1-Bromo-3-fluorobenzene: Deep Dive into a Versatile Chemical

Historical Development

Synthetic chemistry has been shaped by the need for ever more precise building blocks. Take the story of 1-Bromo-3-fluorobenzene, a compound first mapped at a time when halogenated benzenes were gaining respect as foundational tools in both laboratories and industry. In my years shadowing veteran chemists, I found that substances like this one unlocked ways to build tailored molecules when the demand for pharmaceuticals and materials surged through the later half of the 20th century. Multi-halogenated benzenes have stretched the toolkit, allowing for tough cross-coupling experiments before palladium and copper catalysis became routine. The progress wound its way from simple halogenation experiments through academic journals into large-scale manufacturing by industrious players in Europe and Asia. Many that handle the material today stand on the shoulders of that early, determined research, mixing curiosity with necessity as they scaled up methods once limited to milligram quantities.

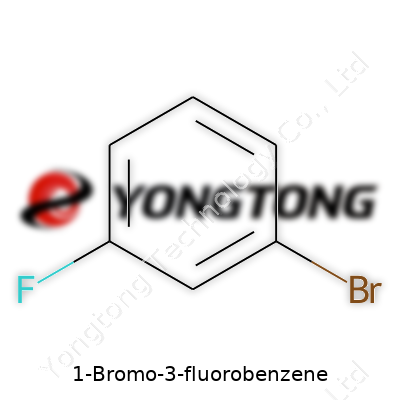

Product Overview

The molecule itself, with a benzene ring hooked to a bromine and a fluorine, packs punch in a small, clear liquid. 1-Bromo-3-fluorobenzene’s structure makes it a neat tool for researchers seeking to build up complexity by adding or swapping functional groups onto aromatic systems. Its broad utility comes from the selectivity offered by the combination of a bulky bromine and a small, electron-withdrawing fluorine, which steer reactivity in predictable ways—no small advantage for those looking to avoid long, wasteful purification processes and tough separations. Simple in presentation but packed with potential, the compound holds a permanent address in supply catalogs for organic synthesis and advanced materials work.

Physical & Chemical Properties

This molecule holds itself as a colorless to slightly yellow liquid, and people who have worked with it will point out its distinctive, somewhat sweetish aromatic smell—noticeable even with a well-sealed flask in a fume hood. Its boiling point hovers near 151-153°C under atmospheric pressure, and the melting point typically sits around -35°C. I remember an early lesson from the lab: make sure to keep it cool in storage to minimize evaporation, since the vapor pressure is significant above room temperature. Its density measures at 1.62 g/cm³, and in terms of solubility, you will not find it mingling with water, but it mixes well with most organic solvents. The molecule’s stability under basic or mildly acidic environments grants a chemist confidence that the ring will not fall apart in the early stages of a multi-step synthesis.

Technical Specifications & Labeling

Manufacturers tend to supply 1-Bromo-3-fluorobenzene with a purity above 98%, backed up with NMR or GC analysis for peace of mind. Bottle labels clearly state the CAS number 401-71-6, hazard icons, and storage advisories. My experience with lab audits underscores how regulators and buyers are unforgiving when it comes to clarity: bottles stuck out of sight with illegible or missing hazard signs cause real trouble. UN transport guidelines categorize it as a dangerous good, so every shipment follows strict paperwork and traceability requirements. Stickers indicating flammability and moderate toxicity don’t just serve legal needs—those small details often prevent incautious blunders among newcomers in the lab.

Preparation Method

Commercial synthesis of 1-Bromo-3-fluorobenzene usually pivots on selective halogenation. Industrial procedures typically begin with 3-fluoroaniline or fluorobenzene, channeling reactions through bromination using sources like bromine or N-bromosuccinimide, paired with iron or other Lewis acids to steer addition to the right ring position. Good process chemists fight side products by tuning temperature, solvent, and reaction time, often making use of column purification or distillation to pull the right isomer free from a soup of closely related compounds. The economics of making this molecule hinge on coaxing high yields and minimizing waste—something all too real to those who’ve slogged through sticky batch reactions full of unusable byproducts.

