coat, with every transfer conducted inside a working fume hood. The acyl chloride functional group loves to react with water, spraying hydrochloric acid mist into the air, which means even a minor spill triggers a full clean-up protocol. Chemical hygiene plans treat every manipulation as a source of hazardous vapor. MSDS documentation warns of delayed skin and lung sensitization effects; from personal experience, a moment’s distraction doubles your chance of chemical splash.

Application Area

Chemists turn to 2,3,4,5-tetrafluorobenzoyl chloride for making stable, fluorine-rich building blocks common in next-generation materials and pharmaceuticals. These motifs show up in antifungal agents, advanced electronic films, and corrosion-resistant coatings. Its reactivity profile helps scientists construct covalent bonds that won’t buckle under thermal stress or metabolic attack. Drug discovery work often leans on its ability to enhance bioavailability or control the pharmacokinetics of lead compounds; some of the most promising cancer-treatment agents come together using this building block’s unique profile.

Research & Development

Academic labs, startups, and big pharma invest in process improvements and greener synthesis routes for this compound. Several groups are trying to move away from thionyl chloride, eyeing milder, less polluting alternatives for transforming tetrafluorobenzoic acid into its acyl chloride derivative. This development matters, since thionyl chloride’s sulfur dioxide output brings both environmental and cost baggage. By shifting to catalytic chlorination methods or continuous-flow processing, researchers look to drive production efficiency and reduce toxic output. These tweaks don’t just clean up the process; they bring supply chain sustainability gains that resonate up and down the value chain.

Toxicity Research

Toxicological assays consistently flag the raw compound as a respiratory irritant and moderate skin sensitizer. Acute overexposure causes tissue damage typical of acid chlorides, but the fluorinated core raises additional scrutiny regarding environmental persistence and bioaccumulation. The body’s detoxification systems, especially glutathione conjugation, process the parent compound only sluggishly; guideline values from agencies like the EPA remain conservative for both workplace and end-use exposures. Waste disposal protocols, in my experience, emphasize neutralization and incineration—landfill routes clearly out of the picture due to environmental mobility of the fluoride ion.

Future Prospects

Innovation around 2,3,4,5-tetrafluorobenzoyl chloride will likely redefine how chemists build stable, high-performance molecules in medicinal chemistry, crop protection, and electronics. Upcoming research focuses on non-phosgene, low-waste synthesis, improved containment for vapor-phase hazards, and more efficient recycling of byproducts like hydrogen chloride. Expansion of fluorine-based medicinal scaffolds and new industrial catalysts depend on access to reliable, safe supplies of building blocks like this one. All signs point to deeper integration of fluorinated benzoyl chlorides in the commercial toolkit, just as global industries keep demanding tougher, more selective chemical answers.

Not Just Another Chemical Reagent

Talking chemistry always feels a bit like inviting the world into a lab. For anyone who’s peeked behind the scenes of pharmaceutical or organic chemistry labs, 2,3,4,5-tetrafluorobenzoyl chloride stands out as more than just a name in a catalog. Researchers grab hold of this compound because it lets them build complex molecules in a way that few others do.

Making Connections in Organic Synthesis

Here’s the deal: in organic synthesis, scientists stitch molecules together to craft new medicines, high-performance materials, and specialty chemicals. They start with smaller building blocks and need tools to link them precisely. 2,3,4,5-tetrafluorobenzoyl chloride provides that kind of tool. Its main role centers on activating carboxylic acids so they can hook up with other groups like alcohols and amines.

This process matters most in peptide synthesis. Peptides, the workhorses of modern medicine and biology, are just chains of amino acids—linked over and over, like beads on a string. Creating pure peptides without unwanted side reactions gets tricky. Here, chemists often rely on this compound. It helps create a reactive intermediate (the so-called "active ester"). This step lets those carboxylic acids on one amino acid bond cleanly to another amino group's nitrogen, forming the chain with fewer mix-ups.

Fluorine: Not Just a Fancy Addition

Adding four fluorine atoms to the benzoyl core doesn’t just look fancy on paper. It changes how the molecule behaves. The high electronegativity from those fluorines makes the chloride more reactive. So the whole reagent gets things moving faster and, often, more selectively. That’s why chemists in both academia and industry go after it when trying to improve yields or fine-tune the purity of their products.

My own work with fluorinated acids brought this home. Running peptide coupling reactions, I found non-fluorinated benzoic acid derivatives often needed more coaxing—heat, longer reaction times, and extra clean-up. Switching to tetrafluorobenzoyl chloride cut headaches by offering a more direct route to clean products.

