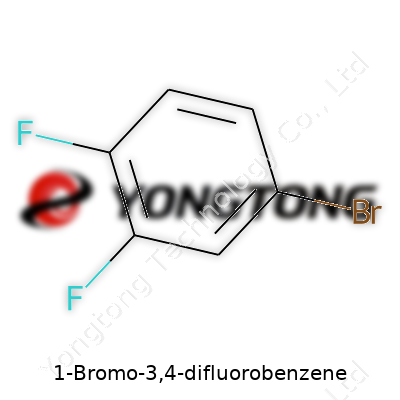

1-Bromo-3,4-difluorobenzene: Analysis and Perspectives

Historical Development

Chemistry has a rich record of small changes leading to big breakthroughs, and 1-Bromo-3,4-difluorobenzene tells part of that story. Decades ago, chemists figured out that tinkering with the benzene ring—adding bromine here, swapping in fluorine there—gave rise to compounds with new features. The effort wasn’t only academic. Chemical companies hunted for substances that fit into manufacturing, pharmaceuticals, and materials science. By the 1970s, improved halogen exchange techniques and selective substitution opened a path for mono-bromo, di-fluoro benzenes. Companies started offering these chemicals as research standards and intermediates, using ever more reliable analytical tools for quality assurance. Every time I worked in a synthetic lab, the simple act of combining old-school halogenation and improved purification made me appreciate how long, and how collaborative, the evolution of such compounds really is.

Product Overview

1-Bromo-3,4-difluorobenzene stands out as a halogenated aromatic compound, carrying both bromine and fluorine atoms on its benzene ring. It serves as a building block in the synthesis of more elaborate molecules. Over the last decade, fine chemical suppliers have streamlined its integration into catalog offerings, providing reliable vials for pharmaceutical labs and industry. Its presence in chemical supply houses speaks to growing demand for tailored fluorinated aromatics, driven mostly by drug development and agrochemical R&D. In day-to-day work, clear labeling and consistent quality made life easier when setting up syntheses requiring halogenated intermediates.

Physical & Chemical Properties

This compound behaves like many of its close relatives. It appears as a colorless to pale yellow liquid, with a molecular weight around 209.99 g/mol, a boiling point in the 174-176 °C range, and moderate volatility. The density lands near 1.66 g/cm³ at room temperature. Fluorine substitutions push the molecule toward greater chemical resistance, while bromine on the ring increases reactivity in certain coupling reactions—handy when modifying the core or extending the molecule. The odor is faint and aromatic, easily distinguished by anyone who has worked with similar halobenzenes. Solubility remains poor in water but strong in organic solvents like dichloromethane and acetone. Its chemical resilience to acids and bases shaped its use in reaction planning, where harsh conditions might degrade less robust substrates.

Technical Specifications & Labeling

Products sold as 1-Bromo-3,4-difluorobenzene generally carry a minimum purity of 98%, with impurity profiles disclosed for research-grade versus industrial-grade material. Key identifiers on the bottle usually include CAS number (38572-80-8), molecular formula (C6H3BrF2), and batch number, plus clear hazard icons in line with GHS guidelines. Reference standards often come with certificates of analysis, providing NMR and GC-MS data so users can trace batch identity and check actual purity. I always checked these before running multi-step syntheses, since even small contamination can derail later reactions.

Preparation Method

Making 1-Bromo-3,4-difluorobenzene usually involves selective halogen exchange, using a difluorobenzene precursor and a bromination agent like bromine or N-bromosuccinimide in the presence of a Lewis acid. Sometimes, alternative routes start from a bromobenzene core, then introduce fluorine through direct fluorination with reagents like Selectfluor or DAST. Each path has tradeoffs: some give better yields, some offer easier purification. Large batches often use liquid-liquid extraction with organic solvents and careful distillation. In university labs, I learned that tweaking temperature or changing the reaction solvent sometimes made the difference between a pure product and a stubborn mixture. Every scale-up demands attention to pressure, temperature, and the exothermic nature of halogenations.

Chemical Reactions & Modifications

1-Bromo-3,4-difluorobenzene steps into many synthetic schemes. Its bromine atom supports cross-coupling reactions—Suzuki, Heck, and Sonogashira couplings—opening the door to crafting biaryls, alkenes, or alkynes. The two fluorine atoms can nudge reactivity patterns, guiding new additions to specific ring positions. Reduction, nucleophilic aromatic substitution, or directed ortho-metalation prove possible, letting chemists adapt the molecule for new drugs, polymers, or agrochemicals. Aromatic bromides like this one provide reliable handles for building complex structures, and as I’ve seen in lab notebooks, the reaction partners often switch based on what functional groups researchers hope to add downstream.

