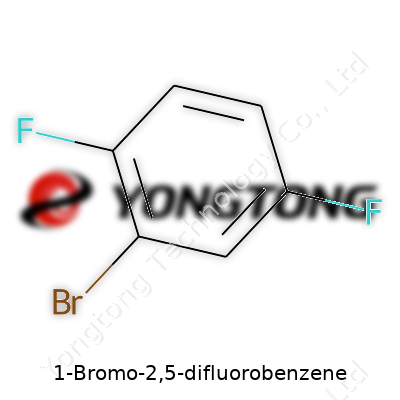

1-Bromo-2,5-difluorobenzene: A Deep Dive

Historical Development

Chemists have tinkered with halogenated aromatics since the early developments of dyestuffs and pharmaceuticals in the late nineteenth century. 1-Bromo-2,5-difluorobenzene owes its roots to advances in selective halogenation in organic synthesis by the mid-1900s, as interest in halogen-flanked arenes ramped up to supply new intermediates for fine chemical manufacture. Fluorinated aromatics gained particular value for their roles in diagnostics and materials science. My own reading of patent literature shows companies in Europe and Japan competing to patent better routes to multi-halogenated benzenes through the late 1970s and 1980s, aiming to cut costs and boost selectivity. This compound showcases how persistent research can transform simple building blocks into powerful, versatile reagents for a surprising range of uses, far beyond the benchtop.

Product Overview

1-Bromo-2,5-difluorobenzene stands out as a specialty intermediate, mostly delivered as a pale yellow liquid for research and manufacturing. It carries the formula C6H3BrF2 and a molar mass near 193.99 g/mol. Chemists recognize it as both a useful reactant and a highly specific molecule thanks to bromine and two fluorine atoms sitting at precise ring positions. Demand for this compound stretches from agrochemical pilot plants to the bustling labs of OLED researchers, since halogens often tweak molecular electronics and bioactivity in vivid ways. The combination of bromo and difluoro substituents rarely occurs by chance in nature, which helps this molecule hold its own in crowded catalogs of fine chemicals, marking it as a real taskmaster for synthetic design.

Physical & Chemical Properties

I've handled halogenated aromatics with comparable properties: 1-Bromo-2,5-difluorobenzene exhibits low viscosity, fair volatility, and a strong, somewhat pungent odor common to its class. With a boiling point reported around 163–165°C and a melting point near -29°C, it can be bottled and shipped in liquid form without special refrigeration. Its moderate density (about 1.69 g/cm³) and refractive index (roughly 1.54) signal its substantial halogen content. The compound resists water but dissolves smoothly into organic solvents like dichloromethane or ether, making it reliable for phase-transfer or extraction. The presence of both bromine and fluorine modifies its reactivity compared to chloro or non-halogenated relatives, creating new opportunities for controlled functionalization. It handles mild laboratory conditions but demands respect for its volatility and potential to cause irritation.

Technical Specifications & Labeling

Manufacturers typically ship 1-Bromo-2,5-difluorobenzene as a clear to slightly yellowish liquid in glass bottles or sealed metal cans, labeled according to international chemical transport rules. Purity usually tops 98%, sometimes reaching above 99% for demanding synthetic work. Labels specify UN numbers and GHS pictograms for hazardous materials, reminding users of risks tied to flammable and irritating substances. Chemical companies often include batch numbers, analysis certificates, and storage recommendations—critical details for ensuring that chemists don’t tackle inconsistent starting materials. Barcodes and QR codes now show up on bottles, linking users to full digital safety sheets and test results, which helps maintain traceability across international supply chains.

Preparation Method

Synthesis of 1-Bromo-2,5-difluorobenzene draws from classic electrophilic aromatic substitution and modern cross-coupling. A common approach starts with 1,4-difluorobenzene, exposing it to bromine or N-bromosuccinimide in the presence of a Lewis acid catalyst. Some use more selective palladium-catalyzed bromination, which grants tight control over ring substitution, suppressing unwanted isomers. In the past, some labs relied on labor-intensive methods, including elaborate protection-deprotection strategies. Modern procedures focus on minimizing hazardous byproducts and maximizing atom economy. Over the years, greener protocols have emerged, cutting down on reaction waste by dialing in the right mixture of solvents, temperature, and reaction time. This convergence of new technology and classic methodology mirrors the broader progress in organic synthesis—always chasing greater precision and lower environmental burden.