Chemical Reactions & Modifications

As an aryl halide, 1-Bromo-3-fluorobenzene shines in transition metal-catalyzed coupling reactions. Suzuki, Heck, and Buchwald-Hartwig couplings tap its reactivity, especially at the bromine position, to attach a rich variety of groups or to stitch together new carbon frameworks. My time handling these reactions underscored how the combination of bromo and fluoro shifts electronic effects around the ring, letting chemists push reactivity or flirt with unexpected selectivity. Nucleophilic aromatic substitution at the bromine spot invites amines or thiols, and even hydrogenolysis under mild conditions can strip the bromine for those needing a fluorinated benzene backbone.

Synonyms & Product Names

Chemists often encounter this compound listed under names such as 3-Fluorophenyl bromide, m-Fluorobromobenzene, or (3-fluorophenyl) bromide, depending on supplier and context. Confusion arises less for seasoned synthetic chemists than for students, who sometimes misorder the substituents during searches. In regulatory filings, clarity counts, so the CAS number 401-71-6 serves as the principal identifier, cutting through naming confusion no matter where you shop or manufacture.

Safety & Operational Standards

Handling 1-Bromo-3-fluorobenzene calls for proper respect. The vapor irritates eyes and lungs, and skin contact brings discomfort or mild inflammation, as many discover the hard way after a tiny splash during transfers. Standard personal protective equipment—nitrile gloves, safety goggles, and use of a ventilated fume hood—are not optional. Storage outside direct sunlight, kept in tightly capped amber containers, cuts down on both evaporation and photo-degradation. Some plants that use this material in scale-up mandate detailed exposure tracking. Emergency showers and eyewash stations, positioned close-at-hand, have seen use, especially from those new to halogenated chemicals. Proper training and adherence to established guidelines, such as those from OSHA or EU REACH, don’t just protect the individual—they safeguard ongoing research efforts from sudden, costly shutdowns.

Application Area

The appeal of 1-Bromo-3-fluorobenzene runs deep in pharmaceuticals, agricultural chemicals, and advanced materials. Drug discovery relies on halogenated aromatics as starting points for candidate molecules, seeking specific activity or metabolic stability. Agrochemical research leans on this molecule’s unique pattern of reactivity and hydrophobicity to fine-tune new active ingredients. I’ve watched research on liquid crystal displays and organic semiconductors draw on the precision offered by both bromo and fluoro tags—these seemingly simple tweaks ripple out to enhance electronic properties or tune light absorption for better devices. Sometimes, just a single atom swap, possible thanks to this compound, marks the difference between a bland intermediate and a billion-dollar blockbuster.

Research & Development

Academic groups and R&D teams steadily push the boundaries of this molecule’s chemistry. I’ve collaborated on projects seeking greener, lower-cost bromination methods, and automation now brings high-throughput synthesis within reach. Teams scrutinize every batch for impurities that could throw off biological tests. Increasingly, research pivots on sustainability: approaches that minimize halogenated byproducts or enable recycling attract investment and regulatory blessings. Beyond medicine and materials, applied research now explores 1-Bromo-3-fluorobenzene’s role in novel catalytic cycles and as a tracer for environmental monitoring studies, given the unique fingerprints left by fluorinated aromatics.

Toxicity Research

Laboratory animal studies and cellular assays indicate that 1-Bromo-3-fluorobenzene presents moderate acute toxicity. I’ve read the reports and seen how exposure can yield irritation and, in large doses, depressive effects on the central nervous system. Metabolism studies reveal both brominated and fluorinated metabolic byproducts, raising concerns about persistent organic pollutants if waste streams aren’t controlled. Environmental chemists caution against releases, citing limited but cautionary data on bioaccumulation and chronic exposure. The need for proper containment and disposal touches every phase, from benchwork to production plant, and remediation techniques continue to evolve as new data surfaces.

