1,2,4-Trifluorobenzene: Unpacking Its Role in Modern Chemistry

Historical Development

Chemists first focused on trifluorinated benzenes in the early twentieth century, when scientists began seeking new compounds for dye production and pharmaceuticals. Early synthesis relied on halogen exchange reactions, tapping into compounds like chlorobenzene as raw materials. Fluorinated aromatics like 1,2,4-trifluorobenzene marked an evolution in both industrial need and laboratory technique, inspired partly by the wider reach of organofluorine chemistry during and after World War II. New routes appeared as catalytic systems matured and feedstocks diversified, driven by the demand for novel agrochemicals and advanced materials.

Product Overview

1,2,4-Trifluorobenzene is a clear, colorless liquid with a sharp aromatic odor that often draws quick comparisons to other benzene derivatives. Chemical suppliers ship it as a specialized intermediate rather than a common laboratory solvent. Many researchers, myself included, have encountered it while building complex molecules for pharmaceutical screening or exploring new electronic materials. Each bottle highlights its purity grade, moisture content, and sometimes even FID-GC chromatograms—details the average end user in fine chemical synthesis cares about far more than flash or marketing.

Physical & Chemical Properties

In the lab, 1,2,4-trifluorobenzene stands out thanks to its boiling point near 111.5°C and a melting point that drops below -30°C. Its vapor pressure rises faster compared to non-fluorinated benzene, making ventilation a requirement in closed spaces. With a density around 1.263 g/cm³ at 20°C, the compound tends to settle below water, a property technicians appreciate during spill response or separation. The relative stability toward both acids and oxidizing agents makes it reliable during storage, but reactions become lively if strong nucleophiles enter the mix. The molecular formula C6H3F3 sets it apart from other trifluorinated aromatics due to this specific arrangement of fluorines, reflected in its unique NMR and IR signatures.

Technical Specifications & Labeling

Bottles arrive labeled with CAS number 367-23-7, common product names, and purity (typically 98% or above by GC). Labels tend to feature hazard pictograms to meet GHS standards, such as exclamation marks warning against inhalation or skin contact. Shipping documents often list UN number 1993, packing group III reflecting its flammability. Handling directions usually remind staff of its low flash point and require chemical splash goggles, gloves, and a fume hood for safe opening. Quality control labs check refractive index (1.441 to 1.443 at 20°C) and confirm the absence of hydrolyzed or polymeric residues.

Preparation Method

Major manufacturers often rely on halogen exchange starting from 1,2,4-trichlorobenzene, treating it with potassium fluoride or other alkali metal fluorides at elevated temperatures in polar solvents such as dimethyl sulfoxide or sulfolane. Catalysts like copper powder help drive the conversion of chlorines to fluorines. In a lab, I’ve seen microwave-assisted reactions cut run times and raise yields, making small-scale synthesis more appealing to academics pressed for time and funding. Distillation under reduced pressure usually follows, purifying the product away from partially fluorinated byproducts, with GC-MS confirmation rounding out the workflow.

Chemical Reactions & Modifications

The reactivity of 1,2,4-trifluorobenzene mimics other activated benzenes, favoring nucleophilic aromatic substitution over electrophilic routes. Strong bases and nucleophiles target the fluorine atoms, swapping them out for amines, alkoxides, or thiols in order to tailor new building blocks for drug discovery. Metal-catalyzed couplings, such as Suzuki or Stille reactions, further extend the platform, allowing chemists to bolt on aryl or heteroaryl groups. My time in medicinal chemistry taught me that fine-tuning such reactions—choosing the right ligand, solvent, or temperature—matters just as much as picking a starting material.

Synonyms & Product Names

On lab shelves or supplier catalogs, 1,2,4-trifluorobenzene sometimes appears as "Benzene, 1,2,4-trifluoro" or even "Trifluorobenzene." Don’t confuse it with its 1,3,5-isomer, which follows a different reactivity pattern. Other common names include "1,2,4-TFB" and "TFB 1,2,4-," abbreviated for sample tubes or internal references. Industry players appreciate standardized naming, but everyday users rely on CAS numbers and purity rather than brand jargon.

Safety & Operational Standards

Exposure to 1,2,4-trifluorobenzene poses health risks, mainly irritation of the eyes, skin, and respiratory tract. The sharp, sweet odor serves as an early warning but won’t substitute for monitoring; vapor can anesthetize awareness over extended exposure. During scale-up, I’ve watched operators gear up with full-face shields, double nitrile gloves, and flame-retardant lab coats. Material Safety Data Sheets instruct immediate decontamination in case of contact and recommend storage away from sources of ignition or moisture. Local exhaust ventilation stands as the frontline defense in both research and production settings.