Chemical Reactions & Modifications

The bromine atom on the aromatic ring creates a versatile handle for further manipulation. Suzuki, Sonogashira, or Heck couplings swap out bromine for carbon-rich fragments, letting chemists build complex structures for material science or drug development. The difluorinated positions present additional handles: mild nucleophilic aromatic substitution installs oxygen, nitrogen, or sulfur-containing groups. In my own lab days, I watched these sorts of functionalizations quickly lead to libraries of analogues with improved thermal stability or altered bioactivity, compared to non-fluorinated counterparts. That combination makes this compound a common launchpad in synthetic projects hunting for new agrochemicals, pharmaceuticals, and advanced polymers.

Synonyms & Product Names

Don’t be surprised to see 1-Bromo-2,5-difluorobenzene listed under different names across catalogs and research papers. You occasionally run across “1-bromo-2,5-difluorobenzene,” “benzene, 1-bromo-2,5-difluoro-,” or “2,5-difluoro-1-bromobenzene.” For regulatory or transportation records, the name sometimes shortens to its chemical formula, and for inventory systems, simple abbreviations like “BDFB” show up. Many large distributors assign their own product codes as well. Recognizing all these aliases helps prevent costly confusion, especially when ordering specialty intermediates or cross-referencing patents.

Safety & Operational Standards

Anyone working with 1-Bromo-2,5-difluorobenzene knows that lab safety isn’t optional. Vapor can irritate eyes and mucous membranes, and liquid spills risk burns or allergic skin reactions. Globally-recognized GHS rules kick in, with recommendations that include gloves, splash goggles, and fume hoods as bare minimum. I remember supervisors insisting on double-checking venting systems whenever handling halogenated arenes. Some older literature downplays toxicity, but current data highlight risks with chronic exposure. Proper waste disposal requires neutralization or incineration, never pouring down the drain, as environmental agencies view heavily halogenated organic waste as persistent and bioaccumulative. Newer production plants build in spill containment, real-time air monitoring, and automated shutoff systems—showing industry’s shift toward strict operational control to protect workers and surrounding communities.

Application Area

Electronics manufacturers covet 1-Bromo-2,5-difluorobenzene for building blocks in OLED emitters, as the unique pattern of fluorination and bromination lets scientists tune optoelectronic performance. In small molecule medicinal chemistry, the compound often kicks off syntheses leading to experimental drug candidates targeting kinases, viral enzymes, or central nervous system targets. Agrochemical companies look for these halogen patterns to modulate metabolic breakdown and improve crop persistence. Environmental chemists cite its use as a tracer or stable intermediate for studying pollutant transport. I’ve seen researchers manipulate core structure to develop sensors, dielectric films, and low-surface-energy coatings. This diversity underlines why demand for specialty halogenated benzenes persists in both classic and cutting-edge application spaces, especially as global research into new therapies and alternative energy sources accelerates.

Research & Development

Research labs keep making new variants that start from 1-Bromo-2,5-difluorobenzene, testing for brighter OLED emission, greater binding to biological targets, or improved chemical stability. Patent filings document a steady uptick in derivatives across the pharmaceutical and electronic materials sectors. My experience shows that as new cross-coupling methods reduce catalyst loadings or tolerate more functional groups, chemists can access higher-value compounds faster and more cheaply. Improvements in regioselective halogenation now make even complicated patterns of fluorine and bromine more practical to achieve. Synthetic chemists, biologists, and engineers all push the boundaries together, working out how tiny changes in the molecular structure produce big leaps in practical properties, from charge transport to water solubility or metabolic stability.

Toxicity Research

Older textbooks brushed past the risks of compounds like 1-Bromo-2,5-difluorobenzene, probably because production volumes remained small. Recent studies pay closer attention, with animal data showing moderate acute toxicity, mostly respiratory and skin irritation, and the potential for longer-term organ impact if mishandled. Regulatory reviews stress that halogenated aromatics often degrade slowly in the environment, making containment and responsible disposal crucial. Modern toxicologists run metabolic fate studies to estimate human and ecosystem exposure, and governments now flag these substances for strict workplace controls. Having spent time cataloging chemical hazards, I can vouch for the complexity of managing compounds that fall between common use and major hazard. Newer trends aim for bio-based, rapidly degradable replacements, but the versatility of this compound keeps it in the R&D pipeline.

