2,3,4,5,6-Pentafluorobenzoic Acid: From Niche Chemical Curiosity to Modern Purpose

Historical Development

Back in the late-1900s, fluorinated benzoic acids caught the attention of chemists chasing unique electronic properties for industrial and analytical use. Among them, 2,3,4,5,6-Pentafluorobenzoic acid (PFBA) broke ground as a sort of poster child for the complete sweep of fluorine over the aromatic ring. Lab notes from the era reveal a combination of curiosity and purpose: researchers wanted both new reagents for chromatography and robust building blocks for specialty polymers. The journey to modern PFBA involved refining halogenation methods, wrangling reactivity issues, and figuring out how to isolate a stable, high-purity product fit for both bench work and scale-up.

Product Overview

Today, PFBA stands as a frequently used compound in labs focused on fluorinated organic synthesis, chromatography, and certain environmental testing workflows. Its full ring-substitution by fluorines puts it into a category where electron-withdrawing power changes everything—from solubility to reactivity. Not just a sideline reagent, this acid attracts interest for its role in analytical standardization, given that it’s detectable at trace levels with simple mass spectrometry methods. The global market, while still a niche compared to commodity chemicals, now recognizes its value across research, chemical manufacturing, and regulatory testing.

Physical & Chemical Properties

PFBA appears as a white crystalline solid, exhibiting somewhat higher thermal stability than more lightly fluorinated versions. With a molecular weight near 214 g/mol and a melting point around 185°C, the compound survives routine handling in lab air but draws moisture enough to merit a dry bottle. Solubility skews toward polar organic solvents: acetonitrile and DMF dissolve it much more effectively than water, despite its carboxylic acid group. The pKa comes in significantly below that of benzoic acid, thanks to the strong electron-withdrawing draw of all those fluorines—making its conjugate base a weaker nucleophile.

Technical Specifications & Labeling

Buyers who care about trace contaminants watch for purity above 98%, with typical labels quoting HPLC or GC profiles for reassurance. Standard labeling details the batch number, net weight, CAS number (327-62-8), and full hazard warnings, including eye, skin, and inhalation irritancy. Some suppliers tack on shelf life and recommended storage conditions, aiming to keep hydrolysis and contamination to a minimum. In regulatory contexts, the details matter; for instance, analytical standards must specify source lots and have accompanying certificates of analysis.

Preparation Method

Commercial-scale PFBA usually starts from pentafluorotoluene or pentafluorobenzoyl chloride. Typical synthesis involves oxidation or hydrolysis, benefitting from the electron-deficient ring to prevent unwanted side reactions. From experience, the steps do get messy—handling perfluorinated aromatic intermediates can challenge both gloves and patience. Reaction yields look decent when conditions stay dry, and purification boils down to crystallization or vacuum distillation when product needs finer tuning for trace analysis work.

Chemical Reactions & Modifications

PFBA rarely just sits on the shelf; its distinctive electron-poor ring opens up new lines of chemical conversation. Nucleophilic aromatic substitution happens more readily at these fluorinated rings, making it a good entry for making custom (or radio-labeled) derivatives. The carboxylic acid itself links readily by forming esters, acid chlorides, or amides, all of which land in advanced material or pharmaceutical projects. Researchers have also leveraged this compound to anchor other functional groups in complex organofluorine syntheses.

Synonyms & Product Names

Most chemical catalogs refer to it as 2,3,4,5,6-Pentafluorobenzoic acid, with synonyms including Perfluorobenzoic acid and PFBA. Some manufacturers use catalog names that throw in identifiers such as “PFB Acid” to distinguish it from other pentafluorinated aromatics or unrelated compounds sharing the same abbreviation.

Safety & Operational Standards

Long hours in the lab teach plenty about keeping work with PFBA safe. While not violently reactive, its strong acidity and potent irritant effect on mucous membranes call for basic PPE—full gloves and splash-proof eye protection. I’ve witnessed cases where colleagues underestimated airborne dust or overlooked combined exposure with other organofluorines, compounding mild respiratory irritation. Safe lab work means good ventilation, thoughtful waste handling (since perfluorinated byproducts can linger in the environment), and careful storage away from bases and heat sources.