Synonyms & Product Names

Across chemical catalogs and academic references, you’ll see a parade of names: 1-Bromo-3,4-difluorobenzene, m-Bromo-3,4-difluorobenzene, or 3,4-difluorophenyl bromide. Some suppliers shorten things to DFBB or 3,4-DFBBr. Though the variations might confuse newcomers, the CAS number ties them together. Each label marks the same structure: a benzene ring with bromine at the 1-position and fluorines at 3 and 4.

Safety & Operational Standards

Working with 1-Bromo-3,4-difluorobenzene involves classic lab precautions. The liquid can irritate skin and eyes, so gloves and goggles count as standard gear. Inhalation of its vapors should be prevented through proper ventilation or use of a fume hood. Storage calls for sealed containers, away from light and moisture. Spill kits with absorbent material keep accidents manageable. Waste disposal follows hazardous organic waste streams, marked by the persistent halogens. Every facility I worked in kept up-to-date SDSs within arm’s reach and required annual hazard training. Simple habits—like clearly labeling all containers and double-checking connections—ease the risk, especially for those handling the chemical in quantity.

Application Area

Scientists leverage 1-Bromo-3,4-difluorobenzene in multiple industries. Pharmaceutical companies use it to piece together fluorinated drug molecules, taking advantage of the metabolic stability brought by fluorine. Agrochemical innovation draws on the same properties, crafting pesticides or herbicides that resist breakdown. Synthetic chemists studying new materials appreciate its easy integration into polymers or electronic intermediates. I’ve seen academic projects use it for ligand synthesis, too, while manufacturing sectors demand bulk quantities for scale-up studies. Every time I encountered this reagent, the context shifted based on the creativity of the chemists—sometimes making branded pharmaceuticals, other times developing specialty plastics or OLED display materials.

Research & Development

In the research world, this compound fosters innovation. Method development teams use it for cross-coupling protocol trials, comparing yields across catalysts and solvents. Medicinal chemists deploy it as a precursor in libraries of potential drug candidates. Instrument companies use it as a check for their GC and LC instruments due to its purity and volatility. Throughout my career, I noticed that R&D output with halogenated arenes surged due to fast communication between academic inventors and private companies. Each year brings modifications on earlier reaction schemes, striving for higher efficiency, less waste, and safer reagents. Efforts also go into tweaking the electronic properties of the benzene ring, aiming for even better selectivity in complex molecule assembly.

Toxicity Research

1-Bromo-3,4-difluorobenzene does not see widespread toxicity studies in the same way as more heavily used industrial chemicals, but halogenated aromatics generally raise red flags concerning persistence and biological effects. Short-term exposure in the lab rarely links to overt health effects if good practice holds, yet agencies still recommend limited handling and avoidance of inhalation. As fluorinated aromatic rings often resist biodegradation, environmental release should be minimized. Companies and universities run precautionary chronic toxicity screening to identify possible risks in new derivates or larger-scale deployments. Governments around the world stress full disclosure of any long-term hazards, and keeping up with evolving safety data stands as an obligation for researchers and manufacturers alike.

Future Prospects

Looking ahead, demand for 1-Bromo-3,4-difluorobenzene will likely grow, especially with the rise of designer pharmaceuticals and specialty fluoropolymers. Chemists keep discovering new methods for site-selective fluorination and efficient cross-coupling, both of which rely on readily available halobenzenes. Sustainability pressures nudge companies to develop greener production techniques—perhaps relying on catalytic or electrochemical halogenation to cut down hazardous waste. As digital technologies make chemical development faster, labs will search for reliable intermediates with proven safety profiles and stable supply chains. In my conversations with industry colleagues, more end-users request compounds with transparent provenance and environmentally responsible certification. The compound’s future will depend not only on its chemistry, but also on how suppliers handle safety, environmental, and regulatory demands.

A Closer Look at the Formula

Anyone who's picked up a chemistry textbook knows that figuring out the formula of a compound usually starts with breaking down the name. In this case, 1-Bromo-3,4-difluorobenzene tells a straight story. One bromine atom sticks itself onto the first carbon of a benzene ring. Two fluorines land on the third and fourth carbons. The rest of the positions on that six-carbon ring fill with hydrogens. Stack those pieces together, and you get C6H3BrF2.