Use Beyond the Lab Bench

The features that draw scientists to this compound pay off outside the lab, too. Pharmaceutical researchers use it to streamline drug candidate synthesis, saving both time and money while lessening chemical waste. Material scientists lean on it for custom dyes and liquid crystals, since the tetrafluorobenzoyl group steers the electronic characteristics of their products.

Being conscious of hazards drives safer use. This chemical reacts aggressively with water and sensitive groups, and it gives off corrosive hydrogen chloride gas. Smart labs build protocols to handle it in well-ventilated hoods and train users for emergency response. It’s another reminder that chemistry relies on both innovation and safety.

Creating Value and Looking Ahead

Demand stemmed from a drive to make synthesis easier, cleaner, and more predictable. Suppliers today compete on purity and documentation partly because of strict drug industry standards. That’s a trend I see as positive, since it pushes everyone to share more data and improve standards one batch at a time.

Are there ways forward? Sure. Greener chemistry demands alternatives, or at least better recovery and recycling. Teams are already tinkering with new coupling reagents that mimic the performance of 2,3,4,5-tetrafluorobenzoyl chloride but leave behind less waste or lower hazards. Until then, this compound remains a go-to for professionals looking for reliable results and efficiency in advanced synthesis.

Learning the Risks Up Close

If you've ever set foot in a chemical lab, you understand pretty quickly that every reagent has a personality. Some demand respect more than others. 2,3,4,5-Tetrafluorobenzoyl chloride is one of those substances. It carries the double punch of high reactivity and toxicity, with corrosive qualities that can quickly harm unprotected skin and lungs. In an environment like this, shortcuts invite trouble.

PPE: Not Just for Show

Once, I watched a coworker shrug off goggles “because it’s only one minute at the hood.” Later, a rogue splash during another experiment sent him to urgent care. Safety glasses and nitrile gloves form the frontline defense, but don’t stop there. Splash-proof goggles shield the eyes. Double-gloving can bring peace of mind during transfers. Lab coats keep the chemical off clothing and skin, but closed-toed shoes matter just as much. One accidental drop tells you all you need to know about the value of good shoes.

Working the Fume Hood

Dust or vapor exposure can send you reeling. Breathing in even faint traces of this compound sets up irritation and potential lung injury. I make it a point to handle it inside a certified, working fume hood—never out on an open bench. Before starting, I check that the airflow arrows move the right way, and the sash sits at the recommended height. Solvents and acids can leave lasting smells in your nose, but acyl chlorides can do serious harm you may not notice until later.

Handling and Storage: Protect People, Protect Product

Some think rushing gets the job done faster. Careless transfer runs the risk of spills. I work methodically: check all joints are tight; use syringes with Luer-lock fittings, not slip tips. Never pour or pipette by mouth or old glassware. I label everything, even the waste, with proper hazard warnings and date. After use, I keep leftovers in well-sealed bottles—never in old soft drink bottles—stored in a dedicated, ventilated corrosives cabinet. These steps keep the air and bench clean for everyone who follows.

Understanding What to Do—Not Just What to Avoid

No one wants to talk about accidents, but knowing what to do saves time and tissue. If I get a drop on my glove, off it comes and hands go under cold running water for fifteen minutes. For splashes to eyes: rinse thoroughly with eyewash, don’t hesitate, don’t tough it out. Respiratory symptoms mean leave the lab straight away and get outside air—waiting around won’t fix throat irritation or dizziness.

Waste Disposal: Think Beyond the Experiment

Too many accidents happen during cleanup. This chemical's waste belongs in acid chloride-specific containers, never in the sink or with ordinary organics. Diluting with a suitable solvent lowers splash hazards. Mark and separate the jars properly, never mixing with incompatible families that could produce heat or dangerous gases. Each step respects not only the workers, but the environment and future custodians of the space.

Respecting Experience and Sharing Knowledge

Everything I learned about 2,3,4,5-Tetrafluorobenzoyl chloride I picked up first from technical sheets, but most of all from tough lessons and tips passed along from senior chemists. If someone new starts their first acyl chloride work, I walk them through the risks in plain language. Safety culture grows only when people speak up, swap stories, and leave the lab as healthy as they walked in. No experiment matters more than that.