Future Prospects

As greener chemistry advances and the pressures on high-purity chemicals mount, manufacturers focus on cleaner, safer, and more selective production methods for multi-halogenated arenes. Automated reactors, inline monitoring, and even engineered biocatalysts are changing the economics, making it easier to meet strict product specs without generating mountains of waste. Meanwhile, the electronics and pharma fields’ hunger for ever more specialized building blocks drives innovation in both design and sourcing. 1-Bromo-2,5-difluorobenzene sits at the crossroads of old petrochemical know-how and new molecular design, linking foundational organic chemistry to the promises of advanced materials and medicines. Teams that manage to cut environmental footprint without sacrificing synthetic utility will shape the direction this versatile tool takes in the coming years.

Chemical Identity Shaped by Structure

In classrooms and labs, chemical formulas look like cryptic codes. Digging into 1-Bromo-2,5-difluorobenzene, I see more than a sequence of letters and numbers. They map the story of a compound built for a purpose. The formula, C6H3BrF2, points to a benzene ring with a bromine and two fluorines tagged to it. Chemists spot this pattern and unlock a world of applications—from pharmaceuticals to specialty materials.

Why This Molecule Matters

Chicago’s old chemistry lab comes to mind. There, utility always trumped theory. 1-Bromo-2,5-difluorobenzene’s structure isn’t just about looking pretty on paper. The electron-drawing punch of fluorine and the bulk of bromine steer reactions in highly specific directions. The placement of substituents makes it a valued intermediate. In hands-on work, this means you get cleaner reactions, sharper yields, and fewer surprises. We see tech firms clamor for halogenated benzenes during the hunt for new materials and drugs—precision counts, and this molecule delivers it.

Authenticity in Everyday Use

Markets tie this compound to the performance-driven world of advanced manufacturing. Major suppliers keep C6H3BrF2 rolling off the line for customers seeking reliability, not just cost-cutting. I’ve talked with synthetic chemists who value its predictable performance. Their stories echo a central truth: trace impurities and inconsistent batches can break multi-million-dollar projects. Consistency in this benzene derivative matters for anyone scaling a process past the flask.

Handling Safety and Environmental Concerns

Halogenated aromatics like this one need respect. Old headlines about mishandled chemicals serve as reminders. Good ventilation and proper PPE turn out to be the only sane approach. In one project, spills led to headaches and wasted days, all because the basics weren’t followed. It’s not just personal harm—improper disposal can send persistent pollutants through water systems. This reality nudges labs toward closed-loop handling and recycling strategies to cut down on waste and environmental risk. Modern protocols put responsibility front and center, and for a good reason: long-term exposure can bring chronic health problems.

Moving Toward Greener Chemistry

Each time I hear about fluorinated intermediates like this one, I remember the broader goal: doing chemistry without shortchanging the next generation. Green chemistry pushes for smarter ways to build these compounds—think solvent recycling, catalytic reactions, and safer reagents. Research groups actively chase new routes for making fluorinated aromatics, trimming both hazards and waste along the way. This movement isn’t just a trend—it’s what keeps the industry on the right side of innovation and ethics.

Final Thoughts

The chemical formula C6H3BrF2 doesn’t stay on the chalkboard for long. It shapes products that touch daily life, from coatings to cutting-edge electronics. But the way we handle and make it determines both its value and its impact. By respecting both the science and the responsibility, we protect people and the planet—while keeping the wheels of progress turning.

Introduction to a Specialized Compound

1-Bromo-2,5-difluorobenzene does not ring a bell for most people outside the chemistry field, yet it quietly finds its way into many important industrial and scientific processes. My own chemistry studies reinforced just how influential these specialized compounds can be, especially when building complex molecules in laboratories or factories.

