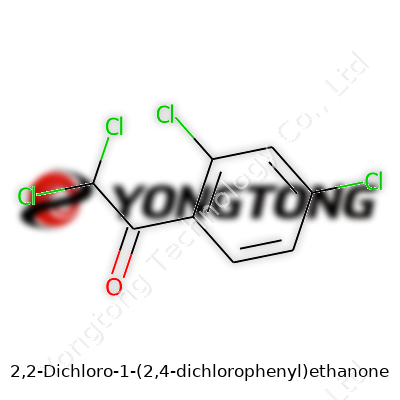

2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone: An In-Depth Look

Historical Development

Scientists started working with chlorinated compounds decades ago, especially as the chemical industry expanded in the twentieth century. Research into 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone dates back to investigations into organochlorides for synthesizing pharmaceuticals and specialty chemicals. As demand grew, researchers explored new reactions with phenyl ethanones, chasing both performance and cost-effectiveness. Early applications taught valuable lessons about stability, ease of production, and safe handling, leading to the protocols many labs trust today. Experiences from these years underscored the ripples that innovation in one corner of chemistry can send through everything from crop protection to advanced materials.

Product Overview

2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone is a mouthful, but the structure says a lot about its use. This molecule features a phenyl group flanked by chlorine atoms, which brings unique properties for synthetic chemistry, especially where halogen reactivity shapes the outcome. Folks in the lab sometimes call it by its trade names or slip into shorthand, but the core stays the same—a pivotal intermediate for creating a medley of target molecules. Most chemists see it as a valuable building block, not an end in itself, with reliable performance in both bench-scale and industrial contexts.

Physical & Chemical Properties

This compound generally appears as a pale yellow solid, often forming crystalline structures when pure. Melting points cluster around 60–65°C, offering some stability at room temperature but suggesting the need for appropriate storage. The molecular weight clocks in at 262.98 g/mol. Limited solubility in water, coupled with better dissolution in organic solvents, makes handling straightforward if you stick to the right protocol. Under normal lighting and lab humidity, the compound stands up fairly well, though chemists note it can degrade if left in the open for too long. Strong electrophilic character, thanks to the multiple chlorines, gives this molecule its signature behaviors in chemical reactions.

Technical Specifications & Labeling

Suppliers label 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone with clear purity data—most batches reach at least 98% by GC or HPLC verification. Packaging usually includes hazard communication, given the compound’s potential for irritation or toxicity, with clear markings about regulatory status depending on the jurisdiction. Careful record keeping tracks lot number, synthesis batch, shelf life, and any known impurities. Labs storing or using this molecule rely on secondary containment and keep up-to-date safety data sheets, signaling both regulatory compliance and dedication to workplace safety. Labels usually feature all alternate product names, which clears up any confusion and helps avoid costly mix-ups.

Preparation Method

Most producers synthesize 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone starting from 2,4-dichloroacetophenone, running reactions with chlorine under controlled temperatures and often with catalysts that favor selectivity. From years working with halogenation, it’s clear that using the right reagent stoichiometry makes or breaks the reaction yield. Experienced chemists know to watch for over-chlorination or unwanted side reactions—something I’ve seen eat through time and raw materials if teams aren’t careful. After chlorination, purification steps knock out unreacted precursors and side-products, usually involving recrystallization or advanced chromatography if high purity is a must.

Chemical Reactions & Modifications

The structure of this compound opens up plenty of chemistry. Nucleophilic substitutions swap out chlorines in a variety of ways, letting chemists tailor products toward different endpoints. In standard routes, modifications on the phenyl ring or the ketone group introduce new functionality, leading to everything from bespoke intermediates to bioactive scaffolds. Reductive methods shave off halogens, while coupling reactions link the structure to bigger frameworks. I’ve watched teams use this compound to springboard into heterocycle synthesis, drawing on those twin chlorines as reactive sites nobody else achieves at this price point.

Synonyms & Product Names

The world of chemical synonyms is always wild, and this one’s no exception. Alongside its IUPAC name, it goes by “2,4-Dichlorobenzal chloride,” in older literature, and sometimes pops up as “CS 5069” or “Chloracetophenone derivative” in catalogs. This naming history makes it wise to cross-check identifiers like CAS numbers during procurement or research, since the wrong label costs both time and safety. Familiarity with alternate names often comes from years in the field, chasing down supply glitches or double-checking references in a stack of papers.