Layman's Lessons From the Lab Bench

Anyone who’s ever handled fine chemicals at a crowded university bench will know one thing for sure: even the best-labeled bottle turns into a headache if storage gets sloppy. Take 2,3,4,5-tetrafluorobenzoyl chloride. Get careless with a moisture-sensitive, reactive liquid like this, and you’ll invite trouble fast. It might not explode under your nose, but leaks, fumes, and ruined experiments come easy.

Real Hazards Demand Respect

Mishap stories pile up: a misplaced acid-sensitive compound eats through a cheap plastic cap, an unsealed bottle taints a batch of solvents by morning, or a forgotten vial clouds the air with unwanted odors. In labs, it only takes a few minutes of distraction to set up a chain of unwelcome reactions. The creeping vapors or corroded shelves might seem harmless, but they’re warning signs most folks ignore until the cost shows up on the chemical waste invoice or the boss’ desk.

Solid Facts, Simple Steps

2,3,4,5-tetrafluorobenzoyl chloride hails from a family that reacts way too well with water. Exposing this sort of compound to humidity means you’ll lose purity, make toxic byproducts, or both. Hydrolysis kicks off faster than you can screw the lid back on. Fumes from hydrolysis--think hydrochloric acid vapor--can damage your lungs and your nearby research gears in equal measure. That’s more than theory: I’ve watched plenty of glassware etched and fingerprints left on stainless steel where a bottle once leaked.

Storage plans rarely get spelled out in glossy catalogs, so relying on direct experience really counts. Keep this chemical in a tightly sealed glass bottle, always with an intact PTFE liner—no aluminum foil, no makeshift plastic wrap. Every researcher on my last team learned quickly to double-check the seal, even if it seemed overcautious. Trust disappears fast once someone finds corrosion creeping across shelves or picks up that faint stinging tang in the air. Don’t stash the bottle under cold, dripping fridge coils. Go for a dry, cool spot. Anything above average room temperature boosts rates for the breakdown reactions, and humidity from cold storage sets off problems even faster. Low humidity dessicator cabinets work best. Use a dedicated area, far from acids and alkalis. Fumes cross-contaminate, and fingerprints on the bottle from bare hands only quicken degradation. Gloves should be the norm—nitrile serves well here.

Clear Labeling and Good Records

Never trust a fading marker or a half-torn label. Use proper chemical-resistant labels with legible, unambiguous contents and warning marks. Dates matter. Rotate stock so no bottle lurks forgotten for years. At every good lab I’ve worked in, a logbook sits by the cabinet. Simple checkmarks show who handled what, so every user knows how old a reagent is and whether any mishandling risks have crept in.

Why Care Pays Off

Ignoring the basics brings the costs front and center: compromised reactions, tainted results, more hazardous waste, and worse, health problems that catch up much later. Time and money saved upfront quickly wash away with one slip. Safety experts hammer this lesson into new staff, not to scare them but because repairing the aftermath of sloppy storage takes oceans more time. Responsible storage habits reflect not just respect for the product, but care for everyone who shares the workspace.

Unpacking Benzoyl Chloride with a Twist

Organic chemistry gets a reputation for complexity, but sometimes, it helps to slow down and get hands-on with the basics. Take 2,3,4,5-tetrafluorobenzoyl chloride. The name alone seems intimidating, yet the journey to its formula builds understanding of both chemical nomenclature and practical implications in real research. The molecular formula for this compound is C7HClF4O.

Understanding Structure to Grasp the Formula

Benzoyl chloride forms the core. Start with benzene, a simple ring of six carbon atoms, adorned with six hydrogens. Swapping one hydrogen for a carbonyl chloride group (COCl), we craft benzoyl chloride: C6H5COCl. The numbers tell a story—seven carbon atoms, five hydrogens, two oxygens, and a single chlorine. For many, running through the logic with pencil and paper solidifies the details far more than any textbook description.

Substituting four fluorine atoms at the 2, 3, 4, and 5 positions pushes curiosity further. Each new fluorine steps in for a hydrogen, adjusting the molecular picture. By the finish, we have seven carbons, a single hydrogen, a chlorine, a single oxygen, and four fluorines. The stability added by fluorine often matters in pharmaceuticals and specialty chemicals. Fluorine atoms don’t just swap places—they tweak reactivity, increase resistance to degradation, and open doors for new applications. This power in modification makes organic chemistry the cornerstone of modern materials science.

Why Does This Matter in the Lab?

