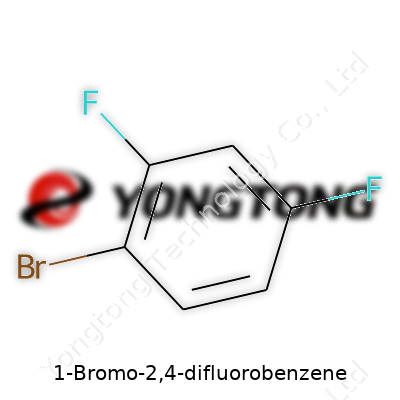

1-Bromo-2,4-difluorobenzene: A Close Look at an Influential Chemical Intermediate

Historical Development

Synthetic chemistry never stands still. Since organic chemists got comfortable playing with halogenated benzenes in the late 19th century, folks kept pushing for greater complexity and control. Early fluorination experiments involved incautious and sometimes hazardous routes, with rudimentary glassware and a lot of patience. The arrival of controlled electrophilic and nucleophilic substitution methods in the mid-20th century put these compounds within reach. By the 1970s, researchers had refined selective bromination and fluorination, making 1-Bromo-2,4-difluorobenzene a convenient building block in academic and industrial settings. Legacy papers from Japan and Germany showcase early uses, with documented improvements that built the robust protocols we rely upon today.

Product Overview

1-Bromo-2,4-difluorobenzene holds a reputation as a reliable intermediate, particularly in synthesis of pharmaceuticals, agrochemicals, and specialty polymers. Chemists see it as more than a reagent; it’s a versatile piece in large-scale and bench-top chemistry. Having worked in a lab where modest runs of halogenated aromatics regularly overlapped, I saw how this compound’s blend of electron-withdrawing elements opens up several downstream routes. Its dual fluorine groups offer a balance between reactivity and resistance to undesired side reactions. Most labs keep it stocked in glass bottles with secure seals, since contamination ruins yields, and shelf-life matters in any busy synthesis scheme.

Physical & Chemical Properties

A clear liquid at room temperature, 1-Bromo-2,4-difluorobenzene sports a distinctly sharp, aromatic odor—as do most brominated and fluorinated benzenes. It has a melting point well below zero Celsius and stays liquid under normal storage. Its boiling point sits near 170°C under atmospheric pressure, enough to accommodate common purification by distillation. With a density notably higher than water, handling calls for glassware designed for heavier-than-expected pours. Chemically, it resists rapid hydrolysis but reacts reliably in controlled halogen/metal exchange or cross-coupling reactions, which accounts for its broad appeal in modern synthetic chemistry. The bond dissociation energies for C–Br and C–F reflect real-world stubbornness in some couplings, so patience and practice both count for a lot.

Technical Specifications & Labeling

Technical data sheets for 1-Bromo-2,4-difluorobenzene provide purity values ranging from 98% up to analytical-grade 99.5%. Reputable suppliers disclose specific gravities, refractive indices, GC retention times, and NMR spectra. Labels include UN identification codes, recommended storage temperatures, flash points, and warnings about inhalation risks. Clear hazard pictograms flag the chemical irritant nature, underlining the need for gloves, goggles, and sometimes a fume hood. Each container usually bears unique lot numbers and manufacturing dates, so traceability lines up with regulatory expectations. Labs ordering this material for regulated research must track it from delivery to use, all for compliance and safe chemical management.

Preparation Method

Synthesis of 1-Bromo-2,4-difluorobenzene starts with a fluorinated benzene, often 1,3-difluorobenzene, and brings in controlled bromination at the ortho-position using a brominating agent like Br2 or N-bromosuccinimide. The process relies on rigorous temperature control, exclusion of moisture, and careful monitoring to avoid over-bromination or ring substitution shifts. Solvents like dichloromethane or acetic acid play a role in steering selectivity, while purification depends as much on vacuum distillation as on column chromatography. The operation draws on lessons from countless student labs, where balancing yield, purity, and safety always felt like walking a tightrope—any shortcut usually means more work later.