Building Blocks in Pharmaceutical Research

Those working in pharmaceutical research appreciate compounds that serve as sturdy starting points for new drug candidates. 1-Bromo-2,5-difluorobenzene fits nicely here due to its bromine and fluorine atoms. These halogens help chemists attach new groups to create potential drugs. For instance, adding fluorine atoms often helps a molecule resist metabolic breakdown. Many pharmaceuticals, including popular painkillers and some antidepressants, sport fluorine because it can enhance a drug’s stability or absorption. When a synthetic chemist wants to design a molecule with unique properties, using compounds like this one saves time and avoids complications.

Tool for Advanced Material Science

Electronics manufacturers often look for ways to engineer organic semiconductors and specialty polymers. The electronics in smartphones or solar panels rely on intricate molecular designs, and the right building blocks make these possible. 1-Bromo-2,5-difluorobenzene offers valuable features for these processes: its bromo group acts as a reactive site, and the difluoro substitutions fine-tune the physical traits of polymers or other electronics-related materials. Its structure gives researchers a way to control electronic behavior, which is critical for improving device efficiency or miniaturization.

Enabling Cross-Coupling Reactions

A lot of chemists, including me during my graduate studies, rely on cross-coupling reactions to link molecules together. Compounds like 1-Bromo-2,5-difluorobenzene act as reliable participants in Suzuki or Heck reactions. These methods dominate modern organic synthesis, especially in the hands of researchers aiming to produce fine chemicals, agrochemicals, or advanced dyes. The bromine atom in this compound reacts in controlled ways, allowing scientists to attach complicated pieces without much hassle.

Addressing Environmental and Safety Concerns

Handling halogenated compounds, especially those with bromine or fluorine, brings some environmental responsibility. Runoff or poor disposal can pollute soil and water. Chemists must use best practices—proper storage, using minimal amounts, and responsible disposal—to keep labs and surroundings safe. Extra training often helps new chemists avoid accidents or improper waste handling. Stricter regulations, smart containment systems, and process optimization inside factories all help lower emissions and protect local communities.

Opportunities in Green Chemistry

Many organizations now push for greener alternatives or adjustments. Improved catalysts and milder reaction conditions reduce the need for excessive reagents and lower waste production. Switching to recyclable solvents or tweaking reaction pathways can also tame the environmental impact. If I learned anything from sustainable lab initiatives, it’s that small changes—like solvent swaps or new purification techniques—add up over time. Developing processes that recycle halogenated byproducts extends the usefulness of each molecule while curbing costs.

Final Thoughts

Even though 1-Bromo-2,5-difluorobenzene does not seem like a headline-maker, it underpins much of the modern chemistry that shapes medicine, electronics, and materials. Its importance grows in the hands of skilled professionals who balance progress with safety and environmental stewardship. Commitment to education and adopting cleaner workflows ensures that chemistry continues to serve industry and society alike.

Recognizing the Hazards

Anyone who’s worked with aromatic bromides and fluorinated compounds remembers the distinctive chemical smell. Forget about casual contact—1-Bromo-2,5-difluorobenzene carries health risks that show up quickly. The nasal sting should remind you to grab gloves and goggles. Direct skin contact can cause irritation. Inhalation of vapors, especially in a poorly ventilated space, brings potential respiratory issues or headaches.

My chemistry mentor hammered home the point: Treat every bottle as a potential spill waiting to happen. This compound sits in the middle ground. It isn’t as notorious as benzene, but one careless move causes damage. Splashing even a tiny amount throws off a whole day in the lab—not to mention storage rooms that absorb the odor for weeks.

Storage Practices that Work

Fluorinated solvents need good-quality containers, but add bromine to the mix and the risk climbs. Store 1-Bromo-2,5-difluorobenzene in tightly sealed glass bottles or high-density plastic. Metal lids corrode, so I prefer ground-glass stoppers. Keep the bottle upright, away from sunlight. UV rays spark unexpected reactions, especially in aromatic compounds.

Shelving should sit in low-traffic areas, far from oxidizers, acids, or open flames. Labeling needs to shine; I’ve seen too many accidents traced back to faded writing or missing hazard symbols. I always double-check compatibility charts before adding a new bottle to shared cabinets. If your building lacks dedicated chemical storage, at least separate organics from oxidizers and acids.