Application Areas

PFBA makes recurrent cameos in trace analytical chemistry, particularly as a marker in LC-MS and GC-MS systems, where its stability helps calibrate fluorinated contaminant detection. Environmental researchers test water and biosolid samples for PFBA residue, since it marks the footprint of both industrial emissions and degradation of larger fluorinated chemicals. Synthetically, the acid bridges into specialty polymer and pharmaceutical intermediates during multi-step organic syntheses. I’ve seen it used as a coupling partner in some pretty tricky perfluorinated scaffolds and noticed its increasing use as a reactivity probe for surface science studies.

Research & Development

Research with PFBA has ramped up as environmental and materials science circles look for “marker molecules” to trace chemical pathways. Advanced laboratories push the boundaries by adapting this acid for click and bioorthogonal chemistry, chasing highly selective labeling of proteins, polymers, or porous frameworks. R&D teams continue to target more efficient, scalable synthesis routes that cut down waste and energy costs—a tall order, given the inherent stubbornness of perfluorinated aromatics. Different labs also share protocols for purifying PFBA down to parts-per-billion contamination thresholds, essential for sensitive environmental monitoring.

Toxicity Research

Ongoing toxicity research tracks how PFBA behaves both inside living systems and out in waterways. Its strong carbon-fluorine bonds guarantee environmental persistence, but its smaller molecular size means it resists cell membrane accumulation a bit less than some bigger PFAS cousins. Studies in rodents and aquatic species register mild sub-acute toxicity, with early evidence showing limited bioaccumulation compared to long-chain analogs such as PFOA. Regulatory teams debate guidance levels for PFBA in drinking water, given uncertain links to developmental or metabolic disorders in animal models. My own read: the compound falls into the gray zone of “caution and control” rather than full-on danger, but gaps in chronic exposure data call for much more transparency and thorough research.

Future Prospects

PFBA’s story isn’t finished yet. Green chemistry researchers want to redesign busier synthesis routes so that fewer waste streams pile up and product recovery gets easier. Environmental watchdog agencies continue to re-test acceptable limits and set up stricter monitoring for possible PFAS contamination in soil and groundwater. Application innovations also continue: new materials depend on nailing the right combination of reactivity and stability, where perfluorinated aromatics like PFBA often prove hard to beat. I’m watching for advances in PFBA’s ability to anchor or functionalize complex structures without leaching or side reactions, especially as nanotech and bioconjugate chemistry push boundaries further. Practical application will depend on keeping its environmental and health footprints lower, forcing every new use to pass through a healthy dose of skepticism, peer review, and cost-benefit calculation.

The Purpose Behind a Complex-Sounding Chemical

2,3,4,5,6-Pentafluorobenzoic acid rings a bell mostly among folks who spend their days in labs, yet its relevance stretches across pharma, environmental science, and technical research. Think of it not as a household item, but as a tool researchers pull out when precise results matter. From my own background in scientific writing, I’ve found that chemicals like this quietly keep progress moving—usually unnoticed by the public, but quietly crucial behind the scenes.

Making Complex Molecules Simpler to Study

This acid stands out because of its structure. Those five fluorine atoms do more than just make the name longer—they change how the compound behaves. Chemists often use 2,3,4,5,6-pentafluorobenzoic acid when they want to attach fluorine in a very controlled way to new drug candidates or advanced materials. Those fluorine atoms can tweak how other molecules interact, stay stable, or even move through living systems. In the pharmaceutical world, adding fluorinated groups can boost the effectiveness of medicines or help them last longer in the body. That’s a huge deal for drug discovery, as I remember from interviews with medicinal chemists who cheer for more reliable, predictable results thanks to neat tools like this acid.

Water Testing and Tracking Pollutants

I’ve talked with environmental researchers who rely on 2,3,4,5,6-pentafluorobenzoic acid for a practical reason: tracking water. Here’s how it works. The acid barely interacts with most things in the environment, so researchers use it as a tracer—mix it in, trace its path, and see how water moves or how pollutants spread. It becomes a visible roadmap, which is especially important in groundwater studies or checking for contamination. The U.S. Geological Survey has promoted this approach for its precision, highlighting just how important it becomes when clean drinking water or public health hang in the balance.

Analytical Chemistry: Pinpointing What’s Where

The acid gives strong signals in both nuclear magnetic resonance (NMR) and mass spectrometry, two detective-like tools chemists use. In NMR, those five fluorines each sit in slightly different spots and create sharp, easy-to-read signals—making analysis less of a guessing game. As someone who’s seen students struggle through muddled chemical spectra, I know how a clear standard makes a difference. It’s like seeing a map with the street names printed large and bold. By providing reliable standards, it becomes easier to figure out what’s in a sample, especially during quality checks for pharmaceuticals or food safety.