Application Area

Specialty chemical synthesis uses 1,2,4-trifluorobenzene as a versatile intermediate, particularly in designing agrochemical actives, liquid crystals, and pharmaceutical candidates. The electron-withdrawing effect of fluorine atoms shapes the molecule’s role in bioactive compounds, often enhancing metabolic stability—a trait prized by drug discovery teams. Electronics manufacturers seek out tailored liquid crystals for display applications, leveraging the unique dielectric properties that fluorination brings to aromatic rings. Custom polymers and advanced coatings reach downstream customers looking for performance in harsh chemical environments.

Research & Development

Recent years show a steady ramp-up in patents and publications centered on selective functionalization of trifluorinated aromatics, spurred by the push for greener synthesis and higher-yield routes. Directed ortho coupling and photoredox catalysis open doors for incorporating new linkers or side chains, allowing more refined control over biological activity or material properties. Graduate students—and I count myself among them—often chase optimization of reaction scope, carefully balancing time, reagent cost, and environmental impact in pilot runs. Companies back such efforts by funding collaborative projects between academia and industry, pushing the limits of safe scale-up and regulatory compliance.

Toxicity Research

Rodent testing exposes neurobehavioral effects and hepatotoxicity at higher doses, while human data remains sparse due to limited direct exposure. Environmental persistence worries regulators, since the carbon-fluorine bond resists breakage under normal conditions. Analytical teams now monitor workplace air for trace contaminants, while medical researchers keep studying the metabolic fate of fluorinated organics in human tissues. Waste management programs focus on secure containment and incineration, aiming to prevent persistent organic pollutants from leaching out of production facilities. My work with safety teams underlines the importance of careful secondary containment and detailed clean-up protocols.

Future Prospects

Growth in demand for 1,2,4-trifluorobenzene tracks advances in high-performance materials and next-generation pharmaceuticals. As nations tighten controls on volatile organic compounds and persistent chemicals, the race toward more environmentally responsible production methods takes center stage. Electrosynthetic and bio-catalytic routes are under development, promising cleaner, faster, and less wasteful pathways for fluorination. Researchers chase the double goal of lowering process risk and cost, knowing that fluorinated building blocks advance both green chemistry and industrial competitiveness. Strengthening the link between bench-scale discovery and plant-scale operation will turn today’s specialized product into tomorrow’s mainstay for innovation across technology and life sciences.

More Than Just a Chemical Name

1,2,4-Trifluorobenzene doesn’t crop up on the nightly news, but for anybody living with the results of modern medicine or enjoying the safety of advanced crop protection, it’s closer than you’d think. In my time working near industrial labs and chemical suppliers, I’ve met enough researchers who rely on this compound that it never felt like an obscure footnote. The world of specialty chemicals feels cold on the surface, but at the end of the day, it determines which medicines reach the pharmacy counter and how much food remains on supermarket shelves.

Pharmaceutical Beginnings

Drug discovery often starts with a list of chemicals that can help scientists build new molecules. 1,2,4-Trifluorobenzene falls right in this group. Medicinal chemists use it as a building block to create more complex agents. The fluorine atoms in its ring change how molecules behave inside the body—boosting stability and helping drugs reach their target without breaking down too soon. As I learned talking to one elderly chemist, swapping just one hydrogen for a fluorine on a molecule can change a drug’s strength or safety profile. That extra control means fewer side effects and longer shelf life for the medicines that patients rely on.

A Tool in Crop Science

Farmers battle invisible threats every day. Weeds, fungi, and insects don’t show up in glossy magazine photos—only in lost harvests. The labs that serve this industry stay ahead by finding new tools for plant protection. 1,2,4-Trifluorobenzene makes it possible to invent the latest generation of herbicides and pesticides. Its chemical structure opens the door to innovative formulations. I’ve seen the impact in local communities when crops resist disease and survive rough seasons thanks to modern agrochemicals.

Material Science and Industry

Not every use sits front and center to the public. Factory workers and engineers turn to 1,2,4-Trifluorobenzene to create specialty products like advanced plastics and coatings. Its role in synthesizing liquid crystals eventually feeds into consumer technology—think flat-screen TVs and high-performance mobile devices. While the headlines celebrate shiny new gadgets, hardly anyone stops to wonder about the chemical fingerprints buried deep inside the touchscreens we use every day.

