Phenolsulfonic Acid

Product name:Phenolsulfonic acid

Synonyms:4-Phenol sulfonic acid, Phenolsulfonic acid, p-Hydroxybenzene sulfonic acid, Phenol-4-sulfonic acid, p-Hydroxybenzenesulfonic acid

CAS NO.:98-67-9

EINECS NO.:202-691-6

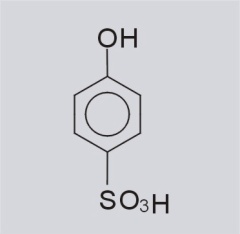

Molecular formula: C6H6O4S

Molecular weight: 174.20

Appearance: Brown-red liquid

Specifications: 65%

Molecular Structure:

Application:

The product is employed in the electrolytic galvanizing baths used in the production of tinplate and in the electrolytic refining process used to clean up raw tin. Additionally, the acid may be utilized in chemical, electrolytic, or electroplating processes. It also works as a chelating agent for fertilizers and an additive for floral foam production.

As an experimental reagent, catalyst, also used in organic synthesis and phenol manufacturing

It is mainly used to make phenol by alkali melting, and also used to make resorulein, etc. It is often used as a catalyst in esterification and dehydration reactions. Benzenesulfonic acid is used in oil field water injection. It can relieve the blocking of the formation and improve the permeability of the formation. As the acid of the acidifying injection well, benzene sulfonic acid is characterized by slow reaction with carbonate, and the greater the concentration, the slower the reaction speed. Compared with hydrochloric acid, benzene sulfonic acid (and mixed aryl sulfonic acid) has a long validity period, small corrosion and safe use. Benzenesulfonic acid is also used as a catalyst for esterification and dehydration reactions and as a curing agent in the foundry industry.Determination of ammonium and potassium salts, determination of zinc, organic synthesis of phenol, resorcinol, catalyst, used as dehydration catalyst, resin curing agent, electroplating additive, and dye intermediate.

Packing: In 250kg/drum.

Q: Handling and storage?

Operation precautions: airtight operation, local exhaust. The operation is as mechanized and automated as possible. Operators must undergo special training and abide by strictly the operating procedures. It is recommended that operators wear full face masks, one-piece adhesive tape protective clothing, and rubber gloves. Avoid generating dust. Avoid contact with oxidants and alkalis. When handling, load and unload lightly to prevent damage to packaging and containers. Equipped with leakage emergency treatment equipment is necessary. Empty containers may be harmful residues.

Precautions for storage: Store in a cool, ventilated warehouse. Keep away from fire and heat sources. It should be stored separately from oxidants and alkalis, and should not be stored together. Storage areas should be equipped with suitable materials to contain spills.

Q: Spill emergency treatment?

Isolate the leaking contaminated area, set up warning signs around the area, and cut off the fire source. Emergency personnel should wear gas masks and general fire protective clothing. Rinse with plenty of water, and put the diluted lotion into the waste water system. In case of a large amount of leakage, collect and recycle or discard after harmless treatment.

Q: The first-aid?

Skin contact: Take off contaminated clothing, rinse thoroughly with soap and water.

Eye contact: Immediately open the upper and lower eyelids and rinse with running water for at least 15 minutes. Seek medical attention.

Inhalation: Get away from the scene to fresh air. Give oxygen if breathing is difficult. Once breathing stops, begin CPR immediately. Seek medical attention.

Ingestion: If swallowed by mistake, drink milk or egg white. Seek medical attention.