Lab refrigerators work for temperature-sensitive stocks, just never household refrigerators. Chemical vapor mixes with food equals hospital trips. Chemical fridges vent harmlessly and alert you to leaks.

Safe Handling: No Shortcuts

Fume hoods exist for a reason. Even a quick measure or transfer benefits from proper ventilation. My early days in research involved “quick” experiments outside the hood, and it only took one surprise vapor cloud to hammer home the lesson: Exposure happens fast, and the irritation lingers. Gloves do more than protect your skin; nitrile gives the best barrier. Eyes need goggles—lab glasses without side shields don’t cut it when splashes happen.

Plan the clean-up as carefully as the experiment. Spill kits should live close by. Paper towels don’t mop up chemicals—they spread them. Absorbent pads, followed by gentle disposal in proper waste containers, stop problems from spreading. Keep a large container on hand for waste, sealed and labeled by date and contents.

Respecting Regulatory Advice

OSHA and EPA both address halogenated solvents. Safety data sheets (SDS) aren’t just formalities—these documents save lives. I always take five minutes to check the latest updates before starting a new batch. Your local waste disposal rules may differ, so contact a certified handler for disposal—sewers and sinks belong to clean water, not complex organics.

Many labs already partner with environmental health officers. If you work solo or in a small startup, find a chemical hygiene mentor. Keeping up with emerging disposal protocols (especially in states with tighter rules) helps everyone avoid regulatory trouble.

Building a Culture of Caution

One lesson stands out: trust your nose, your eyesight, and your training. Take pride in a tidy, well-labeled storage shelf. Put gloves on before you even unscrew the bottle. Never take shortcuts with labeling. Every small action—tightening a cap, cleaning a drip, reporting a cracked bottle—prevents bigger emergencies. Handling 1-Bromo-2,5-difluorobenzene teaches respect for the cumulative effect of dozens of careful choices. That habit keeps people safe, experiments intact, and communities healthy.

Understanding CAS Numbers in Chemistry

Science moves on details. Periodic tables, molecular models, systematic names—they all keep confusion at bay. Unique identifiers like CAS numbers do heavy lifting in labs and supply chains. Without these numbers, even the basics of ordering, discussing, and regulating chemicals turn into a headache. The CAS number for 1-Bromo-2,5-difluorobenzene is 71607-46-4. Punch that into any trusted chemical database and you’ll find a clear match.

Why CAS Numbers Matter for Companies and Researchers

I’ve worked in research where two different supply companies offered what looked like the same product. One used a slightly different IUPAC name, the other relied on a trade name. Researchers scratched their heads until someone found the CAS number. That ended the debate fast. Mistakes are costly: wasted grant money and time, and sometimes safety issues. Chemical suppliers use CAS numbers to guarantee what’s in the bottle. Regulators and environmental agencies also rely on these numbers for tracking and compliance.

A CAS number works better than just a name or formula. A company might label something as “bromodifluorobenzene” and post a molecular formula, but still face ambiguity. Drop the number 71607-46-4, and there’s no argument. Nobody argues about spelling or name formats. No confusion of isomers. Researchers can actually share reliable protocols, and procurement teams don’t stumble through variations.

Safety Hinges on Clarity

Handling hazards is routine in chemistry, but one wrong bottle—picked due to mislabeling—opens the door to disaster. Mixing up 1-Bromo-2,5-difluorobenzene with another similar-sounding chemical means new dangers, altered reactivities, or exposure risks. All because someone guessed and didn’t check the number. In my lab days, everyone double-checked those numbers before opening anything. That was standard, not paranoia.

On bigger scales, chemical transport and storage depend on accuracy. Emergency responders or warehouse crews must know what they’re dealing with. CAS numbers give these teams a single line of defense against chemical confusion, ensuring correct emergency response and documentation.

The Role of Digital Access and Open Information

A decade ago, it took digging through catalogs or printed references to find CAS numbers. Today, with resources like PubChem and ChemSpider, everyone can verify chemicals in seconds. Scientists looking for 71607-46-4 can find physical data, toxicity, and even spectral information on the spot. Transparent, accessible chemical data helps keep experiments precise and safe.