What’s Next: Safety and Waste Concerns

No chemical comes without challenges. Fluorinated compounds often stick around in the environment, leading to questions about long-term effects. This calls for safe storage, proper disposal, and thoughtful use. The scientific community has started to push for green chemistry—designing methods that reduce waste and risk. I’ve seen labs cut down on hazardous solvents or recycle materials more than ever before, offering a practical model for how to handle tricky substances.

The Real Payoff

2,3,4,5,6-Pentafluorobenzoic acid might sound like a mouthful, but the way it smooths out complex research speaks volumes. Its place in labs keeps drug development moving forward, gives a helping hand in environmental protection, and supports sharper analytical work. That kind of versatility is rare in chemistry—and shows that even specialized compounds can have ripple effects far beyond their own flasks and beakers.

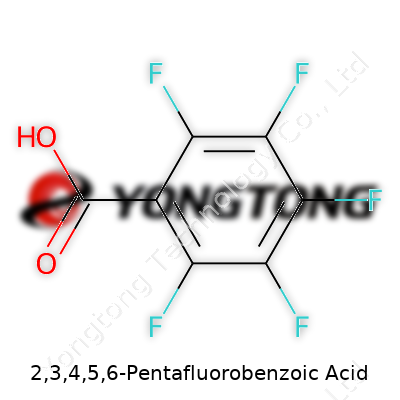

Understanding the Basics

Every molecule tells a story. In labs and factories, 2,3,4,5,6-Pentafluorobenzoic Acid pops up as something more than just a mix of atoms. Its chemical formula, C7HF5O2, spells out seven carbons, five fluorine atoms, a hydrogen, and two oxygens. Swap in a single hydrogen for each carbon on an aromatic ring and plant a carboxylic acid group—the result looks simple, but the detail matters. Any major chemistry class pokes at why swapping hydrogens for fluorines totally shifts how molecules interact with the world.

The Role of Fluorine

Five fluorine atoms stacked on a benzene ring. That changes everything: it makes the structure highly resistant to breakdown. Fluorine bonds don’t break easily. Industrial chemists lean on that stability. This chemical doesn’t just dissolve in water or oil like many acids do. Instead, it stands tough—survives harsh conditions in organic synthesis and environmental studies.

Research and Real-World Use

Consider my own time spent in an academic chemistry lab. We learned to respect fluorinated benzoic acids—no careless handling, no quick waste disposal. They don’t break down easily in the environment. Companies use pentafluorobenzoic acid when a stable standard is needed, for example in chromatography or tracing how other compounds break down. One thing ends up clear: this isn’t a throwaway acid, it’s a specialty tool.

Environmental Questions

The same strength that makes this molecule valuable—its resistance to chemical attack—raises questions about its environmental impact. There’s a bigger story about what happens after research or industrial use. Scientists have found that highly fluorinated chemicals stick around far too long in soils and water. These molecules, sometimes called PFAS compounds, show up in places they shouldn’t. Studies link some PFAS family members to harmful health effects—immune issues and developmental interference—though each compound has unique properties.

Addressing the Challenges

Proper waste handling must stand at the front of mind. Procedures that destroy or capture strong fluorine-based chemicals are on the table in labs now. Burning isn’t enough—some incinerators barely scratch the surface. The best answer combines smart lab practices, tight tracking of chemical use, and constant research on better destruction methods. Green chemistry might swap out persistent molecules for ones that do the same job, yet break down safely.

Looking Forward

Anyone using chemicals like this needs full awareness of both benefits and costs. Companies, researchers, teachers—all shape the journey from discovery to disposal. Day-to-day, it falls to scientists to demand strong regulations for disposal and share any knowledge about safer alternatives. As chemistry presses forward, the weight lands on all of us not just to unlock new tools, but to think ahead about where those tools go next. 2,3,4,5,6-Pentafluorobenzoic Acid packs a lesson in every atom: strength and responsibility go hand in hand.

Understanding What’s in the Bottle

At first glance, 2,3,4,5,6-pentafluorobenzoic acid looks like another tongue-twister from a chemistry catalog. This chemical often shows up in research labs, mostly used as a tool in analytical chemistry and as a building block for synthesizing more complicated molecules. With “fluoro” right in the name, most scientists get the hint that this compound demands respect due to its persistent, stable nature.