Future Prospects

Innovation in organic synthesis and materials development keeps extending the future for compounds like 1-Bromo-3-fluorobenzene. Researchers hope to make these building blocks not just cheaper and cleaner, but more selective, leaning on advances in catalysis and process intensification. As demand grows in precision medicine, smart materials, and environmental probes, those able to master both safety and scale stand to benefit most. Delivering greener synthesis routes, more reliable supply chains, and a detailed understanding of end-of-life impacts will shape the story of this modest but powerful molecule through the decades ahead.

Building Blocks in Pharmaceuticals

I’ve seen the way modern drug discovery depends on minute changes at the molecular level. 1-Bromo-3-fluorobenzene shows up a lot in these conversations as a building block. Medicinal chemists turn to this compound when they want to bring both bromo and fluoro functionalities into a single aromatic ring. This type of substitution can nudge a drug's structure closer to a new patent or even help a promising molecule dodge metabolic breakdown in the body, something that can boost a pill’s shelf-life or its effect in treating illness. According to papers from the Royal Society of Chemistry, the fluorine atom isn’t just another atom—its presence often toughens up molecules, making them less prone to break down too soon. That’s powerful for anyone aiming to design drugs that can survive long enough to reach their target.

Advancing Agrochemical Discoveries

In fields like crop protection, chemists often work under pressure to create pesticides and herbicides that are both tough and selective. By starting with 1-bromo-3-fluorobenzene, they can attach custom groups in a targeted way. Bromine gives a handle for swapping in new side chains using coupling reactions, while fluorine fine-tunes the compound’s effectiveness or even its environmental impact. The global drive for safer and more reliable crop treatments keeps demand strong. Recent studies from the American Chemical Society highlight how these tailored ring systems often lead to better performance when tested against pests but with less toxicity for humans and animals.

Shaping the World of Liquid Crystals

Anyone who’s ever owned a flat-screen television or used a digital clock has benefited from the chemistry of liquid crystals. These materials don’t just look neat; they form the backbone of display technology. Many of these crystals require aromatic rings with specific halogen atoms. 1-Bromo-3-fluorobenzene provides both size and polarity tweaks, leading to new crystal phases that improve how screens handle light and color. Companies in Japan and South Korea, top players in display manufacturing, have pushed for novel fluorinated aromatics to widen the color palettes and slash energy use in next-generation panels.

Roadblocks and Responsible Handling

Use of halogenated aromatics asks for planning and oversight. Before I even get near a lab shelf with this stuff, I see red hazard labels. Bromo- and fluoro-compounds can be stubborn about breaking down, raising eyebrows for environmental chemists. In cities with tight disposal rules, it isn’t just about tossing leftover chemicals in the bin. Proper capture and incineration or chemical neutralization keeps these molecules from slipping into water supplies. Green chemistry research pushes hard for milder reagents and more recyclable catalysts, aiming to protect both lab workers and neighborhoods near industrial sites.

Stepping Stones for Innovation

Every new breakthrough in medicine or electronics borrows from the set of starting materials that organic chemists can trust. 1-Bromo-3-fluorobenzene gives scientists access to more diverse chemical space, carving out a path toward better therapies, safer pesticides, and crisper TV screens. We owe much of this progress to days spent finessing reactions and handling tough molecules with respect for both their strengths and risks.

Getting Down to the Basics

Among the chemicals tucked away in any organic lab, 1-Bromo-3-fluorobenzene stands out because chemists often reach for halogenated benzenes when they’re working through synthesis problems. Understanding its blueprint calls for a close look at both the molecular formula and the molecular weight, as any misstep in either can turn a promising reaction into a frustrated puzzle.

Molecular Formula: What’s Inside the Molecule?