Chemical Reactions & Modifications

This difluorinated bromobenzene stands as a launchpad for a pile of subsequent chemistry. Suzuki and Stille couplings each accept the aryl bromide, enabling carbon-carbon bond formation with all manner of partners. Nucleophilic aromatic substitution (SNAr) leverages the activated positions created by fluorine atoms for amination or alkoxy introduction, bypassing some of the older, less predictable approaches. The underlying stability that comes from the fluorine atoms means you keep a handle on side reactions—a massive help for someone designing a multi-step drug synthesis. These modifications echo through both medicinal chemistry and materials research, where slight changes in the aromatic core yield new biological or physical properties.

Synonyms & Product Names

Across the chemical supply industry, 1-Bromo-2,4-difluorobenzene sometimes appears under other monikers. Trade catalogs often list it as 2,4-difluoro-1-bromobenzene or even by its CAS number (367-25-9). In some older literature, one might see it referenced as 1-bromo-2,4-difluoro-benzol, echoing German nomenclature. Every naming convention follows IUPAC or traditional rules, yet catalog numbers and abbreviation codes end up more useful during procurement or in practical work. Double-checking synonyms always saves from accidental misorders; no one enjoys unpacking a bottle of the wrong isomer after a two-week wait.

Safety & Operational Standards

Safe handling of 1-Bromo-2,4-difluorobenzene reflects broader lab rules for organobromides and organofluorines. Skin contact causes irritation, so gloves stay on throughout weighing, pouring, and transfer steps. Inhalation of vapors brings respiratory discomfort—verified by anyone working with a faulty fume hood. Laboratories demand proper ventilation, defined transfer protocols, and up-to-date safety training before anyone gets near production runs. Waste streams containing this chemical need segregating from regular halogen waste, as regulations flag both brominated and fluorinated benzene derivatives for environmental risk. Fire safety protocols prioritize control of heat sources, and spill kits line bench corners for good reason: brominated liquids do not play fair with most organic or metallic surfaces.

Application Area

Use of 1-Bromo-2,4-difluorobenzene stretches beyond textbooks. In drug development, its presence in the synthetic sequence for kinase inhibitors or antifungal candidates stands as evidence that it supports more than theory. Crop protection chemistry, where selective activity against pests or weeds depends on smart molecular design, finds roles for this intermediate in resistance-breaking compounds. Electronic materials and specialty polymers call on molecular fragments like 1-Bromo-2,4-difluorobenzene to tune conductivity, mechanical strength, or optical response. Each end-use traces its requirements back to this dependable, if unobtrusive, aromatic building block.

Research & Development

R&D teams all over keep searching for faster, cleaner, and cheaper ways to introduce halogens in aromatic systems. Recent articles track advancements in photoredox or electrochemical routes, aiming to lower energy footprints and cut hazardous byproducts. Big chemical manufacturers funnel time and cash into process intensification, since better routes translate to more affordable intermediates and wider application potential. Academic labs drive fundamental knowledge—mapping reactivity trends, studying catalyst improvements, or probing solvent influence on reaction outcomes. As industry puts these advances into practice, everyone along the supply chain benefits from improved yields and safer processes, which impacts both bottom lines and environmental benchmarks.

Toxicity Research

Studies on toxicity give a mixed picture. Acute exposure in animal models leads to central nervous system depression and liver enzyme changes, which matches the broader toxicity profile found in many halogenated benzenes. Chronic exposure data remains less robust but signals concern for environmental persistence, especially in aquatic systems where fluorinated aromatics undergo only partial degradation. Lab protocols now call for closed systems and solvent recovery, reflecting lessons from tox studies done over decades across the United States, Europe, and Asia. Occupational health researchers recommend regular air monitoring and medical surveillance in high-throughput facilities, because early detection means faster intervention—protecting both workers and the public.

Future Prospects

Looking forward, industries tied to pharmaceuticals, agriculture, and advanced materials will continue using 1-Bromo-2,4-difluorobenzene, unless radical shifts in green chemistry or regulatory landscapes upend today’s practices. As scientists find more sustainable halogenation strategies and design benign-by-design molecules, the pipeline for new intermediates grows longer and more competitive. Calls for less persistent and bioaccumulative chemicals inform both regulatory guidance and consumer expectations. Improved catalysis, real-time process analytics, and greener solvent systems could make this compound’s manufacture and use safer, cheaper, and within reach for developing markets. Staying ahead means not just keeping up with technology, but building safety and efficiency into every stage—from concept through scaled production to waste stream management.