Safety & Operational Standards

Labs using 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone set out clear procedures. Exposure risks range from skin and eye irritation to more severe problems at higher concentrations or with poor ventilation. My own training always emphasized using gloves, goggles, and fume hoods—anything less invites accidents, especially as the compound’s dust or vapors can irritate mucous membranes. Spill containment plans and eye-wash access make a real difference since reaction setups involving strong bases or extended heating carry extra hazards. Disposal never goes down the drain; teams collect all waste for proper hazardous treatment, which keeps labs compliant and neighbors safe.

Application Area

This molecule’s core audience comes from specialties like pharmaceuticals, agrochemicals, and materials science. Medicinal chemistry teams often use it as a springboard for more complex scaffolds, given the reactivity those chlorines bring. Crop protection research, aiming to create new pesticides or fungicides, also leans on this compound to build structures with specific toxicity profiles. Industrial teams might explore its use for dyes or specialty coatings, especially where chlorine content delivers the durability or performance required. Each of these fields relies not just on available chemistry but on rigorous standards for purity and supply chain traceability.

Research & Development

R&D pushes the boundaries on what chlorinated ethanones can do. From first hand experience, innovation here feels like both chemistry and strategy—blending known reactivity with high-stakes trial and error. Teams look beyond the original applications, chasing everything from more sustainable syntheses to routes that cut out less environmentally friendly reagents. Cross-disciplinary work stands out: chemists pair with toxicologists or regulatory experts, making sure discoveries aren’t hamstrung by compliance or market barriers down the road. The best progress comes from close networks—tight feedback loops between academic, industrial, and regulatory partners.

Toxicity Research

Studies show that like most highly chlorinated organics, this compound poses significant health risks if mishandled. Inhalation, ingestion, and skin contact all threaten long-term well-being—symptoms run from acute irritation to impacts on organ systems after repeated exposure. Animal studies note a range of toxic endpoints, influencing both workplace safeguards and environmental disposal laws. Teams commit plenty of resources to toxicological investigations, seeking new ways to minimize exposure and handle accidental releases. It’s not just about data for regulators; real-world experiences from lab workers drive improvements in everything from packaging to emergency response.

Future Prospects

Chlorinated ethanones like 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone will keep showing up as chemical innovation pushes forward. Demand for precision intermediates, especially where tailoring reactivity speeds up product development, keeps this category relevant. Researchers continue searching for cleaner synthesis paths, aiming to reduce hazardous byproducts and improve atom economy. My own colleagues talk up the potential for greener chemistry, yet nobody ignores the safety reputation these molecules hold. Regulatory pressure and market shifts may change the field, but as long as new materials and medicines drive discovery, solid intermediates like this one deserve attention and respect at every step.

What Purpose Does It Serve?

2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone often grabs attention in the world of agrochemicals and chemical manufacturing. This compound, roughly classified under the family of aromatic ketones, owes its presence to the production of certain herbicides and fungicides. Everything from its structure to its heavy chlorine presence points toward specialized chemical applications rather than everyday use by the typical consumer.

How It Ends Up in Agriculture

Farmers and agrochemical companies use many tools to protect crops from molds, fungi, and invasive weeds. 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone works mainly as a building block in the process. It forms part of the chain that leads to well-known agricultural products. For instance, it shows up as an intermediate in the manufacture of compounds like diclone, a potent herbicide. Here’s where the story takes a practical turn: without stable chemicals like this in the toolkit, growing enough food to feed large populations turns into a much riskier business, especially with climate swings and unpredictable infestations.

The Chemical Manufacturing Angle

Chemical companies handle this substance inside production plants that rely on a tight chain of custody and clear process oversight. That’s not just for safety, but also to keep waste and pollution in check. In my time working with chemical supply operators, I’ve seen firsthand how a molecule like this can enable large-scale manufacturing. Even a small hiccup during its handling could trigger regulatory alarms due to its persistence and toxicity.

Risks and Concerns

Put bluntly, this isn’t a garden-variety household chemical. Its high chlorine content can spell toxicity — for humans, animals, and aquatic life. Certain studies point to harmful breakdown products if it makes its way into rivers or groundwater. Occupational exposure also brings up valid worries. Chemical workers often wear heavy protective clothing and undergo rigorous health checks to avoid skin absorption or inhalation. In one well-run plant I visited in the Midwest, the health supervisor told me that even a brief lapse in protocol could force a whole line shutdown.