Looking at Toxicity Through Different Lenses

What’s most striking about pentafluorobenzoic acid is the lack of real-world toxicity data. I’ve noticed that chemicals with several fluorine atoms attached tend to linger in the environment. Fluorinated compounds, in general, have drawn global concern because many of them, especially PFAS (per- and polyfluoroalkyl substances), don’t break down easily and can build up in living things. The EPA and various health agencies have already targeted several fluorinated chemicals for restrictions, especially in drinking water.

Lab safety data sheets for pentafluorobenzoic acid flag some basics. The acid can cause serious eye and skin irritation, so I’ve always suited up with gloves, goggles, and a lab coat. Inhalation of dust or direct skin contact could trigger allergic reactions or rashes. Even short-term exposure, especially as powders or dusts, can leave you with burning skin or watery eyes. These signals mean nobody should treat it like table salt.

Digging Deeper—Environmental and Long-Term Hazards

I’ve learned over the years that just because a chemical doesn’t cause instant harm doesn’t mean it’s safe over time. Pentafluorobenzoic acid’s structure hints at stubbornness in the environment. The rings of fluorine lock it in a kind of chemical armor, so it resists breaking down from light, bacteria, or even acids and bases. That means low-level spills or poor disposal can turn into headaches for years. Many places already limit disposal of persistent organofluorine compounds, and for good reason. Biodegradation studies on related compounds show that breakdown is slow to nonexistent, which can allow steady buildup in waterways and soil.

Research hasn’t nailed down whether pentafluorobenzoic acid accumulates in people or wildlife in the way notorious PFAS do. Still, caution makes sense—other stable fluorinated molecules have shown links to hormone disruption, organ toxicity, and cancers in long-term studies. Drinking water standards for similar chemicals have tightened year after year as researchers turn up more stories of bioaccumulation and subtle harm over time.

Raising the Bar for Chemical Handling

Complacency never plays well in labs or factories working with fluorinated acids. Agencies like OSHA and the European Chemicals Agency push for clear labeling and responsible use. In my experience, good chemical management starts with treating every fluorinated compound as a long-term risk, not just a short-term lab hazard.

Best practices involve closed systems for handling powders, high-efficiency ventilation, and training for everyone from veteran chemists to new interns. Anyone generating waste needs access to licensed chemical waste disposal. Leaving acid residues in sinks or regular trash only pushes these persistent molecules into rivers and landfills.

Better Questions Lead to Better Outcomes

If the aim is to stay healthy and keep toxicants out of the environment, companies and labs need to keep pushing for transparency. Demand safety data well beyond the “irritant” label—ask for long-term studies and track any regulations in major markets. Responsible institutions update protocols as science fills gaps. Substituting greener alternatives whenever possible puts health and community safety first.

The bottom line: pentafluorobenzoic acid deserves the same respect that fluorinated compounds like PFAS get in safety circles. Use it with intention, control exposure, and limit releases. Industry won’t solve the problem overnight, but every step toward safer handling and stronger rules keeps risk off people’s hands and out of the water.

A Closer Look at Chemical Safety

2,3,4,5,6-Pentafluorobenzoic acid might not be a household chemical, but it deserves more attention in chemical storage conversations. Those clear crystals pack a punch. If curiosity ever led you through a university chemistry lab or an industrial storeroom, you’ll know every bottle has a story—some glow with danger more than others.

Understanding the Substance

Its five fluorine atoms change the rules. Rather than treating it like every benzoic acid, it’s smart to respect the extra reactivity that fluorine brings. Gloves and lab coats become second nature fast after dealing with fluorinated compounds. Even a quick breath of consultation with chemical datasheets shows this acid isn’t just an organic acid—it acts with unique persistence and, often, increased toxicity.

Handling and Container Choice

Plastic may seem harmless, but it doesn’t always play well with strong acids, especially ones loaded with fluorine. High-density polyethylene or glass stand as solid choices. I’ve seen lesser materials melt or crack after months of slow exposure. Tightly sealed glass bottles with Teflon-lined caps have protected our shelves from fumes and leaks—something you appreciate after cleaning up a spill at 2 a.m.

Keep It Dry, Keep It Cool

Humidity spells trouble. This acid attracts water, creeping silently into a container if given the chance. The solid starts out pure, but stray moisture dilutes and degrades it. Dry cabinets or desiccators help—throw in silica gel packets for good measure. Storing below room temperature slows down decomposition too. We always kept the bottle tucked in the cool, away from sunlight or heat from a drying oven.