A Close Look at Chemical Identity

Anyone who’s poked around a chemistry lab knows how much information a simple formula can pack. 1-Bromo-2,4-difluorobenzene often pops up in organic synthesis conversations. The chemical formula sits as C6H3BrF2. For those who missed the finer points in class, this breaks down to six carbon atoms, three hydrogen atoms, one bromine, and two fluorines clasped to a benzene ring.

Why Care About a Chemical Formula?

Getting a formula right isn’t just for tests. Once, I started a reaction early in my college days using a similarly named compound, and the end result made it clear that small differences in structure change everything. The formula shows you what’s attached, where, and how the molecule might act. Think about the pharmaceutical field, where a misplaced atom can affect a whole medication’s function or safety. Years ago, a minor difference in a set of analgesics led to drastically different pain-relief results and a lot of confusion.

How Structure Shapes Use

Bromine and fluorine on a benzene ring sound innocent at first glance, but these substitutions aren’t just cosmetic. Each atom brings quirks. For starters, the presence of bromine increases the molecule’s heft and reactivity compared to bare-bones benzene. Fluorines on the ring tend to toughen the molecule, resisting breakdown, and sometimes make it less reactive at certain spots. This matters when scientists want to build something more complex, since choosing stable building blocks can save a lot of time and effort down the road.

Take the world of liquid crystal displays. Fluorinated aromatics improve performance, clarity, and lifespan. Electronics demand chemical stability, and fluorines give a solid boost in this department. It’s more than theory — the tech in a smartphone or TV often depends on these quiet advances. Lab workers and engineers get a lot of mileage from the right formula in the right place.

Handling Hazards Sensibly

Every chemist hears about safety alongside formulas, and with good reason. Compounds like 1-Bromo-2,4-difluorobenzene raise concerns around skin and eye irritation, plus the environmental impact if spills happen. I remember chatting with safety officers who said a single dropped flask can mean a call to hazmat, depending on what ends up on the bench or floor.

Solid rules go a long way: good ventilation, gloves, prompt spill cleanup. Disposal requires care, since halogenated compounds persist long after lab doors close. Some organizations now push for safer substitutes, phasing out problematic chemicals where possible—though this takes cooperation and sometimes reworking years of established practice.

Factoring in the Wider Picture

A molecular formula’s just a starting point, yet it speaks volumes for folks developing new products, keeping workers safe, or weighing environmental consequences. Chemistry’s never just about mixing and measuring; it ties into real decisions with real impact. Thinking through the power and implications of a formula like C6H3BrF2 helps make better choices in labs and beyond.

Bringing Chemistry Into Real Life

If you’ve ever walked through a chemistry lab or browsed the shelves of a science supply store, you may have noticed labels with names that almost sound like codes. 1-Bromo-2,4-difluorobenzene is one of those tongue-twisters, but its role stretches far wider than a label. This compound stands out in synthetic chemistry, and its uses reflect the force and ingenuity behind the field.

Synthesis of Pharmaceuticals and Agrochemicals

Chemists have a habit of building molecules piece by piece, like assembling a puzzle. 1-Bromo-2,4-difluorobenzene plays into this process as a starting block. Its benzene core, shaped by both bromine and fluorine atoms, lets teams add or swap chemical groups with precision. This isn’t just an academic trick—new drugs and crop protectants often start from foundations like this. Drug discoverers love having stable molecules with reactive points for attaching other pieces. Those fluorines matter too. They can affect how a medicine behaves in the human body—longer shelf life, sometimes more potent, and even fewer harmful by-products after metabolism. In farm chemicals, subtle changes to the molecular structure can make the difference between a safe product and one that lingers too long in the soil.