1-Bromo-3-fluorobenzene comes together with six carbon atoms, four hydrogen atoms, a single bromine atom, and one atom of fluorine. So, the formula reads C6H4BrF. Each one of those elements brings something different — carbon builds the aromatic ring, hydrogen fills the empty spaces, bromine takes its spot as a bulky neighbor, and fluorine crowds the other side with its own quirks.

I remember the first time I tried to draw the structure for an undergraduate exam. I made the rookie mistake of putting both halogens next to each other on the ring. The correct placement sets them apart, which changes both the chemical behavior and the reactivity. That simple lesson still sticks with me — structure really does rule everything in chemistry.

Molecular Weight: Crunching the Numbers

Detail matters when you need accurate measurements, especially in large-batch synthesis where a small error quickly multiplies. The atomic weights:

- Carbon (C): 12.01 g/mol

- Hydrogen (H): 1.008 g/mol

- Bromine (Br): 79.90 g/mol

- Fluorine (F): 18.998 g/mol

Add it all together and you find:

Carbon: 6 x 12.01 = 72.06 g/mol Hydrogen: 4 x 1.008 = 4.032 g/mol Bromine: 79.90 g/mol Fluorine: 18.998 g/mol Total: 174.99 g/mol

A gram or two off here could spell real trouble in bench work. In one past project, a misplaced decimal on the molecular weight meant the entire batch was way off target and had to be redone. Stories like this help underline the fact that every chemist leans on reliable numbers. The trust built on shared data roots itself in precision, not guesswork.

Why Does This Matter?

1-Bromo-3-fluorobenzene isn’t just a name on a label — it’s a starting point for a stack of pharmaceuticals, agrochemicals, and even new materials. With both bromine and fluorine tucked into a benzene ring, it gives chemists the flexibility to run all sorts of reactions, from nucleophilic aromatic substitution to cross-coupling reactions pioneered by folks like Suzuki and Heck. In my experience, using such well-defined intermediates made the difference between fast progress and endless troubleshooting.

Accurate molecular data strengthens safety and regulatory compliance, too. Overstating or understating weights during storage or transport can lead to violations or, worse, unsafe conditions. Years in shared research labs have taught me that the little details like these can impact the whole group’s workflow.

The Road Ahead: Using Scientific Principles Wisely

Every scientist carries a responsibility when handling chemicals like 1-Bromo-3-fluorobenzene. Constructing accurate records and communicating those specifics often saves time, money, and effort across the life of a project. Making sure details like the molecular formula (C6H4BrF) and weight (174.99 g/mol) are right is more than a box to tick; it’s the foundation for good science and safe practice.

Why Storage Practices Make a Difference

Chemicals don’t forgive sloppy storage. I’ve seen labs face plenty of trouble because a bottle ended up next to something incompatible. 1-Bromo-3-fluorobenzene belongs in the “handle with respect” category. With its halogenated structure, you get a compound that behaves differently from your household solvents. This isn’t something to leave sitting on a windowsill or to toss on any shelf. Safety comes before convenience.

Pain Points of Poor Storage

Let’s talk personal experience. Overcrowded chemical cabinets often tempt folks to cut corners. I remember a time in grad school when someone decided the fume hood was good enough for temporary flammable storage. The fire inspector didn’t agree. Regulations exist because chemicals like 1-Bromo-3-fluorobenzene present real hazards—think flammability, vapor hazards, and the risk of reaction with incompatible materials. Ignoring these issues ends careers, sometimes lives.

Effective Storage Habits

Every bottle of 1-Bromo-3-fluorobenzene deserves a sturdy, tight-sealing cap. Use amber glass when you can. Light can speed up chemical breakdown, especially with aromatic compounds laced with halogens. Exposing it to heat or sunlight nudges it past its safe period much quicker. Store it below eye level to cut the risk of spills. I grew to appreciate this rule the hard way after a midnight spill cleanup. Keep the temperature steady—2–8°C works for most organic halides—and avoid freeze-thaw cycles. Moisture sneaks in when you least expect it, so a dry, well-ventilated space behind a lockable door helps keep things under control.