Separate from Incompatibles

Mix-ups lead to disaster. Acids, especially those loaded with fluorines, turn volatile around bases or strong oxidizers. It never takes long to learn the value of separating incompatible substances. Shelves marked by hazard class with clear labeling kept us out of trouble. The best storage area stays uncluttered, organized, and regularly checked. A label with the date gives a quick heads-up on age—no guessing games when mixing up solutions.

Think Long-Term

Disposal proves just as important as day-to-day handling. None of the common lab drains will tolerate a steady stream of pentafluorobenzoic acid waste. Disposal procedures—like using a designated waste container and quick hand-over to hazardous waste professionals—stay non-negotiable. Neutralizing agents, proper paperwork, and regular staff training stack up as vital. The EPA ranks perfluorinated compounds among those requiring extra caution for a reason.

Safe Storage Means Fewer Surprises

Every time a new shipment arrived in our lab, we’d check the label and double up on the usual safety checks. Chemical storage always feels like a mix of preparation, organization, and respect for every compound. For 2,3,4,5,6-pentafluorobenzoic acid, secure containers, cool temperatures, dry air, and distance from incompatibles form the short list. Skipping details only adds risk, and I’ve never met anyone who regrets storing chemicals the right way.

High Purity Fuels Reliable Results

Labs and manufacturing sites count on purity. 2,3,4,5,6-Pentafluorobenzoic acid offers no exception. Everyday research, from trace analysis to custom synthesis, lives or dies on how "clean" a sample proves. Purities for this item usually range above 98%, but top suppliers routinely deliver 99% or higher. That detail matters—trace contaminants skew mass spectrometry, cloud reaction pathways, and could wreck whole batches. I remember hunting for a reason behind inconsistent data during my own grad school days. Turned out, the market source for an acid showed only 95% purity, hidden away in the fine print of a spec sheet. Reactions performed with the higher purity product, though, restored consistency overnight.

Skeptical? Take a quick look at the supply sheets from leading chemical firms. Sigma-Aldrich, Alfa Aesar, TCI America, and Thermo Fisher list their stock of pentafluorobenzoic acid with purity values of at least 98%. In real-world lab settings, even this small one percent gap could set apart a successful reaction from a useless fizzle.

Packaging Sizes Shape Workflow

Next comes the matter of the bottle. Labs and engineers face different needs. Some projects call for just a pinch, others demand bulk loads. I’ve watched well-funded pharma teams and scrappy post-docs both hunt around for the best option, eyeing cost-per-gram more closely than any marketing slick. It’s common to see vials as small as 1 gram or as large as 100 grams. Entry sizes like 5 or 10 grams fit method development, spike testing, or short-term storage. Larger bottles, such as 25, 50, or 100 grams, directly support scale-up chemistry in production environments. Several vendors also supply custom packaging if special requests come in.

If storage conditions hit the radar, pentafluorobenzoic acid typically ships sealed in glass bottles or heavy-duty plastic, with desiccants for added moisture protection. Shipping regulations recognize its low hazard risk, so transport holds up well even under rough handling or lengthy travel.

Why Purity and Packaging Choices Matter

Students ask why “a little impurity” or “the wrong size” sparks stress. The answer is simple: research profits live on the edge of precision. Impurities might seem unremarkable, but chemical reactions can run wild from even small unwanted extras. In regulated settings, food and pharma standards demand stringent documentation. Procurement teams must keep paperwork on purity, batch numbers, and safety for every bottle. If you’re running synthesis of fluorinated intermediates, extra contaminants raise safety questions and upend reproducibility.

For the average buyer, the ideal route means calling suppliers to verify latest purity specs and evaluating which packing weighs best against current demand. Buying too little triggers costly reorder cycles. Taking too much risks letting valuable stocks degrade on a forgotten shelf. I’ve watched research budgets vanish due to bulk purchases left unused, so right-sizing supply ranks as smart practice.

Smart Sourcing, Better Results

The facts point to high purity levels—often above 98%, with 99% more than accessible for most uses. Bottle sizes let you balance budgets against experimental needs, with everything from 1 to 100 grams offered straight from the source. This blend of reliable purity and flexible packaging gives control back to the chemist, researcher, or technician working hands-on. For those running modern labs, these factors represent more than numbers—they are the backbone supporting real, defensible results.