Balancing Benefits and Hazards

Production of chemicals like this helps maintain crop yields but creates waste that needs careful disposal. Regulatory guidance from entities like the EPA and OSHA fills a much-needed gap. After watching a compliance audit a few years back, it stood out how quickly companies would halt the production line if the containment gear failed, reinforcing how high the stakes run.

Potential Solutions

Rethinking current synthetic routes could pave the way for greener alternatives. Researchers keep testing new catalysts or less persistent intermediates with the aim of leaving less heavy metal residue behind. On the ground level, tighter reporting and monitoring protocols reduce environmental escape. Training gets a boost every cycle with real-life drills instead of just slide decks, and that builds a workplace culture where workers buy into safety rather than fear it.

Keeping advance notice on emerging green chemistry trends encourages manufacturers to shift gradually, balancing reliable crop protection with the real need for cleaner processes. Even something as simple as secondary containment upgrades at storage sites has kept accidental releases at bay in more than one facility I visited. Change may not happen overnight, but steady steps count.

Why Safety Can’t Be Overlooked

Anyone who’s spent time in a chemistry lab or worked with industrial chemicals knows accidents happen fast—sometimes because someone skipped a glove, sometimes because the air didn’t get vented right. Experience teaches that proper respect for chemicals sets the tone for health and safety at work. For 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone, a compound used in advanced synthesis, the risks come from its reactivity and toxicity.

Personal Protection: Rely on Layers, Not Luck

Some chemicals slip right through ordinary cloth. This one calls for nitrile or neoprene gloves, not the thin latex kind. Splash-proof goggles matter just as much—regular glasses never cut it. A disposable lab coat, long sleeves, and closed shoes are non-negotiable. No one enjoys burns or lingering rashes. Chemical-sensitive folks benefit from disposable respirators or well-fitted masks if airborne dust or vapor can form, especially during weighing or heating. I once underestimated a fume and felt the kickback in a sore throat for days. Never worth the shortcut.

Air and Storage Set the Stage for Safety

Fresh air keeps trouble to a minimum. Fume hoods with solid airflow pull vapors away from your face. Relying on open windows doesn’t protect enough—proper extraction is key. This compound doesn’t love heat or sunlight, so cool, dark cabinets prove best for storage. Tight, labeled containers with chemical-resistant seals keep spills at bay and make sure that nobody grabs the wrong powder by mistake.

Spotting and Handling Spills

A few years back, I watched a careless spill go from minor to major because no one knew the right cleanup. Small amounts can be trapped with spill pads designed for chemicals. Sweeping powders dry leads to dust clouds; dampen the area slightly and scoop up everything into a sealable waste bag. Never flush it down the sink—waterways don’t need more toxins. Wash the affected area with detergent and lots of water, then double-check with test strips if available.

Long-Term Health: Invisible Dangers Matter

Skin, eyes, and lungs can’t always signal problems right away. This compound irritates mucous membranes and, if inhaled, can set off coughing fits or trigger asthma in susceptible people. Ingestion brings much more serious risks. Chronic exposure can bring headaches, fatigue, and sometimes liver stress. Regular health check-ins and keeping an incident log save a world of trouble later.

Training for Everyone, Not Just the Experts

Clear, hands-on training beats online checklists every single time. Younger staff and everyone new to a job sometimes shrug off older workers’ warnings—until something goes wrong. Sharing stories of close calls makes rules real and memorable. Every operator benefits from knowing where the eyewash is, how to hit the ventilation switch, and whom to call for cleanup support. I’ve watched teams rally fast after good training, saving property and preventing injuries.

Waste Disposal: No Tossing in the Trash

Local, state, and national hazardous waste rules set the minimum. Don’t take shortcuts here. Chemically resistant, labeled waste drums, clear documentation, and certified pickups avoid headaches with inspectors and keep the broader community safe. Neighbors and family outside the lab rarely know how far chemical hazards can reach. Being diligent with disposal protects them just as much as it protects the worker handling the substance directly.

What Happens When People Work Around This Chemical?

Every morning, millions clock in at factories and labs, sometimes without knowing what’s inside those drums and bottles. One of those names that pops up on labels is 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone. This compound sounds like something out of a chemistry textbook, but it pops up in the real world—primarily in labs, agricultural uses, and maybe even in some specialty manufacturing.