Why the Precise Formula Even Matters

In research settings and labs, chemists depend on that specific formula. Guesswork gets people nowhere in synthetic chemistry or pharmaceuticals. I’ve watched a colleague scramble after using a mislabelled reagent—one small difference in atomic structure can throw an entire reaction off course, change a compound’s physical properties, or tweak its toxicity. With fluorinated aromatics like this one, precision is everything. Mistaking where the fluorines sit, or mixing up a chlorine for a bromine, could derail a team’s efforts for weeks or even months.

Application Beyond the Lab Bench

These halogenated benzenes can turn up as core building blocks in everything from agrochemicals to drugs. Adding a bromine or a few fluorines to a benzene ring can completely change how a molecule behaves. More and more, chemists choose fluorines for their knack of influencing metabolic stability and bioavailability. The presence of both bromine and fluorine in this molecule hints at specialized uses or more targeted reactions. Working with a clear formula lets manufacturing professionals meet regulatory controls, keep traceable records, and stay honest with customers.

Stumbling Points Along the Way

Plenty of folks in industry feel the squeeze: pricing, availability, and purity always raise questions. Many labs count on importing basic chemicals or face long lead times. If the documentation doesn’t match up with the real product—especially with imported chemicals—there’s a real risk. On top of that, handling these benzene derivatives isn’t risk-free. Brominated and fluorinated aromatics tend to come with clear warnings regarding skin contact, inhalation risks, and waste disposal.

Smarter Chemical Sourcing and Transparent Communication

Plenty of problems spring from misunderstanding or miscommunication—sometimes labels get lost in translation, or a supplier takes a shortcut. In my experience, double-checking batch records, working with reliable suppliers, and investing in routine analytical checks help keep the labs running. Tech like NMR and mass spectrometry now lets quality control teams verify that C6H3BrF2 really is what’s in the bottle. More open channels with regulators and transparent supply chains make life easier for everyone in the long run.

Best Practices in Chemical Handling

Storing these kinds of chemicals needs a proper approach—separated from incompatible materials, in labeled glass containers, and behind locked doors. Waste must go to licensed processors, not down the drain. Training helps keep new hires alert to the risks, and makes sure no one skips safety steps in a rush. Mistakes due to poor labeling or mixed-up containers happen more often than folks admit, but creating strong habits goes a long way.

The Chemistry Piece

Looking at formulas might not mean much for most people, but a lot happens behind the scenes in science labs that shapes what lands on pharmacy shelves or inside circuit boards. Take 1-Bromo-3,4-difluorobenzene—a mouthful to say, but a workhorse that plays a quiet role in several practical fields. Working in a research lab, I saw how specialty chemicals like this one show up across the value chain, making sure vital reactions happen the right way.

Medicinal Chemistry and Drug Discovery

Drug design always needs building blocks that add the right properties to molecules. 1-Bromo-3,4-difluorobenzene comes in handy here. Scientists use it to tack on difluorinated pieces in drugs. Those two fluorine atoms aren’t just for show—they help potential medicines last longer in the human body and sometimes stop drugs from breaking down too soon. Adding a bromine group means chemists can swap things out mid-reaction, tweaking molecules for better performance. Some projects at our lab focused on exploring new cancer therapies and antiviral drugs, and this compound regularly showed up on reagent lists. Its stable structure helps push research forward faster when the clock matters.

Materials Used for Electronics

Moving from medicine to gadgets, organic compounds with halogens like bromine and fluorine help electronics play nice with heat and electricity. Researchers use 1-Bromo-3,4-difluorobenzene to create polymers and organic materials for semiconductors. In my time talking to friends in the electronics field, they pointed out how certain molecular tweaks improve a material’s insulating strength, which keeps chips from failing. Fluorinated aromatic rings provide thermal stability, and the bromo group acts almost like an anchor for connecting to other pieces.

Organic Synthesis and Crop Protection

Most students don’t get excited about organic synthesis, but chemists in agrochemical companies rely on compounds like this to craft better pesticides or herbicides. Fluorine atoms make the resulting products more resistant to breakdown in sunlight or rain. Bromine gives flexibility for adding new features. I’ve seen research that shows difluorinated benzene derivatives can deliver stronger activity against weeds and pests without as much chemical drift. That helps farmers use less product while keeping yields strong.

Challenges and Safer Handling

Using chemicals like 1-Bromo-3,4-difluorobenzene comes with responsibility. In the lab, spills and exposure are never a joke. Though not the most hazardous of compounds, proper ventilation, gloves, and eye protection should always be the norm. I once had a colleague who skipped gloves on a busy day and ended up with skin irritation—a reminder that even routine chemicals deserve respect. To reduce risks, many facilities now switch to closed systems and automation for handling halogenated benzenes, cutting down on human error.