Label Everything—No Exceptions

Faded or missing labels spell disaster. In one routine audit, we found a bottle nobody could identify. It took three anxious days, lots of paperwork, and hazmat suits to deal with it. Good labels include the full name, date of receipt, and hazard warnings. This habit saves time and nerves.

Segregation Beats Regret

Store 1-Bromo-3-fluorobenzene away from oxidizing agents, strong acids, and reactive metals. This isn’t a suggestion. A minor mix-up can trigger dangerous reactions. Chemical compatibility charts aren’t just classroom posters—they’re essential field tools. Large institutions use barcode tracking, but even a small-scale setup can manage proper segregation with color-coded shelves and simple inventory logs.

Ventilation and Personal Protection

Don’t depend on sealed bottles alone. The right cabinet provides more than a physical barrier; built-in ventilation pulls fumes away from work areas. I’ve seen workplaces invest in ducted cabinets, paying off in lower chronic exposure rates. Store personal protective gear nearby—nitrile gloves, goggles, and lab coats should stay close. It’s not overkill; it’s baseline protection.

Treat Every Step as Risk Management

It’s easy to treat chemical storage as a chore. Over time, I learned that mistakes compound. Every layer of care—from choice of storage container to habitually checking inventory—acts as insurance against accidents. The consequence of getting it wrong might not show up on day one. It’s the slow buildup that turns into a crisis.

Looking Toward Better Practices

Modern labs invest in smart inventory systems and continuous training. Even so, old-fashioned habits—closing lids tight, double-checking labels, sorting by hazard class instead of alphabet—still prevent most accidents. Make sure new staff get regular briefings. The chemicals don’t change, but the people handling them always do. Culture sets the tone for safety. That’s what keeps both the science and the scientists going strong.

Looking Beyond the Lab Bench

1-Bromo-3-fluorobenzene, a clear organic liquid, pops up in chemical research and the production of more complex molecules. Folks working in labs see it as just another compound stocked between solvents and reagents. On paper, this substance doesn’t jump out as some notorious toxin, but calling it harmless would leave out essential context. Not every chemical that lands on our shelves spells danger for the general public, but missing caution with this one brings real risks for anyone handling it directly.

Direct Exposure Risks

Europe’s CLP Regulation flags 1-Bromo-3-fluorobenzene as an irritant for both eyes and skin. Touching contaminated surfaces with bare skin can bring on redness or itching. Breathing in its vapors might lead to coughing, a scratchy throat, or more serious respiratory symptoms in poorly ventilated rooms. Splashes causing eye contact can sting much more than a bottle of vinegar, pushing anyone affected to rinse or seek help.

Long-term effects don’t always play out right away. Many aromatic halides, including this one, can accumulate after repeated or prolonged exposure. Chronic inhalation or skin contact—ten or twenty years on the job—raises the possibility of organ damage. We’re not talking about a drop splashed on your glove by accident, but ongoing carelessness building up over the years.

What the Science Tells Us

Neither the US Environmental Protection Agency nor the International Agency for Research on Cancer places 1-Bromo-3-fluorobenzene high on their danger lists. Its toxicology profile isn’t as dramatic as benzene or formaldehyde, but that shouldn't downplay everyday precautions.

Rodent studies suggest moderate acute toxicity. LD50 data point to harmful effects in gram-scale doses but not the kind of instant threat seen in cyanide or certain pesticides. Still, the unknowns about chronic effects mean that calling it “safe” creates a false sense of security. Just because a chemical’s risks aren’t spelled out by government panels doesn’t mean no danger exists, especially when dealing with specialty materials.