Accurate CAS numbers also drive ethical sourcing. Environmental and trade regulations reference these numbers. It’s possible to check if a supplier follows all legal and ethical safeguards—or if they’re cutting corners. Companies must keep honest records because authorities use these registry numbers during audits and investigations.

Building Solutions through Chemical Transparency

Accurate documentation leads to good science and fewer mistakes. Labs must train early-career scientists to use CAS numbers in all communication. Procurement forms, shipping labels, and lab notes all benefit from the clarity these numbers provide. Such habits cut down on miscommunication, reduce dangerous mistakes, and save money in the long run.

For me and many others, chemical work just works better when we skip uncertainty. The CAS number for 1-Bromo-2,5-difluorobenzene—71607-46-4—lets us skip the drama and get the science right the first time.

What’s in a Chemical’s Purity?

Purity isn’t just a word printed on a label—it’s the difference between a successful experiment and a waste of effort. Most research-grade chemicals demand high purity, and 1-Bromo-2,5-difluorobenzene fits that bill. Major chemical suppliers consistently offer this compound at 97% or greater purity. Some premium lots reach as high as 99%. At these purity levels, trace contaminants stay minimal, so your chemistry gives reproducible results.

Once, during a student research project, I tracked down two batches from different suppliers. The 97% sample completed the synthesis smoothly, while a lower-purity version sparked side reactions. With 1-Bromo-2,5-difluorobenzene, even a small drop in purity can muddy the waters for advanced materials or pharmaceutical intermediates. Academic and industrial labs lean heavily on reliable sources—they avoid dodgy suppliers because nobody has time to re-run columns just to clean up purchase mistakes.

Why Packaging Sizes Matter

People don’t think about bottle sizes until they order the wrong one. Most suppliers know their customers: university labs, pharma R&D teams, and specialty manufacturers. Bottles ranging from 1 gram up to 100 grams land on the shelves, with 5-gram and 25-gram sizes proving especially popular. You get a sturdy glass vial with a screw cap (often PTFE-lined), clear labeling, and tamper evidence. Some companies extend to 250 grams for pilot projects, though for that scale, procurement needs tight coordination with safety managers.

I learned after a late-night call to a campus stockroom that going too big only means more trouble. Unopened containers of volatile organics take up valuable fridge space, and nobody likes dropping a big chunk of budget on a chemical that might expire before its next use. Smallest packs fly off the shelves for undergraduate labs and one-off syntheses, while the medium grades support steady research work.

It’s impossible to ignore shipping restrictions too. 1-Bromo-2,5-difluorobenzene qualifies as hazardous under many regulations, so packing in small, leak-proof containers keeps everyone safer. Larger packages mean extra paperwork, special courier services, and often higher costs—for labs, time spent chasing after regulatory clearance is time stolen from real research.

How Packaging Choices Affect Lab Safety and Success

The right packaging isn’t about aesthetics. Spillage, evaporation, and cross-contamination turn into headaches if you try transferring flammable liquids from oversized drums under a fume hood. Scraping for the last drops out of an inconvenient bottle wastes both material and time. From my experience, sturdy containers with tight seals prevent corrosion and accidental leaks.

Suppliers that include comprehensive documentation with their shipments—certificate of analysis, traceable batch numbers, hazard communication—ensure accountability. This attention to detail sets professional suppliers apart and makes audits as painless as possible for lab managers. Thorough training and an emphasis on good labeling reduce the risks when students or new employees handle reactive liquids like this.

On one project, the Chemistry Department adopted a new vendor for aromatic halides. Their clear labeling and incremental quantities cut down on wasted stock and over-ordering. Transparent batch purity details encouraged better planning for multi-step syntheses.

Finding a Middle Ground

Balancing purity and package size calls for an honest look at your workflow and demand. You shouldn’t chase ultra-high purity if standard grade meets your needs, but underestimating the importance of clean starting materials leads to unpredictable results. Buying in sensible amounts and checking supplier credentials safeguards not only your budget but everyone’s safety and time.

With experience, I’ve seen that a careful approach—verifying batch specs, choosing suitable bottle sizes, and sticking with reputable vendors—saves countless headaches. In chemistry, these basics make all the difference between moving science forward and getting bogged down by preventable errors.