Looking Forward: Smarter Approaches

Science rewards those who chase better, safer, and greener options. Researchers continue to explore how difluorinated aromatics can boost performance without raising toxicity or creating long-lived environmental byproducts. Companies fund new ways to recycle solvents and reduce emissions. By supporting solid research practices, sharing safety stories, and backing eco-friendly tweaks, we avoid shortcuts that might harm workers or the world outside. Experiencing the busy pace and high standards up close made me realize that choosing the right chemistry isn’t just smart—it’s necessary.

The Reality of Handling This Chemical

Years of working in labs and talking with folks who handle industrial chemicals have taught me one thing: underestimate a material, and things can go wrong fast. 1-Bromo-3,4-difluorobenzene may sound like just another reagent on a shelf, but it packs real risks for those who get too comfortable. Beyond odd names and scientific jargon, basic respect for safety separates a smooth experiment from a trip to the doctor.

Direct Risks and Why They Matter

This compound brings eye, skin, and respiratory irritations. A splash to the eyes stings intensely, redness follows quickly. Touching skin can cause rashes or even chemical burns with enough contact. Breathing its vapors doesn't help lungs any, either; headaches or dizziness sometimes show up, especially if ventilation falls short. Safety data sheets spell this out, and they don’t exaggerate based on hundreds of reported lab incidents and poison control guidance. A bottle cracked during shipping once, and the irritation nearly cleared the whole room. That left a mark on our team’s caution.

Personal Protective Gear Isn’t Optional

Some colleagues scoff at goggles or gloves, figuring short tasks don’t need full PPE. That approach lands workers in trouble more often than they admit. Basic lab gloves (nitrile holds up well) stop most splashes. Tight-fitting goggles block stray drops. A simple lab coat keeps chemical stains off clothes—those can transfer residue to skin hours later. Chemical fume hoods do more than look official; they whisk harmful vapors away from anyone standing close by.

Storing and Moving with Care

Keep this compound in a sealed, chemically compatible bottle, away from heat and direct light. Even low humidity matters—too damp, and you risk container corrosion or label decay. After a leaky lid at our bench, extra inspection of bottles became a habit. Labeling may sound basic, yet mix-ups caused by faded ink or mismatched scripts sideline experiments and waste money. Transportation outside the lab needs secondary containers. Spill kits should always be nearby, ready for a quick clean-up.

Ventilation Takes Center Stage

Safe spaces start with good airflow. Fume hoods pay off in both big research sites and cramped teaching labs. Mechanical ventilation, with air pulled outside, removes not just smells but invisible vapor hazards. Opening a window helps in a pinch yet leaves too much to chance in case of a big spill. Maintenance checks on ventilation equipment catch failing fans before fumes find human lungs.

Disposal: Not Just a Toss in the Trash

Waste disposal for anything brominated falls under strict rules. Tossing leftover solutions with regular trash or pouring them down the sink doesn’t cut it. Licensed disposal companies collect chemical waste and process it so local water or soil stays clean. Many places also log each gram discarded to prevent accidental releases or environmental fines. It sounds tedious, but these records back up safe operations and satisfy inspectors.

Building a Culture of Caution

Big safety improvements come from teamwork and shared caution, not just reading manuals. New trainees watch how veterans react to small spills and store chemicals, picking up habits that spread out across the lab. Routine training, real talk about past near-misses, open reporting—this stuff matters more than bullet-pointed lists. Rising safety standards and keeping each other accountable keeps everybody safer at work and brings those lessons home, too.

Why Chemists Care About Purity

Purity matters a lot in chemical synthesis. It’s easy to gloss over the numbers, but ask anyone who’s crunched through a multi-step synthesis and seen a bad yield: the smallest impurity can gum up a whole pathway. In the world of fine chemicals, nobody wants surprises. For 1-Bromo-3,4-difluorobenzene, manufacturers typically promise a purity anywhere from 97% to above 99%. A reputable producer often certifies GC content above 99.0%. You see those figures in spec sheets, but real trust comes from third-party validation and solid documentation.

Behind the Purity Numbers

Industry lab habits lean heavily on Gas Chromatography for these purity checks. The main value describes the portion of the sample that matches the intended molecular fingerprint. Moisture content and residual solvents pull the rest down. Analytical tricks like Karl Fischer titration pin down water. Even small levels of water can set off side reactions or slow down a planned halide exchange. I’ve seen a whole team stuck for days simply because leftover moisture kept tripping up a coupling reaction. That’s why water content lower than 0.5% shows up in good spec sheets for this compound.