Safety and Environmental Watchfulness

Public trust has to come from more than just innovation. Responsible producers acknowledge the risks chemicals can pose during manufacturing or disposal. Having seen neighbors grapple with industrial spills, I can’t stress enough how careful supervision of these processes matters. Regulators set strict rules, and companies keep detailed safety records. Investing in clean production and closed-loop systems helps reduce the chance of accidental environmental leaks. Armed with real-time monitoring, firms catch problems quickly instead of cleaning up after them later.

Building a Better Future

Researchers keep pushing for greener chemistry—making molecules like 1,2,4-Trifluorobenzene with less waste and lower energy use. Newer catalytic processes and micro-reactor technology allow fine control over reactions, offering better yields and fewer unwanted byproducts. Encouraging this shift helps both workers and local neighborhoods. If manufacturers share best practices, everyone benefits: safer jobs, smaller carbon footprints, and medicines and crops that improve lives. That’s the real measure of progress in the hidden world of chemical manufacturing.

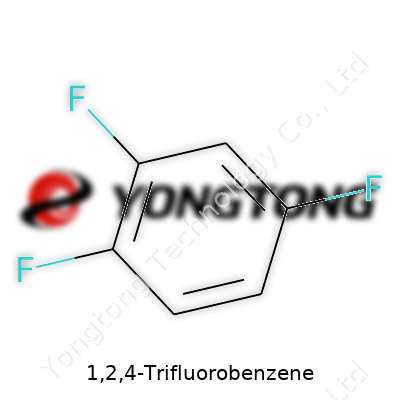

The Chemistry Behind 1,2,4-Trifluorobenzene

1,2,4-Trifluorobenzene isn’t exactly a household name, but it’s one of those chemicals that keeps popping up in the background of labs and research papers. The chemical formula for this compound is C6H3F3. Get a benzene ring, a classic in organic chemistry, and swap three hydrogen atoms with fluorine at the 1, 2, and 4 positions. This subtle switch brings out a lot of unique features, whether you’re talking about reactivity or just how the molecule behaves in a flask.

Molecular weight gives researchers a concrete number to work with. For 1,2,4-trifluorobenzene, the weight adds up to 146.09 grams per mole. This isn’t just a stat for a textbook—it matters every time a chemist weighs out a batch for synthesis or analysis. It’s easy to take for granted. You hit “calculate” on a digital balance, but building up that number from the atomic weights—carbon 12.01, hydrogen 1.01, and fluorine 19.00—really grounds you in the realities of what’s being handled in the lab.

Why It Matters in Real Work

Fluorinated aromatics like this one have a reputation. Adding fluorine to a benzene ring changes almost everything about it. The electron withdrawing character of those fluorines doesn’t just play games with basic reactivity; it lets chemists fine-tune the properties for everything from electronic devices to pharmaceuticals. For example, drug developers often toss in a fluorine just to see how it affects metabolic stability or binding affinity. Sometimes, it’s the difference between a promising lead compound and a failed experiment.

1,2,4-Trifluorobenzene brings value to synthetic organic chemistry. This compound serves as both a building block and a reference for developing new fluorinated materials. In the search for stronger, more precise pharmaceuticals, adjusting the position and number of fluorine atoms can lead to improved absorption or less toxicity. Electronics engineers rely on fluorinated benzenes for their stability and insulating properties. I’ve seen companies push for more specialized materials and this sort of molecule sits right at the source of that trend.

Handling Safety and Environmental Aspects

The practical side of working with any aromatic fluorinated compound calls for caution. Inhaling fumes or spilling something like 1,2,4-trifluorobenzene isn’t just an inconvenience. Regulatory agencies like OSHA and environmental standards from the EPA recommend treating such chemicals with care—use fume hoods, wear protective gloves and goggles, and clean up using spill kits designed for organic solvents.

Concerns don’t end at the lab bench. The fluorine-carbon bond is strong, making the molecule stable, but this same feature means it can linger in the environment. Persistent organofluorines have been highlighted in scientific debates about groundwater and bioaccumulation. Responsible disposal and looking for greener synthetic routes—like catalytic fluorination or less hazardous reagents—carry real weight outside a lab notebook.

Solutions and Future Directions

Researchers and industry partners keep searching for better ways to produce and dispose of compounds like 1,2,4-trifluorobenzene. Moving toward closed-loop systems in synthesis, recycling solvents, and tracking emissions aren’t just checkboxes for compliance—they represent real steps to safer and more sustainable chemistry. Training new chemists to respect both the power and the risk of fluorinated aromatics can help keep these compounds serving us, instead of ending up in places they shouldn’t.