Keeping People Safe

Years of handling all kinds of chemicals have made me cautious. Proper usage always means gloves, goggles, coats, and, sometimes, fume hoods. Training matters. Teaching lab newcomers the habit of double-gloving solvents and keeping unfamiliar liquids under ventilation prevents those regrets that only show up when a safety report lands on someone’s desk. A lack of visible injuries never means the substance is harmless.

Facility managers and supervisors serve as gatekeepers. Clear chemical inventory logs, emergency showers, spill kits, and waste containers trace a direct line to fewer health scares. On the regulatory side, labeling and safety data sheets give teams up-to-date info. For smaller companies and university labs, regular safety drills and encouraging open reporting of any near misses can go a long way in building a culture that prizes safety over bravado.

Practical Solutions

To lower risks, companies should check that their safety data sheets are current and specific to this compound, not just generic templates. Rotating hazardous materials so no one worker gets overexposed keeps teams healthy. Setting up closed transfer systems or automated liquid handlers cuts down on spills and inhalation. Education offers perhaps the most cost-effective buffer between an accident and a well-run operation.

1-Bromo-3-fluorobenzene doesn’t call for panic, but it doesn’t deserve neglect either. Staying informed and following routine safety habits protect workers and communities alike from the slow build-up of avoidable harm.

Digging Into Purity Claims

Anyone sourcing 1-Bromo-3-fluorobenzene knows purity isn't just another checkbox—it's the difference between a successful synthesis and wasted resources. In the chemical business, I’ve had my fair share of headaches caused by “95% pure” labels, only to discover unwanted side products holding up the next step. Manufacturers usually offer 1-Bromo-3-fluorobenzene with a listed purity of 97% or higher. Lab-grade and ACS-grade options often reach 98% or just above, sometimes advertised as "high purity," but not quite hitting pharmaceutical standards. Only a handful of suppliers push their certification to 99% or more and those batches usually command a premium.

Why Purity Matters on the Lab Bench

During one project, contaminants in what should have been a simple halogenated aromatic led to unpredictable yields in a palladium-catalyzed reaction. We traced it back to low purity solvent, not the fluorobenzene, but it hammered home the lesson: overlooked contaminants threaten the whole result. Impurities can sneak through as isomers, unreacted starting materials, or trace moisture. The cleaner the starting material, the fewer headaches downstream, especially in medicinal chemistry or materials science labs.

Sourcing and Supplier Transparency

Not all product listings include a full Certificate of Analysis. Some just say “97% minimum” and leave it there. I always ask for a recent COA, not last year’s, to catch any batch-to-batch drift. In my experience, the best suppliers don’t flinch when you dig for data—they provide full NMR, GC-MS, or HPLC spectra to back up their claims. Chinese and Indian manufacturers sometimes offer lower prices, but purity ranges can vary more widely. North American and European vendors tend to stick closer to their stated numbers, though you’ll pay for that certainty.

The Role of Regulatory Requirements

Research, pilot plant, and large-scale production all place different demands on purity. For pharma intermediates or active pharmaceutical ingredients, limits on impurities can get very strict. The main issue I’ve seen in larger operations involves supply chain consistency. One supplier's 98% might be someone else’s 99%, just depending on the detection method. The best practice is always to specify which impurities matter—water, heavy metals, residual solvents—and double-check the data yourself, not just trust the number on a catalog.

Fixing the Purity Problem

End users hold more power than they think. Labs and buyers who consistently demand transparency create market pressure for better disclosures. Developing an in-house analytical check—NMR or GC—can catch surprise impurities before they trash your experiment. For the rare few who really need 99.5% or even higher, custom purification through distillation or preparative column work solves the problem, though it means extra work and cost. Some companies have started sharing more batch-data online, allowing quicker comparisons.

Raising the Bar

Seemingly small gaps in 1-Bromo-3-fluorobenzene purity carry big consequences in research and industry. The price shoppers might take home a few grams of trouble, while those who double-check purity, ask smart questions, and build relationships with reputable vendors save time and money. Getting the real story about purity always pays off, both in the lab and out in the production field.