Aspiring chemists reading up on drug patents may notice the frequent use of halogenated benzenes, including difluorinated versions like this one. As of 2024, over fifty published medicinal syntheses have involved such intermediates. The trend shows no signs of slowing as research on cancers, infections, and neurological conditions keeps scientists hunting for molecules that act just right in a human cell.

Linking Advanced Materials

Building materials for high-tech uses depends on compounds that don’t break down or lose their edge quickly. The electronics industry remains hungry for materials that can insulate or conduct exactly as needed. Aromatic rings with fluorine atoms excel at resisting heat and chemical stress. 1-Bromo-2,4-difluorobenzene lets engineers introduce those hard-to-get features into polymers. Fluorinated arenes often end up in liquid crystals, which make the crisp displays on modern screens possible. There’s an arms race—companies always looking to make screens sharper, more responsive, and longer-lasting.

The bromine atom, here, gives chemists a quick handle to snap this fragment onto much bigger molecules. This connection point helps create custom polymers for applications far from the basics of classroom chemistry.

Tools for Teaching, Research, and Diagnostics

On the education side, 1-Bromo-2,4-difluorobenzene ends up as a sample in teaching labs or as a model for chemical behavior in textbooks. Synthetic experiments with this compound help new chemists see how reactions proceed and why certain patterns matter. Graduate-level classes often include exercises that require real-world intermediates, not just theoretical models.

In research, specialists in organic and materials chemistry use difluorinated benzenes to test new reactions, catalysis methods, and separation techniques. Chemical suppliers report growing demand in universities and private labs, showing that basic molecules like this one drive breakthroughs across generations.

Thinking About the Future

Shortages and cost jumps keep reminding users to look for alternatives or greener synthesis methods. Efforts to recycle halogenated intermediates or use less hazardous chemicals are gaining steam. Sustainable approaches, tighter regulation, and clear reporting from chemical suppliers will help protect both the environment and workers. Researchers already look for ways to swap harmful solvents and create smarter recycling loops.

Chemistry holds a mirror to society's priorities, and molecules like 1-Bromo-2,4-difluorobenzene show how interconnected daily challenges and scientific opportunity have become.

Why Purity Levels Matter for 1-Bromo-2,4-difluorobenzene

My days working in a small chemistry lab taught me there’s no shortcut around purity. One slip-up with chemical quality, and your experiments can veer off course or, worse, fail to meet safety requirements. For reagents like 1-Bromo-2,4-difluorobenzene, purity reflects whether the material can play its role in fine chemical synthesis, pharmaceutical work, or analytical testing. Purity typically lands above 97%, often going up to 99% or even higher from top-tier suppliers. Reputable distributors publish clear Certificates of Analysis with every purchase, so you know exactly what’s in your bottle—often breaking it down to the second decimal.

Research teams and manufacturers look for details like residual solvents, total impurities, and water content because even a trace of the wrong contaminant can mess with reactions or disrupt product stability. In production, problems from off-spec materials reach thousands of people—so not checking for data like gas chromatography analysis or NMR documentation opens the door to huge costs and real safety risks.

Reliable Packaging Adds an Extra Layer of Safety

While spending countless hours sorting bottles in storerooms, one thing became clear: packaging holds more weight in chemistry than people think. Even the purest chemical falls flat if packaging lets contaminants in or leaks out toxic fumes. Trusted suppliers don’t just slap 1-Bromo-2,4-difluorobenzene in generic containers. Instead, you see amber glass bottles or fluorinated HDPE containers, sealed and labeled with batch numbers and expiration dates. Amber glass shields light-sensitive compounds, stopping degradation over time. HDPE resists breakage during transit and guards against chemical seepage that could endanger anyone handling the bottle.

For bigger users—say, manufacturers running multi-step synthesis—drums and bulk packs exist, but even then, chemical-resistant linings and tamper-evident seals keep the product safe until the last drop leaves the warehouse floor. I’ve seen firsthand how cheap packaging causes storage nightmares: leaks, label smudges, evaporation losses, even accidents that lead to regulatory headaches.