Fluorinated compounds like this chloro-acyl derivative show up in synthesis of agrochemicals, active pharmaceutical ingredients, and advanced materials. With over ten years in a university chemistry lab, I often saw firsthand how a small formula shift could turn an average day’s experiment into a maddening puzzle or a breakthrough. Missing a single atom in planning, and the purity drops or the yield collapses. Too many graduate students discover this lesson the hard way.

The true importance lies in more than the numbers. A molecular formula such as C7HClF4O means more than just the sum of its atoms: it shapes how chemicals behave. Fluorines on the benzene ring dial down reactivity in some areas and nudge it higher in others. Manufacturers keep this formula close as they look for compounds with better shelf-life or greater performance in harsh environments. The formula acts as a compass, guiding synthetic chemists as they chase reliability in everything from agricultural sprays to innovative materials for electronics.

Building Trust with Accurate Information

The internet drowns in conflicting chemical data. Trust starts with fact-checking and trusting only sources that cite experimental evidence or peer-reviewed chemistry databases. As someone whose own results once depended on the right formula scrawled on the corner of a notebook, I know accuracy isn’t optional—wrong numbers cost time, money, and sometimes safety. PubChem and ChemSpider rank among the reliable places to double-check molecular formulas, and seasoned chemists return to these sites over and over since publication mistakes happen.

Solutions for Avoiding Mix-Ups

Carefully training students and professionals to trace every functional group change helps keep formulas correct, especially with complex molecules. Using up-to-date, verified chemical databases closes gaps before experiments even begin. Relying on manual cross-referencing instead of blind trust in search results safeguards both research success and lab safety. The best results stem from a blend of book rigor and bench-top practice, carried out with patience and respect for the details.

Understanding What’s in the Bottle

Most folks don’t think twice about chemicals beyond the label, but the number on that bottle, the purity grade, makes all the difference. In the world of 2,3,4,5-tetrafluorobenzoyl chloride, purity means more than just a decimal on a certificate. The kind of research you want to do, or the product you’re trying to make, often depends on it.

Getting the right grade isn’t just about chasing numbers either. For researchers, even a fraction of a percent of impurity can throw off an experiment. Imagine spending weeks tweaking a reaction just to find out that an unseen contaminant from the starting reagent is to blame for poor yields or mystery byproducts. High-purity material—typically 98% or above—gives peace of mind, especially with finely tuned pharmaceutical syntheses or specialty polymers. In my own lab experience, switching to better purity reagents turned stubborn failures into smooth successes.

What the Grades Mean in Practice

Different applications demand different grades. If a lab is working in analytical chemistry, producing reference standards, or supporting drug discovery, choosing a reagent at 98–99% purity reduces the risk of results tainted by trace contaminants. Lower grades—around 95%—show up more often in early-stage process optimization or in large-scale runs where cost matters more, and ultra-trace impurity concerns take a back seat.

In several cases, waste management and energy bills rise fast when you use lower-quality 2,3,4,5-tetrafluorobenzoyl chloride. Extra purification steps, more TLC plates, and endless columns eat up both time and solvents. Every synthetic chemist learns this lesson quickly after burning through a few weekends in a hot lab for what amounts to savings of a few dollars on the bottle.

Real-World Challenges and Industry Practices

Most reputable suppliers flag the purity right on the spec sheet. It’s worth noting, though, that every lot can vary, and the listed purity might reflect the lowest guaranteed value, not the average. Reading transport and storage notes, like warnings against moisture or light, is just as important—they affect real-world material quality long before it reaches a flask.

In regulated industries, even 99% isn’t always enough. Pharma companies regularly commission extra rounds of testing or purification, demanding certificates of analysis with breakdowns for each impurity. Each “unknown” peak in an HPLC trace can slow a project or send it back for more cleanup. This focus on details ripples back through the supply chain, and lessons in chemical sourcing carry over to food, batteries, and beyond: purity matters everywhere.

Toward Better Purity and Transparency

The conversation doesn’t end at the label. Recalls and failed batches hit the news whenever a raw material source changes or a new contaminant is discovered. Faster, cheaper analytical tools give more transparency, but trust grows from open dialogue between suppliers and users, not fine print. More companies have begun to embrace open-access spectral libraries, letting anyone cross-check a bottle’s contents before a major project starts.

From a chemist’s perspective, I know that every percentage point of purity can prevent headaches, save days of work, and sometimes protect entire projects. Making informed choices on purity grades, knowing how to ask suppliers the right questions, and pressing for clear standards helps keep science on track—and projects delivered on time.