Understanding 1,2,4-Trifluorobenzene

1,2,4-Trifluorobenzene carries a reputation as a specialty chemical. Chemists use it in laboratories or as an intermediate in more complex processes. Most of us never cross paths with a vial of this clear, colorless liquid, but for workers in chemical plants or research labs, safety questions matter every single day.

Evaluating Risks and Toxicity

Scientists rely on data and case studies to determine if a chemical like 1,2,4-Trifluorobenzene poses a threat to health. Published records show that its acute toxicity to humans remains low. Contact with skin or eyes can cause irritation, just as it would with many solvents or industrial chemicals. Breathing in high concentrations produces dizziness or headache. These effects echo my own stint in a chemical lab, where the need for gloves and proper ventilation applied to nearly every bottle on the shelf.

Animal studies suggest more serious concerns if exposure lasts too long or involves large amounts. In rats, the chemical only showed mild toxicity at very high doses and didn't trigger birth defects or cancer in standard tests. Still, the exact impact on humans lacks a full profile, which is not unusual for less common solvents.

Environmental Concerns and Industry Safety

Chemicals with several fluorine atoms tend to stick around in the environment. Persistence matters, especially given lessons from other fluorinated compounds like PFAS. While there's no evidence that 1,2,4-Trifluorobenzene lingers or accumulates the way PFAS do, researchers point out the need for careful disposal. Wastewater streams and spills could add up if companies ignore best practices.

At a previous workplace, a minor solvent mishap taught me the value of spill kits and up-to-date training. Even less hazardous chemicals turn costly if they reach groundwater or storm drains. Regulators require companies to document how they handle these compounds, monitor air quality, and supply personal protective equipment. OSHA guidelines treat 1,2,4-Trifluorobenzene with the same caution as other halogenated solvents. This means labeling, storage in flame-resistant cabinets, and proper ventilation wherever it gets used.

Working Towards Safer Workplaces

Prevention cuts more risk than cleanup after the fact. Regular hazard training and transparent communication at work go a long way. Companies that keep safety data sheets current and easy to read empower workers to react fast in emergencies. Substituting less toxic solvents, wherever possible, also makes a real difference. Chemists over the years have engineered safer alternatives to legacy chemicals, reducing the chance of harm for both people and the wider environment.

Sharing toxicology findings, investing in up-to-date safety infrastructure, and listening to feedback from front-line workers each add a layer of protection. We all deserve confidence in the products and jobs that rely on specialty chemicals, knowing that risks have been assessed and reduced at every turn.

Respecting Chemical Hazards in the Real World

Working with chemicals like 1,2,4-trifluorobenzene demands honest attention. In my early days handling solvents in the lab, I realized pretty quickly how easily a small mistake could lead to much bigger problems. 1,2,4-Trifluorobenzene brings its own set of risks—flammability, inhalation hazards, and skin contact issues—so shortcuts just aren’t worth the trouble.

Choosing the Right Space for Storage

I’ve learned never to stash chemicals in just any spot to save time or space. For 1,2,4-trifluorobenzene, always pick a cool, well-ventilated place, far from heat or ignition sources. Electronics, open flames, and even powered ventilation fans with exposed motors can start a chain reaction you don’t want. Once, I saw a container left near a sunny window—one careless decision led to stinging fumes in the room. Take the time to label everything and store it with similar solvents, away from acids and oxidizers.

Packing It Up: Containers and Seals Matter

Experience shows that screw-top glass bottles work well for storing 1,2,4-trifluorobenzene. Weak or ill-fitting lids will let volatile fumes seep out, which means headaches or worse for anyone nearby. Double-sealing with a sturdy plastic liner inside the cap helps a lot. In the past, a loose lid wasn’t just annoying—it made the whole cabinet smell sharp and sweet, and that odor is a clear red flag. Never overlook the condition of the container before use; it must stand up to chemicals and regular handling.

Practical Handling—It’s All About Consistency

Gloves and safety goggles became second nature to me after a few close calls. Nitrile gloves offer good resistance, and splash-proof goggles keep your eyes protected. Pouring from the container should happen under a fume hood, not out on an open bench—the chemical’s vapors can dizzy you fast or cause longer-term health issues. Once, I skipped the hood because I was in a hurry, and fifteen minutes later I regretted it. Never work alone with volatile substances; if things go wrong, you’ll want backup.