Heavy metals and halogen impurities are another headache. Sometimes tin or palladium creep in from catalysts used in previous steps. Makers with a strong track record often report levels well below 10 ppm for each. Unless the supplier gives a full Certificate of Analysis with these details, you’re rolling the dice for pharmaceutical applications or electronics.

Traceability and Real-World Demands

It’s one thing to hit a high number on a fancy instrument. Another thing to actually verify the batch hasn’t picked up contamination in the warehouse or shipping process. Purity guarantees fall apart without good storage and traceability. Reputable suppliers invest in ISO-certified processes. They back every shipment with batch numbers and shelf lives. This transparency helps users trace issues when something goes wrong in the lab.

I remember hearing about a materials startup that spent weeks probing an unexplained signal in their NMR spectra. The culprit? Tiny amounts of dibromide left over from a poor separation process. Small mistakes travel a long way—especially if you’re pushing for trace-level analysis in electronics or pharmaceuticals.

Solutions and Steps Forward

One path that’s worked well in my experience is building direct relationships with suppliers. Anyone running sensitive chemistry benefits from getting samples analyzed in-house. Simple comparative testing often flags lot-to-lot variation that doesn’t turn up in paperwork alone. If a spec sheet lacks details or skips method descriptions, that’s a warning sign. Demand to see validation data, especially for methods like GC, NMR, or ICP-MS for metals.

Bigger labs often invest in contracts with added quality clauses, which guarantee not just purity but also documentation around safe handling, stability, and remediation procedures if something looks off. Those safeguards save money down the line. There’s a real risk in shortcuts, and real value in knowing exactly what’s in your chemical bottle. These steps support safer workflows, cleaner outcomes, and ultimately more trust between producers and users. Transparency and routine checks—those keep the science moving forward.

The Real Risks of Mishandling Chemicals

In every lab I’ve worked in, storage practices separate smooth, safe days from real headaches and hard cleanups. 1-Bromo-3,4-difluorobenzene isn’t the sort of compound you want to cut corners with. It’s not just another bottle on the shelf. If you let a halogenated compound like this sit out, you’re asking for slow changes to its chemical makeup and slow leaks of its fumes. A small shift in stability can mess up reactions, introduce new hazards, and even cost your project weeks of work or worse.

Temperature and Protection from Light

A room’s warmth and a room’s chill may not bother us, but they sure impact chemicals on a molecular level. 1-Bromo-3,4-difluorobenzene holds steady at room temperature, but sunbeams streaming across the bench drive reactions you might never see until something goes wrong. From personal experience, nothing spoils a solvent or reactant faster than leaving it in direct sun — discoloration, weird odors, ruined runs. Shelving this chemical away from light is not for peace of mind; it’s for dependable results and safe air quality in the lab. UV rays, even through a window, act like a slow-motion chain reaction on halogenated benzenes.

Tight Lids, Low Humidity, and Ventilation

A chemical like this comes with its own set of annoyances. If humidity creeps into an open flask or loose cap, the whole sample turns from crisp and clean to a puzzle of side-products and gunk. You won’t always notice until it’s too late, and purity tests start coming back off. That’s why those brown glass bottles and screw caps matter so much. Even in a well-run lab, fumes from aromatic halides tend to travel — people might not register a hint of smell, but that doesn’t mean inhalation risks went away. Storing these sorts of chemicals under tight lids, away from moist, musty corners, keeps the work environment healthier for everyone and protects the underlying investment in these expensive reagents.

Labeling and Inventory Control

A safe, well-oiled operation relies on being able to reach for what you need — and knowing exactly what’s inside every bottle. A simple label with the date received, purity, and hazard warnings beats digital spreadsheets on busy days. My own stints in both teaching and industry labs taught me how easy it is to lose track of shelf life or small leaks if the same careful person doesn’t check periodically.

Disposal and Emergency Readiness

No one likes thinking about what happens if a bottle breaks or starts to leak — even less so with organohalides known for their persistence in the environment. Having spill kits nearby, absorbent material, and a clear path to the chemical disposal station helps the team snap into action instead of scrambling. From fire to accidental exposure, these small, daily habits draw a sharp line between safety and a costly mess.

Building Good Habits for Chemical Health

Working with compounds like 1-Bromo-3,4-difluorobenzene means more than locking the cabinet and moving on. It’s about daily routines: checking lids, reading labels, logging storage times, and training the next generation to treat every new bottle with respect. The science community shares plenty of stories about incidents that started because someone dropped their guard. Good storage means thinking ahead, protecting teams, and giving research the chance to succeed without avoidable trouble.