Improving Quality and Transparency

Open communication between buyers, sellers, and regulators fosters accountability and builds trust. Back when regulations tightened, our lab’s policy shifted. We’d never accept a shipment without up-to-date quality assurance paperwork and secure packaging intact—no exceptions, no shortcuts. I remember companies raising their standards to keep clients, investing in more secure lids, inert liners, and clear hazard warnings. This wasn’t just box-checking; it prevented contamination, mislabeling, and costly recalls downstream.

Digital traceability tech makes a real difference. QR codes and online batch tracking now offer fast access to purity specs, storage tips, and even recall alerts, all on your phone. For fast-moving research and global shipments, this means fewer delays and less confusion about what’s really inside a container.

Potential Solutions for Industry Challenges

Better third-party testing and publication of analytical results create confidence in supply chains. Restarting crushed projects or purifying tainted batches hits hard, both in time and budget. Companies have begun adopting independent audits and sharing more transparent testing data. Smaller labs gain from pooled procurement—joining purchasing networks for vetted, quality-controlled chemicals and safe packaging. Industry organizations could develop stricter handling guides for manufacturers, tackling widespread problems like counterfeit labels and poorly sealed drums.

Newcomers to chemical sourcing stand to benefit from published best practices. A training program for lab managers would cut down accidents and wasted spending by walking through how to read a purity certificate, check documentation, and evaluate packaging before chemicals even hit the bench.

Why Getting It Right Really Counts

Anyone in chemistry sees the impact of purity and packaging decisions every single day. Small steps like quality checks and safer containers keep research honest and protect people at work. Facing these challenges sharpened my own skills, and encouraged everyone I worked with to treat every new bottle—especially those as reactive as 1-Bromo-2,4-difluorobenzene—with serious care and respect.

Why Proper Storage and Handling Count

Chemicals like 1-Bromo-2,4-difluorobenzene arrive in the lab with a certain aura—labels marked with hazard symbols and instructions that promise a safe workspace, as long as you actually follow them. Recognized by its sharp, pungent odor and clear appearance, this aromatic halide isn’t just another bottle on the shelf. It deserves respect and a little extra attention.

Before I ever twisted open a bottle of it, I learned to check its data sheet. The National Institutes of Health and Sigma-Aldrich both make it clear: exposure to high concentrations may irritate skin, lungs, and eyes. Spills lead to headaches—both literally and logistically—so avoiding them comes down to smart choices in storage and handling.

What Works in the Storage Room

A cool, dry, dark corner goes a long way for chemicals prone to volatility, and 1-Bromo-2,4-difluorobenzene fits the bill. Heat exposure often degrades halogenated benzenes, but light also nudges them into unwanted reactions. Store this compound at room temperature, away from direct sunlight, with humidity kept in check.

Separate storage helps control risks. This isn’t a chemical to stash beside oxidizers or strong bases, since those combinations spark trouble. I’ve seen cabinets organized with secondary containment trays—simple plastic bins—to catch leaks or spills. The right ventilation keeps vapors from pooling, so flammable storage cabinets with built-in exhaust make sense.

Tightly sealed glass containers handle 1-Bromo-2,4-difluorobenzene best. Most major producers use amber glass bottles for UV-sensitive materials; after each use, the cap goes back on immediately. Proper labeling isn’t just about compliance. It makes sure no one confuses the bottle during hectic shifts, where a quick glance may mean the difference between a safe pour and a costly mistake.

Smart Handling Methods in Practice

Gloves, safety goggles, and lab coats aren’t just window dressing. Nitrile gloves have always been my go-to, since this type of compound sneaks through some lighter plastics. Fume hoods play a crucial role, especially in shared labs. One rushed experiment involving open benzenes outside a hood once forced the whole floor to evacuate, and that embarrassment sticks with you.

Pouring with steady hands, using spill trays, and employing disposable pipettes where needed—all of these cut down on accidents. Controlling exposure reduces the risk of headaches and respiratory irritation. In any spill event, absorbing material (such as vermiculite or sand) and swift cleanup avoid prolonged exposure and chemical damage to surfaces.

Waste disposal matters just as much as storage. Don’t dump halogenated organics down a drain. Segregated waste cans—clearly marked for halogenated organics—become the final destination, and reputable waste handlers collect these at regular intervals. Proper documentation protects everyone, from the person doing the lab work to the environment at large.