Breathing in or touching this chemical causes concern. When chemicals contain several chlorine atoms bound to other rings, I think back to learning about organochlorines: many don’t play nice with the human body. Plunging into the safety data sheets (SDS), red flags show up—skin and eye irritation, possible breathing trouble, environmental persistence. Not the kind of thing to brush off, especially if you spend hours near open containers or apply it to crops.

Short-Term and Long-Term Effects

Brushing liquid on bare skin or inhaling its vapor can cause burning or itching. Folks who get an unexpected splash at work end up racing to the wash station. That's not paranoia—that’s learned behavior from seeing coworkers deal with chemical exposure. Chlorinated organic compounds sometimes irritate the lungs if inhaled. I’ve heard stories from lab techs who report sore throats and headaches after dealing with this family of chemicals for a day.

Longer contact raises more questions. Some studies from toxicology journals link similar compounds to nervous system issues and sometimes to possible carcinogenic properties when used repeatedly or without proper protection. Chlorinated ethanones aren’t just bad news for humans; their persistence lingers in soil and water. Once there, it’s tough to get them back out. That’s how problems grow, in ways most workers never see until someone crunches the numbers years later.

Looking at Safer Handling

I’ve seen safer labs in recent years. Tackling risk means proper gear—goggles, gloves, no shortcuts. Plenty of places now rely on fume hoods and vented storage for handling compounds like this. It’s not about paranoia; it’s about not losing days to coughing fits or worse.

Education helps the most. Training newcomers and giving them the power to question unsafe practices turns out to be one of the best investments. OSHA and international chemical safety boards publish clear guidelines—people just have to read them, ask questions, and expect answers. Companies that show protective measures actually work keep workers healthier. In one research job, regular air monitoring picked up trace chemicals before anybody got sick.

Are There Alternatives?

Green chemistry moves forward all the time. Replacing harsh chemicals with friendlier ones cuts down on health risks. Several companies now look for synthesis routes that skip over the worst offenders. I’ve seen that pressure from workers, buyers, and communities makes a real difference. If something hazardous can get swapped for a safer version, or if less-volatile forms can be developed, damage drops fast.

People shouldn’t have to choose between a paycheck and well-being. Knowing about the hazards hidden in long chemical names protects families, coworkers, and future generations. That’s the plain truth.

Getting the Basics Right

Handling chemicals can make even seasoned scientists a little uneasy, and with good reason. Mishaps don’t just cost money; they can put real lives at risk. This is especially true for substances like 2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone, which brings together some pretty reactive elements in one molecule. A chemical like this doesn’t announce its presence with a bang—more often, it causes slow, sneaky harm unless stored with real care. The danger isn’t just about poisoning, either. These compounds sometimes give off vapors, eat away at containers, or react with everyday materials in ways that catch people off guard.

Shelving Isn’t Just Shelving

It’s a comfort to have a locked storage cabinet, but the job doesn’t stop there. This compound asks for a cool, dry, and well-ventilated space—think storage that feels more like a wine cellar than an attic in July. Heat nudges chemicals to misbehave, and some plastics or cheap metals just won’t cut it as containers. Glass works for many chemicals, but here, a sturdy, chemical-resistant container with a tight-fitting lid keeps both moisture and air out. Any oxygen sneaking in can start a chain reaction. Put it near things like acids, strong bases, or even some household cleaners and you risk cooking up unexpected trouble.

Eyes Wide Open—Label, Separate, Educate

Walking around labs and storage rooms over the years, I’ve seen a simple sticky label—written boldly and clearly—save someone from a bad spill. Glancing down to remember an expiration date or what to do after a spill often happens in chaotic moments. Bottles shouldn’t sit where sunlight heats them or next to chemicals that don’t play nice with organochlorines. A set of shelves that puts this group with other chlorinated kin, and not with fierce oxidizers or solvents, can keep headaches at bay. It pays to check containers aren’t degrading or leaky, especially after a few months—it’s surprising how humidity or light can mess things up even behind closed doors.

Spill Kits Aren’t Optional

Early in my time handling chemicals, I learned the real test comes not on a planned day, but when something goes sideways. A spill kit, complete with the right absorbents and neutralizing agents, signals a lab or plant that pays attention. Responding quickly turns a disaster into a manageable cleanup. It’s not just about having gear, but training everyone who enters that space on how to use it—and practicing often enough that nobody needs to fumble around during an emergency.