Spills and Waste—Clean Up Like It Counts

Any spill demands respect. Keep absorbent materials, like activated charcoal pads or spill kits, handy and within reach before you unlock the bottle. My team drilled cleanup procedures, and it paid off during a late-night spill: neutralized the mess, isolated the waste in a sealed drum, and documented exactly what happened. Ventilate the area and bag contaminated gloves or wipes in dedicated waste containers intended for hazardous organics—don’t toss them with regular trash.

Learning from the Facts

OSHA and the CDC both stress real risks involved with trifluorinated benzenes: irritant effects, flammability, and potential long-term exposure dangers. These warnings aren’t just bureaucracy—they reflect harsh lessons learned over years. Well-documented material safety data sheets reinforce the steps above. Following established procedures shapes safer habits, which carry over into every part of the lab or warehouse routine.

Better Systems, Safer Outcomes

Managing these chemicals safely comes down to discipline and systems. Regular training, practicing emergency drills, and using proper labeling make a real difference in day-to-day safety. I’ve seen workplaces that make chemical safety an afterthought struggle with accidents and staff turnover. Clear signage, orderly records, and peer check-ins go a long way toward avoiding trouble. Staying informed and following proven practices keep everyone healthier in the long run.

Why Chemists Eye Unusual Aromatics

Organic chemistry feels full of regulars—benzene, toluene, dichloromethane. They find work in countless labs for dissolving, extracting, and moving things around. Now and then, though, a niche aromatic like 1,2,4-trifluorobenzene gets pulled into the spotlight. Some folks ask whether this fluorinated compound belongs on the solvent shelf or tucked among intermediates ready for building blocks. The answer depends on knowing the quirks of real lab work and the impact of adding fluorine to a simple ring.

Not Your Grandpa’s Benzene

Fluorine barely lets anything slide by without leaving its chemical mark. Put three fluorines on a benzene ring and you’ve got a molecule that resists oxidation and other harsh treatments. Folks often overlook this kind of resilience until running up against stoppers in pharmaceutical or agrochemical synthesis. Any organic chemist handling tricky cross-couplings or direct functionalization—think Suzuki or Buchwald–Hartwig reactions—will see right away that 1,2,4-trifluorobenzene doesn’t perform like the plain stuff. It’s less willing to swap out hydrogens for newcomers, since fluorines hold their ground so tightly.

Not every reaction needs a high-boiling, inert aromatic solvent. For something as specialty as 1,2,4-trifluorobenzene, price swings are real—supply does not match commodity solvents. Anyone ordering this compound for dissolving everyday organics faces sticker shock. More than the cost, there’s the consideration of toxicity. The compound isn’t as notorious as nitrobenzene, but repeated exposure will raise health concerns. Responsible research asks for good ventilation, gloves, and full awareness of these risks—something that can’t be ignored for scale-ups in production environments.

Boomerang Molecule for Building Blocks

Chemists who design complex scaffolds in pharma or materials science want more than a solvent. 1,2,4-trifluorobenzene carves out a niche as a synthetic intermediate because trifluorinated rings open up possibilities for drugs with new properties. Adding multiple fluorines boosts metabolic stability and changes electronic properties, sometimes improving brain penetration or sharpening selectivity at a biological target. Drug hunters notice these shifts. Companies such as Roche and Novartis have chased fluorinated motifs for years, betting on those altered pharmacokinetics. Specialty agrochemical makers know the same story. Pest resistance and improved field stability matter in crop protection, and fluorines can mean longer-lasting effects out in the soil and sun.

Real-World Choices in the Lab

Day-to-day chemistry demands flexibility. Labs run experiments under pressure to improve yields, scale up, or avoid sticky patent claims. 1,2,4-trifluorobenzene finds work not just in classic aromatic substitutions but sometimes in Grignard-type couplings or forming heterocycles. Using it as a starting block or just a medium for tricky reactions gives chemists another angle of attack when simple arenes fall flat. Synthetic teams weigh the trade-offs of cost, safety, and availability, usually reserving 1,2,4-trifluorobenzene for cases where it genuinely adds value—either in the structure of the desired molecule or by making certain steps actually go to completion.

Room to Grow: Smarter Use, Safer Labs

Moving forward asks for smarter, greener choices. More groups focus on minimizing toxic waste, recycling fluorinated solvents when possible, and exploring alternatives if property profiles allow. Legislation in Europe and North America pressures industrial processes to rethink aromatic solvent use, especially ones with halogen substitutions. That said, the growth of fine chemical synthesis and boutique pharma keeps demand steady for unique molecules like 1,2,4-trifluorobenzene. Chemists with their feet on the lab floor know not every compound makes sense for every task, but with the right vision, even a obscure aromatic can carve out a spot in the next big breakthrough.