Reducing Risks and Improving Practice

I’ve learned that continuous education saves trouble. Training sessions, refresher quizzes, and open-door policies for asking about chemical safety make a real difference. Protocols only work if everyone knows them and speaks up when something looks off. Relying on clear signage, regular inspections, and easy access to material safety data sheets turns a well-stocked cabinet from a hidden risk into a reliable resource.

Safe handling and storage don’t just follow checklists—they grow from experience and clear, shared standards. Focusing on preparation and communication shapes a safer space for all, where chemicals like 1-Bromo-2,4-difluorobenzene support discovery rather than threaten it.

Understanding the Risks: Why MSDS Matters

Nobody likes surprises in the lab, especially the kind that end with a trip to the doctor or damage to expensive gear. For every chemical, especially something like 1-Bromo-2,4-difluorobenzene, a Material Safety Data Sheet (MSDS) makes all the difference. These documents spell out hazards, common sense handling advice, and what you do if things go sideways. Bologna or not, strong regulation has made MSDS sheets a staple in responsible research and manufacturing.

Getting straight answers about safety around 1-Bromo-2,4-difluorobenzene isn’t just a formality. This molecule—used in pharmaceutical synthesis and specialty materials—carries risks you don’t want to guess about. Most MSDS reports put it somewhere between “irritant” and “environmental hazard.” In the lab, folks handle it with gloves and safety goggles. Serious exposures can cause trouble for your skin, eyes, or lungs, and not just in theory: halogenated benzenes have a bad reputation for toxicity.

How Information Gaps Show Up

Finding a full set of safety data on 1-Bromo-2,4-difluorobenzene isn’t always simple. Looking through chemical supplier websites shows a pattern: details show up on big shop platforms (Sigma, Alfa Aesar, Santa Cruz Biotech), but copy-pasted safety sheets can’t keep up with every new study. Some sections get filled in with “data not available” more often than they should. If you’re working in research or handling bulk shipments, this sort of hole can mean a real risk.

Walk into a big lab and you’ll see jars and boxes labeled clear as day with CAS numbers and basic hazards. Yet those labels don’t always hint at the trickier parts, like what happens if this stuff spills near a drain or if it mixes with incompatible solvents. My own time in a synthesis lab hammered in a lesson: reading past the first page of the MSDS matters. Vapor hazards sneak up, small spills linger, and skin exposure can be sneakier than you think if safety data is spotty.

Transparency and the E-E-A-T Standard

It’s more than good practice to demand current data; it’s an obligation for anyone selling or distributing chemicals. Google’s E-E-A-T principles—experience, expertise, authoritativeness, and trust—line up with this need for transparency. Fact-based, traceable info protects both workers and the environment.

Experience shows gaps can go unnoticed until disaster makes headlines. Back in my grad student days, a nearby lab had an unexpected fire when a chemist used a partially understood halogenated benzene variant. All they had was a barebones MSDS from years before, missing key flashpoint details. Costs added up fast—not just cleanup, but shaken confidence.

Authority in safety grows from hard facts—physical and chemical properties, toxicology, necessary PPE, steps for leaks. It makes a difference whether a MSDS came from the manufacturer or from a generic database. With 1-Bromo-2,4-difluorobenzene, authoritative sources review peer-reviewed toxicology studies and don’t gloss over “unknown” fields.

Pushing for Better Practices

If you rely on a MSDS, read beyond the top summary and check for revision dates. Call out missing info. Talk with the supplier: demand updates if the last assessment predates a relevant finding. For labs, hang onto updated digital or paper copies nearby. Use engineering controls (hoods, exhausts), not just gloves. Set up spill kits, plan for proper waste disposal, and never let curiosity outpace documentation.

Sharing updates and routes for anonymous reporting can close the loop on safety. Training new people with real-world examples beats “death by PowerPoint.” Real accountability and vigilance matter a lot more than compliance for compliance’s sake. In the end, nobody wakes up hoping to make tomorrow’s accident report, and that’s a lesson bigger than any single chemical.