Small Steps Make Storage Safer

A stubborn focus on the basics has the biggest impact: using the right containers, keeping lids tight, labeling boldly, and keeping incompatible substances apart. Tossing chemicals into any old cabinet isn’t just lazy; it invites problems that ripple out into headaches, lawsuits, or worse. Storage rules might seem fussy, but each one exists because somebody learned the hard way. Listening to those lessons and taking time for proper storage habits beats trying to clean up after a crisis.

Leaning on Community Wisdom

People who’ve spent years in the trenches handling chemicals tend to agree—doing things by the book pays off. Some of my favorite conversations with mentors started with stories about things going wrong, and how the right storage would have made the day less interesting. It helps to leverage both up-to-date safety data sheets and everyday wisdom from folks who know how stubborn these chemicals can get.

Focusing on Improvement

It helps to review safety protocols regularly with fresh eyes. Small investments in better shelving, clearer signage, or employee training have saved both lives and time. No one expects every staff member to remember every chemical’s quirks by heart, but a few good habits—reinforced every day—go further than any expensive gadget or lock.

Understanding the Backbone

2,2-Dichloro-1-(2,4-dichlorophenyl)ethanone isn’t a name most people throw around in daily conversation. Still, its structure and formula say a lot about why it has earned a place in chemical labs and industrial catalogs. On paper, the molecular formula reads C8H4Cl4O. The core of this molecule sits in a simple, yet powerful scaffold: a carbonyl group (C=O) linked to an ethane chain, decorated with chlorine atoms and a substituted benzene ring.

The Arrangement: Breaking Down the Structure

Peering at a model or a structural diagram, you’ll spot a benzene ring with chlorine atoms tagging the second and fourth positions — not something you find in natural aromatic compounds. This ring links through a single carbon to an ethanone moiety. Chlorines cling to the two available spots on the alpha carbon (the 2-position of the ethanone side chain), giving the whole thing an imposing chemical profile.

Why Structure Shapes Function

Chlorine atoms on organic compounds shift a molecule’s character. From experience handling such chemicals, compatibility jumps up and volatility drops. In practical use, the electron-withdrawing effects of multiple chlorine atoms boost the compound’s resistance to breakdown, making it a keeper in formulations that need persistent activity or stability under pressure. If you run a reaction with this molecule, you'll notice its robustness, thanks to a halogen-heavy scaffold.

EPA databases and the medical literature show that substitutions on aromatic rings change more than reactivity — they also play into toxicity and environmental persistence. With four chlorines, this compound stays put in the environment for longer than its simpler cousins. That’s not just a chemical trivia point; it’s a driver behind regulations and restrictions, especially in countries aiming to limit harmful residues.

Real-World Relevance: Safety and Utility

Many chemists, myself included, have run across similar structures while working on synthetic routes for pharmaceuticals, dyes, or agrochemicals. That 2,4-dichlorophenyl group often shows up in pharmacophores designed to tweak bioactivity. The ethanone chunk with its twin chlorines acts as a stubborn anchor, resisting quick breakdown but posing challenges for safe handling.

Toxicity always tags along with chlorine-rich organics. Documented reports in journals such as Chemosphere flag medium to high toxicity, particularly to aquatic life. Proper personal protective gear and closed systems help reduce accidental exposure. Disposal and cleanup mean more than rinsing a flask; it’s about following legal protocol while considering community and worker health.

Steps Forward: Addressing the Challenges

Synthetic chemists and regulatory teams both have a say in what happens next with molecules like this. For safer laboratory practice, electronic tracking of inventories and real-time air monitoring play a bigger role than ever. Replacing hazardous organics with greener alternatives grabs hold in education and industry, though success leans on performance and economics. For persistent compounds, advanced oxidation treatments and thermal destructors step in as last lines of defense against environmental release.

The Takeaway from Daily Experience

Chlorinated ethanone derivatives like 2,2-dichloro-1-(2,4-dichlorophenyl)ethanone remind us that the chemical world is as much about safety and ethics as it is about function. Clear labeling, training, and a willingness to seek better substitutes remain the strongest shields for anyone using these compounds. Safety and sustainability can’t play second fiddle, no matter how useful a molecule might